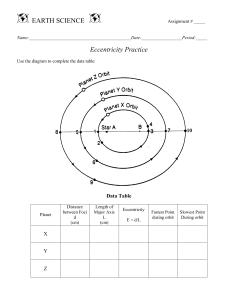

UNIVERSITY OF WINDSOR Faculty of Engineering Mechanics of Deformable Bodies (GENG-2180) Laboratory #4 – Stress Distribution Under Eccentric Load Submitted on March 29 2019 Lorenzo, Pernasilici Student ID: 104 808 810 Objectives The objective of this test is to determine the behavior of steel and aluminum tubular specimens while subjected eccentric loading. Testing Apparatus: Figure 1: Cross sectional area of testing apparatus Figure 2: Positions of strain gauges Figure 3: Diagram of testing apparatus Instrumentation Used: ● Universal Testing Machine ● Spherically Seated Compression Block ● 6 Strain Gauges ● Loading Block and Pin ● Datascan Analog Measurement Processor ● Dalite Datascan Software Test Procedure: Pre-Testing Procedure 1. The inner and outer diameters of each specimen was verified. 2. The six strain gauges were fixed to each specimen in the specified locations around its outer diameter. Testing Procedure 1. The loading block was placed on the specimen with the loading pin in one of the three positions. 2. The specimen was placed in the universal testing machine such that the specimen was centered under the compression tools. 3. The Dalite software was setup to record the six strain gauges. 4. A load of 12.5 kN was applied followed by a 25 kN load. Measurement were recorded at each load. 5. The above procedure was repeated for the other two loading positions. Results: Sample Calculations: Cross-sectional area: A = π4 (do2 − d2i ) = π4 (72.89o2 − 63.562i ) = 999.87mm2 Moment of Inertia: I = 4 π 64 (do − d4i ) = Young's Modulus (12.5 kN): E = 4 4 π 4 64 (77.89 − 63.56 ) = 584477.6697mm P 12.5kN Aεave = 999.87mm2 ×189.56 = 198.702 Error = 0.65% Experimental Stress (steel, 12.5 kN, 20mm eccentricity): σ = E ε = 198.702 × 33.81 = 2.278 M P a Theoretical Stress (steel, 12.5 kN, 20mm eccentricity) σ = P A − Average % error (steel, 12.5 kN, 20mm eccentricity): E rror = My −20×12500(−36.44) 12.5kN I = 999.87 − 584477.6697mm4 σ σ T he Σ( Exp− σ T he ) = 17.05% Experimental Eccentricity (steel, 12.5 kN, 20mm eccentricity.): σ max− σ min 4 dexp = ymax− × PI = 2.565−−25.676 × 584477.6697mm = 18.116 Error = 9.48% y 72.89 12.5 kN min = 3.09 Table 1: Steel Results Summary Eccentricity Load (KN) Strain Gauge % error 1 Centre 20 mm 25 mm 2 3 4 5 6 12.5 Strain -44.039 -70.752 -75.603 -43.980 -65.935 -77.189 σ(exp) -8.751 -14.059 -15.022 -8.739 -13.101 -15.338 -12.502 -12.502 -12.502 -12.502 -12.502 -12.502 25 Strain -87.654 -117.570 -142.396 -102.671 -137.530 -144.768 σ(exp) -17.950 -24.076 -29.160 -21.025 -28.163 -29.645 σ(theor) -25.003 -25.003 -25.003 -25.003 -25.003 -25.003 12.5 Strain 12.907 -34.709 -106.193 -129.217 -90.873 -20.071 σ(exp) 2.565 -6.897 -21.101 -25.676 -18.057 -3.988 σ(theor) 3.087 -4.707 -20.296 -28.090 -20.296 -4.707 25 Strain 24.975 -62.862 -201.122 -263.564 -182.580 -40.181 σ(exp) 5.114 -12.873 -41.186 -53.972 -37.389 -8.228 σ(theor) 6.174 -9.414 -40.592 -56.181 -40.592 -9.414 12.5 Strain -133.509 -107.519 -32.105 30.077 -21.679 -121.436 σ(exp) -26.529 -21.364 -6.379 5.976 -4.308 -24.129 σ(theor) -31.987 -22.245 -2.759 6.984 -2.759 -22.245 25 Strain -280.727 -209.688 -51.492 55.009 -35.354 -235.679 σ(exp) -57.487 -42.940 -10.545 11.265 -7.240 -48.262 σ(theor) -63.975 -44.489 -5.517 13.969 -5.517 -44.489 σ(theor) 20.03% 15.94% 17.05% 13.30% 38.56% 27.30% Eccentricity Load (KN) Modulus of elasticity E (Gpa) Experimental Centre 20 mm 25 mm Average Stress (Mpa) Theoretical Experimental Theoretical Eccentricity d (mm) Experiment al Theoretical 12.500 198.702 200.000 -12.502 -12.502 25.000 204.779 200.000 -25.003 -25.003 12.500 -12.192 -12.502 18.116 20.000 25.000 -24.756 -25.003 18.952 20.000 12.500 -12.789 -12.502 20.852 25.000 25.000 -25.868 -25.003 22.052 25.000 Table 2: Aluminum Results Summary Eccentricity Load (KN) Strain Gauge % error 1 Centre 20 mm 25 mm 2 3 4 5 6 12.5 Strain -129.501 -240.521 -172.149 -139.956 -249.433 -181.797 σ(exp) -8.725 -16.204 -11.598 -9.429 -16.805 -12.248 -12.502 -12.502 -12.502 -12.502 -12.502 -12.502 25 Strain -284.763 -442.447 -347.521 -322.568 -466.648 -349.937 σ(exp) -19.296 -29.981 -23.549 -21.858 -31.621 -23.713 σ(theor) -25.003 -25.003 -25.003 -25.003 -25.003 -25.003 12.5 Strain 33.811 -99.745 -284.778 -384.514 -308.158 -77.218 σ(exp) 2.278 -6.720 -19.186 -25.906 -20.761 -5.202 σ(theor) 3.087 -4.707 -20.296 -28.090 -20.296 -4.707 25 Strain 59.554 -181.803 -571.157 -790.777 -607.431 -143.993 σ(exp) 4.036 -12.319 -38.703 -53.585 -41.161 -9.757 σ(theor) 6.174 -9.414 -40.592 -56.181 -40.592 -9.414 12.5 Strain -406.238 -370.850 -51.477 62.774 -82.907 -251.787 σ(exp) -27.369 -24.985 -3.468 4.229 -5.586 -16.963 σ(theor) -31.987 -22.245 -2.759 6.984 -2.759 -22.245 25 Strain -832.612 -710.338 -91.706 124.721 -151.289 -530.131 σ(exp) -56.420 -48.134 -6.214 8.451 -10.252 -35.923 σ(theor) -63.975 -44.489 -5.517 13.969 -5.517 -44.489 σ(theor) 21.35% 15.46% 15.84% 13.30% 0.3635667 941 0.2953300 849 Eccentricity Load (KN) Modulus of elasticity E (Gpa) Experimental Centre 20 mm 25 mm Average Stress (Mpa) Theoretical Experimental Theoretical Eccentricity d (mm) Experimental Theoretical 12.500 67.372 200.000 -12.502 -12.502 25.000 67.763 200.000 -25.003 -25.003 12.500 -12.583 -12.502 18.079 20.000 25.000 -25.249 -25.003 18.482 20.000 12.500 -12.357 -12.502 20.270 25.000 25.000 -24.749 -25.003 20.807 25.000 Steel Graphs Figure 4: Steel specimen 20mm eccentricity, 12.5 kN load Figure 5: Steel specimen 20mm eccentricity, 25 kN load Figure 6: Steel specimen 25mm eccentricity, 12.5 kN load Figure 7: Steel specimen 25 mm eccentricity, 25 kN load Aluminum Graphs Figure 8: Aluminum specimen 20 mm eccentricity, 12.5 kN load Figure 9: Aluminum specimen 20 mm eccentricity, 25 kN load Figure 10: Aluminum specimen 25 mm eccentricity, 12.5 kN load Figure 11: Aluminum specimen 25 mm eccentricity, 25 kN load Discussion Both the steel and aluminum tubular specimens were successfully tested using experimental procedure. The test results produced strain readings for both specimens from all six strain gauges affixed around the outer diameter of the specimens. Using the given parameters experimental and theoretical values were determined for stress values, Young’s modulus and eccentricity. Each of specimens behaved as expected while subjected to centric and eccentric loads with the aluminum specimen experiencing more deformation than the steel specimen in general. The calculated values for Young’s modulus and the eccentricity were of particular interest as the percentage error from the theoretical values were quite low. The stress-distribution graphs were also quite close to the theoretical relationship as there were relatively low levels of error in those calculations, with peak average percentage error being roughly 38% and most errors being around the 15-25% range. The main source of error in this experiment is likely the positioning of specimen inside the universal testing machine. The positioning of the specimen was done by hand which leaves the possibility for the load to no be applied centrally to the specimen along either of its transverse axes, which may skew the values one way or the other. Overall the level of error is acceptable. The overall shape of the stress-distribution graphs agrees with the theoretical behavior whereby all of the gauges are under some level of stress with the end nearest to the force having the greatest stress and the far end having the least stress. Conclusion In conclusion, the tests were able to produce valid strain readings resulting from the centric and eccentric loads. The values from the strain gauges were successfully used to produce an experimentally calculated values for Young’s modulus and eccentricities along with an experimental stress-distribution for each specimen. The experimental values and theoretically calculated values for the experiment are mostly within a reasonable range of percentage error with a few exceptions. The sources of error in this investigation were mostly mitigated through the use of a loading block and pin and only small sources of systematic errors were present in the experiment.