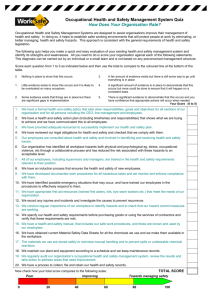

COVER PAGE May 2008 1 NEBOSH International General Certificate UNIT IGC 1 Page Element 1: Foundations in health and safety 3 Element 2: Policy 28 Element 3: Organising for health and safety 33 Element 4: Promoting a positive health and safety structure 45 Element 5: Risk assessment 70 Element 6: Principles of control 88 Element 7: Monitoring, review and audit 109 Element 8: Occupational incident and accident investigation, recording and reporting 116 UNIT IGC 2 Element 1: Movement of people and vehicles – hazards and controls 125 Element 2: Manual and mechanical handling – hazards and controls 129 Element 3: Work equipment – hazards and controls 155 Element 4: Electrical – hazards and controls 170 Element 5: Fire – hazards and controls 181 Element 6: Chemical and biological – hazards and controls 193 Element 7: Physical and psychological – hazards and controls 213 Element 8: Construction activities – hazards and controls 245 Examination Mock Examination Papers Candidate Briefing Sheet Mock Practical Assessor’s Marking Sheet Candidate’s Observation Sheet May 2008 2 UNIT IGC 1, ELEMENT 1: FOUNDATIONS IN HEALTH AND SAFETY 1.1 THE SCOPE AND NATURE OF OCCUPATIONAL HEALTH AND SAFETY The multi-disciplinary nature of health and safety The management and the workforce are both essential components of an organisation. To maximise the contribution of the workforce management need to develop high levels of interpersonal skills in addition to their technical skills such as planning. Human behaviour has a direct influence on health and safety in many aspects of life – at work, in the home, on the road, in the air and at sea. Research has confirmed that most accidents are attributable to human failure (unsafe acts). Indeed some individuals and organisations believe that all accidents, (with the exception of acts of god) including near misses, are ultimately caused by human factors. Even when a process is automated, people are still needed to design, control, and maintain the system. What do we mean by "human factors"? In the HSE publication entitled "Human Factors in Industrial Safety", HS (G) 48, it is described so; "The term human factors is used to cover a range of issues. They include the perceptual, mental and physical capabilities of people and the interactions of individuals with their job and working environments, the influence of equipment and systems design on human performance, and above all, the organisational characteristics which influence safety-related behaviour at work." Over time certain disciplines have developed to try to explain and predict both individual and group behaviour within societies around the world. However, even today, these social sciences are primarily concerned with predicting the behaviour of the majority (group) rather than the individual which is much more difficult. The disciplines within social science with which we are concerned are: (a) Psychology; which is the study of human personality (“the human soul and mind” to quote the Oxford Dictionary). (b) Sociology; which is the study of the history and nature of human society. In particular it is the study of the behaviour of people as members of a group at home, at work or in society as a whole. (c) Anthropology. Which is the study of the whole science of man; human and psychology; the study of man as an animal. physiology The social sciences try to give some general theories based on the observation of human behaviour to explain why human beings generally behave as they do, and predict what they might do in a particular set of circumstances. Our interest in this handout will be strictly limited to the field of occupational safety and health. Since the safety practitioner has to motivate individuals to achieve the highest safety standards by changing attitudes to safety, this will require the influencing of both individual and group behaviour, and as a consequence, it is very important to understand some of the basic theories. May 2008 3 Meanings of and distinctions between common terms Health concerns a state of well being, so involves aspects of the work activity that have direct effects upon employees, and concerns the absence of illness or disease. Examples of health hazards would be hazardous substances, excessive noise, high temperatures, excessive humidity and poor lighting. Safety concerns the absence of danger from physical harm, so involves aspects of the work activity concerned with preventing accidental injury or death. Examples include hazards such as working at height, fire, electricity, plant and machinery. Welfare concerns facilities for workplace comfort and involves issues that impact upon the basic well-being of the employee. Examples would include the provisions of eating, toilets and washing facilities, first aid provision and provision of disabled or pregnant employees. Environmental Protection concerns measures designed to prevent harm to the environment around us, and is aimed at reducing pollution and protecting the environment from work activities. Examples would be protection of animals, plant life, water, land and air quality through noise restrictions, bunded diesel tanks, spillage control procedures and waste disposal procedures. An accident is defined as an unplanned, controlled event which has, or could have in slightly different circumstances, led to injury, damage or some other loss. Examples include: a fall resulting in a fracture, incorrect operation of machinery leading to breakdown, or an event where there is no actual loss this time (near miss) such as someone dropping a tool whist working up a ladder and narrowly missing someone below. A dangerous occurrence is an unplanned and undesired occurrence which has the potential to cause injury and which may or may not cause damage to property, equipment or the environment and is reportable to the national enforcing authority. Many national laws require the reporting of such events to external agencies e.g. the Health and Safety Authority in Ireland. Typical examples would include the failure of pressure vessels, collapse of a scaffold and a serious fire. A near miss (or incident) is an accident that results in no apparent loss. So it is an unplanned, uncontrolled event that has not led to injury, damage or some other loss this time, but could have in slightly different circumstances. Examples include: articles falling near to people, short-circuits on electrical equipment. Work-related ill-health (physiological and psychological) concerns people who are made ill by their work - a recent HSE survey in the UK suggests that over two million people are suffering from illness they thought was caused by work. This ill-health could be physiological e.g. WRULDs, noise induced hearing loss or psychological e.g. stress. Commuting accidents A commuting accident is an accident occurring on the habitual route, in either direction, between the place of work or work-related training and: (i) the worker's principal or secondary residence; (ii) the place where the worker usually takes his or her meals; or (iii) the place where he or she usually receives his or her remuneration; which results in death or personal injury. Source: OECD May 2008 4 Hazard and Risk Hazard is something with the potential to cause harm. The harm will vary in severity – some hazards may cause death, some serious illness or disability, others only cuts and bruises; Risk on the other hand is the likelihood of harm actually being able to realise its potential (in defined circumstances, and usually qualified by some statement of the severity of the harm). 1.2 THE MORAL, SOCIAL AND ECONOMIC REASONS FOR MAINTAINING AND PROMOTING HEALTH AND SAFETY Workplace health and safety is important as a commitment to employees, contractors, visitors, families and friends. It is also important as an investment to the business, the national economy; and because it is a legal duty. Thus there are 3 main reasons for maintaining and promoting health and safety in the workplace; moral, social and economic Moral Injury accidents lead to pain and suffering. Not only to the victim, but to their family and friends as well. Judges around the world have made the point that a worker goes to work out of economic necessity not consent to be injured or harmed by their work activity. Nor should others be effected the employers work activities e.g. neighbours, contractors or the general public. Social In Finland their 2006 Work and Health survey revealed that 40% of the working population enjoy their work. Common causes for concern were increased time pressures long working hours, constantly changing schedules, and the lack of flexible hours and task management, and increased mental and physical abuse. An increasing number of the working population was also torn between work and their care responsibilities, for their own children and their ageing parents. Their research concluded that successful organisations had good personnel management. The reasons behind their success were quite simple: pleasant atmosphere, openness and trust, democratic discussion in everyday work, good managerial skills, the ability to influence one's own work, training opportunities, concern for health and work ability, and permanent employment. Thus good employers will evolve their working practices in- line with society’s expectations. Economic Accidents cost a great deal of money, especially when we add the damage caused by some accidents. Many governments realise that poor occupational health and safety performance give rise to additional costs to the State (e.g. social security payments, medical treatment). Employers also sustain costs as a result of an accident (such as fines, damage to buildings, plant and material, production delays, fines, claims and legal fees, increased insurance premiums, loss of reputation etc). The size of the health and safety ‘problem’ in terms of the numbers of work-related fatalities and injuries and incidence of ill-health May 2008 5 Some 2.2 million people die of work-related accidents and diseases each year, according to an International Labour Office (ILO) report in 2006, adding this number may be vastly under estimated due to poor reporting and coverage systems in many countries. While the number of work-related illnesses and deaths has lessened somewhat in the industrialised countries, the ILO report said the number of accidents - in particular fatal accidents - appear to be increasing, particularly in some Asian countries due to poor reporting, rapid development and strong competitive pressures of globalisation. "Occupational safety and health is vital to the dignity of work", said ILO Director-General Juan Somavia. "Still, every day, on average, some 5,000 or more women and men around the world lose their lives because of work-related accidents and illness. Decent Work must be safe work, and we are a long way from achieving that goal." What's more, the ILO report, entitled Decent Work - Safe Work, also warns that work-related malaria and other communicable diseases as well as cancers caused by hazardous substances are taking a huge toll, mostly in the developing world. The majority of the global workforce lacks legal or preventive safety or health measures, accident or illness compensation and has no access to occupational health services. "The sad truth is that in some parts of the world, many workers will probably die for lack of an adequate safety culture", said Jukka Takala, Director of the ILO SafeWork Programme. "This is a heavy price to pay for uncontrolled development. We must act swiftly to reverse these trends." The report noted that men, in particular, are at risk of dying at working age (below 65) while women suffer more from work-related communicable diseases, psycho-social factors and long-term musculo-skeletal disorders. In several industrial countries, more than half of the retirements are based on early retirements and disability pensions rather than workers reaching the normal retirement age. While not all factors behind these trends are directly caused by work, the employer is in a key position for prevention and maintaining work ability through its management system. The ILO report said reporting systems and coverage of occupational safety and health in many developing countries are poor and in some cases deteriorating. For example, India reports 222 fatal accidents while the Czech Republic, which has a working population of about 1 per cent of India, reports 231, the ILO said, adding that it has estimated the true number of fatal accidents in India at 40,000. The report said such statistics suggested that only a fraction of the real toll of work-related death and disease is covered in a number of developing countries. The ILO report also noted that hazardous substances cause the deaths of an estimated 440,000 workers each year. Of these, asbestos alone kills some 100,000 workers worldwide each year. The number of people killed by asbestos in the United Kingdom, according to that country's own estimates, is some 3,500 every year - more than ten times the number of workers killed in accidents there. The European Union, meanwhile, recently in its own Statistical Portrait Report estimated a total of 120,000 fatalities attributed to work while the ILO's estimate is now at 122,000 workrelated deaths annually. The United States number is estimated to be 103,000. While work-related diseases are the main problem in industrialised countries, safety related accidents are more prevalent in the developing economies where workers are frequently May 2008 6 dying in mishaps that occur in such sectors as mining, construction and agriculture. In the industrialised countries, the share of the workforce in such hazardous sectors has declined while that of safer service industries (office work, banking, commerce) has grown. Furthermore, the findings show younger workers (age 15-24) are more likely to suffer nonfatal occupational accidents than their older colleagues, while workers over the age of 55 appear to be more likely to suffer fatal accidents and ill-health than others, the ILO report said. New data in the report also shows that women suffer much more than men when it comes to work-related communicable diseases, such as agriculture-related malaria and bacterial and viral infections as well as musculo-skeletal disorders. Men tend to die as a result of accidents, lung diseases and work-related cancers, such as those caused by asbestos. The end result is aggravated in certain parts of the world by HIV/AIDS. Life-expectancy rates in many developing countries and economies of transition have plummeted far below the official retirement age of around 65 and even below the average actual retirement age of 59 to 61 years in the industrialised world. Mr. Takala added that most workers in the world are not covered by legal preventive measures and will never receive compensation in case of accidents and diseases. He also said most have never seen an occupational doctor or a labour inspector. The report also says that newly emerging problems such as psychosocial factors, violence, the effects of alcohol and drugs, stress, smoking and HIV/AIDS are rapidly leading to increased morbidity and mortality worldwide. Smoking, which affects mostly workers in the restaurant, entertainment and service sectors, is estimated to cause 14 per cent of all workrelated deaths caused by disease, or close to 200,000 fatalities. The ILO also estimated that the cumulative loss of labour force participants due to HIV/AIDS since the start of the epidemic had reached 28 million worldwide by 2005. The ILO's educational programme, Addressing Psychosocial Problems at Work (SOLVE) is working in many countries to address these problems at both a policy and a shop-floor level. The ILO said action at international, regional, national and enterprise levels is a prerequisite to preventing or reducing work-related accidents and ill-health. It has developed a new fivepoint "Global Strategy" to encourage the use of existing tools such as the Occupational Safety and Health Convention, 1981 (No. C155) and other ILO labour standards on safety and health at work. The strengthening of national occupational safety systems through tripartite collaboration is fundamental and this includes legal provisions, enforcement, compliance and labour inspection capacity and capability, knowledge management, information exchange, research and support services. Management systems, such as the ILO-OSH 2001, (see section 1.5), are vital but they are best motivated by laws, regulations and efficient enforcement. Inspectors should not be considered as a nuisance or threat to business, in fact countries with the best inspection systems are also the most competitive ones worldwide. "The ILO has been actively supporting initiatives in countries developing national policies", Mr. Takala said. "For example, tripartite national construction safety committees have been set up both in Argentina and Colombia, with the purpose of discussing and formulating the respective national policies and programmes for that sector". Ireland, Israel and Argentina have recently formally signed agreements with ILO to adopt the ILO Management Systems Guidelines. May 2008 7 There are other signs of progress as well. Some highlights include Japan, which recently became the 28th member to ratify the ILO Convention on Asbestos and plans a total ban on the substance. Luxembourg has pledged to ratify all 21 ILO Conventions on occupational safety and health. China has established a comprehensive national profile on occupational safety and health with a view to ratifying Convention No. 155. At last count, 134 countries have ratified the Labour Inspection Convention, with Estonia being the latest. In 2001 there were 6,000 workers in the United States killed on the job – an average of 16 workers a day left home never to return. In the same year, there were more than 100,000 deaths from occupational diseases and more than one million lost-time injuries. (BLS website) With China’s entry into the World Trade Organisation, and with average manufacturing wages of 20-25 cents per hour, it is widely predicted that China will become the “export platform” for the entire world in the coming years. In China during the first half of 2001, 47,000 workers were killed at work, according to official statistics, meaning that 258 Chinese workers left for work every day and were killed on the job. (Kurtenbach, 2001) The rate of acute poisoning accidents in Beijing has doubled since 1994, according to the city’s health bureau, and about 2.1 million workers in the Chinese capital are exposed to toxic dusts, chemicals and other airborne hazards at work. (Han, 2002) In the developing world, it is estimated that for every fatality there are 750 disabling injuries. (Levine, 2000) This means for just the first six months of 2001, 35.2 million Chinese workers were permanently or temporarily disabled at work. Worldwide, according to the International Confederation of Free Trade Unions, there are 1.2 million fatalities on the job each year (3,300 deaths per day), and 160 million new cases of work-related diseases. (ICFTU, 2002) Moreover, it is estimated that for each fatality there are 1,200 accidents resulting in three or more days off from work and 5,000 accidents requiring first aid. (Takala, 2002) The need to provide a safe place of work, safe plant and equipment, safe systems of work, training and supervision, and competent employees. Even if there were no statutes (Acts, Regulations or Orders) relating to safety, health and welfare at work – in many countries there are still many areas that are not covered directly by legislation. In such cases there is often a common law ‘duty of care’ that would still apply. In essence, the statutory duties derive from the common law which is law derived from judges’ decisions in courts of law. The duty of care imposes specific duties on employers and these typically are; to provide and maintain a safe place of work; to provide and maintain safe plant and equipment; to provide and maintain safe systems of work; to provide and maintain competent fellow employees. A safe place of work means an employer must ensure that a reasonably safe place of work is provided and maintained for employees. Has the employer applied reasonable foresight in carrying out a hazard identification and risk assessment and then made the findings into an action plan of risk reduction/removal, minimisation or control? May 2008 8 Safe plant and equipment means an employer must take reasonable care to provide and maintain proper appliance, train operatives adequately and provide appropriate personal protective equipment (PPE) if necessary. In the absence of any specific Statute or Regulation covering particular plant or equipment, an employer would be expected to faithfully assemble, operate and maintain such plant and equipment to the standards specified by the manufacturer. Safe systems of work means that an employer must devise reasonably safe methods of carrying out any task, training and supervising employees accordingly. The erection of scaffolding by unqualified operatives that is never checked or maintained would be an obvious example of an unsafe system of work. Asking employees to lift heavy loads when there has been no risk assessment, consideration of using manual handling aids or provision of manual handling training for the employees would be another unsafe system. An overload of administrative work, poorly defined job content and responsibility, and continuous pressure of deadlines leading to occupational stress or ‘burn-out’ would be further example of unsafe systems of work. Competent fellow employees means that an employer must select suitable and competent staff and supervise them adequately. New work systems or plant and machinery may necessitate re-training and newly considered supervisory targets. In other words, competence is not always forever. In order to attain damages at common law for a workplace injury or disease, an employee must show that the employer owed her/him a duty of care, that there was a breach of that duty of care due to negligence, and that there was reasonably foreseeable damage caused to the employee. Furthermore, the employee must prove that the employer’s negligence caused the injury. The Safety, Health & Welfare At Work Act, 1989 In Ireland the Safety, Health & Welfare At Work Act – is an example of legislation that applies to all workers, all employers and all workplaces for the first time. Despite this Act there is an average of over 60 fatalities a year. These figures do not include deaths from road traffic accidents involving commercial vehicles or persons at work; deaths from heart disease caused by work-related factors; or deaths from exposure to carcinogens within the workplace. This latter figure is estimated to be up to 350 per year. In addition, the number of serious occupational injuries average about 8,500 a year. Over 1,000,000 days are lost every year because of accidents and ill health at work. It is estimated that poor safety, health and welfare at work currently costs the economy some €3.3 billion or 6-7% of Gross National Product (GDP). Section 6 of the Act places a general duty on employers, ‘to so far as is reasonably practicable’, to ensure the safety, health and welfare at work of all employees. In particular, employers are obliged to design, provide and maintain plant and machinery so that it is safe and without risk; plan, organise, perform and maintain safe systems of work; provide information, instruction, training and supervision to ensure the safety and health of the workers; where it is not reasonably practicable to control or eliminate hazards, to provide and maintain suitable personal protective equipment (PPE); to prepare and revise as necessary adequate emergency plans; to provide protection against risk from the use of any article or substance; May 2008 9 to provide and maintain facilities and arrangements for the welfare of workers; to obtain, where necessary, the services of competent persons to ensure the safety and health of workers. Some argue that this is all the legislation that is required as this Section of the Act imposes very wide obligations on all employers and self-employed to give effect to their duty of care in every conceivable manner. The business case for health and safety Any accident or incidence of ill-health will cause both direct and indirect costs and possibly lead to an insured as well as uninsured cost. Direct costs are those that are directly associated with the accident. They may be insured (claims on employers and public liability insurance) or uninsured (fines, sick pay). Direct Costs Fines Compensation payouts Medical costs Sick Pay Indirect costs Indirect costs again may be insured (business loss, product or process liability) or uninsured (loss of goodwill, loss of reputation, extra overtime payments, accident investigation costs, production delays). Delays to production following the accident Personnel allocated to investigating and writing up the accident report Recruitment and training costs for replacement workers Damage to equipment and materials Reduction in product quality following the accident Reduced productivity of injured workers on light duty Overhead cost of spare capacity maintained in order to absorb the cost of accidents Lower motivation to work and workforce morale, increased absenteeism Loss of reputation Loss of goodwill Damage to the environment (e.g. from chemical incidents) Insured and uninsured costs Uninsured costs vary between businesses and types of accident. They are, however, several times more than the insured costs. They can be likened to an iceberg. The costs recoverable through insurance are visible. But hidden beneath the surface are the uninsured costs. Like an iceberg, most of the costs are not immediately visible. In the UK studies have given different ratios for these insured to uninsured costs. 1. A study in a cheque-clearing department of a financial institution (a lower risk environment) found the insured: uninsured ratio to be 1:3.3. That means for every £1 recoverable from their insurance, the company had to meet a further £3.30 themselves. May 2008 10 2. HSE studies found that the insurance premium paid: uninsured losses ranged from 1:8 to 1:36. That meant for every £1 they paid in insurance premiums, the companies had to meet a further £8 to £36 themselves for losses arising from accidents. Insured costs; injury ill-health damage to buildings Uninsured costs may include; lost time; sick pay; damage or loss of product and raw materials; repairs to plant and equipment; extra wages, overtime working and temporary labour; production delays; investigation time; fines; loss of contracts; increased insurance premiums loss of experience; legal costs; and loss of business reputation. It is important to note that insurance policies cannot cover all costs of accidents or disease because it may be illegal, (as with fines), or it may not be covered by the policy or the insurance excess might be greater than the particular cost. Employer’s liability insurance It has long been recognised in the UK, USA and some other countries that society has an obligation to compensate workers who are injured or who suffer ill health through the course of their employment. The most common means of society ensuring this is by government legislation requiring employers to fund a variety of insurance schemes. If an employee should be injured at work or become ill as a result of work and decides to claim for compensation, employer's liability insurance ensures that there is at least a minimum level of insurance to cover the claim. Failure to take out an insurance policy which covers the claim can result in the employer being fined. In the UK you must be insured for at least £5 million but once you've assessed your risks and liabilities you may decide that you need more than this. Most insurers offer cover of at least £10 million. You are able to split the cost of cover between different insurance companies as long as the total is at least £5 million. However, in many countries, employer's liability insurance is unknown and injuries at work are compensated automatically under a worker's compensation scheme. In some countries such as Australia there is a combination of both, with the State making a worker compensation payment and the employer guaranteeing any difference to their normal rate of pay with employer’s liability insurance. May 2008 11 1.3 THE ROLE OF NATIONAL GOVERNMENTS AND INTERNATIONAL BODIES IN FORMULATING A FRAMEWORK FOR THE REGULATION OF HEALTH AND SAFETY. The International Labour Organisation (ILO) is a specialised agency of the United Nations that deals with labour issues. Its secretariat — the people who are employed by it throughout the world — is known as the International Labour Office. The primary goal of the ILO today is to promote opportunities for women and men to obtain decent and productive work, in conditions of freedom, equity, security and human dignity." In working towards this goal, the organisation seeks to promote employment creation, strengthen fundamental principles and rights at work - workers' rights, improve social protection, and promote social dialogue as well as provide relevant information, training and technical assistance. Representation Unlike other United Nations specialised agencies, the International Labour Organisation has a tripartite governing structure — representing governments, employers and workers Governing Body The Governing Body is the executive of the International Labour Office. It meets three times a year. It takes decisions on ILO policy, decides the agenda of the International Labour Conference, adopts the draft programme and budget of the organisation for submission to the conference, and elects the director-general. The Governing Body is composed of 28 government representatives, 14 workers' group representatives, and 14 employers' group representatives. Ten of the government seats are held permanently by Brazil, China, France, Germany, India, Italy, Japan, the Russian Federation, the United Kingdom, and the United States. The remaining government representatives are elected by government delegates every three years. International Labour Conference The ILO organises the International Labour Conference in Geneva every year, where conventions and recommendations are drafted and adopted. The conference also makes decisions on the ILO's general policy, work programme and budget. Each member state is represented at the conference by four people: two government delegates, an employer delegate and a worker delegate. All of them have individual voting rights, and all votes are equal, regardless of the population of the delegate's member state. The employer and worker delegates are normally chosen in agreement with the "most representative" national organizations of employers and workers. Usually, the workers' delegates coordinate their voting, as do the employers' delegates International Labour Code One of the principal functions of the ILO is setting international labour standards through the adoption of conventions and recommendations covering a broad spectrum of labour-related subjects and which, together, are sometimes referred to as the International Labour Code. The topics covered include a wide range of issues, from freedom of association to health and safety at work, working conditions in the maritime sector, night work, discrimination, child labour, and forced labour. May 2008 12 Conventions Adoption of a convention by the International Labour Conference allows governments to ratify it, and the convention then becomes a treaty in international law when a specified number of governments have done so. But all adopted ILO conventions are considered international labour standards regardless of how many governments have ratified them. Ratification The coming into force of a convention results in a legal obligation to apply its provisions by the nations that have ratified it. Ratification of a convention is voluntary. Conventions that have not been ratified by member states have the same legal force as do recommendations. Governments are required to submit reports detailing their compliance with the obligations of the conventions they have ratified. Every year the International Labour Conference's Committee on the Application of Standards examines a number of alleged breaches of international labour standards. In recent years, one of the member states that has received the most attention is Myanmar / Burma, as the country has repeatedly been criticised for its failure to protect its citizens against forced labour exacted by the army. Recommendations Recommendations do not have the binding force of conventions and are not subject to ratification by member countries. Recommendations may be adopted at the same time as conventions to supplement the latter with additional or more detailed provisions. In other cases recommendations may be adopted separately and may address issues not covered by, or unrelated to any particular convention. A global health and safety framework According to the ILO, there are more than 250 million work-related accidents every year. Further it is estimated that more than 160 million workers fall ill annually through exposures to hazards in the workplace and that as many as 1.2 million workers die as a result of workplace accidents and diseases. The stark reality is that the human and social cost of production is unacceptably high. In economic terms, it is estimated that annual losses resulting from workplace accidents and diseases may be as high as 4% of gross national product (GNP). These figures include both the direct and indirect costs of accidents and diseases such as medical expenses, lost working days, reductions in production, compensation, training and retraining of workers, equipment damage and repairs, low staff morale, poor publicity and so on. In the past, such figures have had little impact on people as accidents and ill health at work had always been seen as part and parcel of production and why change, especially if there were many unemployed workers outside the factory gates waiting for any form of employment? Such losses, whether counted in human or financial terms, were considered inevitable. But times have changed whereby employers, factory owners, workers and governments are increasingly recognising that the social and economic costs of workplace accidents and diseases are unacceptably high and place a considerable burden on the competitiveness of the enterprise and the economic welfare of the country. Compliance with International Labour Standards (ILS), national laws and best practice and industry codes at the level of the enterprise is now seen as a fundamental pre-requisite for a successful modern company. Improving occupational health and safety is in the best interests of all stakeholders, namely, governments, employers and workers and requires consultation, co-operation and commitment from all concerned. Good health and safety management and practice forms one of the main foundations of success of the business – it is something to which many companies aspire. It has to be seen May 2008 13 as part of a total quality management (TQM) philosophy, whereby “best health and safety practices are managed in” rather than relying solely on “inspecting defects out”. Successful companies in the national and global arenas have clearly recognised that workplace accidents and diseases cost money and that an effective system for managing health and safety, which involves workers in the process, will help to reduce costs, increase productivity and benefit workers and society as a whole. A number of relevant ILO Standards on occupational safety and health (Conventions and Recommendations) have been adopted by countries such as Cambodia. The main ones are as follows: • ILO Occupational Safety and Health Convention, C155 • ILO Occupational Safety and Health Recommendation, R164 • ILO Guidelines on Occupational Safety and Health Management Systems, ILOOSH. • ILO, Fundamental Principles of Occupational Health and Safety, B. Alli (2001) (2001) Convention 155 is designed to form the framework for occupational health and safety law at national and at business level. It contains fundamental principles on safety policies, work organisation and principles for the prevention of injuries and ill health. It also has a Protocol (2002), which outlines requirements for the Recording and Notification of occupational accidents and diseases. This convention obliges Governments and employers to ensure that workplaces, machinery and equipment are safe and without risk to health. Occupational Safety and Health Convention C155 sets out broad requirements for member countries to follow to ensure minimum health and safety requirements are set into national laws. The main requirements for the State are; Article 8 Each Member shall, by laws or regulations or any other method consistent with national conditions and practice and in consultation with the representative organisations of employers and workers concerned, take such steps as may be necessary to give effect to Article 4 of the Convention. Article 4 requires that each Member shall, in the light of national conditions and practice, and in consultation with the most representative organisations of employers and workers, formulate, implement and periodically review a coherent national policy on occupational safety, occupational health and the working environment. National Governments then comply with these legal obligations as they see fit with laws and regulations which best fit with their legal system. Whereas in the past many countries produced national legislation to deal with specific problems associated with specific industries, this requirement addresses the workplace needs as a whole. Two specific examples of compliance with C155 would be the Chinese Labour Contract Law 2007 and the Australian Occupational Health and Safety (General) Regulation 2007 made under the Occupational Health and Safety Act 1989. Role of enforcement agencies and consequences of non-compliance The purpose of enforcement is to deal immediately with serious risk, to encourage good practice, help ensure sustained compliance with the law and hold failing duty-holders to account. May 2008 14 Occupational Safety and Health Act 1994 In Malaysia the Department of Occupational Safety and Health (DOSH), under the Ministry of Human Resources, has been assigned the responsibility of administrating and enforcing legislation related to occupational safety and health (OSH) to ensure that safety, health and welfare of people at work as well as others are protected from hazards resulting from occupational activities in the various sectors which include manufacturing; mining and quarrying; construction; agriculture, forestry and fishing; utilities (gas, electricity, water and sanitary services); transport, storage and communication; wholesale and retail trades; hotels and restaurants; finance, insurance, real estate and business services; public services and statutory authorities. The Occupational Safety and Health Act (OSHA) 1994 provides the legislative framework to promote, stimulate and encourage high standards of safety and health at work. The aim is to promote safety and health awareness, and establish effective safety organisation and performance through self-regulation schemes designed to suit the particular industry or organisation. The long-term goal of the Act is to create a healthy and safe working culture among all Malaysian employees and employers. The Department of Occupational Safety and Health (DOSH) is responsible for enforcing compliance with OSHA 1994. DOSH also enforces compliance with the Factories and Machinery Act 1967. OSHA 1994 defines the general duties of employers, employees, the self-employed, designers, manufacturers, importers and suppliers of plant or substances. Although these duties are of a general character, they carry a wide ranging set of responsibilities. The Act provides a comprehensive and integrated system of law to deal with the safety and health of virtually all people at work and the protection of the public where they may be affected by the activities of people at work. Employers must safeguard so far as is practicable, the health, safety and welfare of the people who work for them. This applies in particular to the provision and maintenance of a safe plant and system of work. Arrangements must also be made to ensure safety and health in the use, handling, storage and transport of plant and substances. Under OSHA 1994, 'plant' includes any machinery, equipment, appliance, tool and component, whilst 'substance' means any natural or artificial substance whether in solid, liquid, gas, vapour or combination thereof, form. Risks to health from the use, storage or transportation of substances must be minimised. To meet these aims, all practicable precautions must be taken in the proper use and handling of any substance likely to cause a risk to health. It is the duty of employers to provide the necessary information, instruction, training and supervision in safe practices, including information on the legal requirements. Employers need to consider the specific training needs of their organisations with particular reference to processes with special hazards. An employer employing 40 or more persons must establish a safety and health committee at the workplace. The committee's main function is to keep under review the measures taken to ensure the safety and health of persons at the workplace and investigate any related matters arising. An employer must notify the nearest occupational safety and health office of any accident, dangerous occurrence, occupational poisoning or disease which has occurred or is likely to occur at the workplace. Some operation, installation, maintenance and dismantling of equipment and process need competent persons. Thus, during the installation of machinery and equipment such as cranes, lifts and local exhaust ventilation systems, competent persons are compulsory to ensure safe May 2008 15 erection, whilst a boiler man and a steam engineer are required to operate high risk equipment such as boilers. Processes that use hazardous chemicals require competent persons to conduct the air quality and personal monitoring, and a safety and health officer and an occupational health doctor are required to ensure the proper surveillance of the workplace. Contravention of some of the requirements can lead to prosecution in court. Where they find a situation that is below the minimum legal standard, but relatively low risk then they can issue an improvement notice. This notice compels the employer to improve the situation to the necessary standard. Where there is a high risk situation then an inspector can issue a prohibition notice. A person who fails to comply with an improvement or prohibition notice that is served on him is liable to prosecution, with a maximum fine of RM 50,000 or imprisonment for a term not exceeding 5 years, or both. Occupational Safety and Health Act of 1970 In the USA, Congress passed the Occupational and Safety Health Act to ensure worker and workplace safety. Their goal was to make sure employers provide their workers a place of employment free from recognised hazards to safety and health, such as exposure to toxic chemicals, excessive noise levels, mechanical dangers, heat or cold stress, or unsanitary conditions. In order to establish standards for workplace health and safety, the Act also created the National Institute for Occupational Safety and Health (NIOSH) as the research institution for the Occupational Safety and Health Administration (OSHA). OSHA is a division of the U.S. Department of Labour that oversees the administration of the Act and enforces standards in all of the USA. CONSEQUENCES OF NON-COMPLIANCE Enforcing agencies may take a number of approaches to their role. A common approach would be, where possible, to take a monitoring and advisory role in the workplace, but where there is a non-compliance, have a wide range of enforcement powers. They will often set out requirements verbally and/or in writing. If a more formal approach is required they will usually issue some form of formal notice of non-compliance, such as an enforcement notice (improvement and prohibition notice) and/or prosecute. Where an individual, rather than the employer, has failed to comply with their health and safety duties then the State might punish by some sanction in the form of fine and/or imprisonment. The enforcement officer will consider a number of factors in deciding what action to take, including: the degree of risk the seriousness of the legal contravention past record and general attitude to health and safety if there has been a blatant disregard for the law if there is sufficient evidence Formal enforcement powers often include the issue of Improvement or Prohibition notices: Improvement notices tell you what the problem is and require things to put right within a certain time. The Inspector would usually discuss the time limit with you and explain how to get it extended if there is good reason. Prohibition notices tell you what the problem is and require you to stop doing something until things are put right. These are only issued if it is considered that there is a risk of serious injury. May 2008 16 Notices will contain, or have attached, an explanation of what you must do to comply. You are often allowed to use a different but equally effective alternative. When notices are issued, a copy will be provided for any employees. In the UK these notices are put in a register, which is open to public inspection. Failure to comply with a notice is a serious offence and is likely to lead to prosecution. An employer has a right to appeal and if there is an appeal against an Improvement Notice, then it is suspended until the appeal is heard. A Prohibition Notice usually remains in force until the appeal is heard. Prosecution is more likely where there: is a blatant disregard for the law (particularly for economic reasons) is reckless disregard for the health and safety of workpeople and others have been repeated breaches of legislation and management is neither willing nor structured to deal adequately with these has been a serious accident or a case of ill-health arising from a substantial legal contravention or where: a particular type of offence is prevalent in an activity or area a particular contravention has caused justifiable, serious public concern What Powers Do Inspectors Have? The law gives enforcing inspectors a wide range of powers, which would typically include the power to: enter premises at any reasonable time carry out examinations and investigations take measurements, photographs and samples take possession of an item e.g. a faulty tool (telling you why and giving you a receipt) have articles dismantled and tested require information and take statements inspect and copy documents Financial Penalties There are two basic types of financial penalty (fine), fixed and variable. Financial penalties where the duty holder is subject to a variable fine, rather than a fixed penalty, are normally imposed by the regulator or enforcing authority without recourse to the courts. In most cases, the duty holder can refuse to accept the administrative fine – in which case matters revert to consideration of a criminal prosecution in the normal way. This system is used for health and safety offences in Germany, Spain, Portugal, Greece, Italy, Austria. By contrast fines decided by the Courts are more common in the UK, Ireland and Malaysia. Restorative justice Restorative Justice (RJ) processes typically provide the opportunity for all parties with a stake in a particular offence to resolve collectively how to deal with the aftermath of the offence and its implications for the future, in particular by enabling offenders to acknowledge the impact of what they have done and to make reparation, and victims to have their harm or loss acknowledged and amends made. This restoration normally will take place in a court of law. Typically RJ is a feature of Sharia law in Muslim countries, such as UAE. Conditional cautioning A scheme, whereby there is formal cautioning dependent upon certain agreed actions by the offender. An offender agrees to comply with conditions to avoid being prosecuted. May 2008 17 The conditions which may be attached to such a caution are those which have either or both of the following objects:– Facilitating the rehabilitation of the offender, Ensuring that he makes reparation for the offence Failing to comply with the conditions attached to the caution will result in criminal proceedings and the caution being cancelled. Enforceable undertakings An Enforceable Undertaking (EU) is a legal agreement in which an organisation has to carry out specific activities to improve worker health and safety and deliver benefits to industry and the broader community. An EU is an alternative to court action for an alleged breach of health and safety law. Typically, an EU will only be used for minor offences and where no-one has been harmed, and compliance with an EU will cost an organisation considerably more than the amount they could expect to be fined in court. An EU will likely involve strict educational and safety promotion obligations for participants, as well as the cost of carrying out safety upgrades, audits and specified training. It will include a commitment to future safety standards, including steps taken to ensure the specific type of incident does not recur. Enforceable Undertakings are used in several Australian States. Fixed penalties There are two types of fixed penalty system: 1. Fixed fines These are issued by enforcing authority, typically subsequent to a health and safety inspection or investigation, as opposed to ‘on the spot’. Used in several Australian States. 2. On-the-spot fines Imposed by the health and safety inspector ‘there and then’. Both variants of fixed fine typically involve smaller sums than would be available to the court upon conviction of an offence. Probation for companies and directors Companies and Directors on conviction being placed on probation for offences committed. Any further offence within a set limit of time would result in the original offence being punished. Available in the UK under the Companies Act but rarely invoked. Used in health and safety systems in USA. Adverse publicity orders Offenders are required to publicise their failings. This could fit in with restorative justice and conditional cautions. These contain the key elements of reasoning in criminal justice: deterrence, retribution and rehabilitation. Used in a health and safety context in some states in Australia, and now the UK. EMPLOYERS’ RESPONSIBILITIES According to ILO Convention C155 employers must ensure, so far as is reasonably practicable, that workplaces, machinery and equipment, and processes under their control are safe and without risks to health. They must also ensure that, so far as is reasonably practicable, the chemical, physical and biological substances and agents under their control are without risks to health when appropriate protection measures are taken. May 2008 18 This includes the provision, free of charge, of, where necessary, adequate protective clothing and protective equipment to prevent, so far is reasonably practicable, risk of accidents or of adverse effects on health. In the case of shared workplaces, the employer shall collaborate in applying the above requirements of this Convention. Employers shall are also required to provide, where necessary, control measures to deal with emergencies and accidents, including adequate first-aid arrangements. This is interpreted in Malaysia under their Occupational Safety and Health Act 1994 as follows; General duty of employers and self-employed persons to their employees. It shall be the duty of every employer and every self-employed person to ensure, so far as is practicable, the safety, health and welfare at work of all his employees. Specific duties of the employer to his employees (a) the provision and maintenance of plant and systems of work that are, so far as is practicable, safe and without risks to health; (b) the making of arrangements for ensuring, so far as is practicable, safety and absence of risks to health in connection with the use or operation, handling, storage and transport of plant and substances; (c) the provision of such information, instruction, training and supervision as is necessary to ensure, so far as is practicable, the safety and health at work of his employees; (d) so far as is practicable, as regards and place of work under the control of the employer or self-employed person, the maintenance of it in a condition that is safe and without risks to health and the provision and maintenance of the means of access to and egress from it that are safe and without such risks; (e) the provision and maintenance of a working environment for his employees that is, so far as is practicable, safe, without risks to health, and adequate as regards facilities for their welfare at work. It shall be the duty of every employer and every self-employed person to prepare and as often as may be appropriate revise a written statement of his general policy with respect to the safety and health at work of his employees and the organization and arrangements for the time being in force for carrying out that policy, and to bring the statement and any revision of it to the notice of all of his employees. General duties of employers and self-employed persons to persons other than their employees (non employees). It shall be the duty of every employer and every self-employed person to conduct his undertaking in such a manner as to ensure, so far as is practicable, that he and other persons, not being his employees, who may be affected thereby are not thereby exposed to risks to their safety or health. It shall be the duty of every employer and every self-employed person, in the prescribed circumstances and in the prescribed manner, to give to persons, not being his employees, who may be affected by the manner which he conducts his undertaking, the prescribed information on such aspects of the manner in which he conducts his undertaking as might affect their safety or health. May 2008 19 Duties of an occupier (employer) of a place of work to persons other than his employees. An occupier of non-domestic premises which has been made available to persons, not being his employees, as a place of work, or as a place where they may use a plant or substance provided for their use there, shall take such measures as are practicable to ensure that the premises, all means of access and egress available for use by persons using the premises, and any plant or substance in the premises or provided for use there, is or are safe and without risks to health. EMPLOYEES RESPONSIBILITIES AND RIGHTS Similarly the ILO sets out workers rights and responsibilities within Convention C155 and these are; Employee’s duties Workers shall co-operate with their employer in the fulfilment by their employer of the obligations placed upon him, and; Report any situation to their supervisor that they believe presents an imminent and serious danger to life or health. Employee’s rights In order to do the above workers shall be given adequate information and training on occupational safety and health. Employees shall also be consulted by the employer on, all aspects of occupational safety and health associated with their work; Employees cannot be charged for any safety and health measures shall necessary for the workers e.g. PPE and access equipment. Finally, the employee has a right not to return to a work situation where there is continuing imminent and serious danger to life or health. Again in Malaysia under the Occupational Safety and Health Act 1994 this is interpreted as follows; General duties of employees at work. It shall be the duty of every employee while at work(a) to take reasonable care for the safety and health of himself and of other persons who may be affected by his acts or omissions at work; (b) to co-operate with his employer or any other person in the discharge of any duty or requirement imposed on the employer or that other person by this Act or any regulation made there under; (c) to wear or use at all times any protective equipment or clothing provided by the employer for the purpose of preventing risks to his safety and health; and (d) to comply with any instruction or measure on occupational safety and health instituted by his employer or any other person for health and safety. May 2008 20 A person who contravenes the provisions of this section shall be guilty of an offence and shall, on conviction, be liable to a fine not exceeding one thousand Ringgit or to imprisonment for a term not exceeding three months or to both. Duty not to interfere with or misuse things provided pursuant to certain provisions. A person who intentionally, recklessly or negligently interferes with or misuses anything provided or done in the interests of safety, health and welfare in pursuance of this Act shall be guilty of an offence and shall, on conviction, be liable to a fine not exceeding twenty thousand Ringgit or to imprisonment for a term not exceeding two years or to both. ABSOLUTE AND QUALIFIED REQUIREMENTS Standards There are four standards that are used on an international level and these are important because the define the extent of a requirement; 1. Absolute statutory requirements Absolute The Absolute standard requires that “it shall be done”, regardless of cost, inconvenience, or even ability to comply. The duty does not allow choice and it is normally expressed by the words ‘must’ or ‘shall’. ILO C155 is a good example, where at national level it requires that; “Each Member shall, in the light of national conditions and practice, and in consultation with the most representative organisations of employers and workers, formulate, implement and periodically review a coherent national policy on occupational safety”. Practicable The Practicable standard requires that “if it is possible”, it shall be done. The only consideration is it possible, again, cost and inconvenience does not come into it. So they must be met even though implementation may be difficult, inconvenient and/or costly. In Malaysia the Occupational Safety and Health Act 1994, Section 15 requires that; “It shall be the duty of every employer and every self-employed person to ensure, so far as is practicable, the safety, health and welfare at work of all his employees”. Reasonably Practicable The standard of Reasonably Practicable requires that “it must be done, if the cost does not outweigh the risk”. We use the weighing scales model to illustrate that when it comes to the extremes of cost or risk, that the decision is easy. However, when the scales balance in the middle, the decision making process is much more difficult. This is where the role of Acts, Regulations, Approved Codes of Practice, Guidance Notes, and Codes of Practice come into their own, by giving us standards to aim for, and assist in deciding what is reasonably practicable and what is not. Reasonable Care Reasonable requirements are those which might normally be expected of an average person taking care of what they are doing. For example in Malaysia the Occupational May 2008 21 Safety and Health Act 1994, Section 15, duty of the employee requires to “take reasonable care for the safety and health of himself and other persons who may be affected by his acts or omissions at work”. SOURCES OF INFORMATION There are various sources of information both internal and external to the organisation. These sources of information are important since they can be useful when making health and safety decisions. Sources of information might be people or paperwork. Internal Sources People would include the employees themselves, their worker representatives, supervisors and health and safety officers. Paperwork would include proactive documentation such as risk assessments, inspection and maintenance records, training records, audit reports, attitude surveys, near miss reports, health surveillance and environmental monitoring data. Reactive documentation would include accident investigation reports, accident/ill-health and absence data, actions taken by the enforcing authorities, civil and/or insurance claims. External Sources People would include enforcement agencies, experts such as health and safety consultants, lawyers, professional bodies such as IOSH, equipment manufacturers, and trade associations. Paperwork would include national laws, international standards such as ILO, Approved Codes of Practice and Guidance documents, material safety data sheets, Trade Union documentation. Additionally there are national sources of information that can be accessed such as OSHA in America, the European Agency for Safety and Health at Work, the Health and Safety Executive in the UK and Worksafe in Western Australia; Occupational Safety and Health Administration (OSHA) The Occupational Safety and Health Administration aims to ensure employee safety and health in the United States by working with employers and employees to create better working environments. OSHA offers an extensive Web site at www.osha.gov that includes a special section devoted to small businesses as well as interactive eTools to help employers and employees address specific hazards and prevent injuries. The agency provides a variety of publications in print and online. In addition, workplace safety and health information or assistance for employees is available during business hours through OSHA's call centre at 1-800-321-OSHA. The hotline remains open 24 hours a day for fatality and accident reporting during non-business hours. OSHA strives to reach all employers and employees, including those who do not speak English as a first language. The agency maintains a Spanish Web page, and Spanish-speaking operators can be reached at the OSHA national call centre during business hours. Various publications, training materials and videos are available in Spanish, and OSHA continues to issue new publications. Many regional and area offices also offer information in other languages such as Japanese, Korean and Polish. The European Agency for Safety and Health at Work The European Agency for Safety and Health at Work was set up to collect, analyse and promote OSH-related information. The Agency's mission is to make Europe's workplaces May 2008 22 safer, healthier and more productive, and in particular to promote an effective prevention culture. They are a reference point for OSH information. They commission, collect and publish new scientific research and statistics on OSH risks. Additionally they share good practice, and communicate information in a variety of ways to reach workers and workplaces. Our publicity campaigns include the European Week for Safety and Health at Work, which focuses on different themes. We also provide information on our website, via our electronic newsletter OSHmail, and in a range of printed publications. Health and Safety Executive These are a UK source of information on current topics and developments in health and safety. They provide information; help or guidance and a number of these publications have been translated into languages other than English such as Chinese, Arabic and Polish. They also offer a telephone interpreting service, which can be accessed by phoning 0800 0320 121. Their website address is www.hse.gov.uk Worksafe (Western Australia) WorkSafe is a division of the Department of Consumer and Employment Protection, the Western Australian State Government agency responsible for the administration of the Occupational Safety and Health Act 1984. The principal objective of the Occupational Safety and Health Act 1984 is to promote and secure the safety and health of persons in the workplace. The library has a large collection of workplace safety and health information including: Over 10,000 books and reports About 150 journals Nearly 400 videos and DVDs Online databases: OSH-ROM, 3 major databases providing information on occupational safety and health OSH-PLUS which provides full text coverage of OSH legislation, guidance notes, newsletters and journals from the UK and European communities Chemwatch, contains information on chemicals including a MSDS database CCH electronic occupational safety and health library. Legislation (Western Australian Acts, Government Gazettes, and Hansard). Mailto:wslibrary@docep.wa.gov.au 1.5 KEY ELEMENTS OF A HEALTH AND SAFETY MANAGEMENT SYSTEM Health and safety management programmes are essential for any organisation wishing to improve health and safety standards. Many organisations do not comply with International, National and Regional legal requirements. This results in major problems when people get injured on their premises. Health and safety management processes should form part of the holistic risk management process in any organisation to ensure compliance with International, National and Regional requirements. Ideally this risk management process should also integrate with the Environmental Management System and Quality systems to form an integral part of the holistic management process. This combined management systems is often referred to as ‘Integrated Management Systems’. This will result in major savings and peace of mind for May 2008 23 middle and top management. The risk management process should ensure that personnel are legally appointed to manage the health and safety process. It should also ensure that personnel are trained and understand the importance of their appointments. Occupational health and safety management systems are continuing to grow around the globe, both as a result of national legislation and via voluntary measures such as the OHSAS 18000 series of international standards. Italy’s National Institute for insurance against occupational accidents and illnesses (INAIL), for example, published in September 2002 a guidance document aimed at promoting broader implementation in industry of voluntary OSH management systems based on the OHSAS 18001 and BS 8800 standards. Mexico is also trying to promote the uptake of OHSAS 18001 and BS 8800 in industry through an Agreement to reduce labour insurance fees on companies that have or develop OSH management systems based on these standards. Guidance was also issued by the government to help companies to assess their OSH management systems. Denmark rewards facilities and companies that voluntarily adopt health and safety management systems. In October 2001, the Danish government implemented a statutory order on the certification of good working environment for company occupational management systems. The certificate is issued by a notified body when a company meets the requirements. Certification is voluntary, but certified companies receive a subsidy and are exempted from inspections for which a fee is charged. Hong Kong, on the other hand, requires, under its Factories and Industrial Undertakings (Safety Management) Regulation, that certain industrial undertakings develop and implement a health and safety management systems. The government has issued guidance on how to develop the appropriate management system. The Canadian province of Manitoba issued guidance at the end of 2002 on workplace safety and health programs to assist employers in complying with their obligations under the Workplace Health and Safety Act. OCCUPATIONAL HEALTH AND SAFETY ASSESSMENT SERIES 18000 1999 VERSUS GUIDELINES FOR OCCUPATIONAL SAFETY AND HEALTH MANAGEMENT SYSTEMS (ILO-OSH 2001) The OHSAS 18000 Series The OHSAS 18000 Series of International Standards for Occupational Health and Safety Management Systems is an International specification for Occupational Health and Safety Management Systems, published in 1999 and corresponding to BS 8800. In structure and approach, it has been developed to be compatible with both the ISO9001 and ISO14001 management system standards. Conformity with this standard is also becoming an important priority for industrial operators worldwide, since the management system is viewed as making a major contribution to the reduction of workplace accidents, injuries and illnesses. This then is seen as leading to a reduction in costs associated with occupational injuries and illnesses, including workers’ compensation costs, lost work-time accidents, and possibly, future liability claims from workers that might otherwise suffer long-term illnesses or disabilities associated with their work. May 2008 24 OHSAS 18001 specifications require businesses to demonstrate that their systems for managing Health and Safety pro-actively seek to eliminate or minimise risks to employees, that they comply with all national & international legal requirements and continuously strives to improve their performance in the areas of Health & Safety. As with ISO 9000 and ISO 14000, company systems are subject to regular external review by an independent Accreditation Body. Whilst BS 8800 provided guidelines for an effective Occupational Health System, OHSAS 18001 provides an assessment specification compatible with established standards for quality and environmental management systems. Organisations may progress from one standard to the next, each being assessed and certified independently. In this way an Integrated Management System (IMS) is achieved by introducing defined standards of excellence in each area and a Performance Management System (PMS) which measures and monitors total performance improvement. OHSAS 18001 is very similar to the ISO 14001 Environmental Management Systems (EMS) standard - even the section numbering is nearly the same. The primary difference is the "risk assessment" section (which replaces the environmental aspects section of ISO 14001) and the substitution of "health & safety" for "environmental". OHSAS helps in a variety of respects... it helps to minimise risk to employees, improve an existing OH&S management system, demonstrates diligence and gain assurance among other benefits. In addition to the overall workplace improvements and clear market advantages gained by OHSAS 18001 certification, companies implementing a compliant OHSMS can realise the following benefits: Operational cost savings through OH&S programs A reduced number of workplace accidents and injuries Increased control of regulatory issues Clear demonstration of legal and regulatory compliance to regulatory authorities, customers and employees Better management of health and safety risks on a planned and ongoing basis Potential to reduce public liability insurance costs OHSAS Model May 2008 25 The International Labour Organisation’s (ILO) Guidelines on Occupational Safety and Health Management Systems (ILO/OSH 2001) The International Labour Organisation’s (ILO) Guidelines were the result of extended international consultations. The Guidelines were prepared on the basis of a broad-based approach involving the ILO and its tripartite constituents and other stakeholders. They have also been shaped by internationally agreed occupational safety and health principles as defined in relevant international labour standards. Consequently, they provide a unique and powerful instrument for the development of a sustainable safety culture within enterprises and beyond. They are intended to benefit workers, employers, organisations, safety and health systems and the environment. In Malaysia the ILO’s Occupational Safety and Health Management System (ILO-OSH-MS) have become mandatory for so-called “high risk” industries, including chemicals and construction. Colombia also requires a mandatory OSH-MS in the form of an annual health and safety working plan. Singapore also issued a number of health and safety guidelines at the beginning of 2003 for a variety of industries, including hotels, biomedical sciences and waste treatment that aim at the identification of workplace hazards and measures for their prevention. Singapore also requires the implementation of a safety management system in factories under a March 2003 amendment to the Twelfth Schedule of the Factories Act. China issued its “Guidelines for Occupational Safety and Health Management Systems" and a related Audit Standard in 2001, also in an effort to promote the voluntary implementation of the ILO’s OSH-MS in Chinese industry. Germany is also aiming to promote the voluntary uptake in industry of the ILO’s OSH management system, by the publication of a National Manual on Occupational Health and Safety Management Systems, which is based primarily on the ILO’s guidance. In addition, the Occupational Insurance Associations (Berufsgenossenschaften) has reduced by half the number of Accident Prevention Rules (BGV) by the end of 2003 in an effort to reduce bureaucratic burdens on industry whilst maintaining the same high level of worker protection ILO-OSH 2001 deals with the occupational safety and health management system at the organisational level. The Guidelines stress that compliance to national laws and regulations are the responsibility of the employer. ILO-OSH 2001 encourages the integration of OSH management system elements into overall policy and management arrangements, as well as stressing the importance that at organisational level, OSH should be a line management responsibility, and should not be seen as a task for OSH departments and/or specialists. Both of these management systems is based on the “plan-do-check-act” management model and embodies the principle of continual improvement as exemplified in the British Standard for quality assurance systems. The OSH management systems in the organisation has five main sections which follow the internationally accepted Demming cycle of Plan-Do-Check-Act, which is the basis to the “system” approach to management. These sections are namely Policy, Organising, Planning and Implementation, Evaluation and Action for improvement. Policy contains the elements of OSH policy and worker participation. It is the basis of the OSH management system as it sets the direction for the organization to follow. Organizing contains the elements of responsibility and accountability, competence and training, documentation and communication. It makes sure that the management structure is in place, as well as the necessary responsibilities allocated for delivering the OSH policy. May 2008 26 Planning and implementation contains the elements of initial review, system planning, development and implementation, OSH objectives and hazard prevention (preventative control measures, management of change, emergency preparedness, procurement and contracting). Through the initial review, it shows where the organisation stands concerning OSH, and uses this as the baseline to implement the OSH policy. Evaluation contains the elements of performance monitoring and measurement, investigation of work related injuries, ill- health, diseases and incidents, audit and management review. It shows how the OSH management system functions and identifies any weaknesses that need improvement. It includes the very important element of auditing, which should be undertaken for each stage. Persons independent of the activity being audited should conduct audits. This does not necessarily mean third party auditors. Action for improvement includes the elements of preventive and corrective action and continual improvement. It implements the necessary preventive and corrective actions identified by the evaluation and audits carried out. It also emphasizes the need for continual improvement of OSH performance through the constant development of policies, systems and techniques to prevent and control work-related injuries, ill health, diseases and incidents. The main sections and their elements of the OSH management system at the organization are shown in figure 1 below: May 2008 27 UNIT IGC 1 ELEMENT 2: POLICY 2.1 THE PURPOSE AND IMPORTANCE OF SETTING POLICY ON HEALTH AND SAFETY The role of health and safety policy in decision making It has often been said that it is better to be safe than sorry, and whilst this is easy to say, the reality of it requires structures and responsibilities, across the organisation e.g. Health and Safety Committees, for ensuring the implementation and maintenance of health and safety standards. Every individual needs to take personal responsibility for their own and their colleagues' safety and health, being aware of potential hazards and acting to ensure they are eliminated, managed or avoided. All incidents should be avoidable given forethought, and taking the appropriate actions or following the correct procedures. A Health and Safety Policy gives staff the essential guidance they need in this decision making process. Needs of different organisations A major part of any organisations business should be risk management, whether technical, commercial, safety or otherwise. The challenge is to adopt a flexible approach that recognises the significance of these risks to individual businesses, in order to minimise their impact. Only senior management can make these decisions and one of the aims of health and safety policy therefore is to give direction to the business as to what will be required to meet these challenges in the form of goals and objectives. All management systems should be policy driven, based on the business strategy, with goals and targets to drive themselves forwards in meeting the businesses requirements, through a process of continual improvement. Aims, Objectives and key elements of a health and safety policy This health and safety policy should influence all of the organisation’s activities, including the selection of people, equipment and materials, the way work is done and how you design and provide goods and services. So a good health and safety policy statement should contain the aims (which are not measurable) and the objectives (which are measurable) of the organisation. Aims will normally remain unchanged during policy revisions, whereas the objectives will be reviewed and modified as necessary on an annual basis. A written statement of the policy and the organisation and arrangements for implementing and monitoring it shows to staff, and anyone else, that hazards have been identified and risks assessed, eliminated or controlled. Overall Aims The overall aim of the health and safety policy is to create a structure to its approach to health and safety. A health and safety policy is a written statement of principles and goals embodying the company's commitment to workplace health and safety. Senior management must be committed to carrying out that policy consistently and completely. Health and safety must enjoy the same high priority as the organisation's other major goals. The policy statement should include as a minimum contain a written statement of principles and goals be signed by the chief executive officer be dated recognise the need to comply with the occupational health and safety laws acknowledge the right of every employee to work in a safe and healthy environment May 2008 28 spell out management's commitment to providing a safe and healthy work environment by eliminating or minimizing the hazards that can cause accidents and injuries recognise the priority of safety in relation to other organisational goals and policies encourage cooperation with unions and workers to involve all employees in putting the health and safety policy into practice. As well the policy should be clearly stated in terms that are easily understood posted in a conspicuous place and distributed and explained to all employees followed by every employee, including senior management, in all work activities kept up-to-date and in tune with current activities of the organization and with the latest legislation. Health and Safety roles and responsibilities of individuals within the organisation In order to achieve the policy objectives the employer must allocate responsibility, accountability and authority for the development, implementation and performance of the OSH management system. This will include: Managers (e.g. directors, works managers, human resource managers and supervisors) Specialists (e.g. health and safety adviser, occupational nurse, first aiders, fire officer, and electricians). For smaller companies, some of these specialists may be employed on a consultancy basis. Employee representatives. Worker participation is an essential element of the OSH Management system. The employer needs to ensure that the workers and/or their safety representatives are consulted, informed and trained on all relevant aspects of health and safety. For an employer with fewer than five employees, a Policy in verbal form is all that is required. However compliance with HASAWA S.2 (3), may present some problems for such employers. A single sheet of paper placed on the notice board may well be sufficient as information in instances where only a few employees are concerned. Normally an organisation will have a single health and safety policy. Sometimes, however, it may be necessary to have a global corporate policy, which is then backed-up with site specific health and safety policies which although site specific, mirror the overall intent of the corporate policy. For instance, in a large petro-chemical company, the head office may issue a safety policy to cover all its working sites, and then discover that part of the policy does not cater for a particular site because the circumstances on that site are so different from all the others. In such a case, the one site would have a different safety policy of its own, since the main policy did not adequately cover its circumstances. In any event, each site needs its’ own section to cover specific hazards, precautions, and responsibilities, duly signed and endorsed by the senior person on site. Specifying the arrangements for achieving general and specific aims The arrangements section of a health and safety policy comprises details of exactly HOW the policy statement will be achieved. This will include health and safety rules and procedures and the provision of welfare facilities such as a first aid room and wash rooms. To be effective it should be; In a number of formats Effectively communicated Revised as appropriate Monitored via audits May 2008 29 2.2 THE KEY FEATURES AND APPROPRIATE CONTENT OF AN EFFECTIVE HEALTH AND SAFETY POLICY Setting targets Organisations should translate their overall aims into achievable targets. A particularly effective way of demonstrating senior management commitment to health and safety is by the signing and communication a policy statement of intent. It sets quantifiable organisational objectives for health and safety. A lack of firm management commitment of this kind leads to a perception within the business that safety is not equal to other business objectives. An addition of a date beside the signature will indicate the last time that the objectives were reviewed. A health and safety policy is divided into three distinct sections: 1. General Statement of intent 2. Organisational structure 3. Arrangements for implementation General Statement of Intent Without integrated and sustained management effort from all levels within an organisation, accident prevention cannot be successful. Only management can provide the authority to ensure this activity is co-ordinated, directed, and funded. The tool required to produce such organisational control is the general statement of intent. It is a visible demonstration of senior management commitment in so far as it contains a general policy statement, signed and dated by the most senior member of the management team. Furthermore, to be effective it requires on-going monitoring at all levels to ensure that the requirements of the policy are carried out by managers, supervisors, and workers. This statement is normally contained upon a single sheet of paper, and is in itself an expression of management commitment with the requirement of a signatory to the statement, and as such does not contain detail. Rather, it is a statement outlining the company philosophy toward health and safety in the form of objectives, which are quantifiable targets. It plays a major role in defining the safety culture of that particular company, by committing the company to a series of objectives, (quantifiable targets) which can never be less than that required by law... These objectives should ideally be proactive and would include issues such as employee training, risk assessments conducted. Reactive targets include a reduction in the number of accidents occurring in the business. a common such target will be ‘benchmarking’ the businesses H & S performance against that of their peers in their industry. This can be done with performance indicators that are measurable such as the number of over 3 day lost time injury accidents (LTIs). What is usually referred to as “the Safety Policy” will contain this statement, together with details of the organisation, (responsibilities at each level within the company), and the arrangements, (how health and safety will be managed in detail). It is important to distinguish between a safety policy and a safety manual - these are quite different, but are often found combined. The safety policy will refer to the manual for details May 2008 30 of technical points. The main problem is that the likelihood of a document being read is proportional to its complexity. Therefore, it is common practice to produce short safety policies, and accompanying explanatory manuals. Organising for health and safety An essential requirement of a safety policy, if it is to be effective, is to define health and safety responsibility in detail within this document, and then to check (monitor) that this is being carried out. This is accountability - the primary key to management action. It is not the same thing as responsibility, since accountability is responsibility that is evaluated, and measured. So there is in-built within the organisation an element of accountability. It is normal to identify individual responsibilities at each management level by position rather than by name. This organisation is often represented schematically via an organisational chart which shows the lines of communication (reporting) within the company structure. The organisation for health and safety should reflect the organisational structure and method of working of the company. Responsibility for health and safety should be given at successive levels of management, from the top to individual supervisors. Responsibilities should be clearly defined, and preferably included in job descriptions, to prevent over-lapping and omission. Particular clarity is required where the health and safety organisation cuts across the company’s organisational lines. The input required from functional management e.g. works engineer, chemist, safety advisor should also be described, as well as the organisation for consultation between safety representatives and safety committees. This allocation of responsibilities is important since it should clearly define the role of managers, safety advisers, workers and therefore, their influence upon the policy and their role in monitoring its effectiveness. The commitment should be demonstrated not only by words but also by actions and provisions specific to the organisation, for example: Resources - sufficient to provide and maintain safe and healthy working conditions Training - in health and safety and first aid Publicity - on availability of training Data collection - collecting and analysing data on accidents, sickness and injury Promotion - of consultation and participation between all employees Develop - safety awareness Arrangements This section of the policy should detail the practical arrangements in force to assist in overall policy implementation. It should consider the arrangements for planning and organising, controlling hazards, consultation and communication and monitoring compliance with, and assessing the effectiveness of, the arrangements. They can be divided into two main categories, i.e. ‘general’ such as first aid, fire safety, welfare, etc. and ‘specific’ relating to plant, processes, etc. Therefore such arrangements should cover: Training and active monitoring, Accident reporting/investigation, May 2008 31 Safe systems of work, Noise/environmental control, Health surveillance PPE, Fire safety and emergency procedures, Electricity, Manual Handling, Work at height, Controlling contractors, Machinery guarding, Communication, Consultation procedures, Statutory examination procedures, Medical /welfare considerations. In other words, this final section should address all of the issues contained within International Labour Organisation’s (ILO) Guidelines on Occupational Safety and Health Management Systems (ILO/OSH 2001) and OHSAS 18000 apart from the policy stage. In practice this section of the policy tends to be very lengthy and is often presented in the form of a manual with appropriate cross-references made to it in the General Statement and Organisation sections. Reviewing the Policy It is important that a health and safety policy is monitored and reviewed on a regular basis. The health and safety policy should be reviewed; Routinely e.g. after a certain period of time, or earlier if there is; Technological change Organisational change Legal changes As a result of identification of a problem via active or reactive monitoring (e.g. a major accident). Conclusion To sum up, a Health and Safety Policy is the essential framework for the successful management of the health and safety function which should be accorded the same priority and importance as other management functions. Standards and guidance relating to health and safety policy There are several standards and guidance documents in the area of health and safety policies. These include; OHSAS 18002 Guidelines of occupational safety and health management systems, ILO-OSH 2001 In the UK the HSE have produced two documents HSG65 Successful health and safety management and INDG324 Stating your Business INDG324 NDG324 May 2008 32 UNIT IGC 1 ELEMENT 3: ORGANISING FOR HEALTH AND SAFETY 3.1 ORGANISATION HEALTH AND SAFETY ROLES AND RESPONSIBILITIES THE EMPLOYER (CORPORATE AND NON-CORPORATE) All employers regardless of their legal status (corporate or non-corporate – see below) have a legal responsibility to protect those that might be harmed by their undertaking. This duty would cover local, national and international businesses, a local Government department of a charity. Depending upon the country this could be a civil and/or criminal responsibility. There are two main types of legal structure for a business: 1. Non-corporate bodies The "body" here is a business created when people come together for a common purpose and the resulting group has no separate legal structure of its own. The most common types are sole traders and partnerships. S.37 prosecutions are not available in the case of unincorporated bodies since the employer and the people are one and the same. Sole traders A sole trader does not share the legal responsibility for his or her business with anyone. Sole traders are self-employed. This doesn't mean they can't employ people. It just means they alone have the responsibility for all matters health and safety. Partnerships A partnership is formed when a group of people - between two and twenty - agree to do business together for the purpose of making a profit. They combine their resources and share the profits. A partnership cannot be prosecuted, because it is has no legal personality for the purpose of the criminal law. In a standard partnership, each partner is jointly and severally liable for the acts of the partnership. This means that any fine imposed on conviction will be the responsibility of all the partners. 2. Corporate bodies When a group of individuals create a separate legal existence, they incorporate i.e. form a separate body. The most usual form of corporate body is the limited company. Limited companies There are four main types of company: Private company limited by shares - members' liability is limited to the value of the shares they hold. Private company limited by guarantee - members' liability is limited to the amount they have agreed to contribute to the company's assets if it is wound up. Private unlimited company - there's no limit to the members' liability. Public limited company (PLC) - the company's shares may be offered for sale to the public and members' liability is limited to the value of the shares they hold. It takes only one person to start a limited company and at least two for a public limited company or a private unlimited company. The owner(s) must abide by company law. May 2008 33 A company registered with the Registrar of Companies, has a legal personality distinct from its members or owners. Therefore the company itself can commit an offence and it is the company that must in general be prosecuted for it. Directors, managers, employees and others may be liable as individuals under HASAWA 1974, sections 7, 8, 36 and 37 in addition to the company’s liability Not-for-profit organisations can incorporate - usually as a company limited by guarantee. A not-for-profit business reinvests its profits back into the business. Joint Ventures In joint ventures the separate companies will constitute a partnership in which the companies are jointly and severally liable for contraventions arising from the venture. ROLES AND RESPONSIBILITIES OF THE EMPLOYER TO EMPLOYEES The main responsibilities internationally are defined in ILO Occupational Health and Safety Convention C155 and Recommendation R164, and these are; Employers shall be required to ensure that, so far as is reasonably practicable; the workplaces, machinery, equipment and processes under their control are safe and without risk to health. the chemical, physical and biological substances and agents under their control are without risk to health when the appropriate measures of protection are taken. provide, where necessary, adequate protective clothing and protective equipment to prevent risk of accidents or of adverse effects on health. Whenever two or more undertakings engage in activities simultaneously at one workplace, they shall collaborate in applying the requirements of this Convention. provide, where necessary, for measures to deal with emergencies and accidents, including adequate first-aid arrangements. provide all necessary information, instruction and training in occupational safety and health consult with the workers or their safety representatives provide, free of charge, anything necessary to ensure the health, safety and welfare of employees implement organisational arrangements, adapted to the size of the undertaking and their work activities, to ensure the health, safety and welfare of the employees. ROLES AND RESPONSIBILITIES OF THE EMPLOYER TO NON-EMPLOYEES Additionally employer’s have a responsibility to other people, who are not employees but could be affected by their work activities. This covers a wide range of people including contractors, sub-contractors, visitors, and the general public. In reality this means doing similar things to those required to protect employees. In certain cases additional information may have to be given concerning these risks, their control measures and any relevant emergency procedures, since these non-employees may not understand or be aware of certain hazards that they might be exposed to or how they should be have towards them. Visitors The precautions that are reasonably practicable with visitors are varied but commonly include; Identification of visitors by signing in and out plus the wearing of badges May 2008 34 Provision of information regarding relevant risks and site rule and procedures including foreseeable relevant emergencies. Provision of escorts, which might mean that there is only a need to sign in and out, as the escort will provide any necessary health and safety information as required. It is critical that all badges are numbered and that at the end of the day (or whenever) a note is made of outstanding badges and action taken to determine the whereabouts of the badge holder. Often visitor badges are of different colours and this helps them to be readily recognised, and can be used to denote areas to which they should have access. Badges for workers and regular contractors should ideally have a photograph to further aid identification. Contractors In any relationship between a business - known as the client - and a contractor, both parties will have duties under national health and safety laws. Similarly, if the contractor employs sub-contractors to carry out some or all of the work, all parties will have some health and safety responsibilities. Measures to ensure contractors' safety aren't substantially different from those to ensure the safety of employees. An employer should: identify the requirements of the job and assess the risks involved consult staff and unions on relevant health and safety issues decide what information and training is required select an appropriate contractor and ascertain their health and safety policies and procedures determine a subcontractors' competence request and approve the necessary risk assessments and/or method statement monitor and review the way work is carried out The client must ensure that there is co-operation and co-ordination at all times between their staff and the contractor/subcontractor. In particular, the client should: provide all parties with information, instruction and training on anything that may affect health and safety make the contractor and subcontractors aware of your health and safety procedures and policies provide management and supervision to ensure the safety of contractors/subcontractors There are actual cases world-wide where clients, contractors and subcontractors have all been fined for failing in their health and safety duties, e.g. failure to: ensure a contractor's competence supervise a contractor take steps to prevent contact with live equipment provide information about the existence of asbestos ensure safe operation of vehicles ensure safe loading to or unloading from delivery vehicles assess risks to health from regular exposure to high vibration levels exercise a duty of care towards a subcontractor provide a formal site induction, risk assessment or method statement May 2008 35 The Public Employers must also consider the impact that their business might have upon the general public, and take appropriate control measures. In certain sectors, such as retail, this is even more important since in such a situation the employer is encouraging the general public to enter their premises to buy goods and services. Therefore it is important that the employer ensures that their premises and activities do not present a risk to the general public by ensuring that; appropriate directions, instructions and safety notices are displayed areas such as changing rooms, toilets, showers and offices that may be used by visitors are kept as clean and tidy as practicable. they are provided with sufficient safety information, for example, regarding dust, noise, fumes, electrical safety, wet floors and fire precautions. excavations on public footpaths are appropriately protected dust from demolition work does not cause a problem for local homeowners. You must consider your impact on the general public with regard to environmental hazards such as noise and fumes and also physical hazards such as concealed exits, heavy works traffic at certain times and mud on the road. Finally, the employer should have a plan of the premises available for the emergency services (in the event of fire) which shows the positions of hazards such as high voltages, gas cylinders, dangerous chemicals, slurry tank covers and dangerous animals (e.g. boars). Directors’ and Senior Managers Responsibilities Protecting the health and safety of employees or members of the public who may be affected by a businesses activities is an essential part of risk management and must be led by the board of directors. Failure to include health and safety as a key business risk in board decisions can have catastrophic results. Many high-profile safety cases over the years have been rooted in failures of such leadership. In some countries Directors and Senior Managers can be personally liable when these duties are breached because it is seen that members of the board have both collective and individual responsibility for health and safety. This is because they are ultimately responsible for ensuring that an appropriate health and safety policy is produced and that it is complied with. Middle Managers Middle managers have a key responsibility in ensuring the successful implementation of the health and safety policy. This responsibility will apply to middle manager in all organisations, regardless of size or nature of the work involved and will specifically include; Visible demonstration of management commitment Effective communication at a local level The motivation of employees Good planning and effective co-ordination of work Effective monitoring and controlling of health and safety procedures Consultation with the workforce Good decision making Supervisors A supervisor has a responsibility to co-operate with their employer in providing all necessary supervision for health and safety. This job is not limited to producing a good quality product. 36 May 2008 Supervisors are a vital link in the chain for effective management of health and safety. Good supervisors lead by example; they get good results and develop a motivated, safety conscious workforce. A supervisor is paid to supervise - and this includes supervising for health and safety. Supervisors are often expected to be management’s ‘eyes and ears’ on the shop floor, but accident investigations have shown that supervisors are often unaware of the full range of responsibilities they have as part of the management team. These responsibilities typically include ensuring that; People are properly supervised for health and safety at all times People work and behave safely at all times People are properly trained People are obeying company health and safety rules Everyone is aware of the hazards in the workplace Machinery is properly guarded when used Machines and equipment are inspected to ensure they are safe to use People are using the correct safety appliances properly, e.g. jigs and push sticks People are not unnecessarily exposed to hazardous substances People are using the correct personal protective equipment The working area is kept clean, clear and tidy Everyone knows what to do in an emergency Action is taken following accidents and near misses Persons with primary health and safety functions (safety practitioners) The Health and Safety Manager, the Safety Adviser or the Safety Officer (the safety practitioner) is responsible for ensuring that the whole of an organisation is aware of existing and future health and safety legislation, and for advising on the implementation, practice and development of health and safety matters. This specifically includes; Provide appropriate advice and support to managers. Maintain up to date health and safety legislation and best practice knowledge. Provide a range of services for departments to meet their health and safety needs. Worker health and safety responsibilities for themselves and other through their acts or omissions All workers have a right to work in environments where risks to their health and safety are properly controlled. Under health and safety law, the primary responsibility for this is down to employers. A worker also has a duty of care (see Unit 1 IGC, Element 1) for their own health and safety and that of others who may be affected by their acts or omissions at work. Failure to comply with this duty may result in a criminal and/or civil action depending upon the local laws. Specifically employees should ensure that they; Take reasonable care for their own and others health and safety Comply with all reasonable instructions given on health and safety grounds Use all safety devices and protective equipment correctly and do not make them ineffective Report immediately any hazard which poses imminent or serious danger which they cannot correct themselves. Report any accident, injury to health caused by or in connection with work. May 2008 37 Health and safety legislation, therefore, requires employers and workers to cooperate. If an employee has any specific queries on health and safety in their workplace, then first they should ask their manager, or if they prefer, their safety representative or trade union representative. Responsibility of persons in control of premises Anyone who is in control of premises regularly visited by members of the public e.g. retail establishments or leisure facilities, or a landlord with tenants needs to manage the health and safety of the premises to ensure the health and safety of third parties caused by problems such as tripping. Property owners (landlords) will have responsibilities in respect of the common parts of offices or blocks of residential accommodation. Any person who has control of non-domestic premises has a duty to ensure, so far as was reasonably practicable, the health and safety of persons who are not his employees, but to whom the premises have been made available. This would include contractors, visitors and the general public. Persons in control of non-domestic premises, such as landlords and occupiers, should, so far as is reasonably practicable, ensure that they; provide safe access and egress including safe routes of entry and exit provide a place of work and any plant or substances which are safe and without risks to health. A safe and healthy place of work includes providing toilets, drinking water, clean air, a comfortable temperature, adequate lighting, cleanliness, enough workspace and safe workstations, sound floors and traffic routes, protection from falls and falling objects and washing and changing facilities. A specific example of such a piece of specific legislation in this area would be Section 10 of the Occupational Health and Safety Act 2000 in Australia, which states that ‘a person who has control of premises used by people as a place of work must ensure that the premises are safe and without risks to health’. This includes doorways, stairways, walkways and lifts to and from the premises. Furthermore, a person who has control over any machinery or substances in non-domestic premises, that has been provided for the use of or operation by people at work, must also ensure that the plant or substance is safe and without risk. Responsibilities of the self-employed There are many self-employed workers in the world today and they are frequently involved in work in other employers’ (and public) premises. They have a responsibility similar to that of the employer and employee combined. So they should ensure that their work does not harm themselves or any other person. The supply chain An increasing number of large organisations have come to the realisation that the health, safety and environmental impacts of the product they may produce or the service they deliver May 2008 38 are often rooted in the components, materials and services supplied to them within their supply chain. Smaller businesses are now facing increasing pressure to supply health, safety and environmental policies when tendering for new work contracts making it a very relevant part of their business agenda. Market leaders in every sector are working more closely with their suppliers and monitoring their performance. The result is that their supply chain is absorbed into the culture of the client. Powerful procurement departments emerge, to define and impose the necessary standards (not just OSH) and guard lists of preferred suppliers. The attitude of the client is extremely important in determining the way in which the supply chain acts. For example, supermarkets demand absolute compliance with legislation and codes of practice in matters of food hygiene, because this is paramount to their business. They have, in turn, rigorous systems for monitoring and inspection to ensure that agreed procedures are being followed. However, there is often an absence of similar regimes for the health and safety of people at work. It is therefore necessary for clients to harness this power and drive forward a more robust approach to health and safety in the supply chain. An example of the importance of the supply chain is in the UK offshore oil and gas industry where approximately 80% of work carried out offshore is by contract staff. A study identified the supply chain as one of the issues that may be affecting the apparent plateau of incidents on offshore installations in the North Sea. Responsibilities of Designers, Manufacturers, and Suppliers Everyone in the supply chain, from the designer through the manufacturer to the supplier of all articles and substances. Is responsible for ensuring, so far as is reasonably practicable that; all articles and substances will be safe and without risks to health at all times when used correctly during set-up, use, cleaning and maintenance. all necessary testing and examination is carried out to ensure that it will be safe and without risks to health Anyone erecting or installing articles for use at work must ensure that they are safe and without risk to health when used properly Provide adequate information about its safe setting, use, cleaning, maintenance, dismantling and disposal. Importers and suppliers often carry the same duties as designers and manufacturers, although it would usually be enough for them to rely on the test and examinations of the manufacturer/designer. An exception to this rule would be plant hire companies who would be viewed as suppliers and expected to conduct all necessary testing and examination of returned plant and machinery to ensure that it will be safe and without health risks before it is rented out again. Relationship between client and contractor and the duties of each has to each others employees Effective health and safety provision depends upon the control. Competence, co-operation and communication between all parties in the workplace. As employers in their own right they will both have duties to protect both their own employees and non-employees from tasks and activities under their control. Likewise self-employed contractors will have a duty towards the protection of third parties also. May 2008 39 Persons working in a host employers or self-employed persons undertakings Host employers and self-employed people must ensure that workers carrying out work on their premises receive relevant information. If reliance is placed upon the employer of the visiting contractor to provide such information, then checks should be made to ensure that this relevant information has been passed on. The information should include any relevant risk assessments and resultant safe systems of work that they are required to follow as well as any relevant emergency procedures and the names of any relevant emergency personnel nominated by the host employer e.g. first aiders, fire marshals etc. Client contractor relationship Both clients and contractors, (anyone brought in by a client to work at the clients premises who is not an employee of the client), have duties under health and safety legislation. If the contractor employs sub-contractors to carry out some or all the work then both parties will still have some responsibilities. Clients Clients need to take certain steps prior to the contractor starting work, these include: Identifying the job that they want the contractor to do and the health and safety implications of the job Selecting a suitable contractor - clients need to satisfy themselves that contractors are competent. Selecting a suitable sub-contractor - the HSE advise that this is best left to the contractor but clients must satisfy themselves that a contractor has an effective procedure for checking the competence of a sub-contractor. In the case of nominated sub-contractors however, this responsibility for checking competence would rest with the client. Other steps that need to be taken by all parties are: 1. Risk assessments of the work, including how each others work could affect the health and safety of the workforce and anyone else (e.g. visitors). 2. Provide information, instruction and training including information about the risks arising from their operations and relevant safety rules and procedures, especially emergency procedures. 3. Co-operation and co-ordination - liaison arrangements must be implemented such as regular meetings and briefings between clients, contractors and sub-contractors. 4. Consulting the workforce is key for the securing of the workforces co-operation. 5. Management and supervision of work being carried out Shared responsibilities in the case of joint occupation Almost all organisations as the owners or occupiers of premises, will at some point take on contractors to undertake construction work. As part of the process they may also consult designers, such as architects, before the work is commenced. Contractors, in turn, use the services of sub-contractors for certain specified works. The interface between such parties is often misunderstood in terms of health and safety responsibilities, and is of key importance as far as preventing accidents is concerned. The occupier of premises often has duties regarding the state and condition of the premises. Therefore, both eth client and the contractor will have joint responsibilities in shared ‘common areas’. The occupier is not normally liable for dangers associated with the May 2008 40 contractors’ work activities, so long as they can that when selecting the contractor, they took all reasonably practicable steps and furthermore, they monitored their SFARP to ensure that it was being carried out correctly, in accordance with the contract documentation. Co-operation and co-ordination Employers who work together in a common workplace have a duty to co-operate in order to discharge their duties under best practice, or where appropriate local laws apply. This will include consideration of each other when conducting risk assessment and any relevant emergency procedures. For example, when considering safe evacuation of a multi-occupancy premises in the event of a fire, the employers in the whole of the building should be involved. It should be appreciated that for the purposes of liability, 'occupation' implies managerial control, and a building owner or client may be just as much in control of a construction project as main/principal contractor and any sub-contractors. Procedures for selecting a competent contractor There are a number of considerations in the selection of contractor. The extent to which they are considered is decided upon the scale of the contract and the associated risks i.e. what is reasonably practicable. These elements are; Records: Health and Safety Policy, risk assessments, training and equipment maintenance records Health and Safety Record: Accident statistics, Prosecutions and Enforcement Notices Previous Experience Membership of Professional bodies Curriculum Vitae of Key Personnel Details of any quality system References from previous clients Regulating the contractor Organisations need to operate some form of practical control of contractors on their premises. This practical regulation may be documented in the form of in-house 'Contractors Regulations/conditions' or 'Rules for the Safe Conduct of Project Work'. This document is issued to contractors at the pre-tender stage of any work, irrespective of the size and scale of the work, and contractors should sign a Certificate to the effect that these Regulations will be strictly adhered to during the work, returning the Certificate to the client before work commences. On larger projects this document would be incorporated into the pre-tender health and safety plan. Contractor operations can cover simple activities, such as window cleaning or maintenance of plant, to large-scale construction projects. For projects to be undertaken safely, there must be co-operation, consultation, communication and co-ordination of activities between the parties involved. Important Considerations The following procedures and systems must be incorporated in written Contractors Conditions: 1. Consultation prior to commencement of project 2. Procedures involving use of the client's equipment 3. Reporting, recording and investigation of injuries, diseases and dangerous occurrences 4. Safe systems of work, including the use of permit to work systems and method statements 41 May 2008 5. Safe operation of plant and machinery 6. Noise prevention and control 7. Fire prevention and protection 8. Hazardous substances on site 9. Personal protective equipment 10. Contractors' vehicles 11. Site clearance 12. Window cleaning and external painting All the above factors must be considered prior to any project or construction activity taking place. 3.2 CONSULTATION WITH EMPLOYEES Difference between ‘informing’ and ‘consulting’. The difference between informing and consulting lies in the fact that upon informing, a trade union or safety representative merely acknowledges certain information presented to them by the employer. Consulting, on the other hand, means a situation where the employer, before making any key health and safety decisions, is obliged to inform the trade union of any proposal and for the safety representatives to consult with their fellow workers and get their views. Those views then need to be reported back to the managers before any final decision is made or any action is taken. Therefore, consultation involves TWO WAY communication whereas informing involves ONE WAY communication. The importance of consulting Consultation is important because it is the process by which management and employees or their safety representatives jointly examine and discuss issues of health and safety concern. It involves managers actively seeking and then taking account of the views, ideas and feelings of employees, either directly or through their representatives, before making key health and safety decisions. Meaningful consultation depends on those being consulted having adequate information and time to consider it, but it is important to remember that merely providing information does not constitute consultation. It is good practice for employers when consulting employee representatives to make sure that all representations are considered and where they are not accepted that reasons are given. In many countries, especially those that have ratified ILO Convention C155, employers are legally obliged to consult within their organisation to ensure that concerns, ideas and inputs of the workers are received, considered and responded to as necessary. Workers, their representatives or the health and safety committee, as appropriate, should be; given adequate information on health and safety matters, so that they can examine factors affecting health and safety and make appropriate recommendations. consulted before any major new health and safety measures are introduced, so that they can obtain the support of the workers. consulted in planning any alterations of work processes, work content or organisation of work which may have health and safety implications. able to contribute to the decision-making process as regards health and safety matters. able to contact labour inspectors. given reasonable time off to carry out their health and safety functions and undergo reasonable authorised training in relation to these functions. May 2008 42 able to access specialist health and safety advice as necessary given protection from unfair dismissal on health and safety grounds whilst carrying out their functions or as members of any health and safety committee. Health and Safety Committees Health and Safety committees can help the employer develop, promote, monitor and amend their health and safety management systems. For a committee to operate effectively it is necessary to define its objectives and functions (terms of reference). It is critical that the membership of the committee is balanced between workers and management. Safety committees should: develop safe systems of work and safety procedures; analyse accidents and causes of notifiable occupational diseases; review risk assessments; examine safety audit reports; consider reports submitted by safety representatives; monitor the effectiveness of health and safety training; consider reports and factual information provided by enforcing authorities (labour inspectors). monitor and review the adequacy of health and safety communication and publicity within the workplace; and continuously monitor all arrangements for health and safety and revise them whenever necessary. Managers and representatives should agree who chairs the meetings, how often meetings should be held, and what they hope to achieve. It is important that safety committees actually review health and safety systems. They should not become reporting centres for matters that should be dealt with by managers. Reasons why a health and safety committee might be ineffective a) Uneven balance of representation b) No clear Terms of Reference c) Infrequent meetings d) No minutes taken e) No respect of each other f) Lack of commitment from management g) Poor chairmanship h) No real influence on decision making i) No access to information/specialist advice j) No formalised procedures with agendas k) Inappropriate items l) Agenda not led by industrial relations Frequency of meetings This would depend upon the nature of the organisation’s business, the risks involved, any legislative requirements and local conditions such as the hierarchy of committees representing departments/locations/sites. Usually meetings are held somewhere between monthly and three monthly. May 2008 43 Minutes and Agenda It is important that minutes are taken of all safety committee meetings since they are the record of the agreed actions. Consequently, the review of the previous minutes is a matter early on the agenda of any safety committee meeting. A typical agenda would involve; a) Apologies for absence b) Review of previous minutes and matters arising c) Agenda Items a) Any problems b) Review of H & S Performance since last meeting c) Analysis of accident statistics - accident trends d) Development of any H & S Arrangements d) Any other business e) Date of next meeting May 2008 44 UNIT 4: PROMOTING A POSITIVE HEALTH AND SAFETY CULTURE 4.1 Concept of a safety culture Definition of health and safety culture 'Culture' is a complex area involving as it does an understanding of human behaviour and its influences but it is often described colloquially as 'the way we do things around here'. A more formal definition given in the HSE's 'Successful Health and Safety Management' is: 'The safety culture of an organisation is the product of individual and group values, attitudes, perceptions, competencies and patterns of behaviour that determine the commitment to, and proficiency of, an organisation's health and safety management'. Correlation between health and safety culture and health and safety performance Traditionally, attempts to improve workplace safety concentrated on technical issues and individual human failures. However, a series of major accidents such as the nuclear reactor accident at Chernobyl, in Russia and the fire at King’s Cross railway station in London and the fire plus explosion on Piper Alpha all highlighted the role that organisational policies and procedures contribute to accidents. Following the Kings Cross Fire, Judge Fennel stated that “..a cultural change in management is required throughout the organisation”. Similarly during the Piper Alpha Inquiry Lord Cullen said that, “it is essential to create a corporate atmosphere or culture in which safety is understood to be and is accepted as, the number one priority” 4.2 Tangible outputs or indicators of an organisation’s or site’s health and safety culture. Developing and promoting a positive safety culture is an important part of any effective health and safety management. These tangible outputs are often referred to as the “health and safety climate”. Features of such a safety culture include; Effective Communication Effective communication is essential in achieving a positive health and safety culture. Therefore the effectiveness of the communication system can be used as a measure e.g. asking the workforce if the health and safety policy has been brought to their attention, or specifically what their role and responsibilities are. Vassie and Lucas (2001) found that organisations who used supervisors within the work environment had little employee involvement in safety activities, had greater reliability on a recognised safety group and showed a lack of specific health and safety communication to staff. In contrast organisations using team leaders showed greater management and employee involvement in safety as well as more open communication. They also found that 5 out of the 35 companies involved in the study did not have any system in place for communicating the results of risk assessments to employees, which is cause for concern. Communication can be improved by organisations making sure employees are kept informed of health and safety objectives through channels such as safety briefings, safety forums, tool-box talks, through notice or bulletin boards, e-mail etc.. Often companies are good at cascading information from management downwards but less effective in establishing two way communication. May 2008 45 One way in which an organisation can improve communication from employees is through establishing boards within the workplace in which employees can highlight safety and production issues and can suggest solutions to there workers problems. The board should be reviewed by a supervisor on a daily basis. This form of communication needs to be carefully controlled as it can be abused, however, managed correctly it can be an effective way of including employees in the safety process. Information on notice boards can be improved by organising the board space therefore companies may wish to colour code and label sections of the board by function e.g. Safety productivity and quality. Important information is best conveyed through verbal face-to-face meetings first and then posted on the notice board (Cooper, 1998). Leadership and commitment Indicators of leadership and commitment can be measured. Senior managers support safety through indirect means such as establishing safety policies and procedures, setting production goals etc. While supervisors act as the link between management and shop floor, they monitor worker compliance to safety and provide feedback to workers concerning their behaviour. Measurement of the level of compliance can be measured using safety climate tools and safety audits. Equal Priority In many organisations’ senior management do want safety to be a key element within their company with equal priority to production, quality etc. but there can be barriers between the senior executive and the workers. Peterson (1993) suggests these barriers are created by middle managers being resistant to change. Managers may hear safety is to be given equal priority from upper management but are then confronted with other, often stronger, messages of cost cutting, downsizing and productivity levels. The key to a positive safety culture lies in achieving agreement within the organisation on how to implement a safety element within the company. Such an agreement must have senior management support, supervisors' accountability and the active involvement of middle managers. Incident (accident) investigation Investigation of incidents provide useful lessons for organisations. However, if they are conducted with the intention of apportioning blame this may lead to employees failing to report accidents or near misses. Thus, investigations should concentrate on the fundamental causes of incidents rather than a procedure to allocate blame. Mearns et al. (2001) found that employees willingness to report accidents was also correlated with how committed they perceived management to be to safety. The procedure for dealing with the findings of the incident investigation will indicate the safety culture together with the quality and implementation of the recommendations. Consultation Proactive involvement of worker on health and safety is important in securing their cooperation and also to harness their ideas, views and feelings in decision making. Specific tangible indicators or outputs an organisation’s (or a site’s) health and safety culture such as; Accident rates Absenteeism Sickness rates Staff turnover Level of compliance with health and safety rules and procedures Number of employee/contractor complaints about working conditions May 2008 46 Factors promoting a negative safety culture Whilst it is possible to promote a positive health and safety culture, it is equally possible to promote a negative safety culture. This is an important consideration since the shared common knowledge or culture unique to each organisation shapes the way it deals with health and safety. It impacts on all aspects of work, affecting the organisation, groups and individuals. Examples of factors which can promote a negative safety culture include; Continual reorganisation Uncertainty Behaviour of management Standard of decision making Poor selection of contractors 4.3 FACTORS INFLUENCING SAFETY RELATED BEHAVIOUR Individual, job and personal factors (Human Factors) In order to begin to develop a fully-fledged human factors strategy, the above factors should be considered during risk assessment, accident investigation, design and procurement as well as in day-to-day operations. Organisations must recognise that they need to consider human factors as a distinct element which must be recognised, assessed and managed effectively in order to control risks". In any workplace, and during any workplace activity, there is a complex interaction between factors relating to job, individual and organisation. This complex interaction can have a profound health and safety implications. Tasks need to be ergonomically designed and matched to the capabilities of the individual employees carrying them out. This matching of the job to the person should involve both a physical match , including the design of the workplace and of the working environment, and a mental match, involving the individual's information and decision-making requirements and their perception of the task and its risks. Individuals vary with regard to their attitudes, skills, habits and personalities and these differences can have important influences upon task-related behaviour. Sometimes these influences are straightforward and obvious. However, often they are complex and much more difficult to identify. Whereas some factors, such as skills and attitudes, can be influenced and modified, others, such as personality, are much more fixed and resistant. Human beings are a necessary component in all production/process systems at work, especially construction. Often accident prevention measures focus on the design of plant and systems, but even where sophisticated control measures are in place, accidents due to human factors can and do occur. Design to prevent accidents and ill-health due to human behaviour at work, concerns factors influencing human error, and the causes of human error. Human factors refer to the organisational and job factors, and human and individual characteristics which influence behaviour at work in a way which can affect health and safety. In other words the three crucial elements of job, individual and organisation. These three principal factors are concerned with the first two dominoes in Bird & Loftus’s Accident Causation Theory: May 2008 47 Organisation Wherever people seek to make a living or achieve specified goals, organisations arise. The one characteristic that they all have in common is structure. They cannot function by allowing their members to do whatever they think needs to be done; they have to be organised. Consequently, organisational factors exert the greatest influence upon individual and group behaviour This formal structure takes place as duties are assigned, and procedures adopted. So rules, and regulations are circulated and the production processes are begun. In health and safety terms this is expressed in the setting of goals of commitment to safety and the demonstration to individuals that deviations are not acceptable. All the above is achieved by the development and implementation of a safety management system, e.g. HS (G) 65 “Successful health & Safety Management”: Setting a Policy. Providing clear direction for the organisation in the form of broad objectives. This is also important since it also demonstrates senior management philosophy and commitment to health and safety to the workforce. Organising is the next stage and involves developing the vague, objectives contained within the policy document into an effective management structure and arrangements. This will ensure that there is a shared common understanding of the organisations values and beliefs (safety culture). This stage can be divided into four distinct activities, which we remember as the four C’s: control, competence, co-operation and communication. Planning and implementing concerns a planned and systematic approach to implementing the health and safety policy with the aim of minimising risks. This involves adequate control of risks by co-ordinated action from all members of the organisation. Risk assessment is employed to decide on priorities and to set objectives for eliminating/minimising risks. Performance standards (safe systems of work, planned preventative maintenance schedules etc.) are established. May 2008 48 Next comes measuring of performance against the agreed standards arrived at in the previous stage. This is necessary to identify when and where improvement is needed. There are essentially two broad strategies to measuring, pro-active and reactive. For example, it will need to decide whether there will be a periodic inspection of the work activity and a sample of permits to ensure proper completion and effective use? Pro-active techniques would include (inspections, safety contact, safety sampling and health surveillance). Re-active techniques would include (accident/near miss reporting/investigation, enforcement notices, prosecutions, civil claims) Finally there is audit and review of performance. This is necessary for the organisation to learn from all relevant experience and apply the subsequent lessons. This is based upon the regular review of performance achieved by the systematic review of data gathered from routine monitoring and from independent audits of the whole safety management system. Although organisational factors have a major influence over individual and group behaviour, they are often ignored. This is true both at the design stage and at the investigation stage following an accident or incident. Cultural factors can exert enormous pressure upon individuals and lead to them adopting behaviour patterns out of a wish to conform. Unfortunately, these cultural pressures can be both negative and positive with regard to health and safety matters. There is little point in a culture, which urges conformity to the rules, if those rules are themselves suspect from a health and safety standpoint. These organisational issues often involve design, managerial and decision-making failures. Trust between employer and employees and open, two-way communications are vital if organisational failures are to be identified and rectified before they lead to human failures and consequently to accidents. Job factors Successful management of human factors involves the development of systems, which have taken into account human capabilities and fallibilities. So careful design of the job is essential, and should ensure that no mis-match, (either physical or mental), occurs between the job requirements and the employees capabilities. otherwise, there will be the potential for human error. Thus all tasks should be designed in accordance with ergonomic principles to take into account the limitations and strengths of the individuals performance, otherwise any mismatch between job requirements and people’s capabilities provide the potential for human error. There are two main considerations – physical and mental match; Physical match concerns the design of the whole workplace and working environment. Mental match involves the individual’s information and decision-making requirements, as well as their perception of the tasks and risks. Job factors need to consider the task, workload, environment, equipment displays and controls, procedures etc. Factors to be considered are: Likely human errors highlighted by risk assessments May 2008 49 Operator decision making - deciding on the optimum balance between human and automatic contributions to safety actions. in other words, the level of automation required within the task. Ergonomics - this concerns the person/machine interface, and concerns how we make the job or machine fit the person. Thus we consider layout of control panels, information displays, control devices etc. Design and presentation of procedures and operating instructions. Do we use operating manuals only, or do we use training sessions and leaflets as well? Do we use words only, or words and pictures? Organisational control of environmental factors; workspace, access for maintenance, and the effects of noise, lighting and the thermal environment etc. Provision of the correct/safe tools and equipment. Scheduling of work patterns to control fatigue and stress - shift organisation, rest breaks, work variety, and arrangements for emergency situations. Effectiveness communications The individual The Organisation and Job factors will lead to a potential accident situation, and it will be the individual factors, which now dictate how the person(s) will behave in that situation. People bring to their job their own personal attitudes, skills, habits and personalities which can be strengths or weaknesses depending on the task demands. Individual characteristics influence behaviour in complex and significant ways. Their effects on task performance may be negative, and may not be prevented by task design e.g. overcoming a machine guard. Some characteristics such as personality are fixed and cannot be changed, whilst others such as skills, and attitudes may be changed. These factors are as follows: Stress Stress is perhaps best understood in engineering terms. In a structure the various members are subject to loading, as in a bridge which is subject to different loadings at different times. For example, when traffic flows over the bridge it gives rise to internal and external stress. Overloading structural members leads to overstress which can result in bending and/or fatigue, without necessarily getting anywhere near the breaking strength. These well known conditions of stress and strain in engineering apply equally as well to people who live and work in stressful conditions. Different personality types are better able to cope with high stress levels, and this is important when considering appointing persons to high stress jobs e.g. fighter pilot, air traffic controller etc. Stress due to organisational and job factors will be revealed in several ways, one of which is increased accident frequency. Skills Skill concerns the performance of a task in a successful and rapid way. Many tasks fulfil this definition from typists to skilled craftsmen. It is recognised that there are individual differences in skill acquisition, and consequently, this must be a consideration in job design, especially when complicated skills are involved. Personality Personality is the word used to describe the individual’s perception of his total environment, including himself. So personality is directly linked to a person’s behaviour as perceived by May 2008 50 others e.g. honest, intelligent, loyal, serious etc. So where a supervisor has a personality that is considered by other workers to be weak, unintelligent, and disloyal this is important from a health and safety viewpoint because he will not be respected, and consequently any instructions that he gives are unlikely to be followed when he is not present. Physique This concerns a physical rather than mental mis-match. Certain jobs require strong physiques e.g. scaffolder, labourer or soldier, whereas other jobs require less physical ability e.g. electrician, manager, receptionist. Again if this is not considered by the organisation then this could result in a person that is not strong enough having an accident e.g. dropping a scaffolding tube from height. Attitude Attitudes are sub-conscious filters that colour all information we receive. Attitudes arise out of our beliefs, and are shaped by our education and experiences. This sub-conscious filter is important because it will colour all information, and will influence the way that we act in a particular situation. DATA PERCEPTION Safe act filtered data Unsafe act (human error) ATTITUDE FILTER Personal Factors Model Aptitude Aptitude is a natural ability to do certain tasks well e.g. play football. It is closely linked to personality. Where a job requires certain traits in an individual e.g. good hand/eye coordination, then identifying someone with an above average such aptitude would mean less time spent on training developing the required skills. Experience Our experiences as we grow older will shape and change our attitudes and thus, perceptions of ourselves and the world around us. The prime influences are economic, parents/friends, school and work. Motivation Motivation is important because it is a requirement within an unsafe individual in order to achieve a lasting alteration in his behaviour form unsafe to safe behaviour. This behaviour change is achieved by altering the persons underlying attitude(s), and this will only be possible with a suitably motivated individual. (see later in this section for more detail). May 2008 51 MOTIVATION Motivation is concerned with what driving forces (positive or negative) which lie behind the way a person acts. Emerson, a philosopher, once said that "every man is as lazy as he dares to be". The study of motivation concerns the examination of all the sticks (negative motivators) and carrots (positive motivators) that overcome this natural laziness and move us, either eagerly or reluctantly, to action. In industry and commerce motivation is divided thus: 1. The motivation of people. Is concerned with actions taken by superiors to influence their subordinates to more effective performance. This is more commonly known as leadership. 2. The motivation within people. This assumes that there are driving forces within people that drive them forward to achieve certain goals. Motivation within people This is the key to understanding and influencing people. It is not sufficient for a Safety officer to believe that his job has been adequately carried out just by providing sufficient information, instruction and training. For research clearly shows that all too often workers who have been successful in learning facts are nevertheless incapable of, or unwilling to use the newly acquired information. Why? Safety is not merely a matter of laying down and enforcing rules as is often pre-supposed by some safety officers. Whilst it is desirable to clearly define operating procedures in order to overcome or minimise a hazard, enforcement of such rules is difficult to achieve. The problem is that human beings are not always rational, and this colours our attitude. Attitude concerns the problem of the difference between what people say they believe or will do, and what they actually do. Methods of change Attitudes are essentially habitual, and as a result are not easily changed. In one way this is good because when an attitude is safe then the individual’s behaviour in that specific area will normally be safe as a result. It is bad because intrinsically unsafe attitudes will be difficult, but not impossible to change. For example, consider how society’s attitudes to drink driving and smoking have changed over the last fifteen years. In times of change, changing attitudes are essential. Attempts to achieve such a change will be met with the sort of resistance characterised by the remark "we have done it this way for the last 50 years and it's been OK, so why change now?" Those wishing to promote change have the task of convincing individuals that change is needed because the old attitude is no longer appropriate. Unfortunately, logic does not lead to a satisfactory change but rather to a hardening of the original attitude. May 2008 52 The following are the three major ways of achieving a change of attitude: 1. Environment Changing the physical or social environment of the individual so that the old behaviour does not reward as well as before. This includes modifications to physical work design and layout, new machinery and work methods, job rotation, the introduction of new incentive schemes, both positive and negative, changes to safety rules, company policy or legal standards. In all cases the change must be brought to the notice of individuals, and conformity to the new rules or situation must be appropriately rewarded and persistent non-conformity punished. Provided that the person or group introducing the change is perceived to have sufficient authority (or legitimate right) to make the change, or is sufficiently powerful in reward or punishment then the change will be accepted and adapted to. 2. Enlightenment This involves the provision of new information to the individual which shows that the existing adaptation is not as close as the individual thought it was, or, as it could be. This would entail extra information, instruction and training on more effective ways of conforming to the changes required, or pointing out the way in which behaviour in one area conflicts with strongly held beliefs in another area. Another approach is to improve communication skills so that people are more open to influence. This involves the manager/safety officer taking the time, and being willing, to listen. It allows the person to express their own attitudes, i.e. involvement, consultation, and leads to better flexibility of attitudes. 3. Evolution This concerns the use of education, media and advertising campaigns to build and change 'images' and also long term changes in law and culture etc. These methods of change are usually very long term. They operate by training people to look at, question and so develop their own goals. Furthermore they expose people to different opportunities and chances for achievement and present them with examples that are labelled 'acceptable' and 'unacceptable' behaviour for people to copy. Finally note that all of the above depend upon emotional release from the target individual. To this end a safety advisor must employ methods which involve the maximum participation of the audience, in order to allow them to express their ideas and feelings. May 2008 53 MASLOW Maslow's theory of motivation is that man's individual needs create motivation. These needs can be split into the following groups: Self Actualisation Self Realisation Social Needs Security Needs Physiological Needs Maslows Hierarchy of Needs Self actualisation (achievement) - e.g. growth, personal development, accomplishment Security - e.g. security, protection from danger. Self realisation (acceptance) - e.g. status, recognition Social - e.g. belonging to groups, social activities, love, friendship. Physiological - e.g. hunger, thirst, sleep, shelter etc. Practical harnessing of Maslows hierarchy of needs Self actualisation (achievement) - e.g. employee development assistance programmes Self realisation (acceptance) - e.g. promotion, recognition, increased responsibility, safety suggestion schemes, involvement in decision making inc. consultation, incentive schemes, provision of information and training May 2008 54 Social - e.g. peer group pressure, management leadership by example, including supervisors. Security - e.g. disciplinary procedures Physiological - e.g. provision of good welfare facilities. Perception of risk Risk perception is the subjective judgment that people make about the characteristics and severity of a risk. This concerns the way a person views a situation, and this is important because two workers can listen to the same information e.g. the need to wear hearing protection and come to very different conclusions. Risk perception is an important concept in safe work activity. Human perceptions of risk are not very accurate. Risk measurement also includes how serious you can be injured by a hazard. Risks can be great (death) to negligible (splinter). Our judgments about risks are based upon many factors. One important factor is how familiar we are with a hazard. If we think we know a lot about a hazard because we are often exposed to the hazard; we often underestimate the degree of risk. Another factor is whether or not we are voluntarily interacting with a hazard. When we voluntarily take a risk, we usually underestimate the chances of being hurt. Clearly there are differences in how risks are perceived by scientists such as epidemiologists and others on the one hand and by the lay public on the other hand. Several factors can influence this differential interpretation. These may include: Personal experience of the adverse effect/event. Social cultural background and beliefs The ability to exercise control over a particular risk The extent to which information is gained from different sources e.g. from the media and so on. There are other considerations - for example has been shown that people have a tendency to over estimate very low risk and sometimes to under estimate very high ones. Errors and violations Human failures are caused by human error and/or violations. Examples of accidents involving human failure include the Three Mile Island nuclear reactor incident in the United States, the King's Cross Underground Station Fire in the UK, and the sinking of the Herald of Free Enterprise in Holland. Although a human failing was the direct cause of the accident in each case, underlying organisational failures led to the human failing. In order to turn fine words into action, organisations need to involve their staff. A positive health and safety culture involves competence of staff, control through the allocation of health and safety responsibility to staff who are committed to improving the health and safety performance within the organisation, co-operation between individuals and groups and verbal, written and visible communication on health and safety matters. These factors are often termed the 4Cs of positive health and safety culture. Organisations with a positive safety culture are characterised by communications founded on mutual trust, by shared perceptions of the importance of safety and by confidence in the effectiveness of preventive measures”. Put bluntly, the higher the risk due to the lack of competence of the individual involved, the greater the degree of supervision that is required. May 2008 55 Even experienced staff can lose their competence when faced with new equipment, new systems of work etc. Until their competence is restored, through experience or training, they will require greater degrees of supervision. If the above are common causes of human failures, the failures themselves can be categorised into various types involving errors and violations. The following diagram, figure 5, illustrates this point: The model above operates with the notion that all human failures can be categorised as either human error or violations depending on whether or not intention was involved with the failure. A human error being an action or decision which was not intended, but which involved a deviation from an accepted standard and led to an undesirable outcome. Errors can be sub-divided into slips, lapses and mistakes. Slip Lapse Mistakes Failures in carrying out the actions of a task. In other words "actions not as planned". These might include: Performing an action too soon or too late, Omitting a step or series of steps from a task, Carrying out an action with too little or too much strength, Performing the action in the wrong direction, Doing the right thing but with regard to the wrong object, Carrying out the wrong check but on the right object. Forgetting to carry out an action, to lose our place in a task or to forget what we had intended to do. Often linked to interruptions and distractions. A simple checklist to follow can help to reduce the likelihood of lapses occurring. Where we do the wrong thing believing it to be right. The failure involves our mental processes which control how we plan, assess information, make intentions and judge consequences. Rule-Based Mistakes occur when our behaviour is based upon remembered rules or procedures. KnowledgeBased Mistakes are often related to incomplete information being available. May 2008 56 Errors are more likely to occur where there are: Work environment stressors Extreme task demands Social and organisational stressors Individual stressors Equipment stressors Risk assessments should therefore identify where such factors are present and assess the likelihood of errors taking place and their consequences. Error control and reduction should take into account the need: To address the conditions and to reduce the stressors, To design plant and equipment in order to either prevent slips or lapses occurring or to increase the chances of detecting and correcting such errors, To ensure that arrangements for training are effective, To design jobs to avoid the need for tasks which involve complex decisions, diagnoses or calculations, To provide proper supervision, To check that job aids such as procedures are clear, concise, available, up-to-date and accepted, To monitor that the measures taken to reduce error are effective. Whereas, a violation is a deliberate deviation from a rule or procedure. Most violations are motivated by a desire to carry out the job despite prevailing constraints and very rarely are they motivated by wilful acts of sabotage or vandalism. Violations can be sub-divided into routine, situational and exceptional. Routine Situational Exceptional Breaking rules or procedures has become a normal way of working within the work group due to: The desire to cut corners, The perception that the rules are too restrictive, The belief that the rules no longer apply, Lack of enforcement of the rules, New workers not realising that routine violations are taking place. Means of reducing such violations can include: Routine monitoring, Removal of unnecessary rules, Ensuring rules are relevant and practical, Explaining the reasons for the rules, Improved design to reduce the likelihood of cutting corners, Involvement of the workforce in drawing-up the rules. Breaking the rules is due to pressures from the job, such as: Time pressure, Insufficient staff for the workload, The right equipment not being available, Extreme weather conditions. Risk assessments should help identify the potential for such violations as will good two-way communications. These rarely happen and only when something has gone wrong. To solve a problem employees believe that a rule has to be broken. It is falsely believed that the benefits outweigh the risks. Means of reducing such violations could include: Training for dealing with abnormal situations, Risk assessments to take into account such violations, Reduction of time pressures on staff to act quickly in novel situations. Effects of age and experience Effects of Age The design of the human body is uniform, allowing for differences in sexes. The spine, joints, muscles and tendons work in the same way and suffer the same wear and tear to varying May 2008 57 extent. Individuals have different capabilities due to age, height, weight and levels of fitness. They also have different personalities, memory and personalities. Young people have higher risk thresholds than adults, are unrealistic about their own mortality, and view themselves as invulnerable and immortal . This can cause them to abandon standard company procedures in favour of taking short-cuts, accepting risks, and ignoring hazards. Young workers may not be aware of workplace hazards or they may assess them differently, leading to unprepared ness and risky approaches that increase injury rates in this group. Children and young people’s organs and musculoskeletal systems are also undergoing rapid growth, creating greater likelihood that they will be harmed through exposure to hazardous substances or develop cumulative trauma disorders. For example, excessive manual handling or exposure to whole body vibration could lead to long term back problems. The body will sufferer wear and tear from all physicals tasks The aches and pains suffered doing certain demanding tasks will eventually impair the workers ability and lead to degradation of performance. It is therefore, important to conduct suitable and sufficient risk assessments to ensure that someone is not put at significant risk, and that there are sufficient breaks and recovery time. Effects of Experience Young workers are also more at risk because of their lack of work experience. They are usually less skilled, and yet may overestimate their own skills and abilities while underestimating their risk of injury relative to their peers. Young people new to a workplace may avoid asking questions in order to avoid looking foolish, incompetent, or unknowledgeable. They often lack a sense of empowerment or self-confidence, as well as communication and social skills, making it difficult to question the safety of a job, convey their concerns to their supervisors, challenge those who might expect them to perform unsafe acts, report accidents, or put into practice what they learn in training. Older workers can have the opposite problem, where they have had an accident-free past and this can mean that the worker no longer perceives the hazard or recognises the risk. More than half of the fatalities from electrocution involve competent people. The influence of Peers: There are many factors that cause people to behave in a particular way, and one of these is peer pressure - people feel pressure from their colleagues to act in a particular way. Nearly all people wish to be in the company of other people. So, when we are in a group situation we are motivated not to behave differently. If the norm behaviour is not to wear eye protection on a grinding operation, then the rules may be broken by the new person, even though he knows the rule and the risks. Young workers suffer work-related injury at a much higher rate than older workers. One reasons for this is peer pressure. Young workers are easily influenced to follow the lead of others, especially other youth showing at-risk behaviour. Peer pressure and a desire to ‘fit in’ can sometimes result in unsafe work practices, particularly when the social and workplace climate is one where risk-taking is admired. May 2008 58 4.4 IMPROVING HEALTH AND SAFETY CULTURE Securing commitment of management Management commitment is a key influence of an organisation’s safety culture. Employees’ perceptions of management’s attitudes and behaviours towards safety, production and issues such as planning, discipline etc. are common measures of an organisation’s safety climate. The various management layers within an organisation affect health and safety in different ways. Collinson's (1999) study suggests that however encompassing the health and safety policy within a company, if the senior executives are geographically removed from the workers then the policies may have little impact. This may also be the case for other large organisations. However, within small and medium sized companies the senior executive is likely be involved at the operational level as well as influencing health and safety. Within large companies the senior manager on the site is likely to be the major influence on health and safety. Organisations should identify key performance indicators (KPIs) for health and safety. These measurable standards must be agreed at the highest level within an organization. These management controls send out a signal that, hopefully, health and safety is an equal partner to the other business objectives. These management controls can take many forms including examination of completed permits, observations of high risk work activities and safety tours. Managers as with the entire workforce require specific health and safety training in health and safety management. Promoting health and safety standards by leadership and example Management actions at all levels influence health and safety by their actions. The attitudes and decisions of senior managers are critical in setting the priorities of the organisation. The attitudes and those of senior managers will impact on the styles of behaviour and priorities of those below us in the organisational hierarchy. Managers get the behaviour they demand and deserve. It is crucial to: Set appropriate standards – rules, procedures etc. Communicate these standards clearly – training, toolbox talks, safety contacts etc, Explain the consequences of breaching the standard, not simply the standard itself. Apply the standards consistently – walk the talk. Inconsistent application from any supervisor / manager will allow the system to fall into disrepute. Use of competent personnel with relevant knowledge, skills and work experience The organisation should identify the safety critical tasks and establish suitable controls. This task analysis should not only consider possible engineering controls such as machinery guards, local exhaust ventilation but the requirements of people involved in the task. This will include ensuring the relevant knowledge (of the risks associated with the activity), skill (application of appropriate experience) and work experience ( history of working in the relevant activity/environment) is established , before everyone gets to work. Factors such as individual aptitude, dexterity, and physical ability/endurance may also be critical, e.g. not everyone would be comfortable working at height or in an enclosed space. High risk activities may utilise simulation equipment to allow the skill necessary to be developed, at no risks to themselves or others e.g. the use of aircraft flight simulators. Similarly, it may be necessary for the trainee to be under close supervision until their skill is demonstrated as appropriate e.g. an electrician carrying out work on live electrical systems for the first time. May 2008 59 EFFECTIVE COMMUNICATION Communication is defined as what we do to inform another of our ideas, feelings and knowledge and in turn receive their feedback. In other words it is what we do to achieve UNDERSTANDING. Effective communication is an essential feature of a positive health and safety culture since it is one of the 4C’s. The importance of communication is emphasised in most health and safety legislation which requires the provision of information, instruction and training as is necessary. Then there are specific communication requirements contained within the consultation legislation. There are 3 methods of communication and these are; Verbal Written Graphic There are two types of communication; One way, and Two way Merits and limitations of different methods of communication Verbal Communication: instructions, meetings, team briefings, tool box talks, induction and refresher training etc. Advantages Disadvantages Barriers Direct No record Hearing defects Two way No reference Noise Quick Unstructured Distance Instant feedback Inconsistent Language(Jargon) Easy to do Too much Lack of knowledge Flexible Limited audience Attitude Duration/Speed Written Communication: Health and safety policy, risk assessments, newsletters, memos, reports, procedures etc. ADVANTAGES DISADVANTAGES BARRIERS Permanent record May go unread Illiteracy Reference One way Competence Consistent message Often no feedback Level of material Accurate detail Time consuming Presentation Wide audience Cost Quality Authoritative Misinterpretation Quantity Attitude May 2008 60 Graphic Communication: road signs, notice boards, posters, safety signs etc. Advantages Consistent message Disadvantages Boring Barriers Relevance Large groups No feedback Volume Emotional Impact Too much Environment Use Humour May be removed Knowledge Eye catching May be subject to graffiti Use and effectiveness of various forms of communication Notice boards: Use for displaying health and safety information and news. Including photos of health and safety representatives and staff with Health and Safety responsibilities is highly effective in raising the profile of worker involvement. For it to be effective it needs to be regularly updated with important information about meetings, safety requirements and accident statistics. as well as displaying fire and first aid notices. It should prominently displayed and should also make use of colour to make it more appealing. Team meetings: Making health and safety a standard agenda item at team meetings is a proven way of raising its profile in the organisation. Managers should encourage feedback from staff and ensure that concerns and suggestions are registered and responded to. Newsletters: Use newsletters to inform staff about health and safety and ways to get involved. You might use a specific health and safety newsletter, or include health and safety news in other newsletters. Try mixing media - e-mail updates and hard-copy newsletters increase the chances of staff receiving the message. Intranet: Giving health and safety a high profile on your staff intranet and keeping it up to date is a convenient way for staff to access information. Remember, you will need to use other more direct communications to draw attention to information on the intranet and to ensure that staff who do not regularly use computers are not excluded. The intranet can includes items such as archives of committee meeting notes, presentations, safety information, regulatory guidance, etc. Toolbox talks: Short talks focused around specific health and safety issues - such as lifting, slips and trips or injuries from workplace vehicles - allow workers, safety professionals and managers to explore risks and develop strategies for dealing with them. Toolbox talks help to demystify health and safety and to show the relevance of specific topics to particular jobs. Memos: Memos are often used to communicate brief points. The memo is faster and easier than the more formal document change procedure. Safety related issue might include job change, working hours or working patterns. They can also be used to highlight near misses. Safety propaganda: films, videos, DVDs and posters . Videos and films nowadays go beyond simply portraying a lecturing “talking head” by using visuals illustrating and reinforcing the spoken lesson can be excellent. Such videos can appeal May 2008 61 to both visual and auditory learners. These videos can be useful and cost effective solutions for inductions, support of training sessions and as a means of refresher training. They can be divided into three broad types ‘funny’ videos, informing videos and high impact, gory videos Posters can be of the slogan, the comic-strip and message varieties, or any combination. However, it must be recognised that their propaganda would remain ineffective without a safety structure in place among the management and workforce of organisation. Employee handbooks: An employee handbook can be an invaluable tool for an employer, serving to inform employees about company policies, procedures and practices and to communicate expected standards of performance and conduct. A well-designed handbook can positively influence employee morale and promote employee loyalty. It can introduce a new employee to the organisation, helping the individual to fit in more easily. In addition, the handbook can create a sense of consistency of practice that will enhance the employee’s feelings of being treated fairly- there are few factors more destructive to the employment relationship than an employee’s belief that employment decisions are arbitrary. The handbook can also serve as a reference guide to help managers and supervisors take appropriate actions in a given situation. CO-OPERATION AND CONSULATION WITH CONTRACTORS The employer should undertake a formal process of consultation with the contractor plus and local Health and Safety Representative and safety officer and any other relevant parties. This important phase focuses on the methods of work that the contractors are proposing to use to complete the contract. Key aspects such as disruption to business, safe work methods and public safety are considered at this stage. The consultation might take the form a single meeting for smaller projects up to a series of meetings prior to and during the work for the larger projects. On-going consultation with contractor might take the form of individual progress meetings as well as site safety committees on larger projects. CO-OPERATION AND CONSULATION WITH THE WORKFORCE Involvement of the whole workforce is essential in tackling the high accident rate in sectors such as the construction industry. Besides compliance with the local regulations, it has been shown that workplaces with safety representatives and safety committees have significantly better accidents records with over 50% fewer injuries than those companies with no consultation mechanism. In every workplace, it is the workers on site who are most at risk of injury and whose firsthand involvement with the work gives them the opportunity to contribute much to improving health and safety standards. Involving the whole workforce is an important step towards reducing the high accident rate in the construction industry. Experience has shown that participation is most effective when workers understand the main health and safety issues and have confidence to communicate with management. Ways to improve Workforce Involvement A Commitment To Communication Have a clear policy on site communications, for example, invite workers to speak to site management or else ask them to pass comments through their site supervisors or via a safety committee; May 2008 62 Tell workers about the site policy at their site induction session; Display notices encouraging workers to express their views on site health and safety; Involve the workforce as they know the job, the risks and the shortcuts: this will help gain ownership and commitment to common goals. It will help achieve these goals and increases likelihood of the workforce following the procedures; Put a suggestion box in the canteen or rest areas; Monitor worker input and encourage/reward participation; Mechanisms to engage the increasing numbers of foreign workers should be put in place. (The poorly literate should also be engaged.) Keep Workers Informed The following types of information will help keep workers up to date about health and safety in the workplace: Training which includes information about site hazards and the results of risk assessments; Information on the results of health and safety inspections; Details of accidents and near-misses and the findings of investigations. By providing feedback to the workforce, an employer shows that commitment is translated into action otherwise the workers will stop getting involved. Provide Feedback To The Workforce Communication policies are most effective if workers see appropriate responses to issues which are raised and so are encouraged to get involved themselves. It will assist in 2 way communication, resulting in the building of trust and co-operation which will help develop a safety culture. This can be done by: Telling the workforce about health and safety successes, including those achieved on other sites; Recording actions taken in response to workers’ suggestions on a safety notice board; Discussing workers’ attitudes to health and safety issues at training sessions and “Toolbox Talks”. On many sites subcontractors deliver a proportion of Toolbox Talks to their own workers. This can be a useful way of developing two-way communication with others and as a means to encourage consultation at the ‘workface’. HEALTH AND SAFETY TRAINING The effect of training on human reliability The effectiveness of participation will be closely tied to the levels of the participant’s knowledge and know-how. The criteria for inclusion, therefore, emerge based on participation in particular social settings, and will generally be predicated on technical safety expertise or experience-based expertise. Research findings suggest, therefore, that in many cases, training is a prerequisite for participation. Furthermore, training has been found to influence participant’s commitment to make health and safety changes. According to the ILO 2.2 million people die of work-related accidents and diseases each year, adding this number may be vastly under estimated due to poor reporting and coverage systems in many countries. Preventing accidents and ill health caused by work is a key priority for everyone at work. Employees are valuable. May 2008 63 Providing health and safety information and training helps the employer to: ensure your employees are not injured or made ill by the work they do; develop a positive health and safety culture, where safe and healthy working becomes second nature to everyone; find out how you could manage health and safety better; meet your legal duty to protect the health and safety of your employees. Effective training: will contribute towards making employees competent in health and safety; can help business avoid the distress that accidents and ill health cause; can help avoid the financial costs of accidents and occupational ill health in the form of civil claims, fines and the associated indirect costs such as increased insurance premiums and loss of reputation.. Don’t forget that your insurance doesn’t cover all these costs. Damaged products, lost production and de-motivated staff can all result. What is training? Training means helping people to learn how to do something, telling people what they should or should not do, or simply giving them information. Training isn’t just about formal ‘classroom’ courses. Health and Safety Principles of training Training has been defined by the Department of Employment as “the systematic development of attitude, knowledge and skill patterns required by an individual to perform adequately a given task or job”. Systematic training The term “systematic” implies the logical, step by step training process, which involves five clearly identified stages , in order to ensure systematic approach to training. The Training Process As mentioned in the DoE definition training should be a systematic process. A framework known as the training cycle is shown below: Identify Training Needs Evaluate Training Effectiveness Prepare Plans to Meet the Training Needs Implement Training The Training Cycle Training Gap Many national laws require employers to take into account an employees capabilities as regards health and safety when allocating tasks, and so ensure that employees are given adequate health and safety training where any training gap is identified. A training gap is the difference between the standards required either by law and/or by management and the standards actually in existence at May 2008 64 any given moment. A training need is the amount of training which is needed to eliminate the gap by bringing those who are needing training up to the standard which is required. STAGE 1: IDENTIFICATION OF TRAINING NEEDS A training need is said to exist when the optimum solution to an organisations problems is through some form of training. For training to be effective, it must be integrated with selection, and placement policies within the organisation. Selection procedures must for example, ensure that the trainees are capable of learning what is to be taught. There are both proactive and reactive methods of identification of training needs. In many cases a training need is identified when an accident occurs and so is indirectly identified as a result of the accident investigation. One of the most difficult problems in training is to establish and maintain a systematic means of identifying training needs. This is achieved by analysing people’s jobs from a health and safety point of view. and can be achieved a number of ways; Pro-active Identification of training needs (a) Performance Appraisals A planned performance-appraisal system ensures that a regular check on training needs is carried out, and the results of this communicated to a central source. Regular performance appraisals can also identify training needs where changes in role, responsibility or some other factors in the work environment are involved. (b) Questionnaires Training managers may issue questionnaires to managers and supervisors as a means of identifying training needs. (c) Interviewing Interviewing as a means of getting information is more time-consuming than issuing questionnaires, but it offers the advantage of greater flexibility. In identifying training needs, interviews may be carried out with: Employees - Discussions with employees about their working procedures, sequencing, tools, equipment and materials used is another way of identifying training needs, by pinpointing any problems which may be overcome by training. Manager/supervisors - some training needs might be defined by the manager or supervisor responsible for the employee. (d) May 2008 Job Safety Analysis The observing and questioning employees about their methods and procedures, (job safety analysis). is another way of identifying training needs. 65 (e) Job specification In the case of new employees the training needs may be designed from the job specification together with the associated risk assessment(s). Where there is no job description we would need to consult other sources of information e.g. risk assessments in order to produce such a specification. Re-active identification of training needs (a) Accident and health records Looking at accident and health records related to specific jobs, (including investigation reports), in order to determine causes and preventative measures. Investigation reports may well make reference to training needs in the form of training recommendations. STAGE 2: TRAINING COURSE DESIGN The result of this so-called training needs analysis (tna), will be a series of training objectives e.g. intended learning outcomes. these learning objectives, if accurately and precisely stated, can become the basis for the later evaluation of the training programmes effectiveness. Once the training needs have been identified , the next step is to define learning objectives in terms of skill and/or knowledge required. If the training need analysis can be viewed as the WHAT training is required, then the training course design may be viewed as the HOW and the WHO. It considers the following; Is the need primarily skill ,knowledge or attitude based? how long will each training need require e.g. 2 hours or 2 days? who will deliver the training? how will the training be delivered? is there sufficient available expertise available in-house, or will we require external consultants? what mix of active and passive learning systems are required? Training methods The choice of various methods of training is another feature of training course design. Some skill is required in identifying which method, or combination of methods, is suited to a particular situation. Again there is a distinction between onthe-job methods and off-the-job methods. Another consideration is the mix between passive and active learning systems; Active learning systems Examples of active learning systems are syndicate work, role play, programmed learning, group discussion and filed exercises e.g. safety inspections and audits. Active learning methods reinforce what has already been taught on a passive basis. Passive learning systems Passive learning systems incorporate lectures, and the use of audiovisual material such as films, videos and reference books. With passive learning systems the objective is to impart knowledge. At this stage we now know what is to be taught, by whom, and over what length of time. The training manager responsible for preparing the training programme now compares this May 2008 66 information with the available facilities. The employer can now decide whether extra facilities, (training rooms), will need to be sourced from outside providers e.g. hotels. Staff availability will also be compared, and the final programme produced. This is the WHEN stage of the training course design.. STAGE 3: TRAINING IMPLEMENTATION. The training programme is now implemented, and staff receive the identified training.. On-the-Job Training This is the most preferred option for the employer, since it is usually the cheapest option, but there are distinct disadvantages, especially with management, who are constantly called away when there is a problem. Such training includes the following; Demonstration Coaching Projects Computer based training Off-the-Job Training Such training would normally consist of one of the following methods; Lectures Seminars Programmed instruction (distance learning) Computer based training STAGE 4; TRAINING EVALUATION It is important for an employer to be able to measure the adequacy of any training provided against the training need identified. This will involve a two-stage process, monitoring and evaluation. Monitoring The purpose of this stage is to be able to produce objective measurements of the adequacy of a training course. This might be achieved through a variety of techniques; evaluation sheets de-briefing examination results job performance (accident statistics) annual appraisals Such material will be gathered, and every so often the results will be analysed. This analysis is the final stage! Evaluation Training will be evaluated to determine that it has achieved its objectives. Managers and supervisors must satisfy themselves that; practical responses to health and safety issues have improved following specific training e.g. FLT training. i.e. there has been a fall in the number of FLT related accidents. May 2008 67 the training has been worth the money spent on it. The training plan, structure, content, and methods are liable to modification following evaluation. The training programme must also respond to the needs of the changing work environment. Eventually, another training needs analysis will be required in order to spot any gaps in the training, so the whole training cycle begins again. Types of training needs During the introduction to this section we mentioned the Department of Employment definition of training, which described it as “the development of attitude, knowledge and skill patterns ...” Therefore there are three fundamental types of training need; Knowledge All jobs require the employee to understand a certain amount of information. Whilst some jobs require extensive knowledge of a wide range of subjects others require somewhat more limited, specific knowledge e.g. a machine minder. Skills Skills are distinct from knowledge. The use of knowledge requires a conscious mental effort, whereas skills when developed work on a sub-conscious level. We best learn skills by a combination of explanation, demonstration and imitation. This is exactly how we learn driving skills, and a Fork Lift truck driver learns how to operate his vehicle. The same is true of First Aid skill training. Attitudes It is imperative to instil the correct attitudes within staff, since attitude influences our behaviour (safe or unsafe) within the workplace. (see human factors for further explanation). Attitude change either individual or as a group (culture change) is often an accompanying need with knowledge or skill training. OPPORTUNITIES AND NEED FOR TRAINING PROVISION Induction training Everyone joining an organisation needs some from of induction training. The precise length of such training will depend upon the relative risks involved with the job, and the relative experience of the individual. Induction courses are usually very general in that they cover site wide issues, rather than specific job issues. The content of such a course will also vary according to level of seniority of the individual within the organisation. Typically an induction course will cover the following issues; health and safety legislation relevant to the organisation the company health and safety policy individual responsibility, authority and accountability. emergency procedures welfare arrangement reporting procedures May 2008 68 Refresher training and tool box talks This is required normally with skill-based activities e.g., fork lift truck training, first aid. It is also provided in high-risk industries on a lesser scale in the form of “tool box talk”. These are short talks (10 mins. maximum). They are designed to maintain and raise health and safety awareness, so fighting the complacency phenomena. This training is brief, and is delivered by someone that the workforce respect, normally the supervisor. These talks require no special training aids, and are delivered on a subject selected by either the safety advisor or the safety committee where a trend has been identified, e.g. eye injuries. Job Change/Process Change This form of training is required when any of the following occurs; an employee is promoted or transferred to another post change of work equipment new technology is introduced changes in work patterns Introduction of new legislation Employers have a duty to bring to the attention of workers specific changes in legislation which are relevant to the specific employee. Such changes would include changes to limits of exposure to noise or vibration, which will have an impact upon the working practices. Ditto any new health surveillance requirements. Introduction of any new technology The introduction of new technology often introduces new hazards into the workplace, so requiring revised safe systems of work. Such training will involve developing skills to interpret the equipment control layout and data display e.g. the introduction of nets and airbags for use when working at height. 4.5 INTERNAL AND EXTERNAL INFLUENCES ON HEALTH AND SAFETY MANAGEMENT STANDARDS There are two broad influences on health and safety behaviour and these are external and internal. Internal Influences on health and safety include: Management Commitment Production demands (realistic or unrealistic) Communication Competence Consultation External Influences on health and safety include: Societal expectations Legislation Enforcement Insurance companies Trade Unions Stakeholders, such a clients and shareholders Economics May 2008 69 UNIT IGC 1, ELEMENT 5: RISK ASSESSMENT 5.1 AIMS AND OBJECTIVES OF RISK ASSESSMENT Definitions of hazard and risk HAZARD Is something that has the potential to cause harm including ill health and injury, damage to property, plant, products or the environment, production losses or increased liabilities e.g. electricity . RISK Is the probability (likelihood) of that harm actually occurring, and the severity of the consequences. The extent of the risk should also take into account the number and type of people likely to be exposed to the harm as this can significantly effect both the likelihood and the consequential severity of any risk. The relationship between hazard and risk must be treated very cautiously. If all other factors are equal - especially the exposures and the people subject to them, then the risk is proportional to the hazard. However all other factors are very rarely equal. Examples: Consider the following examples: 1. Potassium Dichromate is a highly toxic carcinogenic chemical. It is used in some techniques to analyse exhaled breath for alcohol content. However for this purpose it is sealed in a tube, and does not become airborne when air is drawn over it. Therefore although it is a highly hazardous substance, its use as described, does not present any risk to the subject. 2. Flour would not be considered by many to be a hazardous substance. A jar of it on a shelf would not have a skull and crossbones depicted on it together with other hazard warnings, as might have been the case for a bottle of potassium dichromate However, if a baker was exposed over a period of time to airborne flour dust and/or dust by skin contact, he/she could develop dermatitis (an inflammation of the skin), conjunctivitis (inflammation of the eyes), rhinitis (information of the nose) and even asthma - an inflammatory disease of the lungs which can cause a great deal of distress and may even by life threatening. Thus an agent of relatively low hazard can present substantial risk (while conversely an agent with a high hazard as mentioned above might present no measurable risk in certain circumstances). Objectives of risk assessment The objectives of risk assessment are to; Minimise the likelihood and severity of any harm posed by a hazard Minimise the economic consequences (likelihood and severity) of any economic effects of an identified risk Comply with any national legal requirements for risk assessment. May 2008 70 Risk assessment A risk assessment may be defined as an identification of the hazards present in an undertaking, and an estimate of the extent of the risks involved, taking into account whatever precautions are already being taken, and the need for any additional precautions. Risk assessments should be reviewed at regular intervals, but in particular when the nature of the work changes or there has been a reason to believe the existing assessment to be no longer valid e.g. an accident. Suitable and sufficient A risk assessment shall be “suitable and sufficient” if: it identifies all significant risks arising from the work it enables the employer, (or self employed person), to identify and prioritise the measures which need to be taken to comply with relevant national laws, and it is appropriate to the nature of the work and remains valid over a reasonable period of time it will remain valid over a reasonable period of time. What is significant risk? Risk is the probability of an unwanted event occurring, but here risk is taken to mean the probability of an unwanted event occurring and the severity of potential loss. However it is not always clear how the probability and severity of risk can be combined in an objective fashion, and methodological difficulties of this kind mean that in practice even systematic risk assessments contain an element of subjectivity and ambiguity. OUTCOMES OF INCIDENTS IN TERMS OF HUMAN HARM, ECONOMIC AND LEGAL IMPLICATIONS FOR THE OGANISATION The reasons why we prevent accidents can be summarised as follows; 1. HUMAN HARM Any health and safety accident which leads to human harm will involve a degree of pain and suffering for the individual, possibly their family and friends. All cultures have rules against doing unnecessary harm to other people. This moral code may be written or unwritten. 2. LEGAL Failure to comply with health and safety laws within a country, which then cause an incident can then lead to a criminal and/or civil legal action. If found guilty this could involve considerable fines and/or compensation awards. 3. ECONOMIC Accidents cost money both direct and indirectly. In the UK there are an estimated 1.6 million accidents resulting in injury each year and 2.2 million workers suffer ill-health caused or made worse by their work. 30 million working days are lost each year with a cost to industry of some £700 million. Estimates of the overall cost to employers vary from between £4,000 £9,000 million a year, some 5-10% of gross trading profit. On a national basis it is estimated that the total cost to society is some £10-£15 billion per year. DIFFERENT TYPES OF INCIDENT In order to rate the severity aspect of risk assessment many organisations make a distinction between various types of incident. May 2008 71 Ill-health – a hazard with the potential to cause ill-health. Typical examples of ill-health conditions include occupational asthma, asbestosis, hand arm vibration syndrome. Injury accident – may be subdivided into fatals, major injuries, over three day injuries and minor injuries. These are safety related events and include cuts, bruises, fractures, amputations etc. Dangerous occurrence – the precise definition of a dangerous occurrence will vary from country to country and their national accident reporting requirements It is used to cover an undesirable event (as specified by the national government), such as a scaffold collapse which does not result in a reportable injury but could have done so, in slightly different circumstance, for example: collapse, overturning or failure of lifting machinery. collapse of a building or structure, explosion or fire, escape of flammable substances and escape of substances A near miss (or incident) is an unplanned, uncontrolled event that has not led to injury, damage or some other loss this time, but could have in slightly different circumstances. Examples include: articles falling near to people, short-circuits on electrical equipment. It is critical to record and analyse near misses as they are warnings of more serious accidents to come unless corrective action is taken – see Accident Ratios Damage only accidents are accidents which only cause damage to plant, materials, and premises. Workplace fires are a good example of such an event, where no one is injured but there is considerable property, materials and equipment damage. TYPICAL ACCIDENT RATIOS Statistical research over the years has shown that, although the ratio may vary slightly, the severity of accidents and the frequency with which they occur tend to fall into a 'triangular shape'(where the apex represents the more serious outcome). After all, how many 'near miss' incidents were, more accurately, a 'near hit' and how many minor or lost-time injury accidents had the potential for major, or even fatal outcomes? By identifying and responding more appropriately to workplace hazards and 'near miss' incidents it is possible to minimise these and to reduce the size of the base to the 'Accident Triangle'. This in turn reduces the likelihood that more serious, and even fatal, accidents will occur. H.W. Heinrich changed the world of safety fundamentals forever with his pioneering work in the 1930s. One of his concepts that continues to make me think is his accident triangle (pyramid) - for every 300 unsafe acts there are 29 minor injuries and one major injury. However, the most famous such study was carried out in 1969 by F. Bird extended the theory by bringing in property damage and likened the situation to an iceberg, suggesting that much of the loss in the workplace is hidden , in a similar proportion to that of the amount of an iceberg that is on show, versus the amount that is hidden. 1 10 Bird’s Accident Triangle 30 600 May 2008 Major Injury Minor Injuries Property damage Near Misses) (Incidents with no visible injury or damage) 72 The numbers quoted are averages from a great variety of industries and will vary from industry to industry, but the principle applies universally. The position of the waterline on the "iceberg" represents the effective state of any accident prevention control system in any organisation because it denotes the dividing line between what is investigated and controlled and what is ignored. The essential fact to remember is that any "critical incident" might result in personal injury or property damage, or both. There are many examples to illustrate this idea. For example: Whilst walking in the countryside, a person noticed a stone flying through the air. The stone had got there by non-deliberate means, probably as a result of a vehicle flicking it up from its wheels on a nearby road. Once airborne, where the stone lands is a matter of fate, time and distance, or luck. The following scenarios, indicate possible outcomes. 1 The stone struck the walker on the head. Result: a very serious, probably fatal injury. 2 The stone struck the walker one the hand. Result: minor injury. 3 The stone damaged some property. Result: property loss. 4 The stone fell as the walker passed and dropped harmlessly to the ground. Result: no visible injury or damage. This is why it is vital to control "critical incidents" which are the potential sources of personal injury and/or damage. Identification and control of critical incidents leads to a safer work place, fewer incidents, fewer injuries, less damage to property and product. Utility and Limitations Of Accident Ratios in Accident Prevention In reality we are rarely able to measure the number of accidents that actually occur. We measure the number of accidents that are reported. In general, the less severe the resultant injury, the less likely it will be reported. Alongside Bird’s Accident Triangle there therefore exists an inverted "reporting triangle". For every near miss that is reported, there are hundreds to thousands of lost time injuries that are reported. If a change occurs in the number of reported injuries this may be due to: • a genuine change in number of accidents which are occurring; • a random change in the number of accidents which resulted in injury; or • a random change in the severity of the injuries, resulting in a change in May 2008 73 reporting; or • a change in employee attitudes towards reporting. So we must treat these comparisons with some scepticism and use other measures to confirm or deny their general accuracy within a particular business. 5.2 IDENTIFYING HAZARDS Sources and forms of harm The sources and forms of harm are broadly - people, equipment, materials and environment; People – commit unsafe acts, are infectious or violent Equipment – Plant, machinery and tools have 4 broad categories of hazard associated with them – mechanical, chemical, electrical and physical. Materials - can cause harm because they might hazardous to health, combustible, heavy, and cause slips and trips. Environment – the environment can cause harm due to poor lighting, extremes of temperature, enclosed workspace or work at height. Role of inspections There are 4 broad types of inspection and these are; 1. General workplace inspections – carried out by line management or safety representatives 2. Technical inspections – of equipments such as scaffolds, excavations, lifting equipment 3. Preventative maintenance inspections – normally carried out by maintenance staff 4. Pre-use checks of equipment – normally done by the operator themselves. It is now widely accepted that the traditional time-based approach to planned plant inspection by a competent person has a number of shortcomings (types 2 and 3 above). In particular, the use of fixed intervals between inspections may be too conservative and lacks the freedom to benefit from good operating experience. Risk based inspection (RBI) considers the probability of failure and its consequences. The technique is intended to get better value for money from inspection and is intrinsically linked to the risk assessment. . RBI is a technique, which is currently being adopted by some sectors of industry, particularly the refining and petrochemical sectors, to underpin and direct planned plant inspection. It offers the prospect of cost savings resulting from better targeting of resources. RBI recognises that there is little point to spending good money, for example, on very frequent inspection of something that is very unlikely to fail, or if it did fail would have little financial or safety consequence. In line with the principles of SFARP (as low as reasonably practicable) the money saved may be better spent elsewhere. Savings can also arise from reduced direct inspection costs. Job/Task Analysis Job/task analysis is the identification of all accident prevention measures appropriate to a particular job or task and the behavioural factors that will influence whether these control measures will be implemented by the workers. The approach has its roots in work study and is therefore both diagnostic and descriptive; May 2008 74 Analysis can be either; 1. job based: operators of plant e.g. fork-lift truck drivers 2. task based: manual handling, crane lifts The results are used to correct existing risk assessments and to improve such things as emergency procedures, reporting of information and the layout of work areas. The process of job analysis needs to be carried out methodically by breaking the task or job into a series of steps which are then examined for associated hazards, the associated risks and possible control measures. Legislation Information about hazards, and local specific requirements for conducting risk assessments will be contained within national legislation. Also appropriate ISO standards such as ILOOSH 2001, can provide such advice in the absence of any national legislation. Manufacturers information Manufacturers of any article or substance for use at work should provide product health and safety information. This information might include assembly/disassembly and use instructions for a mobile access tower, maintenance schedules and operating manuals for a crane and the material safety data sheets for a hazardous substance. Incident data Statistics can be useful in deciding which activities involve significant risk and therefore, how to best allocate the risk assessors’ time, trouble and budget accordingly. This data might include accident statistics, sickness and absenteeism data etc. Accidents in terms of injury There are several categories of accidents in terms of injury and these include; Slips/trips/falls Falls from height Falling objects Collision with objects Trapping/crushing under or between objects Manual handling Contact with machinery/hand tools Electricity Transport Contact with chemicals Asphyxiation/drowning Fire and explosion Animals Violence – either verbal or physical May 2008 75 Heath hazards Risk assessment is not only concerned with injuries in the workplace but also possible occupational health problems. Health hazards fall into four categories; Chemical – paints, solvents, fumes: see IGC 2, Element 6 Biological– bacteria e.g. leptospirosis, viruses e.g. see IGC 2, Element 6 Physical – noise, vibration, radiation: see IGC 2, Element 7 Psychological– occupational stress: see IGC 2, Element 6 5.3 PRINCIPLES AND PRACTICE OF RISK CONTROL Identifying the population at risk A suitable and sufficient risk assessment needs to identify all those that are potentially at risk and how. When considering who is at risk it is important to r all those who may be affected by the activity being assessed, not just those directly involved. Therefore the assessment would need to consider; Employees Maintenance staff Cleaners Contractors, Visitors General public Within these groups there might be specific groups at risk such as young persons, new or expectant mothers and disabled persons (learning or physical disability) – see later in this section. Evaluating risk and the adequacy of existing controls Determine risk The risk from the hazard should be determined by estimating the potential severity of harm and the likelihood that harm will occur by considering the adequacy of any existing controls. Severity of harm Information obtained about work activities is a vital input to risk assessment. When seeking to establish potential severity of harm, the following should also be considered: Part(s) of the body likely to be affected; Nature of the harm, ranging from slightly to extremely harmful: 1) slightly harmful, e.g.: - superficial injuries; minor cuts and bruises; eye irritation from dust; - nuisance and irritation (e.g. headaches); ill-health leading to temporary discomfort; 2) harmful, e.g. - lacerations; burns; concussion; serious sprains; minor fractures; - deafness; dermatitis; asthma; work related upper limb disorders; ill-health leading to permanent minor disability; 3) extremely harmful, e.g. - amputations; major fractures; poisonings; multiple injuries; fatal injuries; - occupational cancer; other severely life shortening diseases; acute fatal diseases. May 2008 76 Likelihood of harm When seeking to establish likelihood of harm the adequacy of control measures already implemented and complied with needs to be considered. Here national legal requirements and codes of practice are good guides covering controls of specific hazards. The following issues should then typically be considered in addition to the work activity information: number of personnel exposed; frequency and duration of exposure to the hazard; failure of services e.g. electricity and water; failure of plant and machinery components and safety devices; exposure to the elements; protection afforded by personal protective equipment and usage rate of personal protective equipment; unsafe acts (unintended errors or intentional violations of procedures) by persons, for example, who: 1) may not know what the hazards are; 2) may not have the knowledge, physical capacity, or skills to do the work; 3) underestimate risks to which they are exposed; 4) underestimate the practicality and utility of safe working methods. It is important to take into account the consequences of unplanned events. These subjective risk estimations should normally take into account all the people exposed to a hazard. Thus any given hazard is more serious if it affects a greater number of people. But some of the larger risks may be associated with an occasional task carried out just by one person, for example maintenance of inaccessible parts of lifting equipment. Qualitative and semi-quantitative risk ranking For simple hazards a risk assessment can be a ‘very straightforward process based on judgement requiring no specialist skills or complicated techniques.’ This approach is commonly known as qualitative or subjective risk assessment. Alternatively, a quantitative risk assessment is used for complex risk and/or major hazards, such as those associated with complex chemical or nuclear plants. Such a risk assessment attempts to quantify the level of risk and severity. Clearly, the higher the value for severity and likelihood the higher the risk will be. Table 1 shows one simple method for estimating risk levels and for deciding whether risks are tolerable. Risk are classified according to their estimated likelihood and potential severity of harm. Some organisations may wish to develop more sophisticated approaches, but this method is a reasonable starting point. Numbers may be used to describe risks, instead of the terms 'moderate risk', 'substantial risk', etc. Using numbers does not confer any greater accuracy to these estimates. May 2008 77 Table 1 - A simple risk rating table Slightly harmful Harmful Extremely harmful Highly unlikely TRIVIAL RISK TOLERABLE RISK MODERATE RISK Unlikely TOLERABLE RISK MODERATE RISK SUBSTANTIAL RISK Likely MODERATE RISK SUBSTANTIAL RISK INTOLERABLE RISK Qualitative risk assessment involves making a formal judgement on the consequence and probability in the absence of detailed quantitative data. Subjective values of severity and likelihood are determined and multiplied together according to the equation: Risk = Severity x Likelihood A number of guides have been produced by industry and commercial organisations to help in assessing risk. A example from one of these is given below. Since we know that risk is a combination of the potential severity of something to cause harm and the likelihood of this event occurring, we can attach values to both of these variables and undertake risk rankingHazard – the potential to cause harm will vary in severity. The likely effect of a hazard may for example be rated: 3. Major Death or major injury or illness causing long term disability 2. Serious Injuries or illness causing short-term disability 1. Slight All other injuries or illnesses The likelihood of harm may be rated 3. High Where it is certain that harm will occur 2. Medium Where harm will often occur 3. Low Where harm will seldom occur May 2008 78 In this case risk can be defined as the combination of the severity of the harm with the likelihood of its occurrence, or Risk = Severity of Harm x Likelihood of Occurrence This simple computation which gives a risk value of between 1 and 9 enables a rough and ready comparison of risks. In this case the higher the number, the greater the risk, and so prioritises the hazards so that control action can be targeted at the most significant risks in the first instance. Prepare risk control action plan Risk categories shown for example in Table 1 form the basis for deciding whether improved controls are required and the timescale for action. An approach, again suggested as a starting point, is shown in table 2. Table 2 shows that control effort and urgency should be proportional to risk. Table 2 - A simple risk-based control plan RISK LEVEL ACTION AND TIMESCALE No action is required and no documentary records need to be TRIVIAL kept. No additional controls are required. Consideration may be TOLERABLE given to a more cost-effective solution or improvement that imposes no additional cost burden. Monitoring is required to ensure that the controls are maintained. Efforts should be made to reduce the risk, but the costs of MODERATE prevention should b e carefully measured and limited. Risk reduction measures should be implemented within a defined time period. Where the moderate risk is associated with extremely harmful consequences, further assessment may be necessary to establish more precisely the likelihood of harm as a basis for determining the need for improved control measures. Work should not be started until the risk has been reduced. SUBSTANTIAL Considerable resources may have to be allocated to reduce the risk. Where the risk involves work in progress, urgent action should be taken. Work should not be started or continued until the risk has been INTOLERABLE reduced. If it is not possible to reduce risk even with unlimited resources, work has to remain prohibited. The outcome of a risk assessment should be an inventory of actions, in priority order, to devise, maintain or improve controls. The action plan should be reviewed before implementation, typically by asking: will the revised controls lead to tolerable risk levels? are new hazards created? has the most cost-effective solution been chosen? what do people affected think about the need for, and practicality of, the revised preventive measures? will the revised controls be used in practice, and not ignored in the face of, for example, pressures to get the job done? May 2008 79 It is therefore essential that a mechanism for prioritisation is considered. Any action plan must be SMART; Specific Measurable Achievable Realistic Timely Need to review risk assessments Risk assessment should be seen as a continuing process. Thus, the adequacy of control measures should be subject to continual, routine review and revised if necessary. Similarly, if conditions change to the extent that hazards and risks are significantly affected than risk assessments should also be reviewed since there is now reasons to believe that it is no longer valid. Typical circumstances that might require a review of the risk assessment include; Changes of premises – internal or external layout Changes of personnel affected – numbers, ages, disabilities Changes to plant/equipment – power supplies, heating systems Introduction of new work processes – hot work, confined spaces, mechanical handling Changes in legislation Upon availability of new information – revised guidance documents, new research As a result of incident reports As a result of occupational health assessment or monitoring As a result of routine active monitoring – inspections, audits, safety tours As a result of enforcement action As a result of consultation An accident General Control Hierarchy The general control hierarchy is remembered as ERIC PD; Eliminate the hazard – the substance or work practice Reduce (the use or frequency)or Substitute (e.g. a powder to pellets) Isolate – a glove box for handling hazardous biological agents Controls – engineering controls e.g. LEV and safe systems of work e.g. PTW PPE – hard hat, safety boots, gloves etc. Discipline - enforcement of the rules, safety signs, IITS, disciplinary procedures RISK ASSESSMENT PROCESS A number of Guides have been produced to assist organisations in assessing workplace risks in a methodical manner. These include: Health & Safety Executive – Five Steps to Risk Assessment IChemE – Practical Risk Assessment BSI (1996) – BS8800: Guide to Occupational Health & Safety Management Systems (Annex Institution of Occupational Safety & Health (1993) – Risk Assessment The principal difference in these guides is the methodology for estimating risk. May 2008 80 ‘5 steps to risk assessment’ Methodology. Step 1: Identify the hazards (PEME) Step 2: Decide who might be harmed and how Step 3: Evaluate the risks and decide whether existing control measures are adequate or additional control measures are required SFARP – ERIC PD Step 4: Record the findings the significant findings when you employer 5 or more persons and significant findings. Step 5: review your assessment and revise if necessary. This involves setting a routine, scheduled review. The frequency of review depends upon the level of risk in the operation, and should normally not exceed five years. It may be found useful to carry out a review of risk assessments as part of the safety policy/ manual review since the two activities are closely linked. The BS 8800 (18001) approach Classify work activities Identify hazards Determine risk Decide if risk is tolerable Prepare risk control action plan (if necessary) Review adequacy of action plan Classify work activities: prepare a list of work activities covering premises, plant, people and procedures. Identify Hazards: Identify all significant hazards relating to each work activity. Considering who might be harmed and how. Determine risk: make a subjective estimate of the risk associated with each hazard assuming that planned or existing health and safety precautions are in place. Assessors should also consider the effectiveness of the controls and the consequences of their failure. 81 May 2008 Decide is risk is tolerable: judge whether planned or existing OH&S precautions (if any) are sufficient to keep the hazard under control and meet legal requirements. Prepare a risk control plan (if necessary): prepare a plan to deal with any of the issues found by the assessment to require attention. Organisations should ensure that new and existing controls remain in place and are effective. Review adequacy of action plan: re-assess risks on the basis of the revised controls and check that risks will be tolerable. Special Case Risk Assessments Young Persons A young person is statistically at a considerably higher risk of from both a health and safety standpoint in the workplace. There are 4 main reasons for this; Immaturity – both physical and mental Lack of experience Lack of awareness High susceptibility to Peer Pressure Before employing a young person, a specific risk assessment must be conducted and take the following specific factors into account: the fitting-out and layout of the workplace and the particular site where they will work; the nature of any physical, biological and chemical agents they will be exposed to, for how long and to what extent; what types of work equipment will be used and how this will be handled; how the work and processes involved are organised; the need to assess and provide health and safety training; and risks from the particular agents, processes and work. The extent of the risks you identify in the risk assessment will determine whether you should restrict the work of the young people you employ. Except in special circumstances, you should not employ young people to do work which: is beyond their physical or psychological capacity; exposes them to substances chronically harmful to human health, e.g. toxic or carcinogenic substances, or effects likely to be passed on genetically or likely to harm the unborn child; exposes them to radiation; involves a risk of accidents which they are unlikely to recognise because of e.g. their lack of experience, training or attention to safety; involves a risk to their health from extreme heat, noise or vibration. For young persons over 16 years of age, it may be necessary to undertake one of the above special circumstances because the work is necessary for their training, but will be under proper supervision by a competent person, and only when the risks are reduced to the lowest level, so far as is reasonably practicable. Under no circumstances should children of compulsory school age do work involving these risks, whether they are employed or under training such as work experience. May 2008 82 Training and supervision Young people need training most when they first start a job; they need it to increase their capabilities and competencies to a level where they can do the work without putting themselves and others at risk. It is not enough to make training available; you should make sure that it is undertaken and also check that key messages have been understood. Young people will also need training and instruction on the hazards and risks present in the workplace, and on the preventive and control measures put in place to protect their health and safety. This training should include a basic introduction to health and safety, e.g. first aid, fire and evacuation procedures etc. As well as training, you will need to bear in mind that young people are also very likely to need more supervision than adults. Effective supervision will also help to monitor the effectiveness of the training young people have received, and there will be clear benefits in assessing whether a young person has the necessary capacity and competence to do the job. New or Expectant Mothers Pregnant women and new mothers are at significant risk from the whole range of occupational health hazards; Biological e.g. hepatitis Chemical – e.g. lead, CO, mutagens and teratogens Physical e.g. ionising radiation, extremes of temperature, excessive manual handling, prolonged standing,. Psychological - stress As such they should have a specific risk assessment carried out to ensure that neither the employee nor their unborn or subsequent, breastfeeding child are exposed to risks that could damage either of their health and safety. This specific risk assessment should be undertaken when an employee provides written notification that she is pregnant, has given birth within the previous six months or is breastfeeding There are ways to ensure health and safety of expectant and new mothers: Discuss the risk assessment with the employee and get her input. Depending on the outcome of the risk assessment, a new or expectant mother may have their working conditions temporarily altered, be given suitable alternative work or be suspended on full pay. Special health and safety consideration should be given to pregnant night workers. Employers should provide facilities for any pregnant worker or nursing mother to rest. Employers must provide adequate rest and meal breaks. Disabled Workers A disabled person is generally accepted as someone with a physical or mental impairment which has a substantial and long term adverse effect on his or her ability to carry out normal day-to-day activities. This definition includes a wide range of people with differing disabilities such as those who have reduced vision or hearing, those who have restricted mobility, those who are mentally impaired or may be suffering from depression or stress, and those who are suffering from long term or progressive conditions such as multiple sclerosis. Best practice in ensuring the health and safety of an employee with disabilities in the workplace is to identify the hazards of both the work activities and the workplace. An assessment of risks to which the employee with disabilities is likely to be exposed in doing a particular job can then be undertaken. The assessment should also consider the risks to others May 2008 83 who might be affected by the actions of the employee with disabilities. The assessment should take into account the person’s abilities and capabilities both at recruitment and for continuing employment while in the post. It may be appropriate to involve an occupational health physician in the assessment in order to determine the individual’s suitability to perform a particular job, such as in a laboratory. As a result of the risk assessment process the employers must make reasonable adjustments to working conditions and the working environment in order to eliminate, reduce or control the risk. In the case of a person with a progressive disability it may be necessary to repeat the risk assessment periodically and, where appropriate, make further adjustments. Where the adjustments are not reasonable, then this may involve job restrictions, such as someone with a profound hearing problem not being allowed in the warehouse area, since they will be unable to hear the horns and reversing alarms of the fork-lift trucks. Lone worker Lone workers are those who work by themselves without close or direct supervision. This may include those who work alone in a specific area or building (e.g. shop-workers, homeworkers, cleaners, security, library workers, etc) or may include mobile workers, who work alone but in a number of locations (e.g. maintenance, tradespersons, cleaning supervisors, drivers, Staff / Students carrying out research surveys, those who visit external organisations, i.e. home visitors, school liaison personnel). Specific hazards should be assessed on a specific risk assessment form and consider hazards such as hazardous substances, biological agents, display screen equipment, manual handling operations and security. These hazards might include; People: infectious patients, people with a history of violence to staff, mugging. Hazards specific to the individual, which may create particular risks for lone workers e.g. medical conditions, disabilities, female employees, expectant mothers, age, inexperience, immaturity etc. Equipment: hazards specific to the work equipment, which may create particular risks for lone workers, e.g. manual handling, operation of essential / emergency controls and work on electrical systems Materials: hazards such as heavy items including display stands, cryogenic gases. Environment: hazards specific to the workplace / environment, which may create particular risks for lone workers, e.g. remote areas, laboratories, workshops, confined spaces. Consider access requirements, transport and parking. Controls measures Specific information, instruction and training (e.g. out-of-hours procedures, emergency procedures, personal safety training). Improved communication systems such as regular pre-arranged contact by mobile phone, or radio. Supervision by ad-hoc visits to inspect their working practices. Increased security with controlled access, secure car parking, personal alarms. Increased lighting at entrances, exits and car parks. May 2008 84 May 2008 85 May 2008 86 May 2008 87 UNIT IGC 1, ELEMENT 6: PRINCIPLES OF CONTROL GENERAL PRINCIPLES OF PREVENTION In order to control the risks identified by risk assessments, the employer and the selfemployed need to introduce a risk control strategy of prevention. This is based on the following principles; 1. Avoid the hazard/risk altogether – e.g. do not work at height, clean the windows from the ground level, so avoiding the risk of falling. 2. Evaluating unavoidable risks – carry out a suitable and sufficient risk assessment and evaluate the risks. This will allow for prioritisation. 3. Control the hazard at source - e.g. if steps are slippery, replace or treat them rather than just putting up a warning sign. Repair a hole in the floor rather than demarcating the area. 4. Adapt work to the individual - consider ergonomics by improving design, organisation and working and production methods. Also when choosing work equipment or designing work areas. Eliminate monotonous work, where possible, by job redesign or worker rotation.. 5. Adapt to technical progress - keep up to date and informed on new developments in ways of working that reduce or eliminate hazard/risk. Replace old noisy equipment with modern much quieter equipment. 6. Replacing the dangerous by the less dangerous – for example substituting mains powered electrical hand tools with battery powered hand tools or substituting a solvent based chemical for a water based alternative. 7. Developing a coherent policy - Developing a coherent overall prevention policy, which covers production, organisation, working conditions and social dialogue. 8. Give priority to collective protective measures - isolate workers from the hazard/risk by enclosing the process rather than giving out protective equipment. Protect from falls by the use of nets rather than a harness and line. 9. Providing appropriate information, instruction and training - workers need to understand what they need to do to protect themselves. 10. Issue Personal Protective equipment only as a last resort - when all other methods of risk reduction fail to reduce the risk sufficiently. A general hierarchy of controls The hierarchy of control measures is a tool used to control risks in the workplace, where all possible control options are ranked by order of effectiveness. The ‘hierarchy of control’ is a useful tool, as the order tells you which of the types of control measure provides a better level of risk control. The higher in the hierarchy of control, the better and more reliable the control is. Preferably use control measures which are presented first, SFARP. The reason that the first three are more effective is because they are examples of ‘safe place’ strategies, whereas the last three examples of ‘safe person’ strategies. In order to create a safe place or person we must consider a logical route to follow, for example, ERIC PD: Safe place elimination Safe person control SAFE PLACE reduction isolation use of PPE discipline Elimination We should always try to eliminate any unsafe condition or situation. However this is not always a practical or commercial proposition, due the fact that this essentially means May 2008 88 completely stopping the activity entirely. We should, however, always start the protection process with this in mind, otherwise there may well be an occasion when this is the correct approach, and we may well miss the opportunity to prevent further damage, injury, or other loss. A good example would be cleaning out a tank. Our preferred action would be not to enter the tank, and flush out the tank instead. Reduction or Substitution If we are unable to eliminate the harmful situation or substance, we should further consider reducing its capacity to cause harm, or use a less harmful version. For example, in situations where environmental or mechanical damage might occur to electrical equipment we would use reduced voltage equipment, (110v CTE), or even substitute with battery operated tools. Isolation Where we are unable, to reduce or substitute the danger, we can isolate it from people, thereby reducing the human-danger interface. Such isolation could take the form of automation, or creating a ‘safe by position’ strategy, for example placing 432,000 volt conductors high up on pylons is a form of isolation. SAFE PERSON Control Control can be seen as controlling access to danger, using a range of techniques including padlocks, permits to work, authorisation passes, etc.. Personal protective equipment, (PPE) PPE should be seen as the last resort. Unfortunately, as all too often, it is issued as a short term expedient, and remains in use many years later. The problem with PPE is that there is nothing that can be classed as 100% safe, and the user is the weak link in the chain, as they may forget to use such equipment. Discipline There is a place for discipline in any strategy, and this one is no exception. Discipline comes in two forms, self discipline, and enforced discipline. Self discipline Certain workers need to have the self discipline that comes with training, experience and authorisation. For example, the vehicle mechanic who works in and around unguarded moving parts, knows that they should not touch such parts, as does the authorised electrician, who is occasionally required to work live. Both know that they must take extra care not to touch live conductors. However, we all can forget to do or not do something, so this is where safety signs are important. Signs Signs combine shape, colour and a pictogram (symbol) to provide specific health and safety information. Being pictographic they are universal, and do not rely on language or the ability to read. Risk assessment should identify the need for the need to use a safety sign wherever there is a health or safety risk which cannot be avoided or controlled. Thus, safety signs and signals are used as a last resort under the “D” for discipline. May 2008 89 Therefore, as such, signage now becomes part of the employers general control measures that all employers must implement as a result of their risk assessments. Signs should contain a pictogram to convey the message, instead of relying solely on text. In the UK there is a British Standard BS 5378:1980 Safety Signs and Colours which contains these pictograms. So, the significance, and colours of the various signs remain unaltered, and are summed up by the mnemonic SWMPF which stands for: Safety Condition signs are square or rectangular in shape, and have a green background with white pictograms and lettering. Examples of such signs are exit routes and first aid. They mean the safe way to do something. Warning signs are triangular in shape, with a yellow background, and black pictogram and lettering. They mean danger - proceed with caution Mandatory signs are circular in shape, with a blue background and white pictogram. They mean “must do”. Examples are wear hearing defenders in an ear protection zone. Prohibited signs are round in shape, with a white background and a red perimeter band and diagonal stripe. The pictogram is black in colour. Examples are No smoking. Fire equipment signs. These are square or rectangular in shape, with a red background and white pictogram. This sign denotes the location of fire fighting equipment. Illuminated signs and acoustic signals such as alarms, and also verbal and hand signals are also covered in the regulations. We will now look at each of these areas briefly: Dangerous locations/traffic routes: In places where there is a risk of people or equipment colliding with obstacles, or where objects may fall (i.e. storage facilities), these should be marked with yellow and black, or red and white striped tape or boards. Traffic routes for internal transport must be clearly identified by continuous coloured lines, preferably, yellow or white. Illuminated signs: Where such signs are required e.g. on emergency escape routes in the event of an electrical failure, then these must have a battery back-up. May 2008 90 . Safety Enforced discipline There is a role for enforced discipline in a safety strategy. There has to be some sort of sanction for those who will not co-operate with their employer and fellow employees as regards health and safety. Such a sanction can take the form of verbal/written warnings, suspension, or even dismissal. An alternative approach to risk control is looking at ERIC PD as follows: Technical - e.g. design, fencing, ventilation Procedural – e.g. safe systems of work, maintenance schedules Behavioural – e.g. information, instruction, training and supervision May 2008 91 Hazard Identification There are a number of simple ways in which hazards can be identified. A basic approach is to consider PEME. People: incompetent, infectious, violent Equipment: mechanical, electrical, chemical and physical hazards. Materials: heavy, hazardous to health, e.g. toxic, carcinogenic, combustible. Environment: lighting, temperature, lack of oxygen, work at height. In order to achieve a suitable and sufficient risk assessment it is essential to identify all the hazards associated with the activity. For complex activities it can be useful to break down the activity into its component parts. For example with a large machine this could comprise: normal operating breakdown cleaning/spillage lubricating setting/adjustment overhaul installation dismantling Safe systems of work A safe system of work is a step by step procedure that results from a systematic examination of a working process, that identifies hazards and specifies work methods designed either to eliminate the hazards or controls and minimises the relevant risks. There is a legal requirement, to provide and maintain a safe system of work in many countries including Ireland, Australia, Singapore, and Malaysia. Further local laws make specific requirements in respect of safe systems of work, for example those relevant to manual handling, use of hazardous substances and use of display screen equipment. Safe systems of work will frequently be addressed in the ‘Arrangements’ section of an organisation’s health and safety policy and within the risk assessment process. Safe systems of work will be developed by a ‘Competent Person’ i.e. ‘a person with sufficient training and experience or knowledge and other qualities’ to assist with key aspects of safety management and compliance. Staff who are to be actively involved with carrying out the work also have a valuable role to play in the development of the system to ensure it is of practical benefit and that it will consequently be applied diligently. All relevant staff must clearly understand the system of work and it is equally important that it is effectively communicated to others, e.g. contractors, who may become involved periodically. Safe systems must be documented to provide an unequivocal reference point for all concerned including the employer. They may also prove essential if there is an inspection by enforcement agencies or if any proceedings arise from an accident. The safe system of work should comprise three types of control, mentioned earlier in this section: May 2008 92 • Technical - such as engineering controls such as guards. • Behavioural – how individuals or groups should act in relation to the hazard. • Procedural – specifying the exact nature of the task, including sequence, checks and key safety actions. The system will be developed by an analysis and assessment of the risks inherent within the task and the requisite controls. Sources of information that may need to be consulted include reference to legislation, guidance notes, manufacturer’s information, company policy and relevant staff. Where risks of a high risk nature are involved, the safe system of work may be in the form of a ‘permit-to-work’, an extremely robust and detailed procedure including permissions and signatures. Training is vital to ensure a clear understanding of the task, the system and all its associated requirements. Finally, all safe systems of work need to be monitored regularly to ensure that they are fully observed and effective. Appropriate supervision is also, as ever, a strict requirement. In order to maintain the safe system of work it will be necessary to monitor its adequacy and review as necessary. Conclusion For each activity a risk assessment then needs to be made. There are many techniques of risk assessment ranging from complex techniques such as fault tree analysis, and reliability studies to simple, subjective judgement. In simple terms, if there is a risk of a single accident killing many people, then a complex assessment will be necessary. However, for the vast majority of work situations a generic risk assessment will suffice. CONFINED SPACES Definition According to Part XI of the Canada Occupational Safety and Health Regulations sets standards for working in confined spaces. A "confined space" means an enclosed or partially enclosed space that is not designed or intended for human occupancy except for the purpose of performing work; 1. has restricted means of access and egress; and 2. may become hazardous to an employee entering it due to; its design, construction, location or atmosphere, the materials or substances in it, or any other conditions relating to it. Some examples of confined spaces are: manholes, sewers, boilers, tunnels, pipelines, wells, fuel tanks, ballast tanks, storage tanks, tank cars and tank trucks, vats, process vessels, septic tanks, sewage lift stations, silos, boots in grain elevators, trenches, and ventilation and exhaust ducts. Although some of these are easily recognized as confined spaces, others may not be. May 2008 93 In Part XI, "class of confined spaces" means a group of at least two confined spaces that are likely, by reason of their similarity, to present the same hazards to persons entering, exiting, or occupying them. Potential confined space hazards: restricted entry and exit; probable exposure to the same or similar hazardous substances, such as: asphyxiants (these smother people), explosive gases, biological hazards (these are harmful to human cells); exposure to an oxygen-deficient atmosphere; exposure to hazardous substances near or surrounding the confined space; possible leaks from pipes, or water entering; danger of drowning or being covered in flowing material; Duties of the Employer Before permitting any person to enter a confined space, to inspect, clean or carry out maintenance work, an employer shall provide every employee who is likely to enter a confined space with instruction and training in entry and emergency procedures and the use of protective equipment. Where there is a safety and health committee or safety and health representative, the procedures will be established in consultation with that committee or representative. Hazard Assessment The employer shall appoint a qualified person to: 1. carry out an assessment of the physical and chemical hazard that the person who is entering the space may be exposed to; 2. conduct all necessary tests to determine if the person will be exposed to any danger; 3. complete a permit-to-enter accordingly. Specific Hazards Associated with Confined Spaces Accident investigation reports show that accidents are caused when people are not well trained or fully informed about the hazards of entering confined spaces. Accident statistics suggest that about 50 percent of deaths in confined spaces have resulted from oxygen deficiency and that no testing was done in those cases. In addition, more than half of those who die in confined spaces do so while trying to rescue their fellow workers. There are five main risks in confined spaces: oxygen deficiency and oxygen enrichment; fire and/or explosion; toxicity; drowning in liquids and/or entrapment in free-flowing solids. extremes of temperature Ventilation Equipment When ventilation is used in a confined space the employer shall not grant access to any person unless the ventilation equipment is: 1. equipped with an alarm; 2. monitored by an employee. May 2008 94 Oxygen Deficiency and Enrichment Many deaths in confined spaces are caused by a lack of oxygen. The only way to be sure there is enough oxygen is to carefully test with an oxygen monitor before you go in and, if the hazard assessment states that it is necessary, while you are working in the space. There are two main causes of oxygen deficiency: 1. Oxygen is displaced by gases such as nitrogen, an inert gas introduced to displace flammable gases when purging vessels in preparation for hot work. 2. Oxygen is used up by: combustion of flammable substances such as in welding and other hot work; explosions or fires (oxygen levels may stay dangerously low long after the fire is out because the oxygen is replaced by the products of combustion); chemical reactions such as rusting of metal; people working in the space and using up oxygen as they breathe. What are the effects of reduced oxygen levels? Normal air has approximately 21 percent oxygen by volume at normal atmospheric pressure. At 16 percent oxygen your judgment and breathing are impaired and you are quickly exhausted. At 12 percent you become unconscious and will die unless removed to fresh air. At 6 percent you have difficulty breathing and will die in seconds. Employees must be sure the confined space has been tested fully before they enter. Continue to test, if necessary, while they are working there. If the required air quality cannot be maintained, wear the prescribed breathing apparatus. Oxygen Enrichment What happens when the level of oxygen is high? An oxygen-enriched atmosphere contains more than 23 percent oxygen by volume. This will cause flammable materials, such as clothing and hair, to burn violently when ignited. Never use pure oxygen to ventilate a confined space, since an oxygen-enriched atmosphere is a fire and explosion hazard. Fires and Explosions Combustible gases have an explosive range with a lower explosive limit (LEL) and an upper explosive limit (UEL). When the fuel and air mixture is below the LEL, or above the UEL, ignition will not take place. A gas is combustible only between its LEL and UEL. For example, methane is combustible only when mixed with air in a concentration between 5 percent and 15 percent. Other combustible gases have different characteristics. Some have a wider range between their upper and lower explosive limits, making them even more dangerous. Fires and explosions are serious dangers in confined spaces. Chemicals, poor ventilation, static electricity, or machinery may contribute to explosions or fires. Hot Work "hot work" means any work where flame is used or a source of ignition may be produced. May 2008 95 Unless a qualified person has determined that the work can be performed safely, hot work shall not be performed where there are concentrations of explosive or flammable hazardous substances that do not meet the prescribed standards. If hot work is to be performed where concentrations of explosive or flammable hazardous substances exist, a qualified person shall: 1. 2. 3. patrol the area surrounding the confined space; maintain a fire-protection watch; provide fire extinguishers. Where airborne hazards are produced by the hot work, no person shall enter or occupy the confined space unless equipped with a prescribed respiratory protection device. Toxicity Toxic (poisonous) gases present two kinds of risk in a confined space: chemical asphyxiation (smothering); irritation to respiratory system, the skin and eyes. Some toxic gases that are especially dangerous in confined spaces: Hydrogen sulphide (H2S), a by-product of sewage treatment, petroleum, and other industrial processes, may be encountered in mines, gas wells, sewers, and similar installations. Since hydrogen sulphide is heavier than air, it collects in low places. In low concentrations, H2S smells like rotten eggs. However this gas quickly deadens the sense of smell, leading to a false sense of security. Always remember, high concentrations of H2S are fatal. Methane (CH4) is highly explosive. It can leak from a gas line and is a by-product of sewage. It is also found in coal mines. Since methane displaces oxygen, it can smother workers. Sulphur dioxide (SO2) is colourless but has a strong smell. It is poisonous in small amounts. Carbon monoxide (CO) is a colourless, odourless, tasteless and deadly gas. It is a product of incomplete combustion, and a common source is internal combustion engines. Overexposure may cause ringing in the ears, nausea, headache, and sleepiness. Carbon monoxide can be fatal in very low concentrations. REMEMBER! Combustion engine exhaust gases contain carbon monoxide, carbon dioxide, and other harmful gases. Keep generators, pumps etc. away from openings of confined spaces where people are working. TEST CAREFULLY FOR TOXIC GASES BEFORE ENTERING A CONFINED SPACE WARNING! One of the biggest mistakes you can make is to ignore or not believe your test equipment. If a gas detector alarm sounds, get out even if you don't notice anything wrong. Test equipment is designed to detect hazardous conditions long before the employee can. It can save their life! May 2008 96 An employee should never enter a confined space if their employer has not had a qualified person establish entry procedures for the confined space (PTW) and if they have not been trained in these procedures and in the use of any testing or safety equipment to be used in the confined space. Drowning in Liquids or Entrapment in Free-flowing Solids Some examples are: water in a tank; grain in a silo; earth falling into a trench or excavation. Free flowing solid means any substance consisting of solid particles, and which is of, or is capable of being in, a flowing or running consistency, including flour, grain, sugar, sand or a similar material Confined Space Entry When a person is about to enter a confined space, the employer shall appoint a qualified person to verify: 1. by tests, that compliance can be achieved for the period that the person will be in the confined space; 2. that all free-flowing solids and liquids have been removed. Emergency Procedures and Equipment When conditions in a confined space continue to pose a significant risk, the employer shall: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Establish emergency procedures; Rescue and Resuscitation equipment Ensure that the qualified person is in communication with the person inside the confined space equipped with a suitable alarm for summoning assistance; Safeguarding the Rescuers. Fire Safety. Control of Plant. First Aid/ Public Emergency Services. Provide protective equipment; Ensure that a qualified person trained in the entry and emergency procedures is in attendance outside the confined space; Ensure that the person in the confined space is wearing an appropriate safety harness that is attached to a secure anchor outside the confined space and attached to a mechanical lifting device; and Keep records. The above statutory requirements from Canada are fairly typical of legislation world-wide. Some countries have additional requirements such as the UK where; Entry into confined spaces should be avoided SFARP where the work can be done by another method e.g. from the outside by use of a remote camera for inspection Use a safe system of work where entry into the confined space is unavoidable; May 2008 97 Safe System of Work Where entry is unavoidable, a safe system of work must be implemented. In order to identify a suitable safe system, the employer must conduct a suitable and sufficient risk assessment in order to determine hazards present and the appropriate health and safety measures and emergency arrangements. This safe system of work which ensures adherence to a well-defined system of precautions will normally be laid down in writing, in the form of a permit to work. Appointment of “competent persons” to prepare permit to work documents for entry into confined spaces is essential. The competent persons are required to have experience and skills necessary to assess the situation and, where specialised plant is concerned, be thoroughly familiar with the law and the relevant chemistry and engineering. If the atmosphere can be made safe by venting the space, perhaps by the use of forced air ventilation, then this must be done. The atmosphere should be tested and shown to be safe before entry by any person. Multi test gas detectors are now available which can measure oxygen concentration, flammable gases and hydrogen sulphide all at the same time. This initial atmospheric monitoring should be continued throughout the work, and caution exercised if sludge’s etc must be disturbed. If the atmosphere cannot be made satisfactory, then Breathing Apparatus (BA) must be issued, but this in turn creates certain problems: Personnel Employers shall ensure the provision of all necessary competent personnel. Competence is more than just providing all necessary training, it is also about the mental and physical attributes of the individual. Persons who will be expected to work in a confined space must be physically and mentally suitable. It is not a job that is suitable for the claustrophobic or foolhardy. No-one with any of the following disabilities should work in confined spaces: a history of fits, blackouts or fainting attacks a history of heart disease high blood pressure lack of a sense of smell any illness causing giddiness or loss of balance claustrophobia or other mental or nervous disorder Lone Working Automation, subcontracting, teleworking, networking and the "new" self-employment are leading to an increase around the world in the number of people working alone. Working alone is not automatically more dangerous than other employment, but does have its special situations. Workers working alone in small shops, gas stations and kiosks are often seen as "easy" targets by aggressors. In the United States, gas station workers rank fourth among the occupations most exposed to homicide. Cleaners, maintenance or repair staff and others who work alone outside normal hours are at special risk of suffering physical and sexual attacks. Of lone workers, taxi drivers in many places are at the greatest risk of violence. Night-time is the highest-risk driving period, and as in other occupations, customer intoxication appears to play a role in precipitating violence. A 1990 Australian study of taxi drivers disclosed that taxi drivers ran 28 times the risk of non-sexual assault and almost 67 times the rate of robbery compared to the community at large. May 2008 98 Workplace violence - be it physical or psychological - is global, crossing borders, work settings and occupational groups. A new ILO report says some workplaces and occupations have become "high risk", and that women are especially vulnerable. The report highlights this burgeoning global problem, and provides ways for policy-makers to promote dialogue, policies and initiatives which can repudiate violence and remove it from the workplace. Homicide and rape. Kicking, biting, punching. Harassment, including sexual and racial abuse. Bullying, mobbing, victimizing. Leaving offensive messages, name-calling. Deliberate silence. Above are just some behaviours lumped under the definition of "violence in the workplace." The list is large, and contains actions which border on acceptable behaviour. Others can be interpreted differently from one culture to another. Yet despite the ambiguity, the presence of violence in its multifarious forms - whether subtle, overtly physically, or psychological appears to be a growing concern in workplaces worldwide. These are some of the main messages in a new ILO report entitled, Violence at Work. The report found that outbursts of violence occurring in workplaces around the globe suggest that the issue is becoming increasingly global, transcending the boundaries of a particular country, work setting or occupational group. Some workplaces and occupations involving people working alone or at night are increasingly at higher risk than others. Women are especially at risk, because so many are concentrated in the high-risk occupations, particularly as teachers, social workers, nurses, and bank and shop workers. Psychological violence Not all violence is physical. In recent years, new evidence has emerged of the impact and harm caused by non-physical, psychological violence. Such psychological violence includes bullying and mobbing. Workplace bullying is one of the fastest-growing forms of workplace violence. It constitutes offensive behaviour through vindictive, cruel, malicious or humiliating attempts to undermine an individual or groups of employees through such activities as making life difficult for those who have the potential to do the bully’s job better, shouting at staff to get things done, insisting that the "bully’s way is the right way", refusing to delegate because the bully feels no one else can be trusted, and punishing others by constant criticism or removing their responsibilities for being too competent. Research carried out in the UK found that 53 per cent of employees had been victims of bullying at work and that 78 per cent had witnessed such behaviour. The impact on those concerned can be severe. A Finnish study on the effects of bullying on municipal employees indicated that 40 per cent of bullied workers felt "much" or "very much" stress, 49 per cent felt unusually tired on the job, and 30 per cent were nervous "often" or "constantly." Ganging up or mobbing is a growing problem in Australia, Austria, Denmark, Germany, Sweden, the United Kingdom and the United States. It involves ganging up on or "mobbing" a targeted employee and subjecting that person to psychological harassment. Mobbing includes constant negative remarks or criticisms, isolating a person from social contacts, and gossiping or spreading false information. In Sweden, it is estimated that mobbing is a factor in 10 to 15 per cent of suicides. Working and travelling abroad alone Staff can often be involved in short and long-term projects overseas. It should be the policy of all organisations to apply the same standards for their employees no matter where they May 2008 99 work. While such work would normally be subject to the Health & Safety regulations of the country concerned, this cannot allow staff to work to different standards just because they happen to be working abroad. Besides the normal risks associated with the work itself, there are numerous other risks when working abroad: • unfamiliar diseases and medical conditions • the possibility of causing offence because of differences in culture • additional risks in travelling (particularly in less developed countries) • personal safety, especially in cities • language difficulties • poorer communications • lack of immediate back-up in the event of emergency • suitability and safe use of equipment • never really being “off-duty” • preparing for laboratory work overseas. You can deal with these difficulties by; detailed planning in advance controlling the risks as far as possible reviewing problems on return to base and adapt procedures accordingly. provision of information and training to all staff concerned provision of emergency procedures for any foreseeable event It is important to stress the necessity to report all accidents and incidents occurring abroad to the employer’s accident reporting system as soon as possible. Permit –To-Work Systems (PTW) Safety measures, such as the guarding of dangerous parts of machinery or the enclosure of plant containing noxious substances, which are adopted during a normal production run, may have to be disturbed when modifications to machinery or plant, maintenance, repair or other work of a like nature has to be carried out. Such operations, whether done as part of a normal periodic scheme or in an emergency, always necessitate some departure from ordinary production routine. Unless the operation is carefully planned beforehand and competently supervised at all stages dangerous situations can develop in which workers may be jeopardised either by the unwitting actions of others or by their own failure to realise that they are in a position of actual or potential danger. The many serious accidents, some with fatal results, which continue to occur during work of this nature show that in some instances the need for planning for safety has not been appreciated, while in others the plan has failed either because it was not thought out in sufficient detail or because there was a failure to carry out instructions. If accidents are to be prevented, it is vital that there shall be the clearest possible understanding between those responsible for production and those responsible for maintenance and similar work about the maintenance operation which is to be done and the way in which it is going to be tackled. Occasionally, safe working conditions may be achieved by the use of automatic safeguards but more often reliance has to be placed upon the actions of people. May 2008 100 Verbal instructions, requests or promises are always liable to be misheard, misinterpreted or forgotten and must never be regarded as a satisfactory basis for action on which people's lives may depend. Experience has shown that, to achieve the maximum degree of safety, the "human element" must be eliminated as far as possible by using a system which requires formal action. Such a system is that of "permit-to-work" which requires that a written and signed statement, to the effect that all necessary action has been taken, shall be in the possession of the person in charge of the operation before work is begun. General Considerations It is the responsibility of management to ensure that work is done safely at all times and to ensure that specific safety procedures are adopted when special care is necessary. These considerations apply equally to maintenance operations undertaken by a contractor and to those carried out by personnel who are regularly employed in the factory. It should be the aim, when possible, to have maintenance and similar work carried out at a time when the factory is closed down on the production side, but even if this can be achieved, there will very often be a need for the establishment of carefully planned safety procedures. Such a system will be necessary if, for example, several different groups of maintenance staff are at work at the same time or work has to be done on plant containing dangerous substances or there is danger of contact with live electrical conductors. A permit-to-work system is an essential ingredient for any special safety procedure. It consists basically of: an organised pre-determined drill to ensure that ensures that from a specified time, the designated equipment or process is safe nothing is done during the course of the operation to prejudice the safety of the workers all are aware of the limitations to their activities which must be strictly observed if safety is to be assured In operating a permit-to-work system the following, principles should be observed. 1) The information given in the permit must be precise, detailed and accurate. It must say which apparatus or plant has been made safe, the steps by which this safety has been achieved and it must state exactly what work is to be done. 2) The permit must specify the time at which it comes into effect. When work is to be carried out on machinery or in connection with the supply of electricity, the permit should remain in force until the work has been completed and the permit cancelled by the person who issued it or by someone nominated to act on their behalf. If work is being done on plant where there may be a risk from dangerous chemical substances, the permit should specify the time at which the permission expires. This point is considered in greater detail in the section of this handout dealing with work on chemical plant. May 2008 101 3) The permit should be recognised as the master instruction which, until it is cancelled, overrides all other instructions. 4) No-one must, in any circumstances, work at a place which is not specified in the permit as having been made safe. This prohibition must be understood to apply to everyone in the premises, including the directorate and senior staff. No one is too important to comply with safety rules. 5) No-one must do any work whatsoever that is not specified in the permit. If it is found that a programme of work must be changed, no variation whatsoever should be introduced until after the existing permit has been cancelled and a new one issued. The only person who has the authority to agree the change in programme and issue the new permit-to-work is either the person who issued the original permit or the person nominated by management to take over the responsibility from them, e.g. at the end of a shift or during absence on leave. 6) Anyone who takes over, either as a matter of routine or in an emergency, from the person who originally issued a permit must assume full responsibility until they have either cancelled the permit or handed over to another nominated person who is fully conversant with the situation. 7) The person who is to issue the permit must, before signing it, assure themselves that all the action specified as necessary to make the machinery or plant safe for the operation has, in fact, been taken. As a general rule, they should check this by personal inspection. Occasionally in very large undertakings, such as the electricity supply industry, it may be necessary to make an exception to this. In cases where some degree of divided responsibility may arise, as for instance between the electricity supply authority and the occupier of a factory , provision is made for the permit-towork form to be countersigned by a responsible person appointed by the occupier. Such a person is usually the Chief Engineer or their deputy, who have the authority to coordinate the duties and responsibilities of all concerned in attaining and maintaining a safe working condition in a particular operation. It is always advisable to nominate two persons authorised to issue permits to work, to eliminate difficulties in case of sudden illness, holidays, etc.. In practice, the appointment of more than one nominated person will often be necessary apart from illness, etc, and that is to deal with the different types of risks, e.g. electrical, mechanical or chemical and to ensure that they have time to discharge their responsibilities completely in the matter to its final conclusion. It cannot be claimed that the Permit to Work system can eliminate entirely the part which "human failure" plays in causing accidents, but this part can be substantially reduced by the use of an effective system in which all concerned know exactly what they have to do and how to carry out that work. There are many operations in which Permit to Work systems could and should be used. Below are examples of a few without going into specific details connected. May 2008 102 a) Machinery in general. For example phased machinery left in an uncompleted cycle. Hydraulic machinery not properly exhausted or properly isolated from compressed air systems etc.. b) Overhead travelling cranes. Sec. 27 of the Factories Act 1961 requires certain precautions in connection with work near overhead travelling cranes. The first requirement is that the crane must not travel nearer than 20 ft., to a person working on or near the wheel track, access to live wires, etc. c) Permit-to enter. For use in confined space working when there is a foreseeable significant risk arising from the nature of the enclose work space e.g. asphyxiation or fire/explosion. c) Electricity supply. Here the high level of risk involved and the serious consequences of switching errors and mistakes make it essential that a comprehensive safety system is operated whenever work is undertaken on high voltage equipment. d) Chemical plant. Again, effectively planned safety procedures are essential when the types of hazards can vary so widely, not only from plant to plant but also from job to job on any one plant. Each job, therefore, should be considered individually and properly set out on a Permit to Work system. There are many specimens of individual Permit to Work systems, but the important issue in this connection is to ensure that the system is "tailor-made" to suit each individual operation requiring proper execution. One could go on indefinitely with examples of operations where this system would enable the employer to discharge the statutory duties in ensuring safe methods of work. Plant which may contain dangerous fumes or have deficiency of oxygen. Tanks, vats, pits, pipe flues, or similar confined spaces. Explosion in gas drying units, woodworking machinery, etc. So there is plenty of scope in the safety field to introduce this system of safe working practices, i.e. permits to work. SUMMARY - PERMIT TO WORK A permit to work system is absolutely vital for the safe maintenance of plant and equipment, and to safeguard a company's own staff and any outside contractors they may employ. Each stage of the job to be undertaken should be identified and, if the job entails more than one trade, each stage should be completed and a handover signature obtained from the next trade to take over. On completion of all stages outlined in the permit, the plant or whatever has been worked on will be handed back to the person who issued the permit, that person will then cancel the permit, having satisfied themselves that the work has been completed. May 2008 103 What Is A Permit To Work A Permit to Work is a document which combines: 1. 2. 3. 4. 5. 6. 7. 8. 9. May 2008 Issue -A statement of the work to be done A clear description of the plant or piece of equipment involved Indication of the extent to which the plant has been made safe. Warning of possible hazards Precautions to be taken against these hazards Notification of release of the equipment to those who are to carry out the work Acceptance of the tasks concerned, and agreement to abide by the conditions and precautions specified (Receipt) Notification that the task is complete(Clearance) Acceptance that the task is complete (Cancellation). 104 Sample Permit to Work May 2008 105 FIRST AID All countries recognize the importance of first aid provision in the workplace, and there is consequently a legal duty to provide adequate and appropriate first aid provision such as the Occupational Health and Safety Regulations 2001 in Australia and the Malaysian Occupational safety and Health Regulations 2004. First aid has two primary roles; Preserve life and minimising the consequence of any serious injury Treatment of minor injuries that do not require further medical attention First aid is emergency care provided for injury or sudden illness. For minor injuries this first aid treatment might be the only treatment necessary but for more serious injuries and illnesses this might be the initial treatment before emergency medical treatment arrives. The first-aid provider in the workplace is someone who is trained in the delivery of initial medical emergency procedures, using a limited amount of equipment to perform a primary assessment and intervention while awaiting arrival of emergency medical service (EMS) personnel. Priorities of First Aid First Aid is given for three reasons and these are called the 3 P’s! 1. Preserve life - this is the preservation of those going to the aid of the victim, and then, and only then, preserving the life of the victim! This requires for example in a case of suspected electrocution isolating the supply prior to approaching and touching the victim. 2. Prevent the condition from worsening. This means using three main techniques to now save the patients life, maintaining their vital needs which are all abbreviated as ABC! 3. Promote recovery- do not do anything which may result in further damage e.g. moving the casualty, unless absolutely necessary Principles of First Aid Airway Breathing Circulation Employers General Duties 1. To provide, or ensure that there is provided such equipment and facilities as are adequate and appropriate in the circumstances for enabling First Aid to be rendered to employees if they are injured, or become ill at work. 2. To provide or ensure that there is provided such number of suitable persons as is adequate and appropriate in the circumstances for rendering first aid. May 2008 106 Equipment and Facilities All establishments must provide at least one suitable first aid box. Contents and quantities are often decided by national guidance but must be suitable for the particular workplace. They should be strategically placed to allow rapid access. Boxes should be marked and it will be the responsibility of either the appointed person or First Aider to ensure the up-keep of the contents. First Aid Room First Aid rooms should be provided where there are large numbers of employees are at work. However, they should also be provided in establishments with special hazards such as on construction sites or in mines where there are fewer persons at work; and in workplaces or where access to casualty centres, or to emergency facilities are difficult. The first aid room will normally be the responsibility of the first aider/company nurse. Guidance as to what exactly the room must contain are contained within the ACOP. First Aider Local national laws normally require the employer to provide an adequate number of “suitable persons”, for rendering first aid. A person is not considered suitable unless they have undergone training to the approved national standard, and successfully completed the final end test. Risk Assessment When considering the provision of “adequate” numbers of suitable persons, how many first aid kits are required, what their contents should be and whether a first aid room is required, needs a risk assessment to be conducted, and this will consider the following factors: Distribution Numbers Nature of the work Location Shift patterns Distribution The spread of workers throughout the workplace is an important consideration. Are they spread over a large area, e.g. a construction site, or are they relatively tightly located, e.g. an office block. Obviously, it would be much more difficult to cover the whole of a construction site, with all its vast area, and difficult access, than it would an office block with its good communications and good access. Numbers The number of workers employed is another factor but also contractor and visitor/general public provision. Nature of the Work May 2008 107 Is the work high risk medium risk or is the work low risk? Obviously, the higher the risk the higher the level of first aid provision. Some workplaces such as factories will be a combination, with the actual factory being considered to be high risk but the adjoining offices would be considered to be low risk. High risk is classified as, industries such as construction, warehousing, engineering etc.. Medium Risk is light engineering, assembly work and warehousing. Low Risk is classified as things such as libraries, offices, schools etc Location The location of the premises is important. If the premises were next door to a hospital, then the need for a First Aider would be less than if the premises were out in the countryside, in excess of 30 minutes from the nearest emergency services. The risk assessment will consider all the above factors, and it is then up to the employer to decide upon the appropriate provision. However, when making such an assessment the employer must be mindful that in the event of a notifiable accident, and an investigation by the HSE , the employer will be guilty until proven innocent. As a very minimum, any organisation must have an appointed person. However, it is no longer acceptable to use an appointed person to fill in during foreseeable absences such as holidays. Furthermore, if the company risk assessment decides that there is a need for a first aider, then consideration must be made of provision on all shifts should round the clock working be the norm. Shift Work Where there is more than one shift, clearly there will be a requirement for extra first aid personnel be they qualified first aiders or appointed person(s). there will also be implications for people working away from the main workplace. Self Employed The self employed persons must provide, or ensure that there is provided, adequate and appropriate first aid facilities, and personnel as necessary. May 2008 108 UNIT IGC 1, ELEMENT 7: MONITORING, REVIEW AND AUDIT Organisations must monitor their performance in managing health and safety in the same way as any other aspect of their business e.g. productivity, quality. The various monitoring techniques can be divided into active (pro-active) and reactive monitoring. ACTIVE MONITORING MEASURES There are a number of pro-active monitoring techniques and these would include: Health and Safety Audits Health and Safety Surveys Health and Safety Inspections Health and Safety Tours Health and Safety Contact Epidemiological Surveys Environmental monitoring and health surveillance to monitor the effectiveness of health controls and to detect any early signs of a problem. Hazard and Operability Studies Direct observation of employees by first line supervisors OBJECTIVES OF ACTIVE MONITORING The primary objectives of active monitoring, sometimes referred to as pro-active monitoring, are to; Check that the safe systems of work are implemented and effective Monitor the extent of compliance with the organisations systems and procedures and with relevant legislative and technical standards. This assessment of the appropriateness, implementation and effectiveness of its safe systems of work is an element of any safety management system since the employer needs to know; Where they are Where they want to be (targets) What is the difference, why and what are we going to do about it Active monitoring is a good way of measuring the reliability and effectiveness of its systems and procedures. This allows for informed decisions and recommendations for continuous improvement. Active monitoring also provides an opportunity for management to confirm their commitment to health and safety through techniques such as safety tours. Additionally, it also reinforces a positive safety culture by recognising our successes rather than highlighting failures. The business must view this active monitoring as an integral part of its business, with managers responsible for the monitoring of objectives and compliance with standards for which they and their subordinates are responsible. The actual method of monitoring will depend on the particular situation and the function of the person concerned. METHODS OF ACTIVE MONITORING Health and safety performance in organisations that manage health and safety effectively is measured against established standards. This enables measurement of compliance, and remedial action as necessary. This establishes standards of expectation , and so enable deficiencies to be quickly dealt with. May 2008 109 Health and Safety Audit A safety audit subjects each area of the company's activity to a systematic critical examination with the object of minimising loss. Every component of the total system is included, e.g. management policy, attitudes, training, features of the process and of the design, layout and construction of the company operating procedures. As in the field of accountancy, it aims to disclose the strengths and weaknesses and the main areas of vulnerability or risk and is carried out by appropriately qualified personnel, including safety professionals. A formal report and action plan is subsequently prepared and monitored. Health and Safety Survey A safety survey is a detailed examination of a specific field of activity, e.g. major key areas revealed by safety audits, individual plants, procedures, or specific problems common to the works as a whole. These too should be carried out by appropriately qualified personnel and possibly specialist consultants, a formal report and action plan being subsequently prepared and monitored. Health and Safety Inspection A regular, scheduled inspection of a unit or department carried out by one or more persons, possibly involving management, employee representatives and a safety advisor. The inspection would check maintenance standards, employee involvement, working practices and that work is carried out in accordance with procedures etc. It is essentially monitoring PEME – people (unsafe acts) and Equipment, Materials and Environment (unsatisfactory health, safety and welfare issues). Health and Safety Tour An unscheduled examination of a work area, carried out by management to ensure the effectiveness of standards such as housekeeping are at an acceptable level, obvious hazards are removed and, in general, that safety standards are observed. It also demonstrates management commitment and provides an opportunity for informal discussion with the workforce. Health and Safety Contact a) Formal A system ensuring that safety items are discussed at all levels to check that current/proposed systems are adequate. A written record will be generated at each stage for action by a nominated co-ordinator. This is one of the ways that could be used to ensure that the safety representatives are consulted on matters pertinent to health, safety and welfare. b) Informal Person to person communication between shop floor personnel and the safety professional and/or management to obtain information on what that person believes are the hazards of the workplace. Epidemiological Surveys An ongoing survey of the exposure to hazardous materials and conditions and their resultant health record. It is carried out by the medical department assisted by the safety professional. May 2008 110 Hazard and Operability Studies (Hazop) This is the application of a formal critical examination to the process and engineering intentions of new facilities at the design stage to assess the hazard potential of mal-operation or malfunction of individual items of equipment and the consequent effects on the company as a whole. Remedial action is then possible at a very early stage of the project with the maximum effectiveness and minimum cost. The technique can also be applied to existing assets. REACTIVE TECHNIQUES This is the traditional way of monitoring performance, but some of these techniques are unreliable since they are actually measuring failure, and people are not always going to report such events since believe that they might reflect badly upon them. Reactive monitoring techniques would include; Data on accidents Dangerous occurrences Near Misses Ill health Complaints by the workforce Enforcement action Civil claims No one monitoring technique is absolutely reliable, so it is wise to use a range of both proactive and reactive monitoring techniques. Accident statistics Many organisations spend considerable time developing data on the reactive performance data. Whilst it has a place in health and safety, the problem is that you are measuring your failures after the event. So accidents or incidents must occur in order to collect the data, so it must be combined with active data in order to get a more complete picture of the organisational situation. A low injury rate is not a guarantee that the risks are being effectively controlled. In some cases this might be a matter of good fortune, in others a deliberate attempt by staff to hide their failures for fear of blame. The primary use of accident data is to identify trends of failure . However, this trend analysis allows for general trends to be shown in order to identify common root causes within the business, as well as comparison to be made with others to learn of successes elsewhere. It also allows for baseline measurement, so allowing for targets to be set. Accident data can also be useful to help raise awareness of safety in general with both management and the workforce, and specific issues in particular e.g. manual handling injuries. Importantly, accident data can also be used to calculate health and safety costs to be calculated, which can then increase the likelihood of resources being allocated. May 2008 111 Examples of statistical analysis include; Frequency rate= Number of accidents in a period (e.g. 3 months) x 100,000 Total number of hours worked during the period Incidence rate= Number of accidents in a period (e.g. 3 months) x 1,000 Average number employed during the period For statistics to be useful, it is necessary to understand their limitations. Variables in work methods , hours of work, hazard controls, and management efforts make it difficult to make meaningful comparisons outside the organisation. Indices such as these are best used to compare performance internally over similar periods of time e.g. annually. In this way trends can be observed and valid conclusions drawn. Another complication is that different organisations have different definitions of an accident and incident, hours worked (does this include contractors), who is included ( own employees and contractors?). What is the multiplier used e.g. 1,000, 100,000? Dangerous Occurrences A dangerous occurrence is an accident not resulting in personal injury but still is reportable to the national enforcing authority. Many national laws require the reporting of such events to external agencies e.g. the Health and Safety Authority in Ireland. Typical examples would include the failure of pressure vessels, collapse of a scaffold and a serious fire. Ill-health (physiological and psychological) concerns people who are made ill by their work - a recent HSE survey in the UK suggests that over two million people are suffering from illness they thought was caused by work. This ill-health could be physiological e.g. WRULDs , noise induced hearing loss or psychological e.g. stress. These conditions may be notifiable events such as diseases such as dermatitis. Complaints by the workforce Complaints by the workforce might be formal or informal. Additionally they can be verbal or in writing. Ideally, these should be recorded as they can provide additional data to support trends identified through accident data, recorded near misses and trips, slips and falls. Such complaints should be investigated and may require reviews of specific risk assessments. Whatever the outcome feedback should be provided to the workforce. Enforcement Action This involves the issue of formal enforcement notices such improvement and prohibition as well and prosecutions. Again, these can be used as a measure of performance, but must be used wisely as there are rarely enough enforcement officers, so they tend to prioritise their efforts and this could mean an employer in a particular sector being part of a blitz by the authority, which results in a ‘spike’ of enforcement action. Health and Safety Inspection A regular, scheduled inspection of a unit or department carried out by one or more persons, possibly involving management, employee representatives and a safety advisor. The inspection would check maintenance standards, employee involvement, working practices and that work is carried out in accordance with procedures etc. It is essentially monitoring PEME – people (unsafe acts) and Equipment, Materials and Environment (unsatisfactory health, safety and welfare issues). May 2008 112 Factors governing Frequency and Type of inspection The frequency of inspections should be established by devising what is reasonably practicable i.e. risk v cost. In order to establish the risk data such as risk assessments, accident/near miss reports, plant breakdowns and failure. This frequency might be changed due to any of the following; Changes in legislation Modifications to plant/machinery Re-location of equipment or changes in environment Equipment test failures Accident data/Near Misses 7.3 Review of health and safety performance Gathering information to review health and safety performance. Learning from a range of information sources both internal and external to the business needs to be carried out systematically, through regular reviews of performance. This review draws on data from internal monitoring activities and from independent audits. These form the basis of continual improvement. Accident/Incident data Whilst accident data trend analysis is critical it should be remembered that it is reactive and therefore after the event. Any analysis needs to consider the potential for each occurrence to have resulted in a more significant outcome. Two elements need to be considered here; The quality of planning prior to the undesirable event, and Failure of controls . Both of these normally result in a review of the relevant risk assessments. Inspections The primary purpose of workplace general inspections is to identify sub-standard workplace practices and conditions. They aim to pre-empt the hazard becoming a significant risk and realising its potential. Auditing Health and Safety auditing is a valuable management technique that is integral to all health and safety management systems e.g. HSG65 “Successful Health and Safety Management” and ISO 18001. Where reasonably practicable HSG65 recommends that audits are undertaken annually to assist organisations to focus their resources in areas of most need. Auditing systems are an in-depth critical examination of all of the businesses activities and can be used to measure compliance against OHSAS 18001 as well as measuring against legal compliance and internal standards. An audit will show exactly how the business measures up to legal requirements, and whether this performance is up to standard. It will act as a benchmark from which they can formulate a health and safety plan. Scope The auditor will examine the company’s management policies and procedures for securing health, safety and welfare. This is supported by a tour of inspection which will help identify areas where new policies are needed, and where existing procedures are not working effectively in practice. The audit will typically consider the 30 subject areas of health and safety (or as appropriate) described in the model contents list below: May 2008 113 Model contents list Introduction Safety arrangements at the organisation 1. Management of health and safety 2. Accidents and accident reporting 3. Asbestos 4. Contractors 5. Display screen equipment 6. Electrical safety 7. Emergency lighting 8. Environmental protection 9. Fire prevention and emergencies 10. First-aid 11. Hazardous substances 12. Housekeeping and cleanliness 13. Information and communication 14. Kitchens, catering and food safety 15. Lifts and lifting equipment 16. Manual handling operations 17. Noise 18. Occupational health 19. Personal protective equipment 20. Plant rooms, machinery and equipment 21. Risk assessment requirements 22. Safety Policy 23. Safety signs and notices 24. Training 25. Use of vehicles / vehicle safety 26. Water services 27. Welfare provision 28. Working time 29. Work at heights 30. Workplace environment Recommendations Arising from the audit will be a written audit report that identifies where attention is needed to meet legislation or a recognised standard. It will also explain why such attention is needed. Each subject heading will have an action plan on which you can record your own targets and time-frames for addressing, and the people who are allocated with responsibility for the task. Recommendations will be broken down into three categories: RED Actions required to meet an actual or implied legal requirement OR Actions required to address a major non-conformity to OHSAS 18001 or other agreed standard AMBER Actions that are good practice, and would be expected to be taken by your organisation OR Actions required to address a minor non-conformity to the OHSAS 18001 or other agreed standard GREEN May 2008 Other suggestions that, whilst not essential, may enhance the working environment and morale of employees. 114 Scored Audit Systems There are scored audit systems, such as the International Safety rating System (ISRS) which are specially designed for multi-site organisations who wish to measure site-by-site performance. This format can also be useful for single site organisation who wish to measure improvements to their management system year on year. Please call us for further information as to how this works. Difference between audits and inspections Audits are critical in-depth examination of the systems and procedures supporting health and safety in the workplace. This technique therefore focuses about 80% of its effort on paperwork and about 20% of its effort on the reality safe/unsafe acts and conditions. Inspections have a reverse focus with 80% of their effort on the ground focusing on unsafe acts and/or conditions but also spending around 20% of the time examining things such as maintenance records and inspection reports. It also highlights positive as well as negative issues. Also an inspection is normally conducted by an external, independent auditor using an auditing manual, whereas an Inspection is normally internal conducted by a line manager, supervisor, safety adviser, safety representative etc and does occur much more frequently, weekly, monthly or three monthly typically. May 2008 115 UNIT 8: OCCUPATIONAL INCIDENT AND ACCIDENT INVESTIGATION 8.1 THE PROCESS AND PURPOSE OF INVESTIGATION OF ACCIDENTS ROLE AND FUNCTION OF ACCIDENT INVESTIGATION Accidents are a particular type of incident, which may result in personal loss, minor injury, serious injury or death. Where no such outcome results, the accident is classified as a near miss. The primary function of the investigation and reporting of accidents is to prevent further occurrences and to address the issues identified, i.e. the immediate and underlying causes, and compliance with legal standards. Another important function is to develop a safety culture and certain managerial skills. Outside of the organisation, others have different reasons for investigating incidents: Enforcement Agencies look for evidence of an offence and identify those responsible, then the courts or insurance claims assessors look for evidence of liability. In short the reasons for accident investigation are similar to those for accident prevention; Humane Economic Legal Role of the investigation This includes; Data gathering to help identify trends Establish what happened Establish why it happened (immediate and underlying causes). Identify the measures to prevent a recurrence Establish legal and/or worker compensation liability Different types of incident Outcome Outcome is the result or consequence of an unplanned, uncontrolled event. This might include injury, ill health, property damage or a near miss. Injury Physical harm done to or suffered by a person as a result of the accident. This could include fatalities, major injuries such a fractures and amputations, over 3 day lost time injuries, and minor cuts/bruising. Ill-health Harm to a persons well being caused by this term covers both physical ill-health e.g. mesothelioma but also psychological ill-health such as depression. A dangerous occurrence is an unplanned and undesired occurrence which has the potential to cause injury and which may or may not cause damage to property, equipment or the environment and is reportable to the national enforcing authority. Many national laws require the reporting of such events to external agencies e.g. the Health and Safety Authority May 2008 116 in Ireland. Typical examples would include the failure of pressure vessels, collapse of a scaffold and a serious fire. A near miss (or incident) is an accident that results in no apparent loss. So it is an unplanned, uncontrolled event that has not led to injury, damage or some other loss this time, but could have in slightly different circumstances. Examples include: articles falling near to people, short-circuits on electrical equipment. Damage only is an accident where there has only been damage to property, plant and equipment, the environment and production losses. Incident is “an unsafe occurrence arising out of or in connection with work where no personal injury is caused, or where personal injury only requires first aid”. Source: ILO Basic investigation procedures In the UK the HSE produce a publication HSG245 Investigating Accidents and Incidents complements and expands on the accident procedures set out in HSG65 Successful Health and Safety Management, their recommended safety management system. The guidance sets out the four stages of accident investigation: Gathering the information Analysing the information Identifying risk control measures Implementing the control measures To understand how an accident occurs and as importantly, how to investigate afterwards in order to identify the immediate and underlying and underlying (root) causes, we now need to consider the Domino Theory. According to Bird and Loftus, the inventors of this theory, all accidents are preventable, and since they only occur as the culmination of a series of events or circumstances, which occur in a fixed, chronological order – the 5 dominoes. Here a comparison can be made with a series of domino’s, placed on end such that if one falls it will cause the next to fall, and so on throughout the series. However, if the first domino were removed then the chain of events will be halted. The sequence of events are as follows: 1. Lack of management control from the organisation, permitting; 2. Basic causes (i.e. personal and job factors), leading to; 3. Immediate causes (unsafe acts and unsafe conditions), which are the direct cause of the accident, which results in a; 4. Contact with an energy or substance; 5. Loss (which may be categorised as injury, damage or some other loss). This sequence can be applied to all accidents, and is a basic tool for management control and accident investigation. May 2008 117 THE DOMINO THEORY ORGANISATION BASIC CAUSES Lack of Job factors Management IMMEDIATE CAUSES INCIDENT LOSS Unsafe acts Contact with Injury and substance or Damage Unsafe conditions energy Other loss Control and Underlying, (root), DOMINO No. 1: Personal factors causes Organisation Wherever people seek to make a living or achieve specified goals, organisations arise. The one characteristic that they all have in common is structure. They cannot function by allowing their members to do whatever they think needs to be done; they have to be organised. The formal structure takes place as duties are assigned, procedures adopted. So rules, and regulations are circulated and the production processes are begun. In health and safety terms this is expressed in the setting of goals of commitment to safety and the demonstration to individuals that deviations are not acceptable. All the above is achieved by: 1. Controls Producing a Health and Safety Policy. Providing objectives and standards for safety which are communicated to all. Communication of these standards is achieved via Information, Instruction and Training. Carrying out Risk Assessments. To identify possible routes to human failure. Producing rules and procedures to remove or minimise the risks identified by the risk assessments, together with the mechanisms for reviewing them. (Safe systems of work). 2. Monitoring controls Effective monitoring of these safe systems to check on their implementation. (Audits, Surveys, Tours, Inspections, safety contact, safety sampling and hazop studies). Adequate and effective supervision with the power to remedy deficiencies when necessary. 3. Emergency preparedness A strategy aimed at reducing/minimising the effects of an accident. Areas covered will include First Aid, Fire, Explosion and Environmental pollution control. May 2008 118 4. Accident investigation Accident investigations and effective use of the lessons learned. DOMINO No 2: Basic causes: Job factors Successful management of human factors involves the development of systems which have taken into account human capabilities and fallibilities. So careful design of the job is essential, and should ensure that no mis-match (either physical or mental) occurs between the job requirements and the employee’s capabilities. Otherwise, there will be the potential for human error. Factors to be considered are: Likely human errors highlighted by risk assessments Operator decision making - deciding on the optimum balance between human and automatic contributions to safety actions. In other words, the level of automation required within the task. Ergonomics - this concerns the man/machine interface, and concerns how we make the job or machine fit the man. Thus we consider layout of control panels, information displays, control devices etc. Design and presentation of procedures and operating instructions. Do we use operating manuals only, or do we use training sessions and leaflets as well? Do we use words only, or words and pictures? Organisational control of environmental factors: workspace, access for maintenance, and the effects of noise, lighting and the thermal environment etc. Provision of the correct/safe tools and equipment Scheduling of work patterns to control fatigue and stress - shift organisation, rest breaks, work variety, and arrangements for emergency situations. Effective communications Personal factors The organisation and Job factors will lead to a potential accident situation, and it will be the personal factors which now dictate how the person(s) will behave in that situation. These factors are as follows: Stress Stress is perhaps best understood in engineering terms. In a structure the various members are subject to loading, as in a bridge which is subject to different loadings at different times. For example, when traffic flows over the bridge it gives rise to internal and external stress. Overloading structural members leads to overstress which can result in bending and/or fatigue, without necessarily getting anywhere near the breaking strength. These well known conditions of stress and strain in engineering apply equally as well to people who live and work in stressful conditions. Different personality types are better able to cope with high stress levels, and this is important when considering appointing persons to high stress jobs e.g. fighter pilot, air traffic controller etc. Stress due to organisational and job factors will be revealed in several ways, one of which is increased accident frequency. 119 May 2008 Skills Skill concerns the performance of a task in a successful and rapid way. Many tasks fulfil this definition from typists to skilled craftsmen. It is recognised that there are individual differences in skill acquisition, and consequently, this must be a consideration in job design, especially when complicated skills are involved. Personality Personality is the word used to describe the individual’s perception of his total environment, including himself. So personality is directly linked to a person’s behaviour as perceived by others e.g. honest, intelligent, loyal, serious etc. So where a supervisor has a personality that is considered by other workers to be weak, unintelligent, and disloyal this is important from a health and safety viewpoint because he will not be respected, and consequently any instructions that he gives are unlikely to be followed when he is not present. Physique This concerns a physical rather than mental mis-match. Certain jobs require strong physiques e.g. scaffolder, labourer or soldier, whereas other jobs require less physical ability e.g. electrician, manager, receptionist. Again if this is not considered by the organisation then this could result in a person that is not strong enough having an accident e.g. dropping a scaffolding tube from height. Attitude Attitudes are sub-conscious filters that colour all information we receive. Attitudes arise out of our beliefs, and are shaped by our education and experiences. This sub-conscious filter is important because it will colour all information, and so decide whether we perceive to like or dislike this information. Motivation Motivation is important because it is a requirement within an unsafe individual in order to achieve a lasting alteration in his behaviour form unsafe to safe behaviour. This behaviour change is achieved by altering the persons underlying attitude(s), and this will only be possible with a suitably motivated individual. Experience Our experiences as we grow older will shape and change our attitudes and thus, perceptions of ourselves and the world around us. The prime influences are: Economic Parents/Friends School Intelligence Considerations should include: 1. Task analysis for critical jobs will produce a job description and a specification for the person to match the job. This may include age, physique, skill qualifications, experience, aptitude, knowledge, intelligence, personality and will form the basis for recruitment and/or selection. 2. Training should aim to, provide the skills for trainees to understand the workings of the plant and process so that they can work correctly under both routine and emergency conditions. 120 May 2008 3. Monitoring of personal performance. 4. Fitness for work Medical standards, health surveillance, counselling/advice during stressful periods. DOMINO No 3: Immediate causes 88% of all accidents are caused by people - the unsafe act. This error could be on the part of anyone within the chain. Therefore before we examine the unsafe act, we must examine the unsafe condition. Unsafe conditions accounts for 10% and 2% are neither so are called Acts of God. UNSAFE ACTS UNSAFE CONDITIONS ACTIONS BY PERSONNEL WHO INADVERTENTLY OR WILFULLY DISREGARD CORRECT PROCEDURES OR PRACTICES AND THUS REDUCE THE DEGREE OF SAFETY. PHYSICAL CONDITIONS THAT IF LEFT MAY BECOME THE CAUSE(S) OF AN ACCIDENT. 1 2 3 4 5 6 7 8 9 Using equipment without authority or incorrectly. Making Safety devices inoperative e.g. removing, disconnecting. Using unsafe or damaged equipment. Taking unsafe posture or position, e.g. lifting with back bent, exposing body to hazards Unsafe loading or stacking of materials. Failing to use protective clothing. Horseplay, e.g. distracting, teasing, practical jokes. Hazardous movements, e.g. running , jumping, stepping on or climbing over. Unsafe acts not classified above. 1 2 3 4 5 6 7 8 Inadequate guarding of machinery. Faulty design, construction Defects in equipment, tools or machinery e.g. frayed lifting ropes, chipped hammer heads, incorrectly adjusted brakes. Incorrect dress for job, e.g. loose clothing on drilling machines. Lack of knowledge, e.g. skill or training. Poor housekeeping, e.g. material in walkways; untidy stacking Unsafe systems of work. Unsafe physical or mechanical conditions not classified above. Domino No 4: Incident This is the point in the accident sequence where there is a contact with an energy (e.g. electricity) or a substance (a corrosive chemical). Domino No 5: Loss This domino is the end result of the accident injuries to person(s), damage to property (e.g. a damaged forklift truck), or some other loss (bad reputation, environmental pollution etc.). Step 1: Accident Investigation: Gathering the information The first stage of the investigation process is to find out what happened and to gather evidence; this should begin as soon as possible. The first priority should be to treat the victim(s) and secure the area from further danger, making it safe, but secure and where possible, undisturbed. May 2008 121 An accident investigation process should start with the formation of an investigation team. The level of investigation will depend on the accident, its complexity and the severity of its consequences. The investigation should be conducted by, or under the supervision of, a competent person. This would be someone with the knowledge and skills in the specific working practices within which the incident occurred, and who understands the nature of the safety requirements that need applying, for example the immediate supervisor or foreman, a member of management or a safety officer or representative. The investigation should also cover clearing-up operations and reinstatement, as further evidence may throw light on the incident. The next stage is to carry out witness interviews, if possible, at the scene of the accident. It is important not to come to any preconceived conclusions and to allow witnesses to explain what happened, in their own words. There are three types of witness who should all be assured that the purpose of the interview is not to blame anyone, but to attempt to find out the cause and reduce the possibility of recurrence. Such witnesses may be those involved directly in the incident, including the victim(s) or eyewitnesses, as well as witnesses who did not see the incident, but can provide certain information on the actions of people, or can corroborate other witness statements. The physical circumstances should be recorded graphically, through the use of plans, figures and diagrams, and by photographs or video evidence. These should be used to identify environmental conditions, such as temperature, lighting, actions, locations, positions of persons, vehicles etc as well as the extent and severity of the damage, locally and further from the scene. The plans should be accurately labelled to indicate any physical measurements at the time; noise or light levels, substances involved, speeds of vehicles, the moving parts of machines and distances involved, such as reach distances. Once the immediate effects have been dealt with, the relevant records should be consulted: the accident book, information about the people, plant and environment, machinery involved in the incident, as well as inspection and maintenance records, risk assessments, environmental measurements, medical records, specific safety reports and analyses. Checklists are commonly used to list key points, which must be investigated. They also detail what happened and what caused the accident, including physical conditions and acts of persons. Depending on the nature of the workplace and the operations, such as an office environment or machinery workshop, the checklists will contain differing amounts of information. Step 2: Accident Investigation: Analysing the information The next priority of the investigation is to identify the immediate, direct cause of the incident, because there is a risk that the same circumstances may recur. Steps need to be taken to ensure that there is no repetition of the problem, e.g. unsafe acts or unsafe conditions. Whilst there may be an underlying reason for these acts or conditions, it is important to establish exactly what has caused the accident. Unsafe acts –these are where people at the workplace directly cause, or contribute to, the incident. They may include: operating without permission, contravention of specific rules and not using safety devices. These are where the underlying (root causes) need to be identified – the acts or omissions of the organisation, its culture, its management and resources (management systems failures). May 2008 122 Unsafe conditions - these are where the physical conditions at the workplace or the methods of work directly cause, or contribute to, the incident. They may include: unguarded machinery, inadequate guarding, the provision of unsafe equipment, unsafe floors and working surfaces and unsafe systems of work. There must also be a requirement to consider human error as a possible factor. Similarly, one should consider human factors , i.e. environmental, organisational and job factors, and individual characteristics, which influence behaviour at work, and ultimately affect health and safety failure through the organisation, its culture, management, and resources. The next part of the investigation involves finding out what caused the unsafe act (or omission) and/or condition. These underlying reasons for the immediate cause must be remedied to prevent a recurrence. The process of investigating the reasons for each underlying (root) cause goes on until the real root of the problem is established for the incident and to see what lessons can be learnt for the future. However, the purpose of the investigation is not to attribute blame, but to establish all the reasons for the incident so that lesson s can be learned for the future. Step 3: Accident Investigation: Identifying risk control measures The next stage in the investigation is to identify any control measures required. The investigation of a single incident may lead to a range of wider issues relating to immediate and underlying causes. All risk-control-measure options need to be analysed and evaluated according to the control hierarchy; elimination, substitution, engineering controls, etc. They must be prioritised with appropriate control measures and actions specified. Responsibilities and timeframes for actions must be considered and allocated, and most importantly, the controls must be ‘so far as is reasonably practicable’. Wider implications also need to be considered: Can lesson learned be applied elsewhere Could similar events occur elsewhere? Would the recommended controls prevent further accidents? Step 4: Accident Investigation: Implementation of Risk Control Action Plan The final stage is to formulate the risk control action plan from the control measures identified. These may be immediate measure, as well as short or long term actions. These will need to be accurately documented and prioritised accordingly. Control targets, which are Specific, Measurable, Attainable, Realistic and within a certain Time scale SMART) need to be set. These measures need to be reviewed, assessed and appropriate procedures put in place to perform such actions. Similarly, there should be procedures to discuss the findings relating to the incident with staff through safety meetings and verbal and written communication. A properly conducted investigation is useful to understand the causes and possibly prevent similar or parallel accidents happening in the future. Accident investigations are important because they contribute to the continual improvement of the health and safety performance of an organisation. May 2008 123 8.2 THE ORGANISATIONAL REQUIREMENTS FOR RECORDING AND REPORTING OCCUPATIONAL INCIDENTS Internal systems for collecting, analysing and communicating data A number of report forms are utilized to capture and record that accidents and ill-health have occurred. These include; Initial record of the accident (Accident Book) First Aid treatment records Medical treatment records Sickness absence reports Accident reports Maintenance/repair reports External reports for events that are notifiable to government agencies e.g. fatalities, major injuries, dangerous occurrences. Insurance reports The ILO code of practice for Recording and Notifying Accidents and Diseases (RNOAD) recommends that employers make arrangements , in line with national legislation, to record occupational accidents, commuting accidents, occupational disease, dangerous occurrences and incidents. The employer should ensure that records are prepared in accordance with national requirements, and in any case within 6 days. Records should be retained and be in such a form that they are able to be made available in a reasonable time e.g. electronic on a computer. Whist a number of countries have requirements to report to external agencies , few have requirements to make and retain internal records. Amongst those that do are the Philippines, South Africa, United States, Malaysia and Vietnam. Here the requirement extends to all occupational accidents and diseases. In some countries, such as the UK, there is a requirement to record and retain a record of accidents in an ‘accident book’ and keep records of all accident reports to the national enforcing agencies. Records must be retained for a suitable period, and this means 3 years for an injury accident and 40 years for events that might lead to a chronic occupational disease. It is useful to maintain a statistical record of the number and type of accidents (see element 7) as well as descriptive records/reports and this is a specific requirement in some countries such as Vietnam. National practices vary considerably regarding the terms and definitions used in occupational accidents and injuries. Reporting of events to external agencies Typical examples of reportable events to external agencies include major injuries, diseases and dangerous occurrences. May 2008 124 UNIT IGC 2: ELEMENT 1: MOVEMENT OF PEOPLE AND VEHICLES – HAZARDS AND CONTROLS Vehicles and mobile plant moving in and around workplaces are a cause of occupational injuries and deaths world-wide. Reversing, loading, unloading and pedestrian movement are the activities most frequently linked with workplace vehicle accidents. Traffic and pedestrian movement at workplaces should be designed, planned and controlled so that pedestrians and vehicles can circulate safely. Improving workplace traffic safety, in addition to reducing work-related injuries, can also improve workplace efficiency and productivity. Workplace vehicle hazards may occur during: • pedestrian movement at workplaces; • vehicles or plant reversing and manoeuvring; • arrivals and departures; • loading, unloading; • hitching and unhitching of trailers; • mounting or dismounting from vehicles; • securing of loads; and • maintenance work. Movement of people Most at risk from vehicles at workplaces are those who work with or near vehicles and mobile plant, such as cars, vans, forklifts, trucks, semi-trailers, trailers, tractors, loaders, buses and utilities. People also at risk may include other workers, management, self-employed people and customers or visitors at workplaces. Hazards to pedestrians The typical hazards to pedestrians are; Slip, trips and falls on the same level Falls from height Collision with other vehicles Striking by moving, flying or falling objects Striking against fixed or stationary objects e.g. racking Control strategies for pedestrian hazards include conducting a risk assessment in order to identify controls such as; Provision of non-slip surfaces Spillage control kits and bunding/drainage Designated walkways Fencing and guarding Use of signs and PPE Information. instruction, training and supervision (IITS) as is necessary Maintenance of a safe workplace will involve; Clear cleaning and housekeeping standards May 2008 125 Provision and maintenance of suitable access and egress Environmental monitoring and control of issues such as dust, noise, lighting and heat. Employers need to carry out regular risk assessments, identifying hazards, assessing the risk of injury or harm, and considering means of controlling or reducing the risks. As always the control measures can be arrived at by considering ERIC PD; • Elimination of vehicle movement where possible, or removing the need for reversing; • Reduction by minimising the personnel in the area by restricting pedestrian access in certain areas or at certain times; • Substitution of unsafe vehicles, loading facilities, road signage or road surfaces with safer ones; • Isolation of vehicles from pedestrians or vice versa; • Engineering controls, e.g.. pedestrian barriers, handrails, separate access doors for pedestrians and vehicles; • Administrative controls, e.g..: • providing education, training, supervision and safe procedures on vehicle movement at workplaces; • preventing reversing in certain areas or at certain times; • providing designated parking for work and private vehicles; • monitoring risks to ensure they remain as low as possible. • Protective equipment such as safety boots, helmets and reflective jackets are the last line of accident prevention; • Monitoring the effectiveness of safety changes and safe work procedures through regular inspections, checks and record keeping. In detail the control strategies for the safe vehicle operations are; Safe Design Workplace routes should be: • safe for both vehicles and pedestrians at the workplace; • wide enough for the largest vehicle using them; • one-way if possible, with adequate passing space around stationary vehicles; • clearly sign-posted to indicate restricted parking, headroom, speed limits, vehicle movement and other route hazards; • surfaced with bitumen, concrete or other suitable material and well drained; and • free from excessive gradients, with steep gradients that cannot be avoided clearly signposted. Lift trucks and similar plant should operate on gradients only if they are designed to do so. Unsealed routes at temporary workplaces such as construction sites and forestry operations should be designed and controlled to ensure safe vehicle movement. Safe Workplace Workplace routes should be well maintained and: • free from obstructions, grease or slippery substances; • free from damage to surfaces; • immediately cleaned or cleared following substance spills or items falling from vehicles May 2008 126 Clear road markings and signage should alert vehicle operators to: • speed limits; • sharp bends; • junctions; • p e d e s t r i a n crossings; • vehicle crossings; • blind corners; • steep gradients; and • road works. The safest way to protect pedestrians is to provide: • separate footpaths or walkways; • pedestrian barriers at building entrances and exits to prevent pedestrians walking in front of vehicles; • traffic routes wide enough for safety where separation is not practicable; • marked traffic routes, for example lines painted on the floor or ground; • separate access ways for vehicles and pedestrians into buildings or enclosures; and • vision panels in pedestrian doors entering vehicle areas. Workplaces where pedestrians have to cross vehicle routes should have: • clearly visible ground markings and signs; • clear pedestrian and vehicle visibility; and • adequate lighting. Parking Onsite parking, if provided, should enable separation between work and private vehicles. Private vehicles should be parked away from busy work areas where practicable. Walkways leading to and from parking areas should be safely surfaced, clearly marked, adequately lit, unobstructed, sign-posted and separated from vehicle routes. Employees and customers who bring private vehicles to workplaces should be provided with and required to comply with: • specified safe routes; • clear safety signs at parking areas; • clear speed limit signs; and • information and instruction on safe driving on workplace routes. Loading Bays Loading bays should be situated in safe and suitable locations where vehicles can be manoeuvred easily, and near tarping/sheeting areas. Where practicable, they should be protected from adverse weather conditions, and should be subject to risk assessment and safe work procedures. Raised loading platforms should be: • provided with safe access, egress and safe bays for people working at ground level; • clearly marked along the edges; • if necessary, fitted with rails on the non-loading side, to reduce the risk of someone falling off the edge; and • fitted with raised wheel stop edges to prevent vehicles such as forklifts and trolleys rolling over the edge. May 2008 127 Lighting All routes, manoeuvring areas and yards should be: • adequately lit, with particular attention to junctions, buildings, plant, walkways and vehicles routes; and • designed to avoid extreme light variation. e.g.. Drivers moving from bright sunlight into dull light or vice versa. Where practicable, operators exposed to hazardous sun glare should be provided with suitable protection, e.g.. sun visors or screens. Reversing Reversing accidents are a major cause of workplace injury and damage to vehicles, equipment and premises. Most reversing accidents can be avoided by: • removing the need for reversing, e.g.. with drive-through loading and unloading systems; • minimising the need for reversing, e.g.. by reorganizing loading and unloading procedures; • providing clearly marked reversing areas visible to drivers and pedestrians; • excluding non-essential personnel from the area; • ensuring signallers wear high-visibility clothing and their signals can be clearly seen; • using radios and other communication systems; • ensuring drivers have another person to direct them if they cannot see clearly behind before reversing; • ensuring visiting drivers are familiar with workplace routes and reversing areas; • providing larger reversing areas; placing fixed mirrors at blind corners; • fitting refractive lenses on rear windows to help drivers see “blind spots”; • using flashing reversing lights on vehicles if workplace noise is too loud for reversing alarms to be heard. To reduce risks when reversing, rear vision mirrors, fixed safety mirrors and windscreens should be kept clean and in good repair, and reversing alarms kept in working order, loud enough to be heard above other work noises. May 2008 128 UNIT IGC 2: ELEMENT 2: MANUAL AND MECHANICAL HANDLING – HAZARDS AND CONTROLS Manual handling hazards and risks In Europe more than a quarter of the accidents reported each year to the authorities are associated with manual handling. Whilst fatalities are rare major injuries such as fractures are not uncommon. There is more absence from work as a result of injuries sustained during manual handling operations than from any other cause. Most of these injuries could be avoided by using correct techniques for manual handling. Manual handling means more than simply lifting or carrying something. The term is used to describe activities including lifting, lowering, pushing, pulling, carrying, moving, holding or restraining an object, animal or person. It also covers activities that require the use of force or effort such as pulling a lever or operating power tools In order to understand this legislation it is necessary to define a number of key terms used: LOAD: refers to a discrete moveable object. This includes a person, but not a lever attached to a machine MANUAL HANDLING OPERATIONS: refers to human effort required to move a load by lifting, pushing, pulling carrying etc.. Note that the force applied is human not mechanical. INJURY: this is sustained from the external physical nature of the load, not from the contents e.g. a hazardous substance such as a corrosive liquid in a drum. Injuries resulting from the external form of the load would be classed as manual handling injuries, e.g. cuts, bruising and grazes. There are also the internal injuries - hernias, slipped discs, sprains and strains. Manual handling is an area of ergonomics, and so requires the: "Fitting the job to person, not the person to the job". Since weight is only one of the factors to be considered, there are no specific weight limits contained within the Regulations. The regulations place duties upon employers as well as the self employed. Hierarchy Of Measures 1. Wherever possible avoid the need for manual handling operations involving a risk of injury as far as is reasonably practicable.(Eliminate. Automate, Mechanise). 2. Make risk assessments for those operations in which manual handling cannot be avoided 3. Action the resulting preventative and protective measures, so reducing the risk of injury to the lowest level reasonably practicable May 2008 129 Common types of manual handling hazard and injury Manual handling activities exert force during a task (lifting, lowering, pushing, pulling, carrying or moving; holding or restraining any person, animal or thing). Consequently, it covers many tasks and these occur in every workplace, every day. Manual handling affects all employees to a degree and is potentially a major health and safety risk in particular areas. Examples of manual handling tasks include: • Pushing trolleys; • Lifting bags, suitcases or packages; • Loading or unloading cargo; • Handling dogs; • Moving stock or stores; • Shifting furniture; • Unpacking or packing containers; and • Sorting mail. Typical manual handling injuries include; Sprains and strains of muscles and tendons; Back injuries, including damage to the muscles, tendons, ligaments. Slipped (prolapsed) intervertebral discs and subsequent pressure on nerves; Joints injuries, including injuries to the shoulder, elbow, wrist, hip, knee, ankle and joints in the hands and feet; Bone fractures; Nerve injuries such as carpal tunnel syndrome of the wrist; Hernias; and Cuts and grazes Crush injuries to toes from falling objects Most back and spinal pain is caused by continual bad lifting, twisting and stretching and not single trauma injuries. It is not just the back that may be injured. Other muscle groups and joints such as shoulders, arms and legs, are involved in manual handling and may be damaged by bad lifting techniques. Feet can also be damaged by loads being dropped on them. May 2008 130 Avoid the need for hazardous manual handling as far as is reasonably practicable. It may be possible to achieve this by: [a] Carrying out the task in such a way that the load does not have to be transported at all, for example, repairing the equipment in situ where it is safe to do so, thereby avoiding the need for transportation to [and from] the site, or [b] Avoiding secondary handling, for example by arranging for goods to be delivered to the point of use were appropriate, rather than to a central point from which they need to be manually relocated. 2. Handling by other means Alternatives to manual handling to include: [a] Automation, where an instruction for moving or positioning the load is automatically carried out by a machine as part of the process, or [b] Mechanisation, by use of lift trucks, dumper trucks, cranes and conveyors in place of human effort. [c] Manual handling aids, by use of wheelbarrows, sack trucks and pallet trucks etc that reduce the amount of human effort. Note: Whilst automation and mechanisation may reduce manual handling risks, this may not be cost effective and could introduce new and different hazards of their own. These factors must be taken into account during any assessment. Assess the risk of injury from any hazardous manual handling that can't be avoided, and minimise the risk of injury from hazardous manual handling, as far as reasonably practicable. The guidance note supporting the regulations highlights some of the common factors to consider in a manual handling risk assessment and we remember these by the mnemonic LITE. See below for a typical risk assessment form. A manual handling assessment includes: Load Weight, size Does it have handles Stability Hot/cold, sharp edges Individual(s) How many – team lifting? Known history of back, knee, hip problems, etc. Health, fitness and strength Young person or new or expectant mother Are they competent - instruction and training Clothing, including any PPE required Task May 2008 131 Work routine and task layout Duration and frequency Distance Environment Space constraints Environment - thermal, ventilation, lighting, air movements Floors - single level, flat, dry surface and well maintained Prevention A competent person should adopt a good handling techniques when moving loads and this would include: Planning - where the load is going, removing any obstructions, use of appropriate handling aids, help if needed Position feet apart giving a balanced and stable base Wearing suitable footwear and clothing Good posture - straight back maintaining its natural curve, bending knees to position the load level with the waist A secure grip Keeping the load close to the body in a smooth movement Illustration of good manual handling technique Action the control measures arising from the risk assessment, in order to minimise the risk, so far as is reasonably practicable. May 2008 132 A TYPICAL CHECKLIST for MANUAL HANDLING ASSESSMENTS Use this checklist to remind you of the main points to think about while you: consider the risk of injury from manual handling operations identify steps that can remove or reduce the risk decide your priorities for action. SUMMARY OF ASSESSMENT Operations covered by this assessment: _______________________________________ Department: _________________________________ Locations: __________________________ Personnel involved: ________________________________________________________________ Date of Assessment: ................................................ ___/___/___ Overall priority for remedial action: Nil Low Med High (Circle as appropriate) Remedial action to be taken _________________________________________________________ ________________________________________________________________________________ Date by which action is to be taken: ......................... ___/___/___ Date of reassessment: ..............................................___/___/___ Assessor's name: __________________________ Signature ______________________________ Section A— Initial assessment: Q1 Do the operations involve a significant risk of injury? .........................................Yes / No If 'Yes' go to Q2. If 'No' the assessment need go no further. Q2 Can the operations be avoided/ mechanised/ automated at reasonable cost? ...Yes / No If 'No' go to Q3. If 'Yes' proceed and then check that the result is satisfactory. Q3 Are the operations clearly within the guidelines? .......................……………….Yes / No If 'No' go to Section B. If 'Yes' you may go straight to Section C if you wish. Section B— Full assessment See below Section C - Overall assessment of risk: Q4 What is your overall assessment of the risk of injury? . Insignificant / Low / Med / High If not 'Insignificant' go to Section D. If 'Insignificant' the assessment need go no further. Section D - Action: Q1 Is this a generic assessment? ................................................................................Yes / No If Yes a record of the assessment must be kept— Use this checklist Q2 Is this assessment obvious and easy to repeat? ..................................................Yes / No If No a record of the assessment must be kept. If Yes a written record is not required Q3 What remedial steps should be taken, in order of priority? I ____________________________________________________________________ ii_____________________________________________________________________ iii ____________________________________________________________________ iv ____________________________________________________________________ v ____________________________________________________________________ And finally: complete the SUMMARY above if a written record is required compare it with your other manual handling assessments decide your priorities for action TAKE ACTION.....AND CHECK THAT IT HAS THE DESIRED EFFECT Page 2 Section B - Full Assessment (where necessary): Questions to consider Level of Risk May 2008 133 Possible remedial action If the answer to a question is yes place a tick against it and then consider the level of risk Yes Low Med High Make rough notes in this column in preparation for completing Section D The tasks - do they involve: - holding loads away from trunk? - twisting? - stooping? - reaching upwards? - combining risk factors? - large vertical movement? - long carrying distances? - strenuous pushing or pulling? - unpredictable movement of loads? - repetitive handling? - insufficient rest or recovery? - a work rate imposed by a process? - handling whilst seated? - teamwork? The loads - are they: - heavy? - bulky/ unwieldy? - difficult to grasp? - unstable/ unpredictable? - intrinsically harmful (e.g. sharp/hot?) The working environment: are there: - constraints on posture? - poor floors? - variations in levels? - hot/cold/humid conditions? - strong air movements? - poor lighting conditions? Individual capability - does the job: - require unusual capability? - hazard those with a health problem? - hazard those who are pregnant? - call for special information/training? Other factors: - Is movement or posture hindered by clothing or personal protective equipment Deciding the level of risk will inevitably call for judgement When you have completed Section B go back to Section C, overleaf. FORK LIFT TRUCKS May 2008 134 Fork lift trucks, (FLT), are a very useful tool in the workplace, but are also a major cause of injury to people and damage to plant. There are two broad categories of FLT, reach and counterbalance. They both work on the same principle, and that is that a relatively small vehicle is able top carry a very heavy load safely. If we understand that principle of operation of the counterbalance FLT, we will be able to appreciate the basic rules that exist for the safe operation of all FLT. Counter balance truck The mass of a counterbalanced lift truck acts as a counterweight so at the load can be lifted and moved without the truck tipping. However, the truck can be tipped over if overloaded, if the load is incorrectly placed on the forks or if the truck is travelling across an incline or an uneven surface. Instability is increased if the truck travels with the forks raised rather than lowered. Load centre Fuel and fuelling FLT can fuelled by, diesel, gas, battery. Depending upon the fuel type, the hazards and precautions vary, as follows; Fuel Hazards diesel dermatitis, carbon monoxide poisoning fire and explosion gas Precautions training/barrier creams/gloves selection of FLT suitable for task gas explosion, manual handling of cylinders, training/lifting eqpt/no smoking carbon monoxide poisoning battery electrical explosion during charging, acid burns hydrogen build up, electrocution training/PPE/no smoking charge timers, use of RCD’s Hazards May 2008 135 There are numerous hazards associated with the use of FLT, and they may be minimised by the use of competent staff, sound equipment, and good design of the workplace. Below are the main categories of hazard, and their causes. Hazard Contact with vehicles, fixed plant, racks Collision with people and other vehicles Overturning of vehicle Load falling Mechanical failure Operator error Refuelling Causes poor layout/operation lack of room, poor operation, poor layout operator error broken pallets, poor stacking, unstable loads poor maintenance, exceeding SWL poor training and/or supervision poor system, poor supervision Safety rules There are a number of simple rules that can be applied in order to ensure safer operation of FLT in the workplace. Competent FLT operators will have been instructed in these rules and therefore understand their importance, however, it is not uncommon for experienced staff to ignore such rules, to the danger of themselves and others. Rule only raise and lower forks with the mast vertical Reason a tilted mast causes the centre of gravity to move, possibly outside the stability triangle, causing vehicle to overturn only use tilt with the load lowered as above only use the hoist when the vehicle is stationary as above only move the vehicle with the load as low as possible as above never travel, or turn across slopes as above never undertake violent turns as above use speed consistent with the conditions as above always travel with the load up hill, as above NB. when empty the “load” is the rear of the vehicle Factory traffic creates a significant potential for loss, both personal injury and damage to assets. Of the many fatal accidents which occur each year involving the use of transport within factory sites, the most common type involves victims being struck or run over by vehicles. Movement of vehicles now constitutes one of the largest single causes of deaths in factories. Ideally to prevent such accidents occurring the movement of vehicles should be governed by stringent rules which are enforced by management supervision and control. However, as direct supervision of site traffic is not always practicable and as many visiting drivers may be unfamiliar with the site, the layout and design of road systems within sites is a particularly important consideration, as is the correct vehicle for the work involved. May 2008 136 Telescopic (reach) forklift truck and counterbalance lift truck Machine stability and safe load handling Safety in fork lift operation demands that machine stability is maintained at all times. Fork lifts should, therefore, be carefully selected for the work they are required to do. For construction sites, only those types designed for site work should be used. The rated capacity of a machine will be quoted by the manufacturer, but careful checks should be made to ensure that the capacity is appropriate for the work to be done. For example, safe loads will be lower if the mast is tilted forward or the boom of a telescopic materials handler is extended. Stated capacities apply in a static condition and may be far in excess of those which are safe when the machine is moving. Limits of safe operation will depend on site conditions and, as far as possible, machines should be operated only on designated routes. Even with the right machine for the job and satisfactory site conditions, the safe operation of fork lifts on site still depends on the machine being properly operated. The establishment of safe systems of work (in written form where appropriate) and incorporated in operator training programmes is all important. When stabilisers are fitted to a machine, they should be used in accordance with manufacturers' instructions. When operating fork lifts, drivers must be aware of the effect on the machine's stability of induced forces. These are the forces which act upon a machine or on its load due to a change in speed or direction; for instance, when starting, stopping, turning or rolling. The greater the speed of the machine, the greater these induced forces. Accelerating, decelerating and braking must be done progressively and smoothly, never hard or jerkily. Turning must be done carefully, giving due consideration to the weight and placing of the load and the condition of the ground. Accident experience has indicated certain points which need particular attention: Load stability is crucial and should be checked before travelling. Wide loads have tilted and caused fatal accidents. Ensure that loads cannot tip sideways. May 2008 137 Access ways must be checked to see that they are wider than any load, which may be carried along them. Loads should normally be carried; close to the ground but, if they have to be raised to clear obstructions, they must be lowered when the way is clear. The operator should be assisted by a banksman. The weight of timber and other porous material should be re-estimated if it is wet. If the machine has a mast, loads should be lifted with the mast vertical or slightly tilted back. Travelling on slopes, or in poor ground conditions, may be critical and the machine manufacturer's recommendations should be followed. The danger of skidding and overturning is particularly serious on two wheel drive machines where braking can cause weight transfer away from the brake axle when negotiating a slope. There are reversing hazards with fork lifts, as with other transport. Audible warning alarms are a useful aid, but their effectiveness can be limited by general background noise and by operators relying on them, instead of carrying out a visual cheek before reversing. The need for a banksman should always be considered. Whenever the load impairs the operator's vision, a banksman should be used to guide the operator. With articulated fork lifts, a lift should not be made unless the front and back wheels are in the same straight line Unit loads should not be broken down unless the overall weight would overload the machine. Safety of site personnel On sites operating fork lifts, all personnel must be fully instructed in the safe systems of work laid down for their protection, and must observe them at all times. Some of the points which should be covered by safe systems of work are: - Everyone not directly involved in fork lift operations should keep well clear of the machine. The carrying of passengers on fork lifts should be forbidden. Persons acting as banksmen, or guiding the driver in removing his forks from the pallet, should: 1. 2. 3. 4. May 2008 keep a safe distance from the machine and its load never stand under the elevated load of a fork lift never stand between the load and any exposed floor edge, or between the load and a fixed object wear conspicuous clothing, reflective jackets should be worn during poor visibility 138 Operating Areas Another element in a safe system of work relating to lift trucks is the area in which the trucks operate. Accidents often occur when trucks overturn on uneven ground or on gradients or collide with other vehicles, structures or pedestrians, particularly in restricted areas. The following are essential for safe operations: Flat, level and even driving surfaces free from obstructions, spillages and slippery substances as far as possible. Particularly hazardous to small wheeled trucks are potholes and loose material. Where possible, separate routes for pedestrians and trucks, designated crossing points, barriers at danger areas, warning notices, one-way systems. Route ways with sufficient width and height. Where possible, sharp bends and overhead obstructions should be removed. If this cannot be achieved, the hazard should be reduced by the use of warning devices, barriers, signs and mirrors. Identification of pillars, pipe work, racking, pit edges, loading bays and excavations; and, where appropriate, the provision of impact absorbent shields. Adequate illumination, particularly at junctions, near buildings and plant and in pedestrian areas. Glare should be avoided. Attachments Attachments are designed to increase the scope of fork lifts. In each case it must be remembered that the use of an attachment can radically alter the fork lift's stability characteristics and hence its safety. Preferably, any attachment should be made by the manufacturer of the fork lift, and its incorporation on the fork lift done in consultation with them; otherwise it is essential that the attachment is designed by a competent person and that adequate testing is carried out before the equipment is allowed into general use. The use of attachments may involve additional training for operators to ensure overloading does not occur. When using a jib/hook attachment, similar operating procedures to those for mobile cranes should be employed. Safety devices Each rough terrain fork lift should have a device incorporated in its hydraulic system which will not allow the machine to lift weights greater than its rated load. The machine should also have a device, which will prevent a specified load being lifted beyond a given height. The provision of a simple levelling indicator is strongly recommended, with the danger zones, where it is not permitted to raise the load, clearly marked. Such indicators, if not fitted as original equipment, can be fitted by the user, but only after consultation with the manufacturer of the fork-lift. May 2008 139 Every telescopic materials handler should be fitted with an Automatic Safe Load Indicator which gives a continuous read out of forward stability and sounds an audible alarm when the load exceeds 95% of the Safe Working Load. Other safety devices which should be fitted to these machines are: A levelling indicator Check valves which will hold the load in the event of hydraulic pressure loss Indicator lamps which will show when stabilisers are on firm ground. Working platforms Due to height limitations and the necessity to have an absolutely level surface, the use of working platforms on fork lifts will be very rare on site. In the UK there are recommendations in HSE Guidance Note PM 28: Working platforms on fork lift trucks, should be seen as best practice.. The guidance is intended for users, suppliers and designers of working platforms fitted to fork-lift trucks with a vertical mast, or with a telescopic boom. It does not apply to mobile elevating work platforms. The guide provides advice on the platform dimensions, capacity (not more than two people), floor, rail & toe board, gate, hand-holds; Also on securing the platform to the fork arms and truck carriage. Guidance is also provided on selecting a suitable truck, including information on weight, method of securing, guards and inappropriate trucks. For activities involving the use of a working platform with a fork-lift truck, a risk assessment should be carried out, under the Management of Health and Safety at Work Regulations. Where it is intended to use a working platform on a telescopic materials handler, it is essential that the fork tilt control is isolated to prevent inadvertent operation. Typical safety features include low-level kick plates to prevent equipment being kicked off the platform; twin safety harness points, and a high meshed rear guard to avoid contact with the fork truck's moving parts, a fail-safe device in case of mechanical failure. Other features include positive behind heel locking to lock the platform to the truck forks; a backguard, gate and rails which are all of tubular construction and raised in order to reduce risk; automatic locking, self-closing and latching gate locks, and a non-slip, self-draining floor. Maintenance All such plant should be maintained in efficient state, in efficient working order and in good repair. Driver Training Training should consist of three stages, the last being the one in which the operator is introduced to his future work environment; May 2008 140 1. Basic training: Which includes the basic skills and knowledge required for safe operation of the type of lift truck and attachments, which the driver will use. This should be training off-the-job. 2. Specific job training: Broadly, training should cover knowledge of the workplace, any special requirements of the work to be undertaken and the use of specific attachments. Again it should be training off-the-job and is often combined or integrated with basic training. The training should include controls of the lift truck to be used; routine inspections of the truck, which should be carried out by the operator; use of the truck in various locations such as gangways, loading bays, slopes, rough terrain; problems of working in poor weather; site rules such as one-way systems, speed limits, work near overhead lines, excavations; work to be undertaken such as loading particular vehicles and using working platforms on forks. This training takes place in an area prohibited to other persons. 3. Familiarisation training: This is training on-the-job where the driver operates the truck using the skills learned. This will be done under close supervision and under normal working conditions. Driver Selection Of prime importance is the careful selection of potential drivers. The first consideration is age. Drivers should be at least 18 except where the operator is undergoing training under direct supervision. Other factors to be taken into consideration are that operators should be reliable, able to do the job in a responsible manner, and have a reasonable level of physical and mental fitness and intelligence. These parameters do not automatically exclude disabled or handicapped people but, in such cases, it is advisable to seek medical advice to assess the suitability of such candidates. The use of selection tests can avoid wasteful attempts to train unsuitable trainees. Previously Trained Drivers Where an operator possesses previous experience and/or training, the evidence should be examined before the operator undertakes any driving tasks. It is necessary to assess whether previous experience and training are suitable and sufficient to enable the driver to operate safely the type of lift trucks and attachments used in the new work environment. Previous training certificates should be examined and where they are not available the operator should undergo an assessment whilst actually driving the new lift truck. Certification A record of each driver who has successfully completed the training should be retained by the employer. The record should indicate the types of lift truck which the employee may operate, and any special conditions such as area limitations and date of authorisation. The employee should be issued with a certificate or copy as evidence of training which can be used in the event of change in employment. CONVEYORS These are sometimes used to transport materials e.g. minerals, metals, slates and tiles from one place to another, for example from the ground level to the roof of the structure. May 2008 141 Hazards nips or traps between moving parts traps between moving and fixed parts traps and nips created by the drive mechanism sharp edges of guard rails entanglement electricity Eloise Precautions It is important to ensure the safe use of conveyor belts, and we will discuss the precise type of machine guarding required for each different type of conveyor belt after we have examined the general points to be considered to ensure the safe use of conveyor belts: Provision of arrangements for lubrication whilst allowing guards to remain in position e.g. through suitably positioned small openings for maintenance access which do not permit access to the danger zone. Installation of guard rails, or side members, where the conveyor rises more than 1 metre above floor level. An emergency stop should be fitted, or a series of emergency stops, where the conveyor is longer than 20m; stop buttons should be positioned at not more than 10 metre intervals. They should be mushroom shaped and coloured red and remain off until re-set. A belt conveyor transports materials by means of a moving belt. Guards are required at the trapping points where in-running nips are created between the belt and revolving drums. In some cases guards or trip devices will be required along the complete length of the conveyor and at areas where belts change direction. Belt conveyors should be fitted with emergency trip wires or stop buttons which must be fully operative at all times. MOBILE ELEVATED WORKING PLATFORMS (MEWPS) MEWPs divide into two categories; boom-type Mobile Elevating Work Platforms (cherry pickers), and scissor lifts Scissor Lift May 2008 Cherry Picker 142 The most common causes of death with MEWPs are falls from height and the second most common cause of serious injuries at work. This guidance is aimed at those who use or control the operations of boom type MEWPs, used across a range of industries including construction. The most common accident causes were: unsuitable ground conditions; critical parts of the MEWP failing or malfunctioning; or the MEWP being struck by another vehicle. Consequently it is critical that these issues are eliminated or properly controlled. Mobile elevating work platforms can provide excellent safe access to high level work. When using a MEWP make sure that: whoever is operating it is fully trained and competent; the work platform is provided with guard rails and toe boards or other suitable barriers; it is used on firm and level ground. The ground may have to be prepared in advance; its tyres are properly inflated; any outriggers are extended and chocked as necessary before raising the platform; and everyone knows what to do if the machine fails with the platform in the raised position. Do not: operate MEWPs close to overhead cables or other dangerous machinery; allow a knuckle, or elbow, of the arm to protrude into a traffic route when working near vehicles; move the equipment with the platform in the raised position unless the equipment is designed to allow this to be done safely (check the manufacturer's instructions). Some MEWPs are described as suitable for 'rough terrain'. This usually means that they are safe to use on some uneven or undulating ground - but check their limitations in the manufacturer's handbook before taking them onto unprepared or sloping ground. Wearing a harness with a fall restraint lanyard attached to the platform can provide extra protection against falls, especially while the platform is in motion. The selection and use of appropriate personal fall protection equipment used as part of a suitable personal fall protection system. A personal fall protection system is an assembly of individual components, for example, a full body harness and lanyard with or without a shock absorber pack. A variety of equipment is available to prevent a person falling (work restraint) or to save them once they have fallen (fall arrest). Fall protection should not be relied upon as the only means of control because if the MEWP is pushed over or falls over being attached to it by a fall protection system is unlikely to prevent you from being injured or killed. For this reason, advice on controlling the risk by ensuring safe site, safe plant and safe operator are an essential part of this guidance. In the case of scissor lifts fall protection is not normally required, unless a person needs to lean over the guardrail. In this instance, the sections of the guidance that relate to a safe plant, May 2008 143 safe site and safe operator is relevant to preventing falls from scissors lifts due to overturning incidents. CRANES AND LIFTING OPERATIONS Background Cranes come in a variety of types; tower crane gantry crane overhead electric travelling crane mobile crane (tracked or wheeled). There are a number of requirements for ensuring the safety in the use of lifting and moving equipment. These include: Strength and stability Equipment must have adequate strength for the proposed use, with an appropriate factor of safety against failure. Equipment must also have adequate stability for its proposed use. Where appropriate, sufficient resistance to overturning must be provided to be put into place and operating effectively before the equipment is used. Lifting equipment with rails are also covered (devices to remove loose material etc.). Mobile lifting equipment with pneumatic tyres to be inflated to the correct pressure. Means to check this should be supplied. Where there is a significant risk of overloading, need to provide devices such as rated capacity indicators and limiters. All lifting equipment must be sufficiently strong, stable and suitable for the proposed use. The load must also be suitable. Need to consider ergonomic risks when selecting lifting equipment. Material of manufacture needs to be suitable for conditions of use. Means of access/egress need to be safe and suitable. Need to minimise risks from slips, trips and falls from any part of the lifting equipment (e.g. cover or fence any floor openings, suitable edge protection where there is a risk of falling more than 2m, or less then 2m where there are other relevant risk factors involved. Adequate protection for operators (from adverse environmental conditions). Where affected by high wind, need to fit devices to detect dangerous situations (most commonly this would be an anemometer). Position & installation Lifting equipment must be positioned or installed in such a way to minimise risk of a person being struck or the load moving in an uncontrolled manner. Need to minimise the need to lift the loads over people and prevent crushing when the equipment is in its extreme position. Path of travel (where fixed) to be protected by suitable enclosure. Wherever possible, hooks and other similar devices used for lifting to either have safety catches fitted or be shaped to prevent the accidental displacement of the sling. Where two or more items of lifting equipment are used they, or their loads, should be prevented form coming into contact with each other. May 2008 Suitable gates must be provided at any access/egress points to any hoist way or shaft; also fitted with efficient interlocking. 144 Marking of lifting equipment Lifting machinery and accessories to be marked with their safe working load (SWL). Where it is not practicable to mark the equipment itself, a coding system should be used to provide the user with the SWL (e.g. colour coding, label). This also applies where the SWL is dependant upon varying configurations (e.g. fork lift truck fitted with attachments). Where a significant hazard arises from the use of the machinery it should be provided with appropriate equipment or devices such as rated capacity indicators/limiters. Accessories for lifting include single item (e.g. shackle) or an assembly of items (such as a lifting beam and slings). Accessories include slings, shackles, swivel or eye bolts, clamps, lifting magnets, vacuum lifters and lifting beams. Any carrier of person should display the maximum number of persons to be carried in addition to the SWL. Organisation of lifting operations Lifting operations need to be: Properly planned Appropriately supervised; and Carried out in a safe manner. The person planning the operation should have adequate practical and theoretical knowledge and experience of planning such operations. The plan must address: The risks identified; The resources required; and The procedures and responsibilities involved. Where two or more items of lifting equipment are used simultaneously to lift any load, where appropriate a written plan should be drawn up and applied. Proper planning is a combination of; i. ii. iii. Initial planning – to ensure that the equipment is suitable (with regard to consideration of the load to be lifted, its weight/shape/centre of gravity/ availability of lifting points), its travel, frequency of use, environment of use, personnel available and their knowledge, training and experience). Planning of individual lifting operations – for routine operations this will normally be a matter for the people using the equipment (e.g. the fork lift truck operator). For routine operations, an initial plan may only be required once but it may need review occasionally to ensure it is still valid. (e.g. fork lift trucks in a warehouse). For complex operations a plan may be needed each time it is carried out. Supervision should be proportionate to the risk and determined by the nature of the work and the competence of the personnel involved. Where practicable, loads should not be carried or suspended over areas occupied by persons. Where this is not practicable, need to establish a safe system of work to minimise the risk to persons who may need to be below the load. May 2008 145 Operators of lifting equipment must be able to see the full path of the load or have a responsible person with an appropriate means of communication to guide him/her. Lifting accessories must be compatible with the load and used in a safe manner. The person attaching or detaching the load (or some other authorised person) must give their authorisation before the equipment is operated. Lifting equipment must not be used in the open air where weather conditions could cause a hazard to occur Lifting equipment should not be used in a manner likely to cause it to overturn Steps should also be taken to minimise risks from ‘proximity’ hazards Steps should also be taken to minimise risks from ‘proximity’ hazards (e.g. overhead power lines, other equipment/structures, racking). An appropriate traffic management system should be in place Where appropriate, the SWL should be reduced to take into account the environment and mode in which it is being used (termed ‘derating’). Examples include using a carpet boom on a fork lift and the way a sling is attached to a load (i.e. the angle of its legs). Lifting equipment used for lifting persons Work equipment used for raising/lowering people should be specifically designed for the purpose. There are some very limited exceptions but even with these all necessary precautions to ensure safety (including supervision) must be taken. Such equipment may include lift trucks, telescopic handlers and cranes. There are special precautions required for lifting equipment used for lifting people. Persons being carried (i.e. in a hoist) should be protected from being injured by something outside of it (i.e. fully enclosed when in use). Persons working from a carrier need to be protected by suitable edge protection; floor to be slip resistant. Lift cars to have devices to prevent free-fall, independent of the means of suspension of the car. Where practicable, other carriers to have devices etc. to prevent the carrier falling in the event of the failure of the primary means of support. In the event of malfunction, persons being lifted must not be exposed to danger and a reliable means of rescue must be available (incorporating means to summon assistance, emergency means of lowering the carrier or self rescue). May 2008 146 Thorough examination & inspection Lifting operations are statistically very high risk, consequently there is a need for periodic through examination and testing/inspection of lifting equipment and all accessories. Issues involved include:i. ii. Competent person - this should be someone with appropriate practical and theoretical knowledge and experience of the particular lifting equipment. Should be independent and impartial. Thorough examination - equipment which requires a thorough examination should be identified and thoroughly examined as required. The risks arising from failure will determine how thorough the examination needs to be. Thorough examination may be needed at several points in the life of lifting equipment. Before you use any item of lifting equipment for the first time, unless you have received physical evidence that a thorough examination has been carried out and it is safe to use, it should be thoroughly examined by a competent person. The intervals at which these checks should be done should be laid down in an examination scheme drawn up by a competent person. Commonly this involves a recorded inspection once every 7 days. Following each examination or inspection, the person who undertook the task should submit a report to the employer. Through examinations and testing are typically six or twelve monthly, with again a through examination report as an outcome. Employees should be given appropriate training and instruction. Lifting accessories must be stored in conditions that do not lead to damage or deterioration. Planning lifting operations It is essential that employers to ensure that every lifting operation involving lifting equipment is: Properly planned by a competent person, appropriately supervised and carried out in a safe manner. This duty is not new and has been a feature of much health and safety legislation around the world, yet few employers seem to fully understand their responsibilities in this respect. Most accidents involving lifting equipment - some horrific - are caused by failure to plan and effectively supervise the job. In view of this, and as cranes are commonly used for a variety tasks on site, also frequently misused with potentially fatal consequences, it may be useful to consider crane lifting operations in more detail. THE MEANS OF ENSURING SAFETY IN LIFTING OPERATIONS Introduction Each lifting operation tends to be unique, but those that cause the least difficulty in terms of time, cost and outcome have similar elements to them. These common elements which are; Control of the lifting operations (planning, selection of equipment etc.) Certification of equipment Competence of signallers and operators. May 2008 147 A number of different factors affect how a lifting operation should be undertaken. For example, raising of a section of ventilation ducting from floor to ceiling level will need to be handled differently from lifting air-handling units weighing several tonnes from ground level onto the roof of a tall building. However, one common factor in all of these operations, whether large or small, is their potential for going wrong. It is essential therefore that anyone considering carrying out a lifting operation is fully aware of the responsibilities placed on them by the relevant regulations and the likelihood of severe financial loss if a lifting operation goes wrong. CONDUCTING A LIFTING OPERATION The process could begin with the receipt of an invitation to tender for a contract where lifting will be required or the realisation during a job that materials or personnel need to be raised off the ground using lifting equipment. At this stage a preliminary assessment should be carried out to determine whether light equipment such as a gin wheel, chain blocks, mobile gantry or a genie lift can be used for the task or if heavier plant such as a crane, forklift or telehandler will be necessary. If you are unfamiliar with the use and capability of these various pieces of equipment you must seek specialist advice at this point. The following information will prove useful in determining which item is most suited to your needs: - are personnel to be lifted (to be avoided if possible) - maximum weight of load to be lifted - maximum and minimum height for load to be lifted - maximum radius load to be placed at - likely dimensions of load - space restrictions in lift area - number of lifts needed per day and in total - probable length of use LIGHT EQUIPMENT If a light piece of equipment is sufficient for your needs then hire or purchase is possible from one of the many available plant hire and sales outlets. When equipment is delivered to you a hire company must provide relevant health and safety information for the item provided. This is normally in documentary form and outlines the hazards associated with the particular piece of plant. However it is the user’s responsibility to ensure that a risk assessment has been carried out for the use of the equipment and that anyone who is to use the equipment has been made aware of the findings of the assessment. Furthermore, every employer must ensure that all employees have received suitable and sufficient information, instruction and training and that employees are adequately supervised during the use of the equipment. Any explanation of the equipment functions given by the hire company on delivery does not constitute adequate training. This is known simply as familiarisation training and serves to explain which levers or switches operate which functions on that particular model. Advice on training and on the selection and safe use of lifting equipment can be obtained from the Lifting Equipment Engineers Association. May 2008 148 HEAVY PLANT In the event that a crane is needed to complete the task in question there are two possible courses of action depending on the level of competence available within your organisation regarding the safe use of cranes. If you need to use a crane but have never received formal training in the safe use of cranes or have had no experience in the use of cranes then a contract lift is the best option. The crane hire company will then retain certain liabilities and responsibilities for the crane, the load and for the safety of other property and persons. Alternatively, if you employ personnel competent in the safe use of cranes then a normal crane hire should suffice, whereupon you will retain responsibility and liability for the use of the crane. REGULAR USE OF CRANES ON SITE BY COMPETENT PERSONNEL When cranes are used throughout the course of a project by say, principal contractors it is common for them to employ competent personnel to control and co-ordinate the operation of these cranes. Successful management of lifting operations is greatly assisted by a systemic approach as defined in a British Standard B.S.7121 regardless of how simple these tasks may appear. The list which follows outlines the essential elements of such a systematic approach: - Competent personnel must be appointed to be responsible for the planning, organisation, execution and supervision of all lifting operations. - Only equipment which is fit for purpose and which has undergone suitable inspection and test must be used. - Clear, simple and well-defined communication systems must be in operation at all stages of the process PERSONNEL The effective management of lifting operations depends on having key roles defined and responsibilities clearly allocated. One person, sometimes referred to as the Appointed Person, must be in overall control of lifting on site. This person will be principally responsible for the planning of all lifting operations. If the Appointed Person spends a large proportion of their time office bound, performing other duties, then it may be necessary to have an additional person who spends the majority of their time on site acting as a Crane Supervisor. They must ensure that approved methods are being followed in practice. It is crucial that these personnel have the authority to stop lifting operations at any time. Finally the site workforce must be informed of all personnel who are authorised to act as Crane Operators and Slingers/Signallers. These appointments complete the crane team: - Appointed Person (who may also be the Crane Supervisor in certain circumstances) - Crane Supervisor - Crane Operator - Slinger/Signaller PLANNING Best practice regarding the planning of lifting operations begins with a pre-site start assessment of all the lifting to be carried out on the project in question. This will include the selection of cranes and lifting gear for specific work elements. May 2008 149 From the initial assessment a schedule of common lifts can be developed detailing how specific frequent lifts are to be conducted. Lifting operations not included in the schedule of common lifts are then deemed to be special lifts and therefore require more detailed assessment and a method statement. FACTORS AFFECTING SAFETY WITH CRANES Some of the important factors affecting safety with cranes are explained below. The characteristics of the load to be lifted For a safe lifting operation, it is necessary to know the weight, dimensions and position of the Centre of Gravity [C o G] of the load. Therefore, the information provided should, at least, include: a) The maximum weight to be lifted; b) Any non-routine handling instructions that are necessary for a safe lift; c) The position of the C o G of asymmetric loads or loads of non-uniform mass [preferably marked]. Special lifting accessories may have to be designed for lifting asymmetric loads or loads of non-uniform mass. Lifting is made safer when designated lifting points are either provided or marked on the load. Handling of loads is made easier if items to be installed horizontally arrive at the point of installation horizontal, and items to be installed vertically arrive in a vertical orientation. The weight and dimensions of lifting accessories add to the weight to be lifted. The crane position Where the load is to be lifted from, the route it will take during the lift and where it will be landed should be taken into account. Therefore potential obstructions, either permanent or temporary, should be taken into account. Obstacles include: buildings and other structures, trees, overhead power lines, etc. If the crane is to be positioned on or next to an existing structure it may overload such a structure - a design calculation check may be required to establish whether temporary strengthening or propping is needed. The radius over which a crane has to lift will have a significant effect on the loads that can be lifted and to what height they can be lifted Clearances Safe distances of the crane from the structure under construction, adjacent buildings, roads and pedestrian accesses must be maintained. Mobile cranes need adequate space for the correct deployment of outriggers. In addition, they should be able to slew and manoeuvre the load with adequate clearance from obstructions. A minimum clearance of 600mm should be allowed for. Other, equally important, considerations include: May 2008 150 a) Clearance to overhead electric cables: Cranes must never be positioned in the exclusion zone around overhead electricity cables. Lifting operations close to electricity cables or pylons may have to be scheduled during power off conditions. b) Clearance to railway tracks, overhead catenaries and public highways: If a crane is to be positioned adjacent to a railway, canal or public highway an independent design check may be required, proving that the scheme has been planned and engineered such that no damage will occur to existing structures, property or to the public. c) Clearance for aircraft near airfields: cranes operating within 6km can be a hazard to air traffic, especially if their height exceeds 10m, or when the top of the crane is higher than the surrounding structures or trees. Erection and dismantling constraints Cranes have to be erected and dismantled. More space will be needed for these operations. Ground conditions and foundations In order to operate safely, cranes need adequate foundations or support. Therefore, the ground conditions on a site are important. Crane operators need to know about: a) Character of the ground including groundwater conditions; b) Engineering properties of strata relevant to the support of the crane or design of the foundations; c) Location of any underground hazards e.g. open or back-filled excavations, services, drainage pipes, tunnels, trenches and basements. All of these factors can be removed or made less dangerous by considering them during the design. Weather conditions Prevailing weather conditions and exposure of the site can affect a lifting operation. Wind, in particular, can affect how a load behaves when it is lifted. Structural items, which offer a large effective area to the wind can be difficult to control, even in very moderate winds, e.g. shutters for concrete, long-span trusses, deep beams. Manufacturers will specify maximum wind speeds for erection, lifting, out of service and dismantling operations. In very exposed areas (e. g. cliff tops) or areas subject to wind turbulence (e.g. built-up areas), these speeds may have to be reduced. ROUTES TO AND ACCESS ONTO THE SITE Cranes need access routes and space for erecting and extending them and vehicles delivering the loads. Special access may be required for both the crane and high capacity trailers often used for deliveries such as counter-weights and jib sections. When working in city centres, getting the crane on and off the site will require advance planning often in conjunction with police and local authorities and could require facilities for overnight working. May 2008 151 EQUIPMENT Types of cranes There are many types of crane and a detailed classification is given in ISO 4306. However, the vast majority of cranes used in industry can be classed as: a) Lorry Loaders, (HIABs), which are suitable for delivery purposes and routine lifting operations associated uniquely with the vehicle on which they are fitted; b) Truck Mounted Cranes, which are suitable for short duration operations where mobility around site is important; c) Crawler Cranes, which are suitable for longer duration operations and ‘pick and carry duties’ and for use on some types of terrain where a wheel mounted crane would not be appropriate; d) Tower Cranes are suitable for semi-permanent installation for covering large areas whilst taking up relatively little room at ground level. Selection of cranes While economic factors may influence the choice of a crane, it is essential that the crane selected is capable of lifting ALL loads that it would be expected to handle, within its capacity and stability limits. Manufacturers supply duty charts, which show the SWLs for specific duties. These are a good guide but are often compromised by many factors such as the design of the structure to be constructed, the characteristics of the individual loads to be lifted and site and environmental constraints. Ideally a procedure for the procurement of lifting appliances and equipment should be outlined detailing how it is to be done and who is authorised to do it. The Lifting Equipment Engineers Association or most lifting equipment hire centres can provide advice on the selection, suitability, inspection and testing of lifting equipment and gear. COMMUNICATION Effective communication between all members of the crane team as previously defined is vital if lifting operations are to be executed safely. This can be achieved in a number of ways as set out below: - Crane Team meetings - Briefing sessions - Signalling and radio systems - Identification of slinger/signallers (high visibility vests or safety helmets of a different colour to the rest of the workforce) Lifting operations in construction are commonly carried out using cranes and they should be covered in the Health and Safety Plan. When constructing the plan consideration would need to be given to the ways in which the cranes are intended to be used, i.e.. by the manufacturer and hirer, and any limitations that would affect safety in the conditions expected on site. Consequently, information would need to be provided by various parties so that factors influencing crane safety can be assessed at a sufficiently early stage. May 2008 152 71121: Safe Use of Cranes, and Signals LIFTING ON SITES Any plan should include information for everyone involved in the specification, installation or use of cranes to be made aware of the fundamental criteria and planning issues needed to ensure that lifting operations are initiated and proceed in a logical and safe manner. While contractors have a duty to operate cranes safely, these duties can be made extremely difficult by thoughtless design, which could put pressure on to use cranes at their operating limits and sometimes, for lack of other options, encourages their improper use. Therefore, designers should obtain, and make available information relating to the site. This is an important contribution to a safe system of work particularly with regard to planning the lifting operation and selection of the correct crane and associated equipment. Lifting accessories Lifting accessories are items that are used to connect the lifting equipment to the load that is to be lifted. Previously known as loose or lifting tackle. In general, if lifting equipment and accessories receive a thorough examination it is presumed to present a significant risk and it should therefore, also be inspected as necessary at intervals between thorough examinations. An inspection is not required if it will not help identify defects. May 2008 153 The mishandling of materials is the single largest cause of accidents and injuries in the workplace. Most of these accidents and injuries, as well as the pain and loss of salary and productivity that often result, can be readily avoided. Whenever possible, mechanical means should be used to move materials in order to avoid employee injuries such as muscle pulls, strains, and sprains. In addition, many loads are too heavy and/or bulky to be safely moved manually. Therefore, various types of equipment have been designed specifically to aid in the movement of materials. They include: cranes, derricks, hoists, MEWPS, and conveyors. Because cranes, derricks, and hoists rely upon slings to hold their suspended loads, slings are the most commonly used piece of materials-handling apparatus. This section will examine the proper use of slings. IMPORTANCE OF THE OPERATOR The operator must exercise intelligence, care, and common sense in the selection and use of slings. Slings must be selected in accordance with their intended use, based upon the size and type of load and the environmental conditions of the workplace. All slings must be visually inspected before use to ensure that there is no obvious damage. May 2008 154 UNIT IGC 2, ELEMENT 3: WORK EQUIPMENT - HAZARDS AND CONTROL BASIC MACHINERY SAFETY Requirements and Principles Introduction Because of the horrific accidents that occurred in industry as the Industrial Revolution developed public conscience was pricked and laws were passed requiring machines to be guarded. The legal requirements are contained in The Health and Safety at Work etc. Act 1974, Factories Act 1961 and associated Regulations. Certain standards of guarding have been established but the development of more advanced techniques and practices continues. to prevent work people from coming into contact with dangerous parts of machinery. to prevent physical injury from power driven and manually operated machines. to enable machines to be operated safely without interfering with production. Legal Requirements Although the following sections of the Factories Act 1961, have been replaced by the Provision and Use of Work Equipment Regulations 1998, they still act as good guidance as to the intent of the enforcers. s12 every prime mover and flywheel must be securely fenced. s13 every part of transmission machinery such as rotating shafts, flat or vee belts and pulleys, must be securely fenced. s14 every dangerous part of every machine must be securely fenced unless it can be stopped before anyone can reach that part - only dangerous parts need to be guarded not the whole machine. s15 lays down special conditions to be met if it is necessary to work on machinery which is not guarded. moving s 16 requires that guards should be: - of robust construction - constantly maintained - kept in position. s 17 superseded by s 6 of the Health and Safety at Work Act 1974 s 19 self acting machines that move into or across gangways must not approach nearer than 18" to any fixed structure, except for self acting spinning mules where the minimum allowed gap from other machines is 12". May 2008 155 s 20 prohibits the cleaning of moving machines by women and young people s 21 requires that young people working on certain dangerous machines must:- a) be sufficiently trained b) be under adequate supervision The Health and Safety at Work Act 1974 s 2 requires that the employer provides safe plant and systems of work s 6 requires that all new machines must be safe when put to work as they were intended, and when they are cleaned, set etc.. s 7 employees must use safety devices, guards etc., provided. s 8 employees must not damage guards or other safety devices. The guarding requirements for specific types or classes of machine are contained in various Regulations, e.g. The Electricity at Work Regulations 1989 Essential standards of guarding are laid down in: 3.3. MACHINERY HAZARDS MAIN MECHANICAL AND NON-MECHANICAL HAZARDS There is a very authoritative British Standard Code of Practice No BS 5304: 1988 "Safeguarding of Machinery", and additional information may be found in BS EN 292 Safety of Machinery Part 1 1991 Basic terminology and methodology, and Part 2 Technical principles and specifications. May 2008 156 Hazards from machinery Mechanical Hazards These include being: entangled round rotating shafts or wheels Source BS 5304 nipped or drawing-in between two revolving shafts, drums, rolls or gears Source BS 5304 Source BS 5304 trapped between two moving parts or one moving and one fixed part, and include; trap -shear injuries Source BS 5304 May 2008 157 trap -crush injuries Source BS 5304 struck by the impact of a moving part Source BS 5304 coming into contact with sharp or abrasive surfaces Source BS 5304 being hit by ejected items, swarf etc. Source BS 5304 punctured by sharp items, for example puncture wounds created by a needle on a sewing machine, or a heavy duty paper stapler. High pressure fluid ejection is associated with hydraulic systems, where the fluid is under great pressure. Bursting of a pipe, can force the fluid into tissue and the circulatory system. 158 May 2008 Definitions A dangerous part is any part of a machine which, by virtue of its cutting edge or its movement could cause injury to anyone approaching it. Various types are listed below: Rotating Parts drill spindles, shafts with projections or recesses lead screws, shafts with keys or key-ways stock bars, coupling flange bolt, plain shafts drive shafts, fan blades, screw or scroll conveyers shafts with grease nipples, cutting tools, routers In running nips milling cutters, draw rolls, abrasive wheels press rolls, circular and band saws meshing gears, guillotine blades chains and sprockets, flats and vee belts on pulleys rack and pinion gears Other spokes or rotating wheels rotary valve blades spin drier drums Sliding Parts lathe and milling machine slides injection moulding machine platens power hammer rams, power press tools guillotine blades Other Dangerous Parts scissor action of adjacent moving levers and linkages scissor action between moving levers and fixed parts of machine or structure belt clips and other attachments to conveyor belts Work Material Causing Hazards stock bars, steel plate in presses and rolls projections on revolving work pieces Other Sources of Danger on Machines radio-active sources, high frequency welding ultra-violet rays, electricity - both power and static chemicals in process or for cleaning explosives - in metal forming or cartridge tools noise and vibrations, temperatures - both high and low Typical machine hazards Pedestal driller; entanglement, electrocution. Circular saw; shearing, noise, dust, electrocution Guillotine; shearing, electrocution Paper shredders; dust (causing Occupational Asthma), noise, electrocution Abrasive wheels; contact, noise, electrocution Lathes; entanglement, noise dust, electrocution May 2008 159 Simple robots; impact, electrocution Mechanical & hydraulic presses; crush and/or shearing, noise Portable power tools; electrocution, noise, dust Risk assessment from machinery For machinery safety, risk assessment is a key principle for the identification and control of risks. BS EN292 suggests that a European Number will be issued on Machinery safety, making clear that any hazard on a machine could lead to an accident or ill-health. It is desirable that all machinery should be safe, but although absolute safety is not always possible, as technology improves, so does risk management. Therefore, safety measures must be continually reviewed. Factors to be considered Who is at risk? For what length of time are they at risk? Adjacent work, such as internal transport Environment, e.g. temperature, lighting etc. The second stage is to identify the hazards and their severity. After looking at the hazards the process of addressing risk is set in motion. The first question is can we design the risk out e.g. using stops to prevent crush injuries. If this is not possible we must look for other ways, and these results assessed to ensure they are adequate. There is a requirement that adequate safety is met in so far as the need for access, reliability of safeguards, and are personnel using operating procedures correctly. Under Regulation 11 of PUWER - Dangerous Parts of Machinery - measures are described in terms of a hierarchy to address hazards from mechanical operations. These are; Enclosed fixed guards Other guards or protection devices Protection appliances Provision of Information, Instruction, Training and Supervision. Selection of equipment This must be addressed from 3 angles, Initial integrity when supplied The place where it is used and the conditions the equipment has to work under The purpose of its use Also under the Supply of Machinery (Safety) Regulations, the supplier of machinery is required to ensure that equipment is safe, and that appropriate information is supplied. Choice of safeguarding methods There are certain criteria to be met in the selection of the appropriate safeguards set down in PUWER irrespective of the type of guard. These are; that all guards will be fit for the purpose for which it is provided they will be of sufficient strength, sound construction, and sound material they will be maintained in an efficient state, and efficient working order they will not increase risk to health or safety May 2008 160 they shall not be easily bypassed or disabled situated at a sufficient distance from the danger zone they will not obstruct the view of the working area they shall be constructed to allow operations necessary to fit or replace parts, and for maintenance work, restricting access to the area where work is to be carried out. Machine controls The general purpose of these controls is that the operator is not put at risk in the use of levers or buttons that are touched, pulled or pushed. Controls should be clearly identifiable and visible, and located where they do not expose the operator to risk. On larger machines and larger complexes, actions to minimise risk must be in place, and systems in place to safeguard maintainers of machines. Where physical controls are not possible, a system of work must be arrived at to prevent injury on start up. Appropriate warning signals on start up should be sounded, whereby staff can move away to a place of safety if required. Emergency controls should be in place where loss of power may create a hazard. It can be seen that the correct training, information and instruction is essential to ensure compliance, and to ensure procedural applications are adhered to, with the integration of the above with the correct safeguarding of machines. May 2008 161 3.4 PROTECTION FROM MACHINERY HAZARDS MACHINERY GUARDS Fixed Guards Rigidly and permanently attached to the machine and covering the dangerous parts. Held in place by bolts, sockets headed screws or other devices requiring a hand tool to undo them. A very simple fixed guard (Source BS 5304) Source BS 5304 NOTE The space between any fixed guard, or the gap in any mesh used in fixed guards, must comply with the maximum sizes illustrated in BS 5304/EN 292, as in the extract illustrated below Source BS 5304 May 2008 162 Interlocked Guard Device or means attached to a guard which, when the guard is moved from the safe position, stops the machine, it can be mechanical, electrical pneumatic or hydraulic, or a combination of these. The interlocked device must be such that it cannot be manipulated when the guard is open to allow the machine to start. If the machine takes a long time to stop, the interlock system should incorporate a time delay to prevent the guard from being opened before machine movement ceases. Source BS 5304 Trip Device A device across the access to a dangerous part which when actuated stops the machine. It can be mechanical, electrical, pneumatic, hydraulic or a combination of these and may take the form of : o trip bar o pressure sensitive mat o photo-electric equipment o infra red o ultra sonic o trip wire May 2008 163 An example of a pressure sensitive mat Source BS 5304 A photo-electric trip device Source BS 5304 A trip device for radial drilling machines Source BS 5304 May 2008 164 An alternative radial drilling machine guard, (adjustable) Source BS 5304 Distance Guards A guard or fence positioned far enough away from the dangerous parts such that they cannot be reached from outside the guard. If it is provided with gates they should be interlocked with the machine controls. Automatic Guards A device that automatically moves into position when machine movement is initiated. It should move into position in such a way that any person near any dangerous parts is pushed away. Source BS 5304 open position, (unsafe) May 2008 165 Source BS 5304 closed position, (safe) Sequence Guard A moveable guard where the action of closing it automatically starts the machines. Two Hand Control On single stock machines worked by a single operator only, protection may be provided by controls that require 2 separate buttons to be pressed simultaneously and held during the full time the machine movement is dangerous, i.e. when press platen are closing. -release of either button must cause the machine to retract or stop all movement. -the buttons must be positioned more than a hands span apart and be of the recessed type that cannot be wedged. -the control circuit must be such that both buttons must be released before a new operating cycle can be started. Tunnel Guard Fitted to feed and take-off tables to prevent operators reaching dangerous draw rolls, knives etc. Normally comprises top and two sides and should be at least long enough to prevent access to danger, (see BS 5304/EN 292 for details). A tunnel guard on the ‘take off’ side of a machine Source BS 5304 May 2008 166 PROVISION AND USE OF WORK EQUIPMENT REGULATIONS 1998 The Provision and Use of Work Equipment Regulations 1998 (PUWER) replace the Provision and Use of Work Equipment Regulations 1992 and became effective on 5/12/98. Many of the requirements are not new, they build on the requirements of PUWER 1992. The regulations are supported by an Approved Code of Practice and Guidance material. The primary objective of the regulations is to ensure that all work equipment is safe to use regardless of age, condition or origin. PUWER covers all work equipment, including new, existing and any that is leased, hired or second-hand. The regulations apply in most working environments and working relationships where HASAWA applies, including all industrial, offshore and service operations. PUWER applies to all activities involving work equipment, including: starting stopping regular use transport repair modification servicing cleaning. Work equipment includes any machinery, appliance, apparatus or tool, and any assembly of components which, in order to achieve a common end, are arranged and controlled so that they function as a whole, for use in non-domestic premises. Examples include dumper trucks, angle grinders, overhead projectors and scalpels. Items specified as falling outside this definition include substances, private cars and structural items. There is a degree of overlapping/linked requirements between the Management of Health and Safety at Work Regulations 1999, PUWER and LOLER concerning the need for risk assessment. The main legislation is divided into three sections as follows: general mobile work equipment power presses.. Duty Holders The requirements of the regulations apply to employers, the self-employed, in respect of equipment used by them for their work, those who have control of work equipment or the way in which it is used and anyone who supervises or manages the use of work equipment. The general duties require: * equipment to be suitable for its intended purpose and only to be used in conditions where it is suitable * equipment to be maintained in an efficient state, with maintenance records where appropriate * any equipment that depends on the installation conditions to be inspected before first use, and after any relocation, to ensure that it is safe to use, and that suitable records of such inspection are maintained 167 May 2008 * any work equipment that may be subject to deterioration to be subject to regular inspections at suitable intervals, and that records of such inspection are maintained * equipment that poses a particular risk to be only used, repaired and maintained by suitably trained personnel * all those who use, supervise or manage work equipment to have suitable information and instruction for the purposes of health and safety, including written instructions where appropriate * all those who use, supervise or manage work equipment to have received appropriate training for the purposes of health and safety * access to any dangerous parts of machinery to be prevented or controlled by an appropriate method * exposure to risks to health and safety of users to be prevented wherever reasonably practicable, and otherwise adequately controlled * injury to be prevented from any work equipment or components, or any substance in use, having a very high or low temperature * suitable controls to be provided for starting and controlling work equipment * suitable stopping devices to be fitted to work equipment to bring the equipment to a safe condition in a safe manner, as appropriate * suitable emergency stopping devices to be fitted to work equipment (regulation 16) * controls for work equipment to be clearly visible and easily identified * control systems for work equipment to be safe, and realistic in relation to the work being carried out * work equipment to be able to be isolated from all its sources of energy, where appropriate * work equipment to be stabilised where necessary * suitable and sufficient lighting to be provided for the use of work equipment * work equipment to be constructed or adapted such that maintenance work can be carried out without risks to health and safety * work equipment is clearly marked where necessary with any marking appropriate for reasons of health and safety * work equipment incorporates warnings or warning devices as appropriate The new, specific regulations governing the use of mobile work equipment (regulations 2530) stipulate that: suitable roll-over protection should be provided where there is any risk of overturning, except for situations where this would increase the risks to safety, or where, on equipment first provided for use before 5 December 1998, it is not reasonably practicable; it also does not apply to certain types of fork lift truck fork lift trucks should be adapted or equipped to reduce the risk of overturning far as is reasonably practicable so self-propelled equipment, and remote controlled self-propelled equipment, is fitted with appropriate safety features any risk of seizure of a drive shaft between work equipment and its accessories or any towed item is adequately controlled, where it might involve a risk to safety. The specific regulations governing the use of power presses stipulate the requirements for: * May 2008 the thorough examination and testing of power presses, guards and protection devices before first use in a new location, and every 12 months where there are 168 fixed guards only, and every six months in other cases, with all defects being remedied before further use * further inspection and testing during regular use * records of examinations to be kept and maintained Summary Work equipment is found in every workplace and is anything that a person at work has to use in order to do their job, e.g. machinery, tools, ladders, etc. Work equipment must be suitable for the intended work tasks and the people using it. Measures must be taken to prevent contact with the dangerous parts of work equipment. All work equipment should be well maintained and a log of all maintenance records retained. Where specific risks are associated with the equipment, it may only be used and maintained by designated people who have received adequate training. Adequate and comprehensible health and safety information, instruction and training must be provided to people using or maintaining the work equipment and to people supervising or managing such work. All work equipment must comply with any relevant EU requirements. The presence of "CE marking" should demonstrate adequate compliance in most cases. Hierarchy of machine guards and other safety devices for preventing access to dangerous parts of machinery: fixed guards any other guards other safety devices e.g. jigs, holders, push-sticks information, training and supervision. Each measure should be applied to the extent that is practicable. All guards, etc must be: suitable for their intended purpose of good construction, sound material and adequate strength be well maintained (the guard construction should enable easy replacement, repair and maintenance - preferably without having to dismantle the guard) situated a sufficient distance from the danger zone, i.e. the zone around the machinery in which there is a danger of someone coming into contact with the dangerous part in efficient working order in good repair. In addition guards must not increase any risks to health and safety, restrict the operator’s field of vision, or be easily disabled or bypassed. May 2008 169 UNIT IGC 2: ELEMENT 4: ELECTRICAL HAZARDS AND CONTROL Introduction Electricity if used correctly is a safe, efficient and reliable form of energy for lighting, heating and power. If it is misused it can be dangerous, and in a number of cases cause fatal accidents. The instances of injury or death are relatively infrequent compared with the causes of other accidents. This is because the installation and use of electrical plant and apparatus in this country is controlled by high regulatory standards. It is used in most factories, offices and homes, and without it, it is very difficult to perceive how modern society would function. If electricity is not properly used and equipment attached to it incorrectly installed, operated or maintained, then the electric current can cause injury directly, electric shock, or indirectly due to it’s, heating and burning effect. The purpose of this section is to explain the fundamentals of electricity supply and distribution and what steps can be taken to resolve the number of electrical accidents that occur in both the workplace and the home. Statutory Requirements The main statutory requirements are: 1 The Health and Safety at Work Act 1974 Section 2 of the Act places a general duty on every employer as regards, the provision and maintenance of plant and systems of work that are, so far as is reasonably practicable, safe and without risks to health. Additionally, section 2 requires the provision of such information, instruction, training and supervision, as is necessary to ensure, so far as is reasonably practicable, the health and safety at work of his employees. These general duties are just as applicable to electricity at work as to any other area of work. However, by the very nature of HASAWA, these duties are only general and are in any case qualified by the phrase, so far as is reasonably practicable. In consequence, with regard to determining what might be acceptable under HASAWA, in respect of work activities related to electrical matters, reference has often been made to the more specific, now revoked, Electricity (Factories Act) Special Regulations 1908 and 1944, as an appropriate standard to work to. May 2008 170 2 The Electricity at Work Regulations 1989 Following is a summary of the above regulations: All systems should be of such construction so as to prevent, so far as is reasonably practicable, danger, (both systems and danger are defined fully in the regulations, however danger effectively means risk of injury). Every work activity, including the operation, use and maintenance of a system, should be carried out in such a manner as to not give rise, so far as is reasonably practicable, to danger. Any protective equipment provided for the purpose of these Regulations should be appropriate, and be maintained in a condition suitable for that use. Additionally, it must be properly used. No electrical equipment should be put into use where its strength and capability may be exceeded in such a way as may give rise to danger. Electrical equipment may reasonably be forseeably exposed to: Mechanical damage The effect of the weather, natural hazards, temperature or pressure The effects of wet, dirty, dusty or corrosive conditions Any flammable or explosive substance, including dusts, vapours and gasses should be of such construction so as to prevent danger arising from such exposure. All conductors in a system which may give rise to danger should be suitably covered with insulating material in order to prevent danger. Precautions should be taken, either by earthing or another suitable means, to prevent danger arising when conductors are likely to become charged. A conductor should be regarded as earthed where it is connected to the general mass of earth by conductors of sufficient strength and current carrying capability to discharge the electrical energy to earth. If a circuit conductor is connected to earth or to a similar reference point, nothing which might reasonably be expected to give rise to danger by breaking the electrical continuity or introducing high impedance should be placed in that conductor unless suitable precautions are taken. Where necessary to prevent danger, every joint and connection in a system, must be mechanically and electrically suitable for use. Where necessary to prevent danger, suitable means (including where appropriate, methods of identifying circuits), should be available for: Cutting off the supply of electrical energy to any equipment The isolation of any electrical equipment May 2008 171 However, this does not apply to electrical equipment which is itself a source of electrical energy. Nevertheless, precautions should be taken to prevent, so far as is reasonably practicable, danger. No one should be engaged in any work on or so near live conductors, (other than one suitably covered with insulating material), that danger may arise unless: It is unreasonable in all the circumstances for it to be dead It is reasonable in all the circumstances for them to be at work on or near it while it is live Suitable precautions, (including where necessary the provision of suitable protective equipment), are taken to prevent injury No one should be engaged in any work where technical knowledge or experience is necessary to prevent danger or, as the case may be, injury unless they posses such suitable knowledge or experience, or are under proper supervision. Electricity Supply Electricity is produced in the stator windings of generators at 25,000 volts, (25kv), and then stepped up to 275kv or 400kv for transmission. Each generator in a power station has its own transformer, circuit breaker and associated isolators, but the electricity generated is fed onto common bars. The original grid established in the 1930's was designed to work at 132 kV. It was strengthened in 1953 by the 275 system and in 1960 the then Central Electricity Generating Board, CEGB, adopted a 400kv system. One 400 line has 3 times the carrying capacity of a 375 line and 18 times the carrying capacity of a 132 line. A 180 mega watt, Direct Current, DC, cross channel link enables some pooling of spare capacity between England and France. The 132kv system is now owned by the recently privatised Electricity distribution Companies, who use it as a distributor of power much the same as the 11,33 and 66kv circuits. The 132kv system feeds primary sub-stations which in turn feed supplies out at 66 and 33kv. Secondary supplies are fed from these substations at 11kv, with customers fed from these 11kv distribution substations at 415v 3 phase or 240v single phase. Electrical Theory To understand how electricity is utilised it is important that the various terms used are explained. For this purpose, it is traditional to compare electrical circuits to piped water circuits, as there are many similarities between them. Before water can flow in a pipe, it is necessary to have a difference in pressure between one end and the other. Similarly, in an electrical circuit there must be a pressure difference, (or May 2008 172 potential difference), to cause electrical current to flow. The unit of measurement of electrical pressure is the VOLT. For example, the standard pressure difference between the two main terminals in a normal domestic supply is 240 volts. In a water pipe system, the water flow can be increased by making the pipe diameter larger, similarly, in an electrical circuit the electric current flow can be increased, (with certain conditions), by using thicker conductors. The unit of measurement of electrical current flow is the AMPERE. The flow of water in a pipe has to overcome resistance in the form of rough surfaces, obstructions and bends. A similar condition occurs in electrical circuits, where the current flow meets resistance in virtually every conductor. In some cases of course the conductor material is deliberately chosen for its relatively high resistance so that heat will be produced by the passage of electrical current. The unit of measurement of electrical resistance, (or impedance), is the OHM. The expression DIRECT CURRENT, (dc.), refers to electrical systems where current flows in one direction only, between positive and negative terminals, (such as in a battery for instance). Virtually all modern electricity supply mains are ALTERNATING CURRENT, (ac.) systems. This means that the electric current is constantly reversing its direction of flow at a given frequency. The frequency is measured in cycles per second and is expressed as HERTZ. For example, the standard frequency in the UK is 50 cycles per second, that is 50 Hz.. The formula below shows how the previously mentioned terms are all inter-related, this relationship is known as OHMS LAW. V=IxR So if you have any two values, the third can be calculated thus: I=V R or R=V I As the volts force the amps through the Ohms in the circuit, energy is being used in one form or another and the voltage drops in value until at the neutral end of the transformer at the substation is at zero. The power in an electrical circuit is expressed in WATTS, that is, the product of the voltage and current. For example, if the current taken by an electric heater is 5 amperes when plugged into a 240 volt supply, then its power load will be 240 x 5 = 1200 watts. These questions can be used to calculate the current which flows in any circuit given the resistance or power connected to a known voltage. These equations are used to determine fuse ratings for particular loads and the current flowing through a person who may inadvertently touch a line supply. The Effects of Electric Shock on the Body Electricity can cause injury to people in two ways, by electric shock or burns. The effects of electric current passing through any part of the body can range from a tingling sensation to a severe jolt to a complete muscular contraction, respiratory failure and death. May 2008 173 Most electric shocks result from persons touching a live conductor with one part of the body and touching earth with another part of the body. For example, a person touching a live terminal in a fuse box whilst standing on a wet floor will receive a shock. This is due to the fact that most electrical supply systems are deliberately connected to earth at some point and by touching one live terminal the main automatically completes the circuit through their body and feet back to the supply system, through the earth. It is possible of course to get a shock by touching two terminals in an electric circuit. To understand how electricity can cause injury it is necessary to explain that in order to function, the body needs a certain amount of electricity. The muscles are controlled by a small current, in the order of four micro amps, acting on the central nervous system. In order to grasp, a signal is sent down to the nervous system, which causes an increase of current in the muscles. An increase to about 4 milli amps causes the muscles to contract. The firmness of the grasp of the hand, for instance, will depend upon the strength of the contraction of the muscles which is in turn dependant upon the amount of current caused to flow through them. When releasing the grasp the current is first switched off. The hand at this time still in the grasping position but is now relaxed. A similar signal is then sent down the nervous system to cause a current increase in the release muscles. The release current then causes these muscles to contract and thus open out the hand. It is important to appreciate that the release muscles are not as strong as the grasping muscles. Thus, when a hand to hand electric shock is received, the muscles in the arms react to this electric current similarly to the way in which they react to the current generated in the body. If this current is in excess of about 10 milli amps then the contracting muscles overcome the release muscles and thus involuntary grasping takes place which will continue whilst the electric current is flowing. Because this current swamps the effect of the ordinary control current the hand will, if hold of the live source, be able to let go. The value of current which causes this effect is termed the let go value. The following table shows the relative magnitude and effects of electric currents on the human body. The table shows a range of values for alternating current in milli amps at 50 Hertz with the corresponding sensation. The actual values varies from person to person, from men to women, and from adult to child. For example the average perception level for men is approximately 1 milli amp, but for women a lower value of 0.7. milli amp. This is the value of current flowing when a tingling sensation can first be felt. The average let-go value for men is in the order of 10 milli amps whilst the average let-go value for women is slightly lower in the order of 8 milli amps. May 2008 CURRENT ( in mA at 50Hz) SENSATION 2 2-5 < 10 10 - 15 * 20 - 40 * 50 - 200* Max. safe current Threshold of feeling Safe 'Let go’ current Muscular contraction Arrests respiration Ventricular fibrillation 174 Death could be caused by any of the above current values denoted by *. Ventricular fibrillation is nearly always fatal and occurs when an electric current passing through the chest affects the heart. The heart muscles are thrown out of synchronisation, regular pumping motion stops and the heart flutters for a short while and does not pump blood. The blood circulation ceases and the body tissues will be denied the oxygen supply which is supplied by the blood stream. In such a case artificial respiration will do no good since all that is happening is that the air is being inhaled and exhaled the lungs without the oxygen being extracted and circulated. Factors determining the seriousness of an electric shock There are four basic factors which determine the seriousness of electric shock: 1. Body electrical resistance; 2. Amount and nature of current passing through the body; 3. The parts of the body through which the current passes; 4. Length of time current flows through the body. Body electrical resistance The human body can be considered as two parallel resistance paths. Externally the outer skin is a relatively high resistance, whilst internally the blood stream and body tissues offer a relatively low resistance. The average dry skin has a resistance of between 1,500 - 2,000 Ohms hand to foot, this resistance will drop considerably when the hands are wet. Thus once a person is holding and electrical source, the situation can only become worse. The person will immediately feel fear and will perspire. The perspiration reduces the skin resistance and thus the current increases which in turn leads to a firmer grasp of the source of electricity. Heating caused by the passage of electricity is proportional to the square of the current, so an increase in the current will cause an increase of the heating at the skin and the skin will burn. The skin will then be destroyed at the point of contact, leading to a further reduction in the resistance and a further increase of current. Amount and nature of current passing through the body The current passing through the body can be either direct current, or alternating current, the effect is proportional on both the magnitude and the frequency. The maximum current to which a person may safety be subjected is usually considered to be just below the threshold for ventricular fibrillation. The part of the body through which the current passes In order for an electric shock to occur, the body must form part of an electrical circuit. Thus there must be a point of entry and a point of departure for the electrical current. Current paths through the heart are the most dangerous paths, and the most likely to cause electrocution. Examples of such pathways would be shock from arm to arm, from chest to arm, arm to chest, head to leg and arm to leg. May 2008 175 Length of time current flows through the body Very low levels of electric current below the perception level can be sustained almost indefinitely. However a maximum current of for example 100 milli amps can only be endured for about one second. In between these two extremes the let-go value could cause death by asphyxiation if sustained for more than a few minutes. Secondary effects of electric shock Electric shock may also initiate secondary causes of injury. The involuntary muscular reaction may throw the arm back so violently that the muscles become overstrained or ligaments become torn. More often, however, the shock startles the victim and causes momentary loss of control and balance resulting in falls. If working from a ladder the fall can result in more serious injuries than the electric shock. It is not possible to make definite statements to cover all situations, voltages, currents and people. There are many variables which will affect the seriousness of an electric shock to a particular person. For example the electrical resistance of the skin, which would be low in the case of a child with a soft moist hand, and high in the case of an adult manual worker with hard dry hands. The actual path of the current through the body is relevant, so is the general state of health of the person. The major source of burns in an electrical accident is the intense heat produced by arcing. Electric arcs are very often produced deliberately for certain processes, such as welding metal. This is quite safe and acceptable provided that the proper protective equipment is used. There are many cases however where arcing of similar or greater intensity occurs due to accidental short circuits, faulty apparatus or improper operation of switch gear. A person exposed to such heat can be severely burned, and in fact most of the electrical accidents in the Electricity Supply Industry involve burns rather the electric shock. Static electricity In practical terms, it can be said that static electricity produced by movement between and two substances. For example, people walking about a room are constantly charging themselves up electrostatically through shoe contact with the carpet. Normally this charge is simultaneously leaking to earth through the shoes and the carpet because the electrical resistances of the shoes and carpet are low enough to prevent a substantial voltage being built up. Other examples of electrostatic charges are: In road vehicles Aircraft Bulk carriage of liquids and substances Industrial processes, e.g. belt conveyors, paper making rollers Exposure to very high voltage electric fields Although electrostatic charges can produce quite high voltages (thousands of volts in some cases) the direct effect on people is no more than unpleasant. Portable tools and equipment The national accident statistics show that a substantial number of electrical accidents are associated with portable electric tools and equipment such as: drills, saws, grinders and heaters, blankets radios, record players, in fact the majority of domestic appliances. May 2008 176 Portable apparatus, by definition, is subjected to much more wear and tear than a fixed installation, and the greatest danger is that a failure of some part of the apparatus, or an incorrect connection, may result in the user receiving an electric shock by making contact between a live conductor and earth. Particular care should be taken with flexible leads: They should be protected from damage by heavy or sharp objects. The outer covering of a flexible lead should be firmly clamped at its end terminations, to relieve strain on the inner conductors. Apparatus should never be pulled by, or suspended from its lead. The inner conductors of a flexible lead should always be properly connected into the appliance or into a plug or approved type of connector. It is dangerous to have loose ends of a lead temporarily wedged into contacts. Any exposed metalwork on a portable appliance should normally be firmly connected to earth. The reason for this is to cater for the possibility that the metalwork may accidentally come into contact with a live conductor. A 3 core flexible lead is therefore essential with this type of apparatus - the third core being the earth conductor. However, if the apparatus is of the DOUBLE INSULATED or ALL INSULATED type, this means that extra protective layers of electrical insulation have been incorporated into the design and no earthing terminal is provided on the appliance. A 2 core flexible lead (without earth conductor) is required in this case. Incidentally, if DOUBLE INSULATED or ALL INSULATED appliances are used in activities covered by the Factories Act then the appliances must be kite marked as complying with British Standard BS 2769. Double Insulation Symbol = Insulation Double Insulation Another accepted safe practice is to use reduced voltage portable appliances, that is, 110/55 volts or, in the case of hand lamps 25 or 12 volts. The reduced voltage will of course reduce the severity of an electric shock. With any system employing an earth connection, it is essential that the earth conductor is kept intact, and devices are available which will continuously monitor the earth conductor, and automatically disconnect the supply in the event of a fault. May 2008 177 110v Transformer _ 55v earth 55v + + 100 50 Insulator Residual current device + ? Portable hand held tools should be regularly inspected and tested by a competent person, and test sets are available to simplify this procedure. Guidance Note PM32 issued by the Health and Safety Executive gives advice on the installation use and maintenance of portable and mobile electrical apparatus. Overhead lines Overhead lines are used extensively for electric power transmission for several reasons, both practical and financial. For example, it is not technically possible to provide long underground cable systems operating at say 400,000 volts because of practical design problems. The cost of underground cable systems in any event is considerably higher than for overhead systems. The majority of overhead line systems consist of bare wires suspended from insulators and supported above ground by steel towers or wooden poles or concrete columns. Some of the lower voltage wires are covered with rubber or PVC sheaths, but reliance on the integrity of May 2008 178 the insulation is not recommended because it is constantly exposed to varying weather throughout its life. The dangers of accidental contact with overhead lines are therefore fairly obvious. The fatal accidents which occur usually involve a person who is in contact with earth, also making contact with one of the overhead wires, for example: A builder with a metal scaffold pole A child with a control line model aircraft or a kite Construction workers using jib cranes Farmers with agricultural machinery or metal irrigation pipes Timber fellers with steel winch ropes Metal masts on sailing boats, metal poles on tents Overhead lines are also prone to accidental contact by airborne devices such as aircraft, gliders, balloons and parachutists, but generally the damage or injury which results is of mechanical rather than electrical origin. This is because there is usually no direct contact between the person and earth. In fact, the majority of fatal overhead line accidents occur on construction sites, and the Health and Safety Executive have issued a Guidance Note (GS6) - Avoidance of Danger from Overhead Electric Lines, to assist people involved in construction and building operations. The Guidance Note goes into some detail about the erection of safety barriers and clearance distances, one of the most important recommendations is: Consult the local Electricity Board before commencing operations. One important aspect of overhead lines is: Don't be misled into thinking that a single wooden pole with wires on it is a Post Office telephone line. Many overhead lines of this type are in fact electric overhead lines operating at 11,000 volts. Underground cable The obvious difference between overhead lines and underground cables is that you can't see the underground cables until you have excavated the ground which covers them. The excavation process therefore requires care, whether hand tools or power tools are used as it is relatively easy to pierce a cable. Cables are normally laid at depths of 1'6" to 3'6" but it is not safe to rely on these figures as many cables have been in the ground for 50 years or more and ground levels are constantly being altered as land is developed. In many cases protective slabs of concrete or tiles were originally placed over cables but it is quite common for them to be removed or misplaced in the course of excavations by other authorities. Electronic equipment is available for locating underground cables and other metallic objects, but cannot be relied upon entirely. All Electricity Boards are obliged by law to keep records of underground cables, and they should be approached for this information before any work is started. They will in most cases visit the site and mark the cable positions from their plans. It is advisable to excavate carefully with hand tools when it is known that underground cables are nearby. Most injuries from underground cable are burns rather than electric shock, as the result of piercing a cable can be intense electric arc or explosion, or both. The Health & Safety Executive have also issued a Guidance Note, GS 33, Avoiding danger from buried electricity cables giving details to anyone who had responsibilities under May 2008 179 Regulation 44 of the Construction (General Provisions) Regulation 1961 and the Health and Safety at Work Act now revoked by the Electricity at Work Regulations 1989. To summarise , in order to minimise the risk posed by underground electrical cables, we must: 1. Plan 2. Locate 3. Dig May 2008 180 Unit 15 Fire Hazards and Control Fire is a chemical reaction known as combustion which occurs when fuel and oxygen are brought together with sufficient heat to cause ignition Approximately 16% oxygen is required to support combustion Normal air contains 21% Oxygen more than enough and it is readily available Some fuels contain sufficient oxygen within their makeup to promote combustion. May 2008 To reach ignition temperature: 1. 2. 3. 4. 5. 6. 7. Open flame Hot surfaces Sparks and arcs Friction Chemical reaction Electrical energy Compression of gases 181 COOKING OILS AND FATS WOOD PETROL ACETYLENE MAGNESIUM PAPER PLASTIC POLYSTYRENE PAINT GLUES SOLVENTS BUTANE PROPANE METHANE ALUMINIUM TITANIUM LITHIUM COOKING OILS FATS * Become liquids in fire. ** If foam is used, it must be alcohol resistant. BASIC PRINICPLES Introduction In order to understand how fire extinguishers work, you first need to know a little about combustion. The Fire Triangle The concept of fire is represented by the Triangle of Combustion and is composed of fuel, heat, and oxygen. Removal of any one of these essential elements will result in the fire being extinguished. The elements are oxygen to sustain combustion, sufficient heat to raise the material to its flash point temperature, fuel in the form of combustible material and subsequently an exothermic chemical chain reaction in the material. Theoretically, fire extinguishers put out fire by taking away one or more elements of the fire triangle. The triangle although simplistic, is a good analogy, how to theoretically extinguish a fire, by creating a barrier using foam for instance and prevent oxygen getting to the fire. By applying water you can lower the temperature below the ignition temperature or in a flammable liquid fire by removing or diverting the fuel. Finally interfering with the chemical chain reaction by mopping up the free radicals in the chemical reaction using, BCF and other halon extinguishers, it also creates an inert gas barrier. However this type of extinguisher is being phased out and in the future other extinguishing agents may be found using this principle. May 2008 182 A Definition of Fire One generally accepted definition of combustion or fire, is a process involving rapid oxidation at elevated temperatures accompanied by the evolution of heated gaseous products of combustion, and the emission of visible and invisible radiation. Oxidation occurs all around us in the form of rust on metal surfaces, and in our bodies by metabolising the food we eat. However, the key word that sets combustion apart from other forms of oxidation is the word "rapid". The combustion process is usually associated with the oxidation of a fuel in the presence of oxygen with the emission of heat and light. If the fire is in a fire grate/ or furnace we refer to this process as a controlled fire, and it is a building on fire we refer to this process as a uncontrolled fire. Classes of fuel Fuels involved in fires have been broken down into five categories: Class A fires - are fires involving organic solids like paper, wood, rags Class B fires - are fires involving flammable Liquids. Class C fires - are fires involving flammable Gases Class D fires - are fires involving Metals . Class F fires - are fires involving Cooking oils. Summary A fire begins by an external ignition source in the form of a flame, spark, or hot surface. This external ignition source heats the fuel in the presence of oxygen. As the fuel and oxygen are heated, molecular activity increases. If sufficiently heated, a self-sustaining chemical chain reaction or molecular activity occurs between the fuel and oxygen. This will continue the heating process and the resulting chain reaction will escalate without the need for an external ignition source (fire point). Once ignition has occurred, it will continue until 1. all the available fuel or oxidant has been consumed or 2. the fuel and/or oxygen is removed or 3. by reducing the temperature by cooling, or Methods of Heat Transmission and Fire Spread Conduction This involves the passage of heat energy through a substance, usually a solid. Metals are some of the best conductors of heat, whereas materials like glass, plastic, wood, and rubber are good heat insulators. Normally fire spreads by conduction through a steel door or along a steel beam or a metal pipe. Conduction can transfer heat around a structure and start fires in unexpected areas, for example operators doing welding work on one side of a wall may start a fire on the other side where a pipe leads through the wall. Similarly, welding on the outside of a metal tank can result in ignition of any flammable vapour contained in the tank without the need for flame contact with the vapour. Convection The molecules in liquids and gases are constantly moving, if a liquid or gas is heated this movement will increase and the substance being heated will expand. This expansion results in hotter gases or vapours rising and cooler vapours and gases falling, this sets up a circulation, known as convection. In a fire this leads to very hot air and gases spreading May 2008 183 upwards along ceilings, up lift shafts and stair wells. Convection can spread fire within a building very quickly, this was seen in its most drastic form in the Bradford fire. Convection does, however, produce a cooling effect on the surface of the material involved in the fire. Convection also has the effect of drawing air into the base of the fire. Radiation This is heat transmission by invisible rays from a hot object, this radiation travels in straight lines, and is stopped by solid objects. Some materials will absorb this heat radiation, others will reflect it. The heating effect diminishes with distance. Commonly this will cause fires where clothes are close to a heater, heat radiation can spread fire across a road to other buildings. Direct Burning The last of these is normally considered a method in its own right but is, in fact, a combination of the other methods. Direct Burning is where the flames come into contact with the next fibre of the wall covering, pallet etc and so the fire will spread both horizontally and vertically. It concerns the direct spread of the fire through or across the material. Direct burning can be thought of as continuous ignition. As areas of material adjacent to the flame are heated, they release flammable vapours which in turn ignite, spreading the flame. The speed of advance will depend on factors such as wind and air movement; nature of the material. Fire Behaviour Fire in a building will normally spread upwards quickly, more slowly horizontally and very slowly in a downward direction. Any vertical shaft in a building, such as a stairwell or lift shaft, is an ideal route for fire spread and this is why they need to be well protected and isolated from the rest of the building. A fire in a room with all windows and doors closed will take a long time to spread, and will often die down or may even extinguish due to having consumed all the oxygen. When entering such a room fire fighters have to be careful of flashover due to the inrush of fresh air. When a fire occurs in a large open-plan area and heat cannot escape, convection currents will mean that the heat will build up and then descend from ceiling level. One way of preventing this is to in the roof vents with fusible links that open automatically allowing the heat and smoke to escape. Explosions Generally, an explosion is defined as a very rapid release of high-pressure gas into the environment. The energy from this very rapid release of the high-pressure gas is dissipated in the form of a shock wave. The process of a chemical reaction explosion is similar to that of a fire, however, in an explosion the oxidation process proceeds at a greatly accelerated rate. Fire prevention, at its most basic, is based upon the principle of keeping fuel sources and ignition sources separate. May 2008 184 Fire risk assessment When considering fire risk assessment it is useful to understand the definition of fire risk. Fire Risk has two components balanced against each other, one is the possibility of a fire occurring and the other the magnitude of consequences of that fire. For example a metal fabrication workshop has a high possibility of a fire due to the cutting and welding equipment. But providing the house keeping is good and no combustible substances are present, then a fire is not likely to spread, so the consequence is low, therefore the risk can be considered to be normal or even low. In the case of a cellulose paint spray booth an occurrence is highly likely because of the products used and the equipment required for the process. The consequences are also very high because any fire would have a rapid development, consequently it would have to be considered a very high risk. These risks can be reduced to acceptable levels by various methods including good housekeeping, specially designed electric apparatus, equipment located away from the risk and have compressed gasses used in the processes, piped to the risk from a bulk storage or centrally located position. To assist in these decisions a simple matrix below can be used to estimate the level of fire risk. Objective of a Fire Risk Assessment. The person in control of any workplace (responsible person – RP) should undertake a fire risk assessment, and this will have the following objectives : Identify hazards and people at risk. Remove or reduce the hazards. Manage the remaining risks to an acceptable levels by :o Reducing the probability of a fire starting. o Ensuring that all occupants are alerted and can leave the premises safely its the event of a fire. o Limiting the effects should a fire occur. Providing the premises have been built and maintained in accordance with local building regulations and is of normal risk or lower, this should be a simple matter without significant expenditure. If however, if the premises are not in accordance with the building regulations, further guidance and action will be necessary, depending on the complexity, size, occupancy and consequential risks. The RP can enlist the help of other persons who have the necessary experience or skills to assist him and is known as a competent person. The competent person does not have to be an expert to assist the RP, but he/she needs to have sufficient experience or training with regard to the problems they are assisting with. However a risk assessment on a small premises like the news agent shown in the following example, may be undertaken by the R P following the simple guidance in this document. A single lined scaled drawing of the premises is highly desirable and drawn to a scale of 1:50 or 1:100 would be considered ideal. Super impose, using a coloured pencil, any fire safety features and take notes of any relevant information useful to the risk assessment. Note. The Responsible Person always remains responsible for the outcome This is worth remembering, should you require help with your risk assessment. May 2008 185 The Five steps of Fire Risk Assessment. This part is about fire risk assessment and leads you step by step through the assessment process. Step 1 - Identifying fire hazards A knowledge of the fire triangle and the most common causes of fire will assist you in identifying potential fire situations. For a fire to occur it needs a source of ignition, (heat or flame) and a potential fuel hazard. If these hazards can be kept apart, removed, eliminated or reduced, then the risks to people and business is minimised. In order to do this they must first identify possible sources of ignition and fire hazards in your workplace. Identify any sources of ignition, (heat or flame). All workplaces will contain heat/ignition sources, some will be obvious such as cooking equipment or open flames (heating or process). Others maybe less obvious such as heat from chemical processes or electrical equipment. Possible sources of ignition are: Defective electrical fittings and defective or misuse of electrical apparatus - light bulbs and fluorescent tubes too close to combustible materials, misuse or defective electrical extension leads and adapters, faulty or damaged wiring. Matches, Lighters, Candles and Smoking materials. Flame or sparks from a work process such as welding, cutting, grinding or the use of a hot air gun. Sources of frictional heat. Electrostatic discharges. Ovens, kilns, open hearths, furnaces or incinerators. Boilers, engines and other oil burning equipment. Portable heaters. Cooking equipment, including deep fat fryers. The threat of arson must not be overlooked and the malicious firing of combustible materials. The above list is by no means exhaustive and is provided merely as a guide. Potential fuel hazards :o o o o Any combustibles - These can be divided into two main groups; combustible fuels such as paper, wood, cardboard, etc.; and highly combustible fuels such as thinners, solvents, polyurethane foam, etc. Any unsafe procedures or acts - Persons undertaking unsafe acts such as smoking next to combustible materials. Any unsafe conditions - These are hazards that may assist a fire to spread in your workplace, e.g. if there are large areas of hardboard or polystyrene tiles etc., or open stairs that can cause a fire to spread quickly, trapping people and involving the whole building. One hazard that is often overlooked is bad housekeeping and is the easiest to correct. It is responsible for many small fires either starting or certainly spreading and involving far more of the premises than was necessary. An ideal method of identifying and recording these hazards, is by means of the scaled single line plan. Checklists maybe also be useful. May 2008 186 Step 2 - Decide who could be harmed. Identify any staff or persons who are especially at risk Consider the risk to any persons who may be present. In many instances and particularly for most small workplaces there may be nobody particularly at risk, and specific measures for persons in this category will not be required. There will, however, be some occasions when certain people may be especially at risk from the fire, because of their specific role, location or the workplace activity. You need to consider matters carefully if : Sleeping accommodation is provided, Persons are challenged e.g. physically, visual, mentally, etc., People unable to react quickly. Initially a simple single line drawing of the premises to scale, could be drawn, showing any relevant structural features and the use of particular areas e.g. production, storage, office accommodation, storage and plant, etc. A copy of the plan will be useful should you have a fire at your premises, to give to the fire service when they arrive to assist them in fire fighting operations. The plan can then be used to indicate hazards, and persons especially at risk. It will assist you to identify where combustibles and ignition sources come together, or are in close proximity, and the action to be taken. In very small premises a simple naught and crosses system can be used; red circles for combustibles and blue crosses for heat/ignition sources. Step 3 - Evaluate the risks and decide whether existing precautions are adequate or more needs to be done. Having identified the hazards, you need to reduce the chance of a fire, both occurring and spreading, thereby minimizing or removing the chance of harm to persons in the workplace. The risk should be reduced to an acceptable level by : Removing the hazard altogether, Reducing the hazard to the point where there is little or no risk, Replacing the existing hazard with a safer alternative, Segregating the hazard from the workplace, Developing a Fire Safety Policy and culture to ensure hazards do not occur in the workplace. Attempt to classify each area as either high, normal, or low risk. Low risk - areas are those where there is little in the way of heat/flame or fire ignition sources, e.g. a stonemasons workshop where typically there is not much to burn and should a fire occur then people would be able to react in plenty of time. Normal risk - areas will account for nearly all parts of most premises. High risk - areas are where the available time needed to evacuate the area is reduced by the speed of development of a fire, e.g. paint spraying with highly flammable paints, also where reaction time to the fire alarm is slower because of the type of person present or the activity in the premises, e.g. the infirm and elderly or persons sleeping on the premises. If the building has been built and maintained in accordance with building regulations, it is likely that the means of escape provisions will either be adequate, or you will be able to decide easily what is required in relation to the risk. May 2008 187 Matters you will have to consider are : Means of escape & emergency lighting. Are they adequate in size, number, location, well lit, unobstructed, safe to use, etc. Fire fighting equipment - Wall mounted by exits, suitable for the types for hazards present and sufficient in number, should conform to BS EN 3. Means for detecting & giving warning in case of fire, Can they be heard by all occupants? Signs for exits and fire routines. Fire Procedure and Training of employees - What to do in the event of a fire. Measures to mitigate the effects of a fire. Where persons are at risk or an unacceptable hazard still exists, additional compensatory measures will be required from the above list, or repeat all previous stages. It is important that all fire safety provisions are maintained in good order. Arrangements for warning all occupants in the event of a fire must be adequate and fail-safe. Fire alarm systems, smoke detectors, hand bells, or a single shout may be suitable depending on the size and complexity of the workplace. A fire starting in any location should not go undetected and reach a size that could cause persons to become trapped. This is more likely to happen where there is only one way out of an area. Escape, without the use of key, should be possible from all parts of premises to a place of safety or fresh air without travelling in access of recommenced travel distances. They should be walked regularly and a full evacuation drill practiced annually. Ideally, persons should be able to turn their back on a fire and walk in the opposite direction towards a fire exit. Many premises, however, will have areas from which there is no alternative way out, for part or all of the escape route, (e.g. most rooms have only one way out). If your workplace is small and the fire risk has been assessed as normal or low then there will be no need to have alternative ways out but where your escape is in one direction only, the dead end areas should be kept as short, as few, and as low risk as possible. The maximum advisable travel distances, indicated by the green line in the following example, from any area in the premises to a fire exit door leading out to a place of safety should be in accordance with the guidance documents for the RR(FS)O The above guidelines are to be used with caution. You must look at each part of the premises and decide how quickly persons would react to an alert of fire in each area. Adequate safety measures will be required if persons are identified as being at risk. Where these travel distances cannot be achieved, you will be required to provide extra fire safety precautions and you should contact a suitably qualified fire safety consultant. Action Plan Devise an action plan and the prioritise in accordance with the tables be low Fire Risk Evaluation Guide Severity Likelihood Fire Risk Rating H - A major fire H- Certain or 3 = High Risk - immediate action occurring involving loss near certain required of life M - A fire involving a M - reasonable 2 =Medium risk - Action required danger to persons likely unless good reason L - Very seldom 1 = Low risk - No direct action L - A fire or never required but consider improvements May 2008 188 Assessment Table 3 3 2 3 2 1 2 1 1 High Medium High Medium Severity Low Low Likelihood The action taken is common sense and in the main inexpensive Should any requirements prove to be expensive, interim measures should be put in place until they can be implemented (providing persons are not put at an unacceptable risk). All that remains to do is to make a record of the assessment, prepare the action plan and monitor and review as appropriate. A simple practical example The initial situation in a local news agents shop. Hazards in the storage and tea area : Paper and fancy goods. Gas cooker with naked flames to warm food. Heaters with naked flames Persons especially at risk - Should a fire occur in the shop area persons may be trapped by the fire. Hazards in shop area : May 2008 Heaters with naked flames Display with disposable lighters on cards 189 Loose papers and refuse The solution to the local news agents shop. The solutions to the hazards in the previous plan :Storage area. Shelving reduced and a partition put in place to separate the storage area. A torch provided in case a fire affects the lights. Gas cooker replaced by microwave cooker to warm food. Naked flame heaters removed. A fixed convector heater provided in safe position. Shop Area. Fire extinguisher provided for use by trained staff. Disposable lighters moved to a supervised area no heat source. Person at risk - Provide a main wired fire smoke alarm in the main shop area to give early fire warning. Area of papers represents little fire risk as there is no ignition sources near. The final drawing should use standard architectural and fire graphical symbols. Step 4 - Record your findings and actions Findings of the assessment and the actions (including maintenance) arising from it should be recorded. If there are 5 or more employees you must retain a record of the significant findings which may be in writing, or by electronic or other means. It should indicate : May 2008 Date the assessment was made. The hazards identified. Any staff and other people especially at risk What actions needs to be taken and by when. The conclusions arising from the assessment. 190 Prepare your Fire Procedure The aim of the plan is to ensure that in the event of fire everyone, including contractors and casual employees are sufficiently familiar with the action they should take, and that the premises can be safely evacuated to a location where persons will not be in danger. The RP is responsible for preparing the plan, and in most small premises this should not be difficult. In smaller premises it may simply take the form of a fire action notice that everyone has received training on. Step 5 - Review, revise & monitor on a regular basis. The fire risk assessment is not a one-off procedure. It should be continually monitored to ensure that the existing fire safety arrangements and risk assessment remain realistic. The assessment should be reviewed if there is a significant change in the work activity, in the materials used or stored, or when building works are proposed. Prevention of fire and smoke spread in buildings Compartmentation Structures need to be compartmentalised into fire zones in order to limit the spread of fire. These compartments consist of fire resistant walls, floors, ceiling and doors, which are designed to contain the fire within one compartment. The three key elements in structural fire resistance are integrity, insulation and stability. Integrity concerns the resistance of smoke and flame through the element of the structure, insulation concerns the minimisation of heat through a structural element e.g. a wall. Stability concerns the ability of the structure to resist collapse e.g. the world trade centre. Typical structural features that might be built into a structure to minimise the spread of smoke and flame include; Compartmentation Fire Doors Fire Stopping Fire Dampers Smoke Vents Sprinkler Systems As a general rule the minimum fire resistance that is required of a structure or element of a structure is 30 minutes, but this can be anything up to several hours. Extinguishing media Water Extinguishing Action Expelled in a limited quantity under pressure forming a jet, approximately six metres in length, which cools the burning material by absorbing heat. Foam Produced by forcing a solution of foam concentrate and water under pressure through a foam making nozzle this entrains air, aspirating the solution and converting it into foam which blankets the surface of the burning material/liquid excluding oxygen. 191 May 2008 Foam(AFFF) Expelled in a fine spray it does not need to be fully aspirated. Forms a foam film on top of the burning material/liquid excluding oxygen, seals surfaces, prevents retention and has a cooling effect with a wider application than water on combustible materials. Carbon dioxide Expelled under great pressure in a powerful concentration. Reducing oxygen in the air. Dry powder Knocks down flames by chemically inhibiting combustion. Wet Chemical The fine spray gives almost immediate flame extinguishment while the wet chemical agent reacts with the oil and emulsifies to form a soaplike film to seal the surface of the oil and cool it down. Hose reel Cools the burning material by absorbing heat Fire blanket Excludes oxygen Appropriate means for fire fighting should be provided having regard to the fire risk classification given earlier. Provision of fire-fighting equipment for Class A fires is appropriate in most industrial situations. Hence water type extinguishers or hydraulic hose reels are required. The approved standard for hose reel installations is that with not more than 45m of hose no part of the area to be protected is over 6m from the nozzle of a reel when the hose is fully extended. Hose reels must be permanently connected to an adequate mains water supply and be located where they are both conspicuous and accessible. Portable extinguishers should be provided in sufficient numbers to give adequate cover to those parts of a site not covered by hose reels. Portable fire extinguishers and fire blankets are normally provided at strategic points 'm laboratories, offices and in corridors. Their applicability is summarised in the table below. Ideally all employees should be trained how to use fire extinguishers effectively. New fire extinguishers have to comply with BSEN3 which, among other things, requires all fire extinguishers to be red. One clause, however allows for up to 5% to be coloured to indicate contents. This has been implemented by BS7863 which specifies details of the coloured zone. If used, the zone of colour must be on the front of the top half of the body of the extinguisher and be visible from 180 degrees. Training in the use of extinguishers, should only be carried out by authorised personnel. May 2008 192 UNIT IGC 2, ELEMENT 6: CHEMICAL & BIOLOGICAL - HEALTH HAZARDS & CONTROL Introduction Every person is affected by his or her environment and they in turn have an effect on the environment. Therefore, to obtain an accurate picture of the factors at work, the total environment must be considered. There are four main classifications of occupational health hazards: Chemical Biological Physical Psychological Chemical: Acids and alkalis Metals Non – metals e.g. arsenic Gases e.g. carbon monoxide Organic compounds Biological: Human borne, e.g. hepatitis Animal borne e.g. anthrax, toxoplasmodium Vegetable borne e.g. farmer’s lung (aspergillosis) Other – water/land e.g. legionella Physical: Noise/Vibration Radiation Climate i.e. temperature, humidity, air movement, ventilation/extraction Ergonomics Psychological: Stress Violence at work The occupational health problems is at least the same magnitude as the occupational accident with approximately 900 deaths attributed to industrial diseases and about 300,000,000 worker-days lost yearly due to sickness and ill health from all sources. A large majority of these illnesses are caused by: Dust, fumes, mists, gases, vapours Toxic materials Corrosives May 2008 193 Our objective is to reduce this carnage. Monitoring In order to ascertain what are the problems, it is vital to develop a monitoring programme/system. This is essential because: All environments are subject to change, people make mistakes. All hazards and stress causing factors cannot be planned out of an environment. Standards change. Each monitoring system will have the following key points: 1. Recognition of the hazards (situations and materials which can have an adverse effect of the employees) which may exist due to chemical, physical, biological and ergonomic aspects of the workplace. 2. Measurement of the environment by direct reading instruments or sampling followed by analysis. 3. Evaluation of measurements using standards i.e. information on the effects of materials, employee exposure, employee health training, performance, legislation and codes of practise. 4. Instigate control measures to limit employee exposure. To meet the requirements of HASAWA, these control measures must firstly, adequately control the hazard, and secondly be suitable for the user. 5. Instigate training and communication programmes to obtain user assistance in limiting their exposure to hazardous substances and conditions, and to assist in the maintenance of the control programme. This will include gaining social and economic acceptance from operators and obtaining economic and priority acceptance from management. 6. Re-measurement and re - evaluation to check for effectiveness of the control measures and to assist in the fine tuning of these controls. Methods of measuring gases May 2008 194 Measurements There is now a considerable amount of simple and easy to use sampling and direct reading equipment on the market. Your purpose and works situation will determine the equipment chosen, and the distribution, duration, frequency and number of samples taken to: 1. Identify the suspected problem 2. Give warning of the existence of dangerous conditions 3. Assess levels of exposure 4. Assess effectiveness of control measures Workers are exposed to hazardous substances every day of their working lives. There are thousands of hazardous substances in daily use. You don’t have to work in the chemical industry or in manufacturing to be exposed. Virtually all workplaces use or contain hazardous substances. WHAT ARE HAZARDOUS SUBSTANCES? Hazardous substances to include most hazardous chemicals (including waste and byproducts), biological agents (for definition see the separate section later), and any dust. Harmful substances include the vast majority of commercial chemicals, many of which have a warning label. Examples may include: cleaning - bleach and other cleaning agents with a warning label (note that household washing-up liquid has no warning label and so is not covered); building maintenance - wood dust, glues and adhesives, solvents, paints, and oils; grounds maintenance/gardeners – pesticides and chemical fertiliser; healthcare - medicines and biological agents (note that COSHH does not cover patients receiving medicine as part of their treatment); transport - oils and fuels; and office work/printing - printer/photocopier toner, inks, and paper dust. When considering hazardous substances, remember: that they may come in various forms (gas, liquid, and solid), each of which may be more or less hazardous; that some may contain hazardous impurities; and that exposure to more than one substances at the same time may have additional or worse effects. Some hazardous substances may have separate specific laws covering them. THE EFFECTS ON HEALTH There are four main ways a substance can enter the body: inhalation (breathing it in), absorption (through the skin), injection (through a cut in the skin) and ingestion (swallowing it). The effects on health may develop quickly (acute) and be easily seen or may take years (chronic), making linking the ill-health to the exposure difficult. The effect may develop at the area where the substance enters or comes in contact with the body (local) or it may affect unrelated parts of the body (systemic). Workers may suffer: irritation perhaps leading to dermatitis, sensitisation possibly leading to asthma, a loss of consciousness if overcome by toxic fumes, infection by bacteria, and long-term effects such as cancer. A HEALTH RISK ASSESSMENT Best practice in this area requires that employers take actions to prevent wherever reasonably practicable, workers exposure to hazardous substances, and to control it where not. There are four steps which need to be taken May 2008 195 . Step 1 - Assessing the Risks Before exposing employees to hazardous substances, an employer must conduct a health risk assessment. All the hazardous substances used in the workplace including waste and byproducts must be identified, and information on each obtained. The first place to get information is the safety data sheet (more details later) which suppliers must give with each product supplied. Other sources of information include: product labels and other information from the manufacturer/supplier, HSE guidance and publications, technical journals, and the EU List of Indicative Limit Values or the ACGIH list of Threshold Limit Values in America. Next the employer must consider how likely is it that someone’s health will be effected. How much of the substance is used/produced? Who may be exposed? Everyone has to be considered, including for example: visitors, the public, contractors, employees working at other locations or at another organisation, and especially cleaning and maintenance staff who’s work may lead to them being highly exposed; or those who may be at greater risk, such as pregnant, young, or disabled workers, or those more susceptible because of sensitivities or other diseases. How often and for how long may they be exposed? Are employees or others exposed to more than one substance since this may cause worse health effects? Are they also exposed to substances at home which may affect the level or mix of exposure? Again, it may be necessary to seek further information as above. Specialist help may be sought for conducting risk assessments when there is no one with sufficient competence. A competent person is someone with an understanding of the local legal requirement and with all the necessary information, knowledge, training and experience to understand and make correct decisions about the hazards and risks, the work, and actions needed. Step 2 - Deciding what Precautions are needed to protect the workforce and others If significant risks are identified in step one, the employer must consider how to prevent or minimise exposure and whether current controls are working and meet current limits e.g. HSE, Health and Safety Commission (HSC), industry, etc., guidance and good practice. Air monitoring and/or health surveillance results (more details later) will help to indicate whether the controls are working. The risk assessment must be recorded, kept readily available, and explain the findings and the necessary steps to control exposure. How much is recorded depends on the risk. The assessment must be regularly reviewed. The type of work or extent of risk will determine how frequently. Reviews must also take place whenever it is suspected that they are no longer valid or when there has been a significant change. Checks on control measures, air monitoring results, health surveillance checks, work related ill-health, or information on new health risks may all indicate that a review is necessary. A significant change includes: using a different substance or getting it from a new source; or a change in the controls, work process, or methods. When reviewing an assessment employers must consider preventing exposure or improving control measures even further. Changes in technology (control methods or equipment) or in the cost of alternatives may mean that it is now possible to prevent or further reduce exposure. Step 3 - Preventing and Controlling Exposure Next, if reasonably practicable to do so, employers must prevent exposure. This can be done by: May 2008 196 totally enclosing the system or process; developing safe systems of work or processes which minimise the amount of hazardous waste and by-products, and the chances of leaks, spills, and escapes; partially enclosing the process and handling systems and using local exhaust ventilation (LEV); LEV; general ventilation; safe storage and disposal; the prohibition of eating, drinking, or smoking since substances may get stuck on food, etc. and then be swallowed - but suitable areas for eating and drinking must be provided elsewhere; facilities for washing and changing, and the laundering of contaminated clothing; reducing the number of employees exposed and the length of time they are exposed but only after all of the above have already been used where possible; and personal protective equipment (PPE) - but only as a last resort or just to be prudent, in case the other control measures should fail. This cannot be used as an alternative to any of the above. It must also be provided at no cost to the employees. For the control to be adequate an employer must meet the required exposure standards. For exposure by inhalation, this is set at a level at which most workers exposed to on a daily basis would not suffer ill-health. Control The above strategy can be summarised by a slightly modified for occupational health hierarchy of controls and is abbreviated as ERICS CP (for more detail – see later in this section): Elimination Reduce/Substitute Isolate Control Segregation Cleanliness Protective equipment Step 4 – Ensuring that Control Measures are Used and Monitored Employers must keep control measures in efficient working order, good repair, and clean; and ensure that they are properly used or applied. A competent person must exam, test, and maintain them at suitable intervals. Visual checks should be carried out weekly. Control methods such as working procedures must also be reviewed. How often will depend on the degree of risk and the reliability of the control method. Records of tests and examinations must be kept for at least five years. Employees must make proper use of the control measures, store them appropriately, and report defects to the employer immediately. Employers are responsible for providing employees with suitable training, information, and supervision so that they are able to do this Step 5: Record and review Where the assessment identifies a significant risk, then this assessment needs to be recorded together with a route, scheduled review date. This assessment is dynamic so the assessment may need to be reviewed earlier. May 2008 197 Hygiene factors - toxic substances The effect of a toxic substance on the body depends not only on the individual chemical, but also on the dose, and susceptibility of the individual. No chemical can be considered non-toxic; there are only differences in the degree of effect. To meet his statutory commitment an employer/occupier will need to identify the effects of substances used in his premises and to take appropriate measures to protect his employees and other persons. Manufacturers’ suppliers must make available to their customers information to facilitate the safe use of their product. Is the information supplied by the manufacturers etc adequate for your particular use? It may be prudent not only to request the standard information sheet, but also ask for answers to specific questions designed to meet your needs. Data will be required on: Control measures for safe use. Guidance on many substances is published by HSE with information from these sources your own standard in-house hazards sheet can be compiled. Toxic substances affect the body: by Inhalation by Ingestion Absorption through the Skin Injection through broken Skin The harmful effect on the body can vary from skin irritation to cancer. Scale of effect Acute - rapid onset, usually after a single exposure to high levels e.g. narcosis Chronic - effects only become apparent after a period of days, months years and usually after prolonged or repeated exposure to low levels. Site of effect Local - the effect is at the point of contact. Systemic - the site of effect is different from the point of contact. The body usually shows graded response to doses of toxic materials of physical agents. Small doses can produce little or no observable effect. As the dose increases certain effects manifest themselves, becoming more pronounced until death occurs. (A single exposure can produce a permanent harmful effect) (crocidolite - mesothelioma). It is therefore essential that relevant literature is consulted in order to determine the mode of action, mode of exposure, recommended maximum exposure levels and recommended precautions. The most difficult problems relate to long terms exposure to seemingly harmless materials, it is therefore useful to initiate epidemiological surveys for selected workforces. May 2008 198 Inhalation as a route of entry The most significant industrial entry route is by inhalation, it has been estimated that at least 90% of industrial poisons are absorbed through the lungs. (Individuals will breath about 10 cubic metres of air in an 8 hour period). This route is designed to absorb gases into the body. Finely divided chemicals can be present in the atmosphere as dust, fumes, vapours, mists or gases. 50 microns- Smallest particle that can be seen by the naked eye. Below this size need special techniques i.e.. the dust lamp to make the dust visible. 20 to 15 microns- Removed by turbulence in the passage. 10 to 7 microns- Removed by the cilliary ladder in the trachea and main bronchial tubes. 7 to 0.3 microns- Termed respirable as they can enter the inner lung (alveoli) where they are usually moved by macrophages within days. Toxic materials will kill the macrophages and will remain in the lung. It is this dust which is absorbed into the lung to give the toxic effects or scars in the lung causing pneumoconiosis, 0.3. microns or below. Not retained within the lungs and exhaled. Note: One micron is one millionth of a metre. The respiratory system May 2008 199 Classes of Toxic Substances Dusts Solid particles, crushing, grinding etc. Organic or inorganic. ROCKS, ORE, METALS WOOD. Settle under gravity. Fumes Solid particles from condensation of gaseous state, e.g. from volatilised metals. They can flocculate and coalesce. Mists Suspended liquid droplets from condensation of gaseous state or break up of liquids. Splashing, foaming or atomising. Vapours Gaseous form of substances which are normally in solid or liquid state. Gases Formless fluids. Skin contact Corrosive either from acid or alkalis, causing chemical burns. Prompt first aid i.e. immediate continuous drenching with water and removal of all contaminated clothing is essential. Percutaneous. These materials e.g. hydrofluoric acid, aniline and phenol are absorbed through the skin, with these materials it is essential to use specific percutaneous countermeasures. Dermatitis. Caused by contact with substances which interfere with normal skin physiology. Contact Dermatitis: An attack on the surface of the skin. It will not stop until contact with the causative agent ceases. After an attack the behaviour of the skin is unpredictable. Small exposures may be tolerable without further trouble. A return to work with possible exposure to the chemical can be allowed provided caution is exercised. After two recurrences all further contact should be barred. Sensitisation dermatitis this follows an activation of the skins natural immunological processes, after a symptom free period while the body's defences are being primed. Once this threshold is reached, dermatitis will occur if contact continues. Healing is often prolonged and only occurs when the sufferer is completely removed from further contact. The skin can become sensitive to and react with molecular quantities. Once sensitisation dermatitis has been diagnosed no further exposure can be permitted. Dermatitis can be prevented by: 1. Clean working conditions and properly planned work systems 2. Careful attention to skin hygiene principles. 3. Prompt attention to cuts, abrasions and spillages onto the skin. 4. Use of protective equipment. 5. Barrier creams can help. 6. Pre-employment screening for sensitive individuals. May 2008 200 Note: Testing can cause sensitisation. In short we: Protect Cleanse Moisturise Splashes in the eye Strong alkalis are particularly damaging and must be used with great care. Suitable eye protection is essential. All eye injuries require prompt and prolonged gentle irrigation with water, followed by expert attention. As with all exposures to chemicals, details of the chemical involved, and the treatment given should accompany the patient. Ingestion This route represents the least problem as it is unlikely that any significant quantity of harmful liquid or solid will be swallowed without deliberate intent. However, accidents will occur if pippeting by mouth, and eating and drinking in chemical areas allowed. .The Eight Principles The eight principles will apply to all substances assigned a Workplace Exposure Limit: Design and operate processes and activities to minimise emission, release and spread of substances hazardous to health. Take into account all relevant routes of exposure - inhalation, skin absorption and ingestion - when developing control measures. Control exposure by measures that are proportionate to the health risk. Choose the most effective and reliable control options which minimise the escape and spread of substances hazardous to health. Where adequate control of exposure cannot be achieved by other means, provide, in combination with other control measures, suitable personal protective equipment. Check and review regularly all elements of control measures for their continuing effectiveness. Inform and train all employees on the hazards and risks from the substances with which they work and the use of control measures developed to minimise the risks. Ensure that the introduction of control measures does not increase the overall risk to health and safety. Workplace Exposure Limits (WELs) In the UK the COSHH regulations introduce an occupational exposure limit system the WEL. It is concerned with concentrations of airborne hazardous substances that people breathe over a specified time period and these are referred to as the time weighted averages. Two time periods are used; long term (8 hour) time period intended to control the effects by restricting the total inhalation over one or more work shifts and short term (15 minutes) to control the acute effects that may be seen after a brief exposure. Definition of substances hazardous to health COSHH contains specific definitions of hazardous substances including any chemical classified and labelled (under the Chemicals (Hazard Information and Packaging for Supply) Regulations 1994 (as amended) as being: May 2008 201 Harmful or irritant warning label is a St. Andrew’s cross Corrosive warning label is two horizontal dripping test tubes over a hand and a bar of steel Toxic or very toxic warning label is a skull and crossbones Note: All warning labels are an orange square with the appropriate black symbol, and will be clearly displayed on chemical containers. Safety data sheets for any hazardous substances, including ones with occupational exposure limits from the inventory and identifying any existing and necessary control measures. Biological agents do not come conveniently labelled so any contact with biological agents e.g. body fluids, must not be forgotten. Note: By-products of processes must also be considered and assessed. Monitoring exposure in the workplace Once control measures, which are as low as is reasonably practicable, (ALARP), have been decided on and implemented using the OHH Hierarchy of control measures, they must be maintained and monitored. Monitoring techniques will depend upon the substance being monitored e.g. a gas or vapour would be monitored via static or portable gas monitors, whereas solids (dust, fumes etc.) would be monitored by using personal sampler’s, bubbler's etc. Note: Records of all monitoring must be kept for 30 years. Health Surveillance Another aspect of monitoring is health surveillance. COSHH specifies several instances when health surveillance is considered appropriate, including when an identifiable disease or adverse health effect is associated with exposure to a hazardous substance, and this is reasonably likely to occur under normal working conditions. There must also be valid techniques for detecting the resultant health condition. Any health record must be made and retained for 40 years. May 2008 202 OHH hierarchy of control As with any problem, we need a hierarchy of control measures for occupational health problems. The hierarchy within COSHH revolves around the following: Eliminate or prohibit the substance Reduce/substitute with a safer form e.g. replace a dust with a pellet/granule or suppress by changing to a wet process Isolation of a particularly dangerous process/substance to a room/area of the plant e.g. dust enclosures, paint spray booths, fume cupboards etc. Controls (Ventilation) make use of LEV or dilution ventilation Segregation this is used when controlling toxic materials or physical hazards e.g. noise and radiation. It may be segregation by time, distance, age or sex. The Young Persons Regulations are relevant in this area. Cleanliness or good housekeeping regular hand washing, prohibition of smoking and eating in the workplace, need for removing and cleaning contaminated clothing. PPE Personal Protective Equipment Information, Instruction and training Employees must be given information on any risks associated with hazardous substances that they may be exposed to whilst at work along with the necessary control measures, and the results of any monitoring carried out (except where this includes personal health related information which is confidential). They must also be instructed and trained in the use and limitations of any control measures provided. Where a maximum Exposure Limit has been exceeded, employees must be informed. Local exhaust ventilation above, an example of LEV, is a flanged extraction hood system Respiratory protective equipment May 2008 203 1-way inhalation valve Pre-filter 1 way exhalation valve Filter Housing for filter May 2008 204 THE CHEMICALS (HAZARD INFORMATION AND PACKAGING FOR SUPPLY) REGULATIONS (CHIP) In the UK these regulations are frequently up-dated and require that suppliers of substances and preparations (mixtures) classify them on the basis of the hazard in accordance with the regulations. Suitable Packaging This requires the manufacturer to supply such a hazardous product in suitable packaging. Furthermore, where they are sold to the public then they must carry suitable tactile warning signs and be fitted with child resistant closures. Material Safety Data Sheets (MSDS) The manufacturer (or supplier) is also required to provide a safety data sheet upon request and this MSDS must contain the following information; Contents of a Material Safety Data Sheet Name(s) of substance Physical description Route(s) of entry into body Occupational exposure limits Toxic/physical effects on exposed persons First aid recommendations Control measures Personal protection Storage requirements Spillage control Hazardous reactions Fire precautions, fire extinguisher required May 2008 205 ENVIRONMENTAL PROTECTION WASTE DISPOSAL AND CONTROL OF POLLUTION Basic environmental issues relating to waste disposal and effluent Environmental pollution is a major issue with the industrialised countries of the world, concerned about the long term effects on the Earth’s resources and on human, plant and animal life. Major concerns on health are often blamed on pollution and there are many pressure groups that focus on environmental issues, particularly pollution. The problem with pollution is not new, it has been with us since Roman times and the land around old lead mines are still contaminated with the heavy metal today. Since the industrial revolution industry has relied on the capacity of the environment to dilute and disperse pollutants by discharging them to the ground, water and air. This has left a legacy of polluted areas, land pollution being the most persistent, but discharges to air and water are more global in their effect. An example of an intentional release of pollution is the emission of sulphur dioxide (SO2) and nitrogen oxides (NOx) into the atmosphere by coal fired power stations. This example also illustrates the global, as well as local, impact that such emissions have which in this case, results in acid rain falling in Scandinavia, a country which emits very little sulphur dioxide itself. A further impact by the same power station is caused by carbon dioxide emissions which lead to global warming. The local effects of the mission of particulates and sulphur dioxide is illustrated by London’s smogs of the 1950s and the more recently by the increase in road traffic – many cities in Britain now have pollutants above recommended limits, especially in warm, still conditions. Plant failure and accidents can lead to abnormal releases following higher than expected temperatures and high pressure systems. This has led to a loss of process control with uncontrolled venting to the environment. Lack of control can lead to losses e.g. overfilling. A definition of pollution The introduction into the environment of substances or energy liable to cause hazards to human health, harm to living resources and to ecological systems, damage to structures or amenity or interference with legitimate use of the environment. The principal duties imposed by Parts 1 and ii of the Environmental Protection Act 1990. The Environmental Protection act 1990 (EPA) is the primary legislation relating to environmental protection and management. The key parts are; Part 1: Integrated Pollution Control and Air Pollution Control Part II: Waste on Land The EPA was introduced in response to European Union pressures but partly because of perceived needs in the UK to up-date the Control of Pollution Act 1974 (CoPA) and to introduce ‘prior approval together with a more integrated approach’. EPA Part 1 – Pollution Control The main features of the EPA affecting industry are: The introduction of Integrated Pollution Control (IPC) and Air Pollution Control by Local Authorities (LAAPC). May 2008 206 The classification of Part A – EA and Part B – LAAPC processes, depending on the type of material being processed and the size of the facility. Note that the powers of the Environment agency are affected by the following factors: Part B processes in regard to air pollution control being dealt with by local authorities. Their relationship with the HSE – there are potential problems over COSHH Regulations 2002 and extracting workplace pollutants and venting directly to atmosphere. EPA Part II – Waste on Land Please refer to section in this element ‘Waste Disposal’. AIR POLLUTION The atmospheric system The atmosphere of the planet is a complex fluid system of gases and suspended particles. Five gases – nitrogen, oxygen, argon, carbon dioxide and water vapour make up 99.9% of the total volume of the atmosphere. The balance is made up of suspended particles such as water droplets, dust, soot and minor gases. In this system a range of pollutants are released. Common sources of air pollutants Many sources of air pollution are introduced to the atmosphere as a deliberate release from local exhaust extraction and ventilation stacks due to combustion and other industrial processes. Sulphur Dioxide The major source of sulphur dioxide is the combustion of fossil fuels containing sulphur. These are predominantly coal, and fuel oil since natural gas, petrol and diesel fuels have relatively low sulphur content. Suspended particulate matter The main source of primary man-made particulate pollutants is combustion of fossil fuels, especially coal. Power stations use large amounts of coal. There has been a massive decrease in urban concentrations of smoke. The main source of black smoke in urban air in the UK is diesel engined road vehicles. Oxides in Nitrogen The most abundant nitrogen oxide in the atmosphere is nitrous oxide, N2O, and this is formed by microbiological action in the soil. It is not normally considered as a pollutant, although it does have an effect upon stratospheric ozone concentrations and there is concern that the use of nitrogenous fertilisers may be increasing atmospheric levels of nitrous oxide. The main concentrations are nitric oxide, NO, and nitrogen dioxide, N2O, which combined form NOx. The major source of NOx is in high temperature combustion processes. Carbon dioxide Increasingly carbon dioxide, CO2, is viewed as an air pollutant because of its importance as a ‘greenhouse gas’. Its source lies in animal and plant respiration, and anoxic decomposition processes. It may be both absorbed and released by oceans. Fossil fuel combustion receives a lot of attention, but it is a minor source. However, a small imbalance in the CO2 cycle is leading to a steady increase in atmospheric concentration. May 2008 207 Carbon monoxide The main source of carbon monoxide, CO, is petrol engined road vehicles. Car exhaust gases contain several per cent carbon monoxide under normal operating conditions., and greater amounts when cold and operating on the choke. Hydrocarbons The major sources of hydrocarbons in the air are the evaporation of solvents and fuels, and the partial combustion of fuels. Ozone Ozone is a naturally occurring gas in the atmosphere and it is important because in the upper atmosphere it forms a protective blanket (the ozone layer) that filters out potentially harmful rays from the sun. Holes in the ozone layer have been discovered at both the North and South poles and severe thinning over large parts of North America and Europe. People living in these areas have a greater risk of skin cancer due to the increased ultra violet exposure from the sun. In addition, plant and aquatic life can be affected with corresponding problems for the whole food chain. Chlorflourocarbons (CFCs) are in this group and when they react with this UV radiation from the sun, release chlorine that reacts with and destroys ozone. However the chlorine is not destroyed and can go on to repeat this process up to 100,000 times. Ozone depleting gases include not just chlorine but also bromine, halons, and carbon tetrachloride. WATER POLLUTION Water is present on planet Earth in all three of its phases; as a solid, liquid and gas. Most water is found in the atmosphere; the oceans store most of the water in its liquid form and the poles and the high mountains store water in the form of ice. Water moves between each of these three states by processes such as evaporation, condensation, melting and freezing. Operating together these are known as the hydrological cycle. And these processes make a major contribution to the weather of the planet. Over 97% of all water on Earth is salt water. Of the 3% that ifs fresh water 77.5% is locked in the ice caps and glaciers. The atmosphere, rivers, lakes and underground stores hold less than 1%. In terms of water pollution it is water in the liquid phase that is most vulnerable. Common sources of water pollution A good way of considering any pollution is too much of something in the wrong place and so there are many water pollutants. This fact is recognised within the European Union (EU) by the listing of the black and grey list materials, sometimes referred to as List I and List II substances. Black List or List I substances are considered to be toxic, persistent and bio accumulative, so priority is given to eliminating them as a cause of pollution. This includes waste substances such as organhalogens, organophosphorous, cyanide, cadmium, and mercury and their compounds. Sheep dip and solvents are included in this list. The grey List or List II covers those substances considered to be less harmful when discharged into water. Included here are metals such as zinc, nickel, chromium. Lead, arsenic, and copper. Also included are various biocides such as used in cooling towers or humidifiers and substances such as phosphorous and its compounds (detergents) and ammonia (present in sewage effluent). May 2008 208 Basically heath and safety legislation is concerned with the protection of workers and those affected by work activity. There is a link between these considerations and those of environmental protection, and in many cases an overlap. The Environmental Protection Act 1990 (EPA) provides the basic framework for pollution control legislation. The EPA established two systems of control: Integrated Pollution Control, administered by the Environment Agency and control of air pollution for all other specified processes which is the responsibility of Local Authority environmental health officers (EHO’s). EPA is concerned with all aspects of pollution; Air (including noise) Land Water Waste Management The more waste we generate, the more we have to dispose of. Some methods of waste disposal release air pollutants and greenhouse gases into the atmosphere. Waste recycling offers one means of reducing the impacts of waste disposal on the atmosphere, but there are other methods of waste disposal which are more environmentally friendly. The most common disposal methods, particularly in the UK, are landfill and to a lesser extent incineration. Each year approximately 111 million tonnes of controlled waste (household, commercial and industrial waste) are disposed of in landfill sites in the UK. Some waste from sewage sludge is also placed in landfill sites, along with waste from mining and quarrying. There are over 4000 landfill sites in the UK. As landfill waste decomposes, methane is released in considerable quantities. Currently it is estimated that over 1.5 million tonnes of methane are released by landfill sites in the UK each year. Methane is a strong greenhouse gas and contributes to global warming. Furthermore, the leachate fluids formed from decomposing waste can permeate through the underlying and surrounding geological strata, polluting groundwater which may be used for drinking water supplies. Containment landfills however, can limit the spread of this waste leachate. Incineration is the second largest waste disposal method in most countries. In the UK, approximately 5% of household waste, 7.5% of commercial waste, and 2% of industrial waste is disposed of by incineration. When burning waste, a large amount of energy, carbon dioxide and other potentially hazardous air pollutants is given off. Modern incinerators however, can use this waste energy to generate electricity and hence prevent the energy from being wasted. Incineration plants range from large scale, mass-burn, and municipal waste incinerators to smaller clinical waste incinerators used in hospitals. During the 1990s many UK hospital incinerators were forced to close owing to tougher emissions legislation introduced by the 1990 Environmental Protection Act. Today, hospitals tend to share one large incinerator to dispose of the wastes for a number of hospitals. A less common but more sustainable method of waste disposal is anaerobic digestion. In this process waste decomposes in an enclosed chamber, unlike in a landfill site. Digestion takes place in an oxygen-free environment. Bacteria thrive in this environment by using the oxygen that is chemically combined within the waste. They decompose waste by breaking down the May 2008 209 molecules to form gaseous by-products (methane) and small quantities of solid residue. Anaerobic sewage plants produce significant quantities of methane, which can be burnt to generate electricity. Liquid and solid organic fertilisers are also formed, and can be sold to cover operating costs. For several years, sewage sludge and agricultural waste has been treated by anaerobic digestion, and the process is now being used for municipal solid waste. It requires the biodegradable section of the waste to be separated from other material and put into digestion chambers. Currently, the UK has only a small number of plants, and each can handle only a few hundred tonnes of waste each year. However, the usage of anaerobic digestion as a sustainable waste disposal method is forecast to increase. Many other countries already utilise anaerobic digestion to dispose of large amounts of waste. Denmark for example, treats 1.1 million tonnes of waste by anaerobic digestion every year. Sources of Waste The UK produces around 330 million tonnes of waste annually - a quarter of which is from households and business. The rest comes from construction and demolition, sewage sludge, farm waste and spoils from mines and dredging of rivers. Waste Regulation The types of waste regulated by us are called 'controlled wastes'. These include household, industrial and commercial waste. Other wastes called 'non-controlled' (agriculture, mines and quarries) are not currently regulated in the same way. Certain wastes are classified as hazardous - a very broad term for a wide range of substances that present different levels of risk. Some present a serious and immediate threat to the population and the environment, for example those which are toxic, could cause cancer or infectious disease. Others, such as fluorescent tubes or cathode ray tubes in televisions, pose little immediate threat but may cause long term damage over a period of time. If your business produces hazardous waste you have a 'duty of care' to make sure it's disposed of properly. Waste will fall into one of the following categories: Waste considered to be hazardous under the hazardous waste regulations - for example, lead acid batteries, fluorescent tubes Waste that is not considered to be hazardous - for example, paper, edible oil Waste that needs to be assessed to find out whether it is hazardous or not - for example, ink or paint WASTE HIERARCHY OF CONTROL The waste hierarchy is the internationally recognised approach to waste management, and forms the basis of the Government's approach to waste management. The waste hierarchy sets out in order, the best practical environmental option for dealing with the disposal of waste. As you go down the list the environmental impact increases. The waste hierarchy is as follows: 1. Reduce (most favoured option) 2. Re-use 3. Recycle 4. Recover energy through incineration or from landfills 5. Landfill without energy recovery (least favoured option) The 3 R's represent the three most important waste management options in the waste hierarchy: May 2008 210 1. Reduce - reducing waste saves both materials and energy, and removes the need and expense of disposal. 2. Re-use - this reduces the need to buy new items and therefore saves resources. 3. Recycle - this saves valuable raw materials, and cuts down waste collection and disposal costs Waste Transfer Notes (WTN). A Waste Transfer Note (WTN) is a document which must be completed and accompany any transfer of waste between different holders. A WTN must be created for each load of waste that leaves your site. For repetitive transfers, there is provision to use a 'season ticket’ i.e. one transfer note will cover multiple transfers over a given period of time of up to 12 months. The use of a season ticket is, however, only permissible where the parties involved in each transfer are the same and where the description of the waste transferred remains the same. What information should it contain? The WTN must contain enough information about the waste to enable anyone coming into contact with it to handle it safely and either dispose of it or allow it to be recovered within the law. Failure to give enough information may result in prosecution. The sanctions available under environmental legislation are broadly similar to those under the Health and Safety at Work etc. Act 1974. The waste producer should describe on the WTN both in words and by reference to the appropriate codes in the European Waste Catalogue (EWC) and the quantity and types of each different waste being transferred. The requirement was introduced in England, Wales and Scotland by the respective Landfill Regulations. Both parties to the transfer must sign the transfer note e.g. you and the waste carrier must sign the WTN before the waste leaves your site. If the waste producer transports the waste themselves, then they and the operator of the waste management site to whom you hand over your waste must sign the transfer note. This is your record of the nature and quantity of waste you transferred, how it was packaged, when you transferred it, where it should go and who you transferred it to - all requirements of the Duty of Care. You must keep copies of all WTN's for at least two years. Whatever the destination of your business wastes and whichever organisations are handling them, it will help you to prove that you have properly discharged your Duty of Care if you undertake periodic audits. This will help you to ensure that your wastes are being handled correctly from the moment they leave your premises to the final point of disposal or recovery. WTN's and Hazardous/Special Waste The transfer documentation for Hazardous/Special Waste is referred to as a 'consignment note'. If the material you are handling has hazardous properties, it may need to be dealt with as Hazardous/Special Waste. In this case, completion of a Consignment Note (requiring similar information to a WTN) will fulfil the Duty of Care requirements; a separate waste transfer note is then not required. May 2008 211 Waste defined by the EWC as hazardous (i.e. those where the description matches an entry with an asterisk) can only go to a waste treatment facility that is licensed to receive hazardous waste. Issues to be addressed to ensure the safe collection and disposal of waste • Identification of waste by its hazardous properties (general, contaminated or hazardous waste) • Identification of waste by its nature (e.g. solid or liquid) • Quantity produced • Need for separation of incompatible wastes • Means of containing the waste and its marking and labelling • Provision of safe storage on site • Methods of transportation to and from the storage facility • Appointment of a competent and/or licensed contractor • Spillage emergency procedures • Competence of staff • Keeping of necessary records(waste transfer notes/consignment notes as applicable) May 2008 212 UNIT IGC 2, ELEMENT 7: PHYSICAL AND PSYCHOLOGICAL HEALTH HAZARDS AND CONTROLS TASK AND WORKSTATION DESIGN Designers and site management can play a major part in minimising workers’ exposure to operations, which may cause or contribute to musculo-skeletal injury [MSI]. All construction projects involve the bringing together, transporting and placing of materials. These activities are all site related and as such are frequently ignored by designers of works when assessing risks of ill health to those constructing the works. Generally, the processes used by the contractor will be the most cost effective ones to themselves. The majority of ill-health experienced by site workers is caused by the following: a) Lifting heavy or awkward materials or equipment; b) Carrying out repetitive strenuous activities; c) Using damaging equipment; or d) Working in awkward positions. It is not acceptable for the designer to simply carryout their design and then expect the contractor to control all the risks resulting from the design, on site. HAZARDS ASSOCIATED WITH LIFTING, ETC When workers have to operate under any of the conditions listed above, the body is put under strain. If the condition is too strenuous, the worker is exposed to the risk of MSI, which could manifest as strains and sprains, causing short-term discomfort or, in more serious cases, longterm injury. Constant exposure to overstraining could be cumulative, meaning that a worker never recovers fully, leading to permanent disability. Role of the designer Designers, through their early involvement in projects, are ideally placed to reduce the incidence of MSI, by eliminating or minimising the hazardous conditions listed above. This may be achieved in two ways: a) Controlling the hazard by design; or b) Providing adequate information to allow the hazard to be effectively managed by a contractor. It may also be possible to control hazards indirectly by influencing the project specification, selection of contractors and so on. Controlling the hazard by design At the design stage, designers should assess the risks to health introduced by their requirements and change the details if necessary. In certain circumstances it may be possible to discuss, with a contractor, the construction methods likely to be employed. If not, designers will need to consider how the work is likely to be constructed. Generally, overall design concepts should, as far as possible, reduce the need for long duration repetitive or strenuous activity. May 2008 213 Some of the common construction operations, in which operatives are exposed to MSI are given below. Generally, designers should consider details, which avoid these operations. For example, designers should consider: a) Eliminating the need for manhandling heavy components, e.g., high density blocks b) Designing to allow use of plant for materials handling and processing rather than manual methods, i.e.: i) by using layouts, which provide sufficient space for mechanical plant, and ii) by detailing, components so that their sizes are compatible with machines currently available; c) Not specifying operations, which require i) hand-held tools, which vibrate, e.g., needle guns, power saws, etc, or ii) tools, which are heavy or awkward to use, e.g., concrete drills, pneumatic breakers; because they are likely to contribute to MSI; d) Not specifying operations, which will require people to work in awkward or cramped conditions. Information on anthropomorphic measurements is widely available; e) Detail the works to allow for maximum off-site prefabrication, e.g.: i) using reinforcing mesh instead of individual bars wherever possible, ii) detailing reinforcement to allow fabrication off site; f) Dimension the works to allow the use of non-hand held tools for cutting, excavation and compaction. For example: i) Trench widths should be sized to allow remotely controlled compaction, ii) Trench widths should not be narrower than minimum excavator bucket sizes, iii) Detail reinforcing mesh so that it arrives on site at the correct size, rather than to be cut on site; Layouts, dimensions of buildings and structures and clearances should allow good access for building and maintenance tasks, for example: a) Heights of work should fit with module sizes of temporary works equipment (TWE). b) Corridor widths should allow use of mobile TWE; c) Service runs should be at heights, which fit in with TWE module sizes; d) Service runs should be detailed with enough space around them, so that they can be grasped properly; Controlling hazards by information When it is not possible to eliminate the hazards, it is essential that this is communicated to the contractor and others involved in the project. This is the Planning Supervisor’s duty but designers must supply relevant information on hazards. This information is best included on the drawings for abstraction for inclusion in the Health and Safety Plan. May 2008 214 Some examples of how the designer might be able to help are given in Table 1. Note that this table is not exhaustive and is for guidance only. It is for the designer to identify the risks and to set out appropriate control methods. Activity Health Risk Control Measure Laying block paviours WRULDs Brick laying Tying reinforcement WRULDs WRULDs Block laying Materials Handling WRULDs WRULDs Working in small or awkward spaces WRULDs Use of hand tools, e.g., a) in RC work, b) compaction HAVS Pile cropping HAVS Design for machine laying: space, component size, etc Design to reduce long repetition Use welded mesh; detail to allow prefabrication and lifting in. Use lighter blocks Adequate space for available machines; Specify low weight packages Dimension: height, width, to fit modules of TWE; Size RC components to minimise pushing /pulling while fixing re-bar. Design for: a) use of crack-inducers; or nonscabbled joints; b) Remote compaction Design spacing and pile re-bar for machine cropping a) Provide ducts, detail boxb) Use crack inducers, c) minimise number of cuts HAVS Cutting, e.g., a) chases, b) joints in RC, c) blocks, etc WORK RELATED UPPER LIMB DISORDERS WRULDs are a cumulative disorder, caused by continuous exposure to the conditions, which cause it. In its advanced stages it can be extremely painful and debilitating, sometimes rendering sufferers disabled. Generally, any activity, which requires a person to work under strain or in an unergonomic position, is likely either to cause or contribute to MSI. Construction operations in which workers are particularly exposed to MSI include: a) Bricklaying – high density blocks; b) Glazing – installing heavy windows; c) Manoeuvring heavy components while laying paving and kerbstones; d) Working while bent over, e.g.: i) Concrete work requiring – hand spreading, vibrating, hand floating large areas of concrete and cutting joints; ii) Steel fixing, especially in ground slabs; May 2008 215 e) Working while stretching, e.g.: i) Fixing services in ceiling spaces; ii) Steel fixing in retaining walls; f) Using tools, which vibrate, e.g.: i) breaking out concrete, ii) scabbling concrete, iii) pressure washing; iv) compacting equipment; g) Using hand held diggers and breakers; Common types of MSI and the activities, which can cause them, may be summarised as follows: a) Back injury: caused by lifting and carrying of plant and materials or working in awkward conditions; b) Work- related upper limb disorder [WRULD]: caused by carrying out repetitive tasks over long periods; c) Hand arm vibration syndrome : caused by exposure to vibrations from plant and machinery. The situation is exacerbated by: a) Workers who often do not recognise that carrying out tasks in a particular way may result in long-term ill-health. Their working methods are frequently based on ‘how it has always been done’; and b) Contractors work methods, which are usually driven by site, planning, time or financial constraints; c) Sometimes thoughtless design creates the problem. NOISE Control of Noise at Work Regulations 2005 Noise is usually defined as unwanted sound so the question really is what is Sound? Sound may be defined as any pressure variation (in air, water or other medium) that the human ear can detect. It has been common knowledge for many years that exposure to high levels of noise can cause impairment of hearing. The reduction of noise can be both complex and expensive, consequently, the problem has had a mixed reception. Some companies have gone to considerable lengths and expense to identify the problem and eliminate or reduce at source, other companies have made available personal protective equipment and, finally, perhaps because the problem has not been recognised, some have done nothing. The tragedy of the situation is that the deterioration of hearing is so slow that it is not realised until too late, for hearing lost in this way cannot be recovered. How Hearing Works First it is important to have a practical knowledge of the ear itself, to understand what noise is, to be familiar with proposed legislation aimed at conserving the hearing of workers and then to know what devices are available to protect against a hazard which we all face in certain conditions. May 2008 216 Let's look at this human hearing mechanism to see how it works so we'll know what we have to protect and how. HUMAN AUDITORY SYSTEM From left to right we see the pinna, the auditory canal, the eardrum, the cavity of the middle ear and finally, the inner ear cavity, including the inner portion called the cochlea which resembles a snail shell. The semi-circular canals which are tied into this cavity have nothing specifically to do with hearing, but they may be affected by many conditions that exist in the inner ear. We call these semi-circular canals the spirit-level of the human body because they help us keep our balance. The outer ear consists of the pinna, including ear lobe, which is used to collect or channel sound into the ear canal which in turn carries the sound to the eardrum. The ear canal averages about 3/8" in diameter and 11/4" in length. It ends at the eardrum which is a membrane that, in good condition, completely seals the inside end of the ear canal. The eardrum separates the outer ear from the middle ear. The cavity of the middle ear contains the three smallest bones in the human body: the hammer, the anvil and the stirrup. Together these are called the ossicles. They form a mechanical linkage which transmits movement of the eardrum (to which the hammer is connected) to an oval window which separates the middle ear from the third section called the inner ear. The ability to conduct movements of the eardrum to the oval window can be impaired through damage to the ossicles. These are bones and are subject to the same damage that effects other bones in the body, such as breakage of calcification. Through modern surgical techniques, any or all of these bones may be replaced. The inner ear contains the analysing function of the human hearing system, located in that portion called the cochlea. In size, the middle and inner section of the ear together are no bigger than your little fingernail. May 2008 217 In cross-section the cochlea, which is filled with a lymph fluid, looks like a snail shell. Within this is a series of levels on which are located 30,000 minute hair cells. As movement of the eardrum is transmitted through the ossicles to the oval window, a pulsating or wave effect is generated inside the cochlea. The movement of this wave stimulates the hair cells in proportion to the tone and loudness of the sound. Each little hair cell when stimulated will discharge a minute amount of electrical current which is transmitted along the auditory nerve to the brain where the pulse is translated into the sense of hearing. Hearing loss due to excess noise directly affects the ability of the inner ear to receive sound, because the hair cells can become permanently deflected and thus lose their ability to pass the sound wave along. Once the ability to distinguish sound is lost in this location, it can never be restored. There are two types of hearing losses of the human ear, conductive and sensory neural. Conductive loss of hearing may occur in either the outer or middle ear; this is a loss of the ability to conduct vibrations to the inner ear. Damage to the pinna - or outside part of the ear can reduce its ability to collect and focus sound into the ear canal. The ear canal can become infected because of foreign bodies; it can also become plugged with ear wax. Either of these conditions should be checked and treated by competent medical personnel. Background The Control of Noise at Work Regulations 2005 came into force on 6 April 2006. The new regulations implement the European Union's Physical Agents (Noise) Directive within Great Britain. These regulations bring significant changes to the actions which were required by employers and employees under the previous Noise at Work Regulations 1989. Employers now have extra responsibilities, and noise exposures and level limits are lower. The Regulations cover not only the obviously noisy industrial premises and construction sites, but virtually all workplaces with few exceptions, including workplaces where the risk of the noise may not be immediately obvious. So they apply for example, to motorcycle couriers, and to call centre workers who are exposed to noise (including speech) through headphones. The regulations also cover the self-employed, as employers and employees. An outline of the regulations is given below. The previous Noise at Work Regulations 1989 continue to apply to the entertainment industry for a transition period. The effects of exposure to excessive noise Health Effects Acute •Acoustic trauma •Physical stress •Excessive fatigue •Temporary Threshold Shift •Temporary Tinnitus Chronic May 2008 218 •Permanent Threshold Shift (NIHL) •Permanent Tinnitus Safety Effects •Increased likelihood of human error Terminology Decibel db(A) The Decibel dB is a sound's intensity, or loudness or volume is measured in Bell's, named after Alexander Graham Bell. A Bell is a very large measurement so the loudness scale is shown in decibels Frequency The number of pressure variations per second is called the frequency of the sound, and it measured in Hertz (Hz). The frequency of a sound produces its distinctive tone. Thus, the rumble of distant thunder has a low frequency, while a whistle has a high frequency. The normal range of hearing for a healthy young person extends from approximately 20 Hz up to 20 000 Hz (or 20 kHz) Frequency Ratings The following frequency weightings are defined by the Standards to which sound level meters are designed. ‘A’ Weighting The ‘A’ Frequency Weighting network is the most widely used, and is used to represent the response of the human ear to loudness. Measurements made with this frequency weighting will be displayed as dB(A) or dB(A). ‘C’ Weighting This frequency weighting has a wider frequency range than ‘A’ weighting, and is often used for the measurement of noise levels from machinery. ‘C’ weighting gives much more emphasis to low frequency sounds than the ‘A’ weighting response ACCEPTABLE AND UNACCEPTABLE LEVELS OF NOISE Action Values and Limit Values The Control of Noise at Work Regulations 2005 specify action values and exposure limit values for daily personal noise exposure (or weekly personal noise exposure) and peak sound level. Daily personal noise exposure (LEP,d) is a measure of the total noise received by an employee over the working day. Daily personal noise exposures depend both on noise levels experienced at work and on the time spent in the noise. A high level noise for a short time will give the same noise exposure as a lower level noise for a longer time, if the total sound energies of the two noises are the same. For an eight-hour working day, the average noise level over the eight hours is numerically equal to the daily personal noise exposure. For example, an employee working for 8 hours in a noise level of 75 dB(A) will have a noise exposure of 75 dB(A) LEP,d. However, if the time spent is less than 8 hours the noise exposure will be less than 75 dB(A) LEP,d, and if the time is longer than eight hours the noise exposure will be more than 75 dB(A) LEP,d. Most international standards are based on an 8 hour time weighted average (work shift). May 2008 219 Weekly personal noise exposure (LEP,w) is a measure of the total noise received by an employee during a working week. It is similar to the daily noise exposure but is calculated for a 40-hour week (five 8-hour days) instead of an 8-hour day. Useful where the worker is sporadically exposed to excessive noise e.g. a supervisor. Peak sound pressure level (LCpeak) is the instantaneous C-weighted peak sound pressure level occurring at any time during the working day. In the European Union the limits for noise exposure are as follows; The lower exposure action values are 80 dB(A) LEP,d or 80 dB(A) LEP,w - i.e. a daily or weekly personal noise exposure of 80 dB(A) 135 dB(C) LCpeak - i.e. a peak sound pressure level of 135 dB(C). The upper exposure action values are 85 dB(A) LEP,d or 85 dB(A) LEP,w - i.e. a daily or weekly personal noise exposure of 85 dB(A) 137 dB(C) LCpeak - i.e. a peak sound pressure of 137 dB(C). The exposure limit values are 87 dB(A) LEP,d or 87 dB(A) LEP,w - i.e. a daily or weekly personal noise exposure of 87dB (A); i.e. a daily or weekly personal noise exposure of 87 dB(A) 140 dB(C) LCpeak - i.e. a peak sound pressure of 140 dB(C). The exposure action values are ambient noise levels in the workplace at the worker's location and do not take into account the effect of any hearing protection. The exposure limit values however, do take the effect of hearing protection into account. Actions required General - assessment of risk Employers must ensure that risk from the exposure of his employees to noise is either eliminated at source or, where this is not reasonably practicable, reduced to as low a level as is reasonably practicable. If one of the lower exposure action values is likely to be exceeded, an employer needs to carry out a risk assessment to assess whether any employees are likely to be exposed to noise at or above a lower exposure action value, an upper exposure action value, or an exposure limit value The risk assessment should consider (a) the level, type and duration of exposure, including any exposure to peak sound pressure; (b) the effects of exposure to noise on employees whose health is at particular risk from such exposure; (c) any effects on the health and safety resulting from the interaction between noise and the use of cytotoxic substances at work, or between noise and vibration; (d) any effects of noise on audible warning signals or other sounds that need to be audible for safety, or in order to reduce risk at work; (e) any information provided by the manufacturers of work equipment; (f) the availability of alternative equipment designed to reduce the emission of noise; (g) any extension of exposure May 2008 220 to noise at the workplace beyond normal working hours, including exposure in rest facilities; (h) appropriate information obtained following health surveillance, including, where possible, published information; and (i) the availability of personal hearing protectors with adequate attenuation characteristics. At and above a lower exposure action value Where noise exposures exceed the lower exposure action value the employer must make suitable hearing protection available to any employee who wants to use it, though employees do not have to wear it. The employer must also provide information and training on (a) the nature of risks from exposure to noise; (b) the organisational and technical measures taken in order to reduce noise exposures; (c) the exposure limit values and upper and lower exposure action values; (d) the significant findings of the risk assessment; (e) the availability and provision of personal hearing protectors and their correct use; (f) why and how to detect and report signs of hearing damage; (g) the entitlement to health surveillance and its purposes; (h) safe working practices to minimise exposure to noise; and (i) the collective results of any health surveillance undertaken. At or above an upper exposure action value If any employee is likely to be exposed to noise at or above an upper exposure action value, the employer must reduce exposure to as low a level as is reasonably practicable by establishing and implementing a programme of organisational and technical measures, excluding the provision of personal hearing protectors, which is appropriate to the activity. (a) other working methods which reduce exposure to noise; (b) choice of appropriate work equipment emitting the least possible noise, taking account of the work to be done; (c) the design and layout of workplaces, work stations and rest facilities; (d) suitable and sufficient information and training for employees, such that work equipment may be used correctly, in order to minimise their exposure to noise; (e) reduction of noise by technical means; (f) appropriate maintenance programmes for work equipment, the workplace and workplace systems; (g) limitation of the duration and intensity of exposure to noise; and (h) appropriate work schedules with adequate rest periods. The provision of hearing protectors is a last resort, to be used where the preferred methods of reducing noise exposures (engineering controls) are not reasonably practicable. Hearing protection zones must be marked and employees must wear the protection provided when in the zones. Health surveillance including audiometric testing should be provided for employees if daily exposures regularly exceed the upper action values. The health surveillance is likely to be required even if hearing protection is worn, to provide a check on the effectiveness of the protection. At or above an exposure limit value The exposure limit values must never be exceeded. If a limit value is exceeded the employer must identify the reason and take steps to ensure that it does not happen again. May 2008 221 ACTIVITY LIKELY NOISE EXPOSURE LEP,d Average Range Agent (up to 50% day on site) <80 Asphalt paving <85 Blasting 100+ Bricklayer 83 81-85 Carpenter 92 86-96 Concrete chipping/drilling 85+ floor finishing 85 grinding 85+ Concrete worker 89 Crushing mill worker 85+ Driver crawler tractor 85+ dumper 85+ excavator <85 grader 85+ loader <85 roller 85+ wheeled loader 89 wheeled tractor <85 supervising pour 96 surveying <80 Engineer May 2008 222 Foreman supervising workers Formwork setter Ganger 92 89-93 concrete pour 93 92-93 general work 94 Uniting Labourer M&E installer 80 85+ concrete pour 97 digging/scabbling 100 general work 84 shovelling hardcore 94 shuttering 91 general 89 Piling operator 85+ Piling worker 100+ Reinforcement worker Sandblasting building site 86 95-98 82-96 82-89 85+ Engineering controls have to do with limiting sound output of equipment as used. This may be accomplished in the initial ordering of the equipment or by noise reducing enclosures. There are 5 types of Engineering Control which we remember as AIIDS; Absorption – is the reduction of reflected sound energy by the use of porous materials such as foam, mineral wool and curtains such as in wall linings, and acoustic screens in open plan offices. Insulation – is the use of absorbent materials inside the piece of equipment to prevent the noise actually emerging from the machine, an example would be the lagging used on the inside of a car engine compartment. Isolation – separation of the person from the noise source by a physical enclosure such as an acoustic booth, putting the compressor in a separate room or by putting the operator in an acoustic haven depending upon what is considered to be most reasonably practicable. Damping – the use of rubber, cork, stiffening ribs and springs to reduce the structural; borne noise e.g. by stiffening panels and using rubber grommets in fixings. Silencing – these are used to suppress the noise generated when an energy (air, gas or steam) flows in pipes or ducts and is exhausted to atmosphere, and work by using baffles to absorb the energy on its pathway. May 2008 223 VIBRATION Introduction Exposure to vibration, i.e. contact with a "shaking" object, is a common occupational hazard in construction which, if left uncontrolled, can cause physical discomfort, a reduction in productivity and adverse health effects. The two transmission routes for vibration are wholebody vibration and hand-arm vibration. It can also occur through airborne "vibration" i.e. high-level sound. Whole-body vibration This is vibration which is transmitted to the whole-body of a person who is in direct contact with a vibrating surface and consequently affects all the body organs. Associated symptoms include dizziness, headaches, nausea, weight loss, varicose veins, blurred vision, spinal damage, rectal bleeding, lung damage and in some cases heart failure. The effects are often reversible once exposure ceases. The most dangerous frequencies from a work point of view are between 60 and 70Hz, which affects the eyeball, causing blurred vision, and 10 and 20Hz, which affects the brain and induces sleep. Typical construction examples; Construction vehicles Rollers/compactor Piling rigs Hand-arm vibration This is vibration which is transmitted to the hands and arms through direct contact with a vibrating tool; it is generally more serious than whole body vibration. The main effect is a thickening of the arteries carrying blood to the fingers thus impeding the flow of blood which results in blanching (whitening) of the fingers and eventually the hands. In extreme cases, the blood vessels become completely blocked and tissue death (gangrene) occurs, possibly leading to amputation. The effects are made worse by secondary factors such as smoking. The most damaging frequencies are between 5 and 20Hz. Typical construction examples; Percussive tools Chain saws Scabblers Stihl Saws Vibrating pokers Grinders May 2008 224 THE CONTROL OF VIBRATION AT WORK REGULATIONS 2005 Background The above Regulations came into force on 6th July 2005. They impose duties on the employer to protect employees who may be exposed risks from either hand-arm or wholebody vibration at work, and others who might be affected by the work. These regulations set out specific requirements for the control of health risks from exposure to both hand-arm and whole-body vibration in the workplace. Hand-arm vibration is vibration transmitted from work processes into workers' hands and arms. It can be caused by operating hand-held power tools (e.g. hammer drills), hand-guided equipment, (e.g. powered lawnmowers), or by holding materials being processed by machines, (e.g. pedestal grinders). Hand-arm vibration is the cause of significant ill health such as painful and disabling disorders of the blood vessels, nerves, joints and muscles of the hands and arms with an increased risk of symptoms for those working in cold and wet conditions. An example of such a condition is Vibration White Finger. Whole body vibration is shaking or jolting of the human body through a supporting surface (usually a seat or the floor), for example when driving or riding on a vehicle along an unmade road. Risks can occur where any commercial/industrial/ construction vehicles are driven regularly for most of the day particularly on rough ground. Vehicles such as vans, which are normally driven on well maintained public roads, may also expose their drivers to some whole body vibration, but the levels are likely to be relatively low and therefore the likelihood of related health risks is low. Some drivers of road-going vehicles may report back pain, but this is more likely to be caused by other factors such as poor posture, prolonged periods confined to the driver's seat or doing related work such as regular manual lifting and carrying of vehicle loads. Like many other pieces of health and safety legislation there is a requirement to: • Carry out risk assessment of the risks to health created by vibration at the workplace. • Eliminate or control exposure to vibration in the workplace. • Provide health surveillance if the risk assessment indicates that there is a risk to the health and safety of employees who are, or are likely to be, exposed to vibration: or, as mentioned above, if employees are likely to be exposed to vibration at or above an EAV. • Provide suitable and sufficient information, instruction and training where the risk assessment indicates that there is a risk to health or where exposure is likely to be at or above an EAV. The Regulations introduce an exposure action value(EAV) and an exposure limit value (ELV) for daily exposure to vibration (see below). The exposure action value (EAV) is a daily amount of vibration exposure above which employers are required to take action to control exposure so far as is reasonably practicable. So the greater the exposure level, the greater the risk and the more action needed to reduce the risk. The exposure limit value (ELV) is the maximum amount of vibration an employee may be exposed on any single day. May 2008 225 The Regulations Summarised: require risk assessment; require elimination or, where elimination is not reasonably practicable, reduction of exposure to as low a level as reasonably practicable; absolute duty for action to be taken when exposure is at a limit value; allow weekly averaging of exposure to vibration in specific circumstances; require health surveillance; and require information, instruction and training to be provided to staff who may be exposed to vibration at work. In Detail The Regulations allow a transitional period for the exposure limit value until July 2010 (or until 2014 for the agricultural and forestry sectors). This only applies to machines or vehicles first supplied to staff before July 2007. The exposure limit value may be exceeded during the transitional periods so long as you have complied with all the other requirements of the regulations and taken all reasonably practicable actions to reduce exposure as much as you can. Duties of Employers The Control of Vibration at Work Regulations 2005 states that employers must: • Assess the risk of vibration to your employees • Decide if the employee is likely to be exposed above the daily exposure action value (EAV) and if they are: - eliminate the vibration risk or reduce exposure to as low a level as is reasonably practicable - provide health surveillance to employees who continue to be at potential harm • Decide if the employee is likely to be exposed above the daily exposure limit value (ELV) and if they are: - Reduce their exposure below the ELV • Provide suitable and sufficient information, instruction and training to your employees on the health risks associated with vibration and the actions you are taking to address these risks • Consult with trade union or non-union representatives on your methods of controlling risks and health surveillance • Keep records of risk assessments and the actions taken to control the risks presented • Keep records of health surveillance for employees working with vibration • Regularly review and update risk assessments relating to vibration Duties of Employees The Control of Vibration at Work Regulations 2005 also places duties on employees. Employees must: • Present themselves for Health Surveillance if the risk assessment indicates a risk to health May 2008 226 Exposure Levels The assessment should include control measures required to meet the requirements of the regulations. When completing the assessment the employer should take into account the magnitude, type and duration of exposure including exposure to intermittent vibration or repeated shocks, effects of vibration on employees, workplace and work equipment, information provided by the manufacturers of the equipment, specific working conditions, alternative equipment and health surveillance information. The regulations define daily exposure as the quantity of mechanical vibration a worker is exposed to during a working day, averaged over an 8 hour reference period, which takes into account the magnitude and duration of the vibration. There are 2 levels of exposure that require identification and action: Exposure action value - when the level of daily exposure for any worker if reached or exceeded requires specified action to be taken to reduce the risk. For hand arm vibration this is 5 m/s2. For whole body vibration this is 1.15 m/s2. Exposure limit value - the level of daily exposure for any worker must not be exceeded, except where other levels are defined. For hand-arm vibration this is 2.5 m/s2 . For whole body vibration this is 0.5 m/s2. Within the regulations there are details on how to calculate the exposure levels. The employer is required to eliminate the vibration at source or reduce it to as low a level as reasonably practicable. Also the employer is required to ensure that employees are not exposed to vibration above the exposure limit value. Where the vibration level is usually below the exposure action value but varies markedly, it may occasionally exceed the exposure limit value provided that any exposure averaged over a 40 hour week is less than the exposure limit value, there is evidence that the risk from the actual pattern of exposure is less than the corresponding risk from constant exposure at the exposure limit value, the risk is reduced and the employees affected have increased health surveillance. Health surveillance should take place on employees exposed to vibration. Appropriate information and training should be provided to employees at risk from exposure to vibration. There is no specific legislation covering vibration so employers must apply the provisions of the Management of Health and Safety at Work Regulations 1999, particularly the requirement to carry out a risk assessment, to any work which involves exposure to vibration, whether whole-body or hand-arm. The general duties to ensure the health and safety of employees at work, so far as is reasonably practicable, under the Health and Safety at Work, etc Act 1974 (HSW Act) also apply. There is however HSE Guidance literature available: HS (G) 88: Hand-Arm Vibration IND (G) 126L: Hand-Arm Vibration: Advice on Vibration White Finger for Employees and the Self employed INDG175L: Hand-arm Vibration: Advice for Employees May 2008 227 Vibration exposure The adverse health effects caused by exposure to whole-body and hand-arm vibration have been known for some time. The case of Armstrong and Others v British Coal Corporation confirms the date of knowledge as 1973, i.e. from this date employers should have been aware that there are adverse health effects associated with work-related exposure to vibration. Risk Assessment A vibration risk assessment should identify: 1. 2. 3. 4. 5. 6. what the vibration hazards are, e.g. tractors, drills, etc. the type of vibration, its frequency and duration who is at risk what control measures are already in place what the resulting risk evaluation is what additional control measures are necessary (if any) Particular at risk employees Both pregnant women and young persons are recognised as being at particular risk from exposure to vibration, especially whole-body vibration. In pregnant women such exposures may increase the chance of miscarriage and possibly premature births and low birth weights. Young people are at risk because of their physical immaturity - common problems include back pain and spinal disorders as their back muscles and bones have not fully developed and strengthened. They may also be unable to perceive the risks associated with vibrating tools etc. Vibrating machinery and tools The Supply of Machinery (Safety) Regulations 1992 require the suppliers of hand-held or hand-guided machinery to provide instructions on the correct installation of that machinery in order to control any associated vibration. Suppliers must also provide information on the vibration levels that operators are likely to be exposed to. In addition, the Provision and Use of Work Equipment Regulations 1998 require equipment used at work to be suitable for its intended task - part of this includes taking into account any inherent risks to the operator. Effective planned preventive maintenance programmes will help prevent machinery and tools vibrating through wear and tear. Health surveillance Given the progressive nature of many ill-health conditions associated with exposure to vibration, employers should consider pre-employment medical examinations for all new employees who will be exposed to vibration. This will establish the exact state of any preexisting conditions and if necessary may form a basis for the defence in claims made by employees for personal injury. It will also help to establish employees who may be at special risk when exposed to vibration, e.g. smokers and pregnant women. Generally speaking, where a relevant condition already exists it will be advisable to avoid offering such work in situations where the vibration cannot be dampened. Initial health checks should be repeated after six months and then annually unless a valid reason becomes apparent for more frequent checks. May 2008 228 The provision of information, instruction and training to employees in the use of tools, damping measures and reporting relevant health concerns are important. Parts of the body particularly susceptible to vibration The parts of the body affected by the vibration will depend on the type of vibration, its frequency and the duration. However, all parts of the human body have different natural resonances which means that they will amplify any vibration which is at the same frequency as their natural resonance, i.e. the overall effects of the vibration will be increased - in some cases the amplification can be up to four times that of the original vibration. The frequency ranges for some of the most susceptible body parts, where harm on exposure to vibration is likely to occur, are: Upper torso 4-8Hz Head 25Hz Eyeball 30-60Hz Hand 50-150Hz. Control measures for whole-body vibration are as follows: - design out vibration - use low-frequency seats in all terrain and similar vehicles - suspension of driving seats - maintenance - damping of high-vibration surfaces - use of rubber mats under feet - job rotation - isolation of operator from vibrating source - isolation of vibrating machine from its surroundings - substitution with less hazardous alternative equipment - process re-design to eliminate the need for vibrating tools Control measures of hand-arm vibration include: - design out vibration - use of low-vibration tools - correct installation of machinery - maintenance - training - personal protective equipment (PPE) including warm gloves - reduced time exposure May 2008 229 THE THERMAL ENVIRONMENT The human body requires to be maintained within a limited range of environmental conditions (temperature, humidity, lighting, noise etc.). Thus the workplace is important since it effects the health and safety of people at work. All employers have a duty under section 2 of Health and Safety at Work Act 1974 to ensure the health and safety and welfare at work of all employees, so far as is reasonably practicable. A comfortable work environment will depend on many factors including temperature, humidity levels and the rate of air flow. Legislation covering temperature includes: Workplace (Health, Safety and Welfare) Regulations 1992 The Construction (Design and Management) Regulations 2007 Provision and Use of Work Equipment Regulations 1998 Health and Safety (Display Screen Equipment) Regulations 1992 Manual Handling Operations Regulations 1992 Personal Protective Equipment Regulations 1992 The recommendation is that a minimum 16 0 C is provided and maintained for sedentary work but where physical work of a strenuous nature is undertaken, this may drop to 13 0 C. Where it is not reasonably practicable to achieve this e.g. outdoors, in a cold store or on a construction site, then it would be necessary to achieve this minimum temperature by use of personal protective equipment (warm clothing). There is no statutory maximum temperature, but this too must be reasonable. A thermometer must be on display in every factory workroom where sedentary work is carried out. In offices and shops it is sufficient to locate a thermometer on each floor of the building. Effects of Heat In general at temperatures much below 15 0 C and 25 0 C the concentration of workers suffers and to obtain safe and efficient working, extra control measures should be considered (see later in this section). The body's vital biochemical processes are sensitive to changes in temperature, these processes produce heat and relatively small rises in temperature increase their speed of reaction. Hence, living cells can not withstand large rises in temperature causes loss of control over the biochemical processes. In the event of temperature rise occurring, enzymes may be inhibited or, as a more severe effect, inactivated permanently. Enzymes are proteins and the effect of temperature rise on proteins is to cause them to become denatured. This is an irreversible change demonstrated by the difference between hard and soft-boiled eggs. Cellular biochemistry is sensitive to decreases in temperature, which cause it to slow down. The slowing down of cellular biochemistry is innately less damaging than its speeding up. Unless the temperature falls so low that ice crystals form within cells, the changes from moderate cold are largely or wholly reversible. This explains why, at the cellular level, rises in temperature are essentially more damaging than decreases. May 2008 230 The Thermal Environment Normal body temperature is somewhere in the range of 36 to 37.5 0 C. Metabolism produces heat and therefore most of the time the body is warmer than the surroundings and loses heat. When the rate of heat loss is not significant, we are neither too warm nor too cold and therefore thermally comfortable. Thermal stress occurs when the body core temperature rises by a significant amount. A number of indices have been developed which take into account the main factors: a) b) c) predicted four hour sweat rate (P4SR) Belding and Hatch heat stress index (HSI) wet bulb globe temperature (WBGT) As well as gaining heat, the body can lose heat too rapidly. The rate of loss can be accelerated when very cold winds are blowing, (Arctic conditions), known as the wind chill factor. This is not uncommon in construction. Thermal comfort can be achieved by raising or lowering air temperature as appropriate, increasing or reducing rates of air movement, especially around the head, by increasing the radiation from surroundings, or by increasing or reducing the insulation of clothing. Hot temperatures There are a number of possible effects arising out of work in a hot environment such as a construction site in mid-summer. Dehydration - The body’s response to a rise in temperature is to increase sweating. The normal daily sweat rate ranges from 500 to 900 millilitres (between one and two pints). However, when working in extremely hot temperatures this can increase up to 1.7 litres (3 pints) per hour up to a maximum of about 12 litres (21 pints) over a 24-hour period. If this water is not replaced then dehydration will result. Heat Exhaustion - this condition occurs due to a lack of salt intake or of water intake or a combination of both. The symptoms are lethargy, giddiness, headache, loss of appetite, and sometimes muscle cramps and nausea. Heat Stroke - this is a more severe from of heat exhaustion. Here the body temperature rapidly rises due to the bodies heat regulating system failing. This is a very serious condition and if left untreated, the victim may die within one to two hours. The onset is sudden, with symptoms of dry skin (whilst everyone else around is sweating) vomiting, collapse and death. Heat Cataracts - a cataract is an opacity of the lens, giving the eye a milky appearance. The result is a gradually increasing mistiness of vision. It is caused by excessive exposure to heat and microwaves, and is common in glass blowing and chainmaking where there is direct exposure to furnaces. Radiant Heat burns - the ultraviolet light from heat can produce skin burns which are essentially the same as sunburn with a reddening of the skin, then to a blistering and finally to a weeping and peeling – second degree burns! May 2008 231 If hot work cannot be avoided then there are certain possible precautions which can be taken: Acclimatisation – is the physiological adaptation of the individual to extreme temperatures. Time is required for the various systems to adapt to the new conditions and this normally takes between one to three weeks depending upon the person and the situation. Drinking large amounts of fluids – It is necessary for those working in hot environments to learn to drink little and often. The thirst sensation is thought to diminish when the body is lacking salt, and in addition, a peculiarity of human beings is that thirst is satisfied when only about 75% of the water requirement is made good. Prevention therefore depends on drinking water (ideally salted) past the point of thirst quenching. Work breaks – when control is by change to work/rest regimes, the rest period is preferably taken in an environment which is less extreme. Taking frequent breaks to chiller rooms will allow the body to rapidly cool. Other options include reducing the duration of work exposure and/or changes to work/rest regimes. Ventilation – lack of air movement is one of the most common problems relating to thermal discomfort in the workplace. If ventilation is increased, air temperature has also to be increased to compensate for greater cooling. The rate of heat loss is effected by the amount of air movement, since sweat will evaporate more quickly when air is passing over the skin surface. At its most simple this can be achieved by providing fans. Control of humidity – humidity is the amount of moisture in the atmosphere, and is critical since it influences the body’s ability to lose heat. The more humid the atmosphere, the slower the rate of evaporation of sweat from the skin surface, and so the hotter the body becomes. So a comfortable level of humidity needs to be provided and maintained. Suitable Clothing - by improving insulation in garments, by water or air cooling of the body, (e.g. ice vests), and wearing reflective and heat resistant clothing. Screening against radiant heat – an effective precaution against radiant heat includes the use of screening e.g. furnace doors etc. Health Surveillance – is the regular monitoring of the state of health of individual workers and can be useful in identifying the early signs of heat related problems. Cold Temperatures There are a number of possible effects arising out of work in a cold environment such as a construction site, agriculture, fishing etc, and these can be: Rapid fatigue Shivering Loss of hand dexterity Cold burns May 2008 232 Frostbite – which is a result of severe narrowing of fine blood vessels at the extremities leading to blackening and death of effected tissue. Hypothermia – which is a general lowering of the core body temperature. It is typified by fatigue, and apathy, mood swings and eventually death. If cold work cannot be avoided then there are certain precautions which can be taken. These control measures would include much of what is discussed above plus: Wearing of PPE, especially on the whole body in order to avoid hypothermia and frostbite to the extremities. Entering the cold area for the least amount of time Monitoring of the worker by fellow employees Fail to safe locking mechanism or alarms inside cold stores RADIATION Radiation may be defined as the process of emission of energy as waves or particles The spectrum of radiation, in declining order of wavelength is: radio waves microwaves infra red visible light ultra violet ionising radiation Long waves Short waves A definition of ionising radiation is radiation that produces ionisation in the material that it passes through. This can be electromagnetic (as with X and Gamma) or particulate (as with alpha and beta particles). Ionisation is the process whereby a neutral atom or molecule acquires an electric charge when it interacts with radiation. IONISING RADIATION Radioactive sources Sources of ionising radiation may be either sealed (as with a gamma source for nondestructive testing) or unsealed (as with luminising compounds and some material used for laboratory purposes). In the latter instance, the control of the workplace is vital, since this may itself become contaminated as with any toxic substance. May 2008 233 Radioactive sources have been used for the following purposes: smoke detection, radiography, medical diagnosis, cancer treatment, level indicators, luminising. X-ray sets are used for: medical diagnosis, X-ray crystallography, in airport security for examining baggage, in organisations for examining letters and parcels and for radiography. Alpha particles An alpha particle consist of two protons and two neutrons bound together. These are helium nuclei and there are, positively charged. They are ejected from the nucleus of the radioactive substance with considerable energy, but are relatively large particles and are easily absorbed by matter. They are commonly used in smoke detectors. Beta particles These are electrons, not from the orbiting electrons of the atom but within the nucleus. They are ejected with great speed and have a range of up to 15 cm in air. These are used in paper manufacture where beta radiation is passed through the paper and detected on the other side. The thicker the paper the weaker the radiation passing through, and so the rollers which control the thickness of the paper are adjusted accordingly. Gamma rays These are very high-energy electromagnetic waves that are emitted at the same time as the alpha and beta particles. They are similar in nature to light but of very much shorter wavelength. They are very highly penetrating, being capable of passing through several centimetres of lead. Radionuclides are normally described in terms relating to their activity, i.e. the rate at which spontaneous decay occurs. This is expressed in Becquerals (Bq). One Becqueral corresponding to the decay of one radionuclide per second. The amount of time taken for a radioactive substance to decay to half its activity is described at its half-life (tl/2). This is a unique property of each radionuclide, and can range from fractions of a second to millions of years depending on the substance. Radiation generating equipment is usually described in terms of energy at which the radiation is produced. This is in units of electron volts (ev). This is the equivalent to the energy gained by an electron passing through a potential difference of one volt. Multiples of this unit are frequently used, especially one million electron volts (MeV). Gamma ray radiation is used in non-destructive testing, typically in the checking of the integrity of welds on pipelines. May 2008 234 Radiation - preventative and protective measures For sealed radioactive sources there are three basic principles: a. TIME b. DISTANCE c. SHIELDING Time Reducing the time spent in a radiation field obviously reduces the accumulated dose as DOSE = Dose Rate x Time. Time taken to undertake a task can often be reduced by pre-planning and practice runs. Distance Increasing the distance from a source decreases the dose rate and dose. This is due to the inverse square law. Doubling the distance decreases the dose by 25%. Shielding Interposing material between the source and the person will reduce dose rates. The effectiveness depends on the type of radiation and its energy and the type of shielding used. Alpha radiation Is easily absorbed by a thin sheet of paper. Beta radiation Is more penetrating and requires about 10mm Perspex for complete absorption. When beta particles are slowed down their kinetic energy is turned into X radiation call Bremstrahlung. The more rapidly they are slowed down, the more penetrating the X-rays. For this reason, light materials e.g. aluminium or Perspex are used. Gamma radiation Unlike alpha and beta radiation, gamma radiation is never completely stopped, only reduced in intensity. As most of the gamma interactions in matter are with electrons, materials with high mass numbers (and hence high electron densities) are chosen for shielding. Typical materials are lead, etc, other materials may be chosen for cheapness e.g. water. Radiation monitoring instruments These fall into three categories: Geiger - Mueller tubes, Ionisation chambers and scintillation counters. Effects of radiation exposure The effects of radiation exposure can be of two types: Somatic effects Somatic effects are those which may be observed in those who are exposed to radiation, reddening of the skin, hair loss, cataracts, skin ulcerations etc. and include: death from leukaemia (radiation damage to blood-forming bone marrow) eurethyma (reddening of the skin) skin damage May 2008 235 breast cancer epilation lung tumours Genetic effects Genetic effects are those which are not so easily observed in those exposed to radiation, genetic, blood disorders etc.. Hereditary Effects death of a germ cell = reduced fertility chromosome damage = cells may not survive reproduction gene mutation = most gene mutations are recessive IONISING RADIATIONS REGUALTIONS 1999 (IRR 99) Background Legislative controls contained in the Ionising Radiations Regulations 1999 require employers to assess any risks of exposure to ionising radiation and reduce such exposures so far as is reasonably practicable. Strict control measures are given along with detailed dose. These Regulations came into effect on 1st January 2000. Notification and assessment Before starting work with ionising radiation, employers must carry out a suitable and sufficient risk assessment. Additionally, the Health and Safety executive (HSE) must be notified of work with ionising radiation at least 28 days before work is due to start. Radiation Protection Advisers The regulations require a ‘suitable and sufficient’ risk assessment before work commences with ionising radiation by a competent person. This competent person is known as the Radiation Protection Adviser (RPA). Additionally the employer shall consult an RPA on how to comply with IRR99 before undertaking work with ionising radiation. Radiation Protection Supervisor It will be the role of the RPS to monitor compliance with the requirements of IRR99 and to see that Local Rules are observed. The legal duty for ensuring compliance with the regulations remains with the radiation employer. Control measures These might include engineering and design controls such as shielding, ventilation, containment and minimising contamination, as well as safety features and warning devices. In addition, there must be detailed working arrangements for all work with ionising radiation and eating, drinking, smoking, taking snuff and applying cosmetics is prohibited in all “controlled areas”. Personal protective equipment may only be used as a last resort where adequate control cannot be achieved by other means. Dose limits Dose limits specified in the Regulations are both internal and external doses over a calendar year, and include values for the whole body, individual organs and the eye lenses. Further May 2008 236 dose limits are given for the foetuses of pregnant women. Workers who have received an overdose may not usually continue working with ionising radiation. “Classified persons” and other specified persons must be provided with personal dosimeters. Workers who have received an overexposure of ionising radiation must undergo medical surveillance. Record Keeping Certain records relating to ionising radiation must be maintained: Dosimeter exposure records (50 years) Health records of medical surveillance (50 years) Records for monitoring instrument performance tests (2 years) Accurate accounts of radioactive materials Radioactive substances The Radioactive Substances Act 1993 regulates the storage, use, accumulation and disposal of radioactive materials, and is administered by the Environment Agency. Certificates of registration and authorisation are required for the storage/use and the accumulation/disposal of radioactive materials. NON-IONISING RADIATION There are numerous types, sources, and common effects upon the human body, of nonionising radiation. Below are some examples. Radiation Emitted from Examples of Hazards Radio frequency and microwaves Plastic welding, action catering, drying and heating equipment Excessive heating of exposed parts of the body, cataracts Infra-red Any hot material Visible Radiation All visible light sources. High intensity beams, e.g. lasers, are especially penetrating Ultra-violet Welding, some lasers, mercury vapour lamps carbon arcs Reddening of skin, burns cataracts Heating and destruction of tissue 'sunburns', conjunctivitis, skin cancer, production of toxic levels of ozone Microwaves and radio frequency Microwaves are emitted at extremely high radio frequencies. Typical examples of use are radar in military installations, certain drying processes and medical diathermy. It is relatively simple to shield such sources since microwaves cannot penetrate even thin metal. Although leakage of radiation from microwave ovens is normally very small, care should be taken to reduce it by cleanliness and maintenance especially of the door seals. If your May 2008 237 microwave oven is used in commercial catering, a regular maintenance contract should include a check on the radiation leakage. Safety interlocks, on the access door for instance, should be checked routinely. Occupational exposure to radio frequency (RF) energy from RF heaters, driers and presses is best minimised by properly designed and installed shielding around the electrode applicator. Systems of work which limit exposure time or approach to the source may also be necessary. Simple techniques can often reduce the risk of deep-seated burns due to contact with energised RF electrodes. Adequate precautions must be taken to make sure that unauthorised persons cannot gain access to the high voltage electrical equipment, e.g. by interlocking all cubicle doors. Infra-red Infra-red radiation is emitted by all hot bodies, particularly radiant fires and furnaces. Long-term exposure to even low doses of infra-red radiation may damage the eyes, burning the lens and causing heat cataracts. Shields which reflect the heat may be installed as a form of protection. Personnel in frequent contact should wear the correct type of eye protection with appropriate filters to overcome discomfort and prevent long term injury. Appropriate clothing will provide some body protection. Low levels of heat stress caused by low levels of infra-red radiation can be minimised by increasing ventilation. Lasers Lasers are being used in industry for distance measurement more and more. (The word 'laser' means Light Amplification by Stimulated Emission of Radiation). These very high energy beams of light are used widely in the construction industry for reference lines, since the beam is straight and does not spread like a torch beam. Lasers are also used for welding and cutting, and in surgery for the sealing of fine blood vessels. The organ most vulnerable to all sources of non-ionising radiation is the eye. A laser beam can destroy the retina, causing blindness. Use of the appropriate goggles can, in most cases, protect the operator from this danger. Even on low powered lasers it is unwise to view the beam directly. Do not override any interlocks provided. Maintenance workers who have to examine inside machines may be most at risk. They need to be properly trained and follow a defined system of work which includes use of eye protection. High powered lasers must only be used with expert advice on safety precautions - which would normally include positioning the devise inside a safety interlocked enclosure. Ultra violet Ultra violet radiation is produced in arc welding and exposure may cause the condition known as 'arc eye'. As with lasers, protection may be obtained by the use of goggles. Ultra violet radiation also burns the skin and may cause cataracts and inflammation of the cornea. All workers exposed to ultra violet radiation must wear the correct type of protective glasses. May 2008 238 During welding, for instance, precautions are needed to screen UV radiation from passers-by; welders should use special goggles or a face screen. Some UV lamps are more dangerous than others. Make sure, particularly when fitting replacements in UV devices, that you choose the correct type specified by the manufacturer. Insect killing devices with bright UV sources are often found in food premises. They are not hazardous to the eyes in normal use and are usually positioned out of reach. STRESS Work related stress affects as many as one in five employees, and has been estimated to cost employers around £370 million and society £3.75 billion each year. It has been defined as ‘the adverse reaction of people have to excessive pressures or other types of demand placed on them.’ The problem with stress is exactly what are excessive pressures upon an individual, since this threshold will change from person to person as it is linked to our personality type. There is an important distinction between beneficial effects of reasonable challenges and pressure which can be stimulating and motivating, and work-related stress which is a natural but adverse reaction to demands or pressures that a person feels unable to cope with. Anyone can suffer from work-related stress. Although not an illness in itself, where the stress felt is prolonged or intense it can lead to ill health effects. These effects include heart disease, back pain, gastrointestinal disturbances, anxiety and depression. Stress can also lead to other behaviours such as excessive smoking, excessive alcohol or caffeine consumption and skipping meals, all of which can contribute to secondary health problems. The problem with stress from a management perspective is that most people cannot keep their private life separate from their work life, so private life issues such as marital problems, illness, financial difficulties and bereavements etc. can all add to the pressure upon that individual. An employer is not under any legal duty to prevent ill health caused by stress due to problems outside of work. But non-work problems can lead to reduced performance. So being understanding to staff in such a position is in the employer’s own interests. The criminal position as regards stress is contained within s2 HASAWA 1974 which requires employers to SFARP ensure the HEALTH, safety and welfare of their employees. Furthermore, the Management of Health and Safety at Work etc Act 1999 requires employers to risk assess all tasks and activities, and where stress may be caused or made worse by work and so could lead to ill health, the employer would be expected to ensure that adequate control measures are implemented. Under civil law employers have their common law duty of care, and any excessive pressure that causes stress in an employee could result in a civil claim. So both criminal and civil law require employers to ensure that employees are not made ill by their work. Control measures to reduce stress can be very cost effective. The costs of stress to an organisation may show up as a high staff turnover, an increase in sickness and absenteeism, reduced productivity, poor timekeeping and increased customer complaints. Stress in one person can also lead to stress in other members of staff who may have to cover for their colleague. May 2008 239 Managers need to understand stress, and the associated signs and symptoms of any such excessive pressure, which will include: Mood swings Deteriorating relationships with colleagues` Weight loss/weight gain Excessive smoking/drinking Frequent headaches Absenteeism Indecisiveness Irritability Poor concentration Trouble sleeping The risk assessment would follow the standard five steps to risk assessment approach; Identify the hazards Culture of the company Demands of the job Lack of control over work activities Inter-personal problems e.g. bullying, harassment, racial abuse Poor communication leading to uncertainty Job ambiguity Identify who and how many employees are at risk Look for signs and symptoms within employees Look for increases in absenteeism Look for lateness Look for disciplinary problems Look for high staff turnover in particular sections or departments. Consult the workforce directly or via safety representatives and/or representatives of employee safety Possibly use one of the off-the –shelf questionnaires to identify problems Annual appraisals Talk to the supervisors Examine the adequacy of existing control measures This really revolves around good management practice and would examine issues such as: Recruitment and selection procedures Organisational structure Competence of all members of staff Adequacy of channels of communication Consultation procedures Physical stressors e.g. extremes of heat, noise, vibration etc. Consider additional control measures SFARP These might include; Provision of access to a confidential counselling service A clear policy on working hours, bullying and harassment. A clear grievance procedure Training on time management for all staff Training on stress and inter-personal skills for managers Delegation of responsibility Clearly defined objectives for all members of staff May 2008 240 Record and review If you employ more than five members of staff then you will need to record the significant findings of any such risk assessment, and review the adequacy of that assessment routinely or whenever you have reason to believe that it is no longer valid. LONE WORKING AND VIOLENCE Lone working may be defined as any work activity which is intended to be carried out in isolation from other workers by an individual or a small team of people. The work activity should normally last for some time. Types of lone working Lone working can take place when people: work as individuals at a fixed site, e.g. in a shop or petrol station are separate from others, e.g. employees working for a building maintenance company work away from their base or at remote locations, e.g. construction workers, work at home work outside normal hours, e.g. cleaners or security staff travel as part of their work, e.g. delivery drivers provide services to the public, e.g. social workers, home helps, community nurses Some construction workers will come into more than one of these categories. Hazards Hazards which lone workers can encounter are: accidents or emergencies arising out of the work including inadequate provision of first aid sudden illnesses inadequate provision of rest, hygiene and welfare facilities violence from members of the public Legal duties of employers For most circumstances, there are no specific legal duties on employers in relation to lone working. However, employers are under a general duty under Section 2 of the Health and Safety at Work Act to maintain safe working arrangements and under Regulation 3 of the Management of Health and Safety at Work Regulations to carry out a risk assessment of the hazards to which their employees are exposed. Where there are more than five employees, the risk assessment must be kept as a permanent record. Employers are under a duty to provide facilities for first aid under the Health and Safety (First Aid) Regulations and welfare under Workplace (Health, Safety and Welfare) Regulations and to report accidents suffered by their employees, including assaults, wherever they occur under RIDDOR - Reporting of Injuries, Diseases and Dangerous Occurrences Regulations. Welfare provision on construction sites is covered by the Construction (Health, Safety and Welfare) Regulations. There are certain activities where there are specific legal duties: erection of scaffolding, use of unsupported access equipment, demolition on construction sites , diving operations May 2008 241 (provision of suitable supervision); young people doing woodworking (supervision plus instruction and training); work with certain chemicals (staffing levels). Risk assessment The key to maximising safety wherever lone work is under consideration is the performance of a satisfactory risk assessment which should address two main features: whether the work can be done safely by a single person what arrangements are required to ensure the lone worker is at no more risk than employees working together The risk assessment should prescribe arrangements for systematic monitoring of the hazards of lone working by qualified supervisors/managers. Staffing levels The critical question is whether the job can be done safely by a single person at all. There is scope for disagreement between an employer primarily motivated by cost considerations and employees and their representatives concerned with safety. The employer should demonstrate that a lone worker is not exposed to extra risk compared to a group of employees doing the same job. Where the job involves a significant risk of violence from the public, doubling of staffing levels will almost always substantially improve security. Remoteness and isolation For a lone worker at a remote location, the following factors must be considered: how long should the work take and how frequently should the worker report in has the worker a safe means of travel to and from the location, especially out of normal hours is there access to adequate rest, hygiene, refreshment, welfare and first aid facilities can emergency services approach the location without hindrance. Procedures for responding to "worst-case" emergencies should be in place Condition of the workplace Appropriate conditions are: there is a safe means of entry and exit to the workplace there is adequate illumination, heating and ventilation for the job to be carried out all equipment, especially powered tools and access equipment such as ladders, can be used safely lifting operations can be performed safely by one person fire precautions are sufficient for the job Home visits especially for the provision of personal care can involve exposure to infectious diseases in addition to other hazards and the condition of premises should be assessed by qualified staff before visits commence. Communications and personal alarms Appropriate communications should be maintained with the lone worker especially when continuing supervision is required. The lone worker should be equipped with a means of twoway communication, a pager or a personal alarm. The system should enable the worker to raise an instant alarm or be located accurately if assistance is required. Rooms used for confidential interviews should be equipped with a hidden alarm. May 2008 242 Preventing violence In addition to the provision of personal alarms, procedures should be devised to minimise the risk of violence from the public, e.g. elimination of handling cash, constant changes of route when transporting valuables, adequate building security for out of hours working. Consideration should be given to the fact that women working alone are particularly at risk. Medical suitability Two points need to be determined: does the job impose any extra demands on the lone worker's physical or mental stamina? does the lone worker suffer from any illness that might increase the risks of the job? Home working If the home worker is an employee, the employer is obliged to carry out a risk assessment of the job and the workplace. This must cover the provision of supervision, education and training and result in sufficient controls to be in place so as to protect the home worker. The employer should accept liability for accident or injury as for other employees. Information and training Sufficient training and information must be provided to the lone workers to enable him/her to identify hazards and take appropriate action to avoid them. S/he must be entitled to leave the workplace if there is serious and imminent danger. Permits to work These are detailed, written instructions provided by the employer on the performance of hazardous activities such as entry into confined spaces or electrical testing, etc. They should specify: check-in arrangements tests of communications equipment length of the work period suitable first-aid equipment equipment, tools and electrical safety checks suitable personal protective equipment suitable manual handling arrangements in bad weather exit to safety after job DRUGS AND ALCOHOL As far as business is concerned there are two main issues associated with drugs and alcohol(DNA): May 2008 DNA-related absenteeism. Alcohol is estimated to cause 3-5% of all absences from work; about 8 to 14 million lost working days in the UK each year3. How much is alcohol-related absence costing your business? The effects of DNA on productivity and safety. Alcohol and drug consumption may result in reduced work performance, damaged 243 customer relations, and resentment among employees who have to 'carry' colleagues whose work declines because of their drinking. There are no precise figures on the number of workplace accidents where DNA is a factor, but they are known to affect judgement and physical co-ordination. Contrary to popular belief, the majority of people who have a drinking problem are in work. The good news is that people with drink problems can and do cut down, and that there are places throughout the country where people with drinking problems can go for expert help. Any business, however small, can and must take practical steps to minimise the risks associated with inappropriate drinking. This booklet includes examples of action taken by businesses to prevent alcohol-related problems. On pages 20-22 there is a list of organisations that can provide further information and help. The Legal Position Employers have a general duty under the Health and Safety at Work etc Act 1974 to ensure, as far as is reasonably practicable, the health, safety and welfare of your employees. If you knowingly allow an employee under the influence of excess alcohol to continue working and this places the employee or others at risk, you could be prosecuted. Similarly, employees are also required to take reasonable care of themselves and others who could be affected by what they do. In the transport industry, there is additional legislation in place to control the misuse of alcohol and drugs. The Transport and Works Act 1992 makes it a criminal offence for certain workers to be unfit through drink and/or drugs while working on railways, tramways and other guided transport systems. The operators of the transport system would also be guilty of an offence unless they had shown all due diligence in trying to prevent such an offence being committed. Management Plan A straightforward process for dealing with alcohol problems at work is set out below. All companies - large and small - can benefit from an agreed policy on alcohol. A model policy is described under Step 3. . You may find it useful to find out from your employees what they know about the effects of drugs and alcohol on health and safety, what they feel currently about taking drugs and drinking alcohol during working hours and their understanding 1. 2. 3. 4. Find out it you have a problem. Make a list of who you need to consult. Decide how your company expects employees to limit their drinking.)policy Consider how you can make sure that if an employee has a possible alcohol problem, this is noticed and help is offered. 5. Decide at what point and in what circumstances you will treat an employee's drinking as a matter for discipline rather than a health problem. 6. Think about how you will let your workforce know about company policy on alcohol - consider introducing a formal written alcohol policy. 7. Find out if any of your managers or other staff need more information or training May 2008 244 UNIT IGC 2, ELEMENT 8 CONSTRUCTION ACTIVITIES – HAZARDS AND CONTROL 8.1 General construction hazards and control An ILO report in 2005 identified the 2 most high risk sectors world-wide as; Agriculture and forestry Construction In certain countries where they are industrialising rapidly, the construction sector will be particularly high risk, similarly in poorer countries, where agriculture and forestry are very labour intensive this will mean that workers here are also at particular risk. Scope of construction The term ‘construction work’ is a very wide ranging and as such includes building, maintenance, renovation and demolition work. 'Construction work' includes the carrying out of any building, civil engineering or engineering construction work, and includes any of the following: a. The construction, alteration, conversion, fitting out, commissioning, renovation, repair, upkeep, redecoration or other maintenance (including cleaning which involves the use of water or an abrasive at high pressure and de-commissioning, demolition or dismantling of a structure, b. the preparation for an intended structure, including site clearance, exploration, investigation (but not site survey) and excavation, and laying or installing the foundations of the structure, c. the assembly of prefabricated elements to form a structure or the disassembly of prefabricated elements which, immediately before such disassembly, formed a structure, d. the removal of a structure or part of a structure or of any product or waste resulting from demolition or dismantling of a structure or from disassembly of prefabricated elements which, immediately before such disassembly, formed a structure, and t e. he installation, commissioning, maintenance repair or removal of mechanical, electrical, gas, compressed air, hydraulic, telecommunications, computer or similar services which are normally fixed within or to a structure, and landscaping. The main hazards are: Falling through fragile roofs and roof lights. Falling from ladders, scaffolds and other work places. Being struck by excavators, fork-lift trucks, dumpers and delivery lorries Vehicles overturning such as dumper trucks and MEWPs Being crushed by collapsing structures Excavation issues such as collapse, striking services, falling into and water Equipment such as cement mixers Site security issues and preventing unauthorised access. Safe stacking and storage of materials and flammable substances Management controls that can be applied for significant construction projects: assessment, selection and control of contractors. May 2008 245 8.2 Working at height Work at height is statistically the most common cause of death in the construction industry. This work accounts for more than half of all deaths in the industry every year, and a significant amount of all major and over 3 day lost time injuries. Typical activities and injuries associated with falls from height It is common for building to be above one story in height, therefore much construction work is done at height. Typical work activities associated with falls from height include; Steel erection Cladding fixing and general roof work Painting and decorating Demolition and dismantling Bricklaying Scaffold erection Mechanical and electrical service installation and maintenance. Typical injuries associated with working at height include; Fractures Spinal injuries Impailment of re-bar (reinforcing bar – used in concrete) significant risk concerning working at height has begun with work over 2 metres. There is already a general requirement to consider work at height risks for all types of work and specific requirements for the construction industry. The new regulations spell out specific requirements and principles for all types of work at height where there is a risk of a fall liable to cause injury, regardless of the height In the UK the Work at Height Regulations 2005 (WAHR) came into force on 6 April 2005 and consolidate previous legislation on working at height. The Regulations will apply to all work at height where there is a significant risk of a fall liable to cause personal injury. They place duties on employers, the self-employed, and any person that controls the work of others to the extent of their control (for example facilities managers or building owners who may contract others to work at height). The Regulations will require duty holders to ensure: all work at height is properly planned and organised; those involved in work at height are competent; the risks from work at height are assessed and appropriate work equipment is selected and used; the risks from fragile surfaces are properly controlled; and equipment for work at height is properly inspected and maintained. The Regulations include Schedules giving requirements for existing places of work and means of access for work at height, collective fall prevention (e.g. guardrails and working platforms), collective fall arrest (e.g. nets, airbags etc), personal fall protection (e.g. work restraints, fall arrest and rope access) and ladders. The WAHR will have major implications for all businesses where height work is a factor, and are designed to reduce this risk and the number of related injuries each year. May 2008 246 The new regulations contain a hierarchy for working at height similar to that contained within the now revoked Construction (Health, Safety and Welfare) Regulations 1996, except that the so-called ‘2 metre rule’ has now been abolished. In the Hierarchy of Working at Height, emphasis will be placed on elimination of the need to work at height in the first instance. Where this is not reasonably practicable then consideration must be given to the use of; collective fall prevention (e.g. guardrails and working platforms), collective fall arrest (e.g. nets, airbags etc), personal fall protection (e.g. work restraints, fall arrest and rope access) and as a last resort ladders. Hierarchy of controls for working at height Emphasis will also be placed on emergency response measures and the provision of resources to affect the rescue and recovery of personnel in the event of an emergency. The selection of the correct equipment, not only for work purposes but also for rescue, will be paramount in the overall planning and management of the work. A summary of the regulations Any work at height needs to be planned in advance of the work activity, with careful consideration given to the selection and use of work equipment. The safe system of work needs to take account of: • Any supervision of workers that may be necessary, e.g. work equipment selected lower down the hierarchy of control, such as fall arrest equipment, will require a higher level of supervision. • Any weather conditions that workers may be exposed to, e.g. carrying out maintenance on an icy roof, or working in rainy conditions on a slippery surface; May 2008 247 • Any emergency or rescue procedures that may be required, e.g. if persons falls while using a fall arrest system. It is not acceptable just to rely on the emergency services, it needs to be covered in the risk assessment and planned prior to the work activity being carried out. For example, how will an unconscious person be rescued after having fallen into a net? How will a person be rescued after having fallen in a fall-arrest harness? You may need to consider the use of a mobile elevated work platform (MEWP), ladder or tower to undertake a rescue. • equipment is carefully selected – consider working conditions, working height, distance and consequences of a fall, duration and frequency of use. • the risks from fragile surfaces (roof lights, asbestos roofs etc) are identified and properly controlled and • any equipment used is properly inspected and maintained. • injuries as a result of falling objects are prevented. Who is competent to work at height? Competency is the knowledge, training and experience that enable a worker to identify the risks arising from a situation and the measures needed to be taken. Those undertaking a height work activity need to be trained in the selected system of work and any particular work equipment chosen. For example if a MEWP is selected then the operator must be trained in its use. If nets are used the net riggers must be trained in how to erect them safely. Managers should check that those doing the work are adequately trained. For employees who regularly carry out work at height, e.g. roofers, it may be necessary for them to attend a formal training course on safe working procedures when at height, rather than just on-the-job training. Examples of the type of work now covered by regulations include:• many types of construction work • clearing gutters and rainwater pipes • painting walls and ceilings • changing light bulbs • working on flat roofs. • working from a ladder What action is needed? Check that existing risk assessments you have carried out for work at height activities take the above into account. If you haven't done any risk assessments then one needs to be carried out. As always in a risk assessment you need to: a. Identify the hazards. b. Decide who might be harmed and how. c. Evaluate the risks by considering the type and duration of the work and decide whether any existing precautions are adequate or whether more should be done SFARP. d. Record your findings where necessary. e. Review your assessment. May 2008 248 Examples of what to consider include concerning the work activity; People: their physical and mental capabilities, e.g. pregnancy, vertigo sufferers. Equipment: to be used; scaffold, MEWP, mobile tower scaffold or ladder. Also any PPE required. Materials: fragile roof materials, asbestos roof materials. How will all materials be raised and lowered to the workplace at height? Environment: the location where the work activity is due to take place, i.e. presence of hazards such as overhead power lines, open excavations, underground services weather conditions, lighting, • condition and stability of existing work surfaces; So what is work at height in construction? Work at height is work in any place, including a place at, above or below ground level, where a person could be injured if they fell from that place. Access and egress to a place of work can also be work at height. Examples of work activities that are classified as working at height include: • working off a flat bed trailer; • working on a flat roof; • erecting falsework and formwork; • working from a ladder; • working at ground level adjacent to an open excavation; • working on formwork within an excavation; • working near or adjacent to fragile materials. What is required when planning to do work at height? Any work at height needs to be planned in advance of the work activity, with careful consideration given to the selection and use of work equipment. The safe system of work needs to take account of: • Any supervision of workers that may be necessary, e.g. work equipment selected lower down the hierarchy of control, such as fall arrest equipment, will require a higher level of supervision. • Any weather conditions that workers may be exposed to, e.g. carrying out maintenance on an icy roof, or working in rainy conditions on a slippery surface; • Any emergency or rescue procedures that may be required, e.g. if persons falls while using a fall arrest system. It is not acceptable just to rely on the emergency services, it needs to be covered in the risk assessment and planned prior to the work activity being carried out. For example, how will an unconscious person be rescued after having fallen into a net? How will a person be rescued after having fallen in a fallarrest harness? You may need to consider the use of a mobile elevated work platform (MEWP), ladder or tower to undertake a rescue. Who is competent to work at height? Competency is the experience, knowledge and appropriate qualifications that enable a worker to identify the risks arising from a situation and the measures needed to be taken. May 2008 249 Those undertaking a height work activity need to be trained in the selected system of work and any particular work equipment chosen. For example if a MEWP is selected then the operator must be trained in its use. If nets are used the net riggers must be trained in how to erect them safely. Managers should check that those doing the work are adequately trained. For employees who regularly carry out work at height, e.g. roofers, it may be necessary for them to attend a formal training course on safe working procedures when at height, rather than just on-the-job training. How can employers avoid working at height? A risk assessment for undertaking work at height should always consider how the work activity at height could be avoided. This may require modifying a design, e.g. erecting guardrails on steelwork at ground level and then craning the steel and the guardrails into place, or doing the work from underneath, e.g. using a MEWP or a mobile platform inside a building to repair a roof internally. However, in most instances in the construction industry, avoidance will not be possible and control measures for working at height will be required. How can I prevent someone from falling when working at height? Falls from height can be prevented through the use of working platforms with guardrails, or particular access equipment, such as MEWPs (cherry pickers, scissor lifts, mast climbers etc). Personal protective equipment can also prevent falls, such as a work restraint system, but this form of protection is lower down the hierarchy and should only be considered if the collective method of protection, as mentioned above, has been ruled out. However, in selecting work equipment for fall protection, all risks associated with that equipment must be considered, e.g. the risks involved in installing, using, dismantling and rescue related to that equipment. Windows being cleaned from the ground rather than off ladders. Steel beams designed with prefixed sockets to insert the edge protection at ground level and so preventing scaffolders being exposed to a risk from height What is an existing place of work? An existing place of work is best thought of as a ‘safe’ place of work - somewhere where you don’t need to use or add any additional work equipment to remove the risk of a fall from height occurring. If you do have to add or use anything to address the risk of a fall from height, then it is not an existing place of work. Work at height may be undertaken from an existing place of work, such as a flat roof. If the flat roof has permanent edge protection fitted around the perimeter of the roof, then it is unlikely that further work equipment would be necessary, as the risk of falling from the roof has already been controlled. Other examples include a machine or storage tank with fixed guard rails, mezzanine floor with edge protection, parts of a demolition or construction site where work equipment is not needed to make a working position safe because there is no risk of a fall. An existing place of work may be transitory. For example soft strip demolition may be taking place on the fourth floor of an office building and during this process there is unlikely to be a risk of a fall occurring. However, as soon as the windows are removed, the openings created will give rise to the risk of a potential fall occurring and measures will need to be taken to prevent a fall, therefore this place of work is no longer an existing place of work. May 2008 250 What are collective and personal measures? Collective control measures should always take priority over personal control measures. Collective measures protect more than one person at any one time, e.g. scaffolds, airbags, nets etc and they are usually passive (i.e. they require no action by the user to work effectively). Personal control measures rely upon personal protective equipment and only protect the user, e.g. fall-arrest harnesses. They are usually active (i.e. they require the user to do something for them to work effectively, such as clipping PPE lanyard onto an anchorage point at all times). What are ‘appropriate ergonomic conditions’? Ergonomics covers how people interact with their environment and how a person adopts the correct work position or posture for the work in hand. The work position should have characteristics (including dimensions) that are appropriate to the nature of the job being carried out, e.g. a working platform should be wide enough to allow safe passage and movement, and allow safe and comfortable handling of materials. What is the hierarchy of controls for working at height? Under Regulation 6 of the Work at Height Regulations, there is a hierarchy of control for determining how to work at height safely. The hierarchy has to be followed systematically and only when one level is not reasonably practicable may the next level be considered. It is not acceptable to select work equipment from lower down the hierarchy (e.g. personal fall arrest, such as harnesses and lanyards) in the first instance. Duty holders must: • avoid work at height where they can; • use work equipment or other measures to prevent falls where they cannot avoid working at height; and • where they cannot eliminate the risk of a fall, use work equipment or other measures to minimise the distance and consequences of a fall should one occur. It is not necessary to implement all parts of the hierarchy, e.g. in the case of a fully boarded and guarded scaffold, workers would not be expected to wear personal fall-arrest equipment in addition. May 2008 251 THE HIERARCHY OF CONTROL MEASURES WITH PRACTICAL EXAMPLES Hierarchy AVOID Examples - Design out the need to work at height. - Cast in mesh in riser ducts in floor slabs at positions of services - Erect handrails/edge protection at ground level and crane in. - Fix nets by working from the floor below using extending poles. PREVENT by using an existing place of work: PREVENT by using equipment: COLLECTIVE - A flat roof with permanent edge protection. - A tanker roof with fixed edge protection. - Access equipment fitted with guardrails: MEWPs, work scissor lifts, mast climbers, work equipment cradles, tower scaffold, independent scaffolds. PREVENT by using - PPE used in a way so it is impossible to get to a fall work equipment: position, e.g. work restraint. work equipment PERSONAL MITIGATE by using -Nets and soft landing systems, such as air bags positioned work equipment to minimise under work surface distance and consequences COLLECTIVE MITIGATE by using work - A personal fall-arrest system with the anchorage point sited equipment to minimise above the head (fall factor zero). distance and consequences - Rope access PERSONAL - A work positioning system. - A personal fall arrest system with anchorage level at sternum/dorsal attachment point (fall factor 1) -A personal fall arrest system with an anchorage point sited at the feet (fall factor 2) MITIGATE using work equipment -Nets positioned at a lower level to minimise the consequences -Soft landing systems COLLECTIVE MITIGATE using work equipment - A personal injury system (life jacket whilst working to minimise the consequences next to unguarded water) May 2008 252 PERSONAL MITIGATE through training and instruction or other means - Ladders. - Hop ups. PERSONAL - Stilts What do I have to do for falls below 2 m? The Work at Height Regulations require the risk of a fall to be prevented wherever a fall is liable to cause personal injury. This means that for any height where there is a risk of a fall causing personal injury then measures should be taken to prevent injury. The old division between low and high falls has gone. The duty is to prevent falls. It is worth noting that there are almost as many low-fall injuries as high-fall injuries. The Work at Height Regulations require you to take a sensible risk-based approach to preventing falls. Where it is reasonably practicable to take precautions to prevent a fall, steps should be taken to do so. Examples of what you have to do include: • using edge protection on bandstands for bricklayers; • ensuring that handrails to scaffolds and towers are provided and not deliberately removed for work less than 2 m. However it is essential that a sensible and pragmatic approach is taken when addressing low falls, so precautions should only be taken when the scope and duration of the work presents a risk of injury. If the risk is trivial, it is not reasonably practical to take precautions, then no action needs to be taken apart from training and instruction. What about falls at 2 m or more? Where the fall height is 2 m or more, inspectors will always expect action to be taken to prevent falls. When selecting work equipment, the expectation is that guardrails and working platforms will be used. These are always the preferred measures to protect from falls unless a risk assessment clearly identifies other equipment as providing better protection given the nature and duration of the task. There will be no dilution in existing standards for work at height above 2 m. How high should handrails be? The new Regulations require that handrails have a minimum height for construction work of 950 mm, increased from 910 mm in the old regulations. Where existing 910 mm handrails are fixed in place they can remain at that height until they are changed. Any gap between the top rail and any intermediate rail should not exceed 470 mm. What do I need to consider when selecting equipment for working at height? When selecting work equipment for use at height, the following need to be taken into account: • The working environment: what are the ground conditions, are there space constraints, are other people working in the same area, will members of public be affected? • The duration and frequency of use: is the work activity of short duration, is it repetitive? May 2008 253 • Emergency and rescue procedures: can a timely evacuation and/or rescue be instigated? • The distance and consequences of any potential fall: can a fall from the work equipment occur? If so, does this have the potential to cause injury? • In the case of access and egress, what is the distance to be travelled? • Any other additional risks posed by the installation, use, dismantling or removal of the work equipment. • The dimensions of the work equipment, to ensure a safe working area and safe passage. • The potential loadings of persons, equipment and materials. • Is it appropriate for the nature of the work to be undertaken? The type of work equipment required should be selected in conjunction with the risk assessment in accordance with the hierarchy of control. What about using ladders and stepladders? These regulations do not ban ladders but require consideration to be given to their use. They require that ladders should only be considered where the use of other more suitable work equipment is not appropriate, such a towers scaffolds, podium steps or temporary stairs. For example ladders are frequently used during fit-out installations, but in most cases other work equipment is more appropriate. Where ladders and stepladders are used they should only be used as a work place for light work of short duration. What are working platforms? The Work at Height Regulations have changed the meaning of working platforms, which have traditionally been understood to mean a fully-boarded platform with handrails and toe boards. A working platform can now be virtually any surface from which work is carried out, such as a roof, floor, platform on a scaffold, a MEWP, the treads of a stepladder. What do I need to take account of when considering emergency procedures? Emergency procedures need to be considered for reasonably foreseeable circumstances, such as stuck access equipment, deployed fall arrest in order that a person or persons can be rescued. The method selected needs to be proportionate to the risk and there should not be reliance on the emergency services. The method of rescue may well be simple, such as putting a ladder up to a net and allowing the fallen person to descend, or pulling a worker hanging on a deployed lanyard onto the surface below. In other situations, consideration may need to be given to the use of other work equipment, such as MEWPs or proprietary rescue systems. Whatever the situation selected, you should be able to demonstrate that if someone falls, that there are arrangements in place that are capable of rescuing that person and that those involved are trained in the procedures and the equipment required is available. What is a work-restraint system? A work-restraint system is a fall-prevention system, which relies upon personal protective equipment, consisting of a harness and a lanyard, which is adjusted or set to a fixed length that physically prevents the person from getting to the place where they could fall. This system requires close supervision. While it is normal to use a specific work-restraint lanyard for this purpose it is acceptable to use a fall-arrest lanyard, provided the lanyard and energy absorber are correctly sized and used. May 2008 254 What is a work positioning system? A work-positioning system is a personal fall-protection system, which includes a harness connected to a reliable anchor to support the user in tension or suspension in such a way that a fall is prevented or restricted. Examples of this type of equipment include: boatswain’s chairs; or people working on telephone poles. The Regulations require that all workpositioning systems be provided with a back-up system in case the primary support fails. What are rope access and positioning techniques? Rope access is a personal fall-protection system using two ropes each secured to different anchors. One rope is connected to a harness and the other acts as a safety back-up. Rope access is often used to access cliff faces or the sides of tall building when cradles are not suitable. What is a personal fall-arrest system? A personal fall-arrest system is a fall-protection system that uses a harness connected to a reliable anchor to arrest and restrict a fall and prevent the user hitting the ground. It is designed to limit the forces on the body by having an energy-absorbing device. Fall-arrest harnesses should only be used where other collective measures cannot be used. To minimise the distance a person falls, the anchor point should be positioned as high as possible above the feet of the user. Personal fall-arrest systems should be regularly inspected for signs of wear and damage. What about scaffolding? Do I have to design scaffolding? What is a generally recognised standard configuration? Most scaffolds can be erected following a generally recognised standard configuration. Such as those given in the National Access and Scaffolding Contractors (NASC) guide TD 20:05, or used in accordance with the manufactures guidance for system scaffolds. Where scaffolds due to their complexity or size cannot be erected to these established configurations they should be designed generally in accordance to the principles given in BS EN 12811 or based on fundamental engineering principles. In these cases a note of the design should be available. Competent scaffolders should always erect tube and fitting, or system scaffolds, and a safe system of work should be followed, i.e. as described in NASC’s guidance note SG4. What do I have to do about falling objects? The risk of falling materials causing injury should be minimised by keeping platforms clear of loose materials. In addition, a way of preventing materials or other objects rolling or being kicked off platform edges should be provided, e.g. toe boards, solid barriers, and robust brick guards or similar at open edges. If the scaffolding is erected in a public place, debris nets, properly designed fans or covered walkways may be needed to give extra protection for people who may be passing below. High-visibility barrier netting is not suitable for fall preventing objects from falling. Where material is deliberately dropped it should be done in a controlled manner with the receiving area secured to keep people out of the drop area. May 2008 255 Summary of steps to take before working at height • Check there is a safe method of getting to and from the work area. Decide what particular equipment will be suitable for the job and the conditions on site. • Make sure work platforms and any edges from which people are likely to fall have guardrails, toe boards or other barriers. • Make sure that the equipment needed is delivered to site in good time and that the site has been prepared for it. • Check that the equipment is in good condition. • Make sure that whoever puts the equipment together is trained and knows what they are doing. • Make sure that those who use the equipment are supervised so that they use it properly. The more specialised the equipment (e.g. MEWPs, boatswain's chairs and rope access equipment), the greater the degree of training and supervision required to ensure safety. • Check any equipment provided by another company to make sure it is safe before using it on site. • Find out who to tell if any defects need to be remedied or modifications need to be made and keep them informed. Remember: • Only when other methods are not reasonably practicable or when work platforms cannot comply with all requirements for safe work should a way of arresting falls (such as nets or air bags) that provides collective protection to all those who are working be used. • If no other means of providing a safe place of work at height is available then an appropriately anchored harness (personal fall arrest) should be worn. However, whenever fall-arrest harnesses are used, a rescue method must be available should the user fall and be left suspended in their harness. Further information on safety harnesses can be obtained from Appendix 3 of Health and safety in roof work HSG33 (Second edition) HSE Books 1998. • Nets or harnesses may also be needed to protect those working to put guard rails or • When selecting a safe system of work at heights, all the risks have to be considered before one method is selected. If nets are selected, is there adequate clearance under the nets to prevent injury to those who may fall into the net? If harnesses are used, is there sufficient clearance from the ground to allow the shock-absorbing lanyard or inertia reel to fully extend? • Before installing or using any system of work to enable safe work at height to be carried out, check that there is adequate clearance for equipment. For example, overhead power lines can be a risk when erecting scaffolds or using MEWPs; there can be a risk of crushing against nearby structures when mobile access platforms are manoeuvred and that the ground is strong enough to support the MEWP. May 2008 256 • Ladders should always be secured if possible, and be primarily used for access and only be used at workplaces to do light work of short duration, and then only if it is safe to do so. It is generally safer to use a tower scaffold or MEWP, even for shortterm work. Heavy work activity carrying heavy loads should never be carried out from a ladder. When using a ladder ensure that the person on the ladder always has three points of contact, i.e. two legs and a hand. Safety belts and safety lines Safety belts or harnesses must be adequately anchored to the structure when the worker is at his working position or at rest. Anchoring points should be at or above waist height to limit any fall. Terylene or other suitable man-made fibre rope should be used for safety lines. Safety lines fitted to safety belts must limit a fall to 0.6m. Where a fixed length line that would permit a longer fall is needed, a full harness must be worn and a shock absorber incorporated. In such cases the line must not be longer than that length that will limit free fall to 1.8m. In a situation where a fixed-length line would not limit a free fall to 1.8m or less, an inertia reel type of safety block must be used with a full harness. Safety lines, safety belts and safety harnesses which suffer accidental damage or shock loading, must be taken out of service immediately. They must either be discarded or returned to the supplier with a full report. Belts and harnesses must be properly stored to avoid damage. Particular care must be taken to avoid contact with any chemicals that may harm the material. All safety equipment must be thoroughly examined on a regular basis and an inspection record maintained. Ladders Working above or below ground level, a safe means of access must be provided and maintained. In order to work above or below ground, usually means that someone is going to use a ladder as a means of access. So we will begin by looking at ladders; Ladders/Step Ladders are not to be used unless a risk assessment indicates that the use of more suitable work equipment is not justified because of the low risk and: May 2008 work is of short duration existing features on site cannot be altered. 257 Ladders It's a fact that more accidents occur at work from the use or mis-use of ladders than from any other single piece of work equipment. The hazards involved in the use of ladders are; person falling from the ladder materials/equipment is falling from the ladder ladder falling ladder falling under load electrocution (alloy ladders) manual handling injuries (wooden ladders). Precautions The principle precautions to be taken to ensure the safe use of ladders are defined within the Provision and Use of Work Equipment Regulations 1998, since a ladder is merely another piece of work equipment; correct selection correct use inspection and maintenance records conforms to a recognised standard e.g. BSI, CE etc. Ladders are used as a means of access in factories, offices, shops and construction sites. As well as for access, they may of course, also be used as a place from which to work - the golden rule is "only undertake work from a ladder where the work can be done with one hand", i.e. one hand for the work, the other for the ladder. There are very few operations which only require one hand and examples are window cleaning, rubbing down, and painting. Thus, the main function of a ladder is as a means of access. There are two main types of ladder - alloy and wooden, and they both have their advantages and disadvantages. Aluminium ladders Advantages light in weight require relatively little maintenance Disadvantages May 2008 258 do not withstand sudden shock, or overloading, and fail without warning; aluminium is a conductor, so such ladders must never be used where there is the potential for contact with live electrical cables or flash over (arcing). Wooden ladders Advantages Good insulator, therefore the risk of potential electrocution is greatly reduced. Disadvantages Relatively heavy, so there is a greater risk of manual handling injuries when using this type of ladder. Require considerable maintenance Correct use of ladders timber ladders must never be painted or treated in any manner which prevents defects from being easily seen. ladders must be strong enough for the job, and kept in good repair. ladders must be securely fixed or lashed near the top, in which case it should be the stiles and not the rung that is secured. footing ladders is only acceptable with ladders under 6m long, and is only permissible if they cannot be lashed or fixed. ladders under 3m need not be fixed or footed if they are securely placed to prevent slipping ladders must extend least 5 rungs above a landing or workplace (platform), unless there are other suitable hand hold available. ladders must be erected at the 1 out: 4 up rule, or 750 Storage, maintenance and inspection when not in-use, ladders should be stored covered, or in a protected and well ventilated position away from sources of heat. ladders should be stored on racks, supported on the stiles only, with enough supports to prevent sagging. aluminium ladders are susceptible to corrosion when exposed to lime or cement. it is best practice to have a visual inspection of all ladders prior to use, with a formal recorded inspection to be made once every 7 days. Ladder precautions – checklist May 2008 are ladders stored properly has a suitable ladders been selected for the job (is it fit for purpose)? is the ladder in use in good condition, and free from obvious defects? is it positioned on a firm, stable and level ground or surface. If it is a surface e.g. a roof , is that of suitable strength? are all ladders secured correctly near the top? if the ladder cannot be secured near the top, is it secured near the bottom or footed? 259 does the ladder project at least five rungs beyond the working platform? If not, is there a handhold at the place of landing? are ladders inspected, and inspections recorded? If the ladder is providing access and egress to a scaffold, then it is deemed to be part of the working platform, and must be included in the 7 day inspections. SCAFFOLDS According to the Concise Oxford Dictionary, a scaffold is "an elevated platform of timber used for the execution of criminals". Construction workers are not convicted criminals therefore, the law aims to minimise such risk of death through the Work at Height Regulations 2005. A scaffold is any "temporary structure on to, or from which persons perform work or which enables persons to obtain access to or which enables materials to be taken to any place at which such work is performed..." 1. Independent tied scaffold An independent tied scaffold is designed to carry its own mass, and the full load of all materials and workers upon the scaffold. The total load is in turn supported by the ground on which the scaffold has been erected. The scaffold is not totally independent, however, since it must be tied to the building or structure where it is positioned, in order to provide resistance to any push (towards the structure), and pull (away from the structure) movements, but may also include Gin Wheels and Pulley Blocks to facilitate the lowering and raising of equipment to the working platform. The whole arrangement must be strong enough to support the load, and be secured against movement, and the correct ties be present in the structure. Basic component parts May 2008 260 There are five main factors in deciding the stability of a scaffold and it will be one or more of these that are normally responsible for a scaffold collapse; foundations ties bracing standards couplers We will now look at each of these factors in some more detail; Foundation Any structure is only as sound as its foundations. So all foundations must be positioned on firm, level, ground. Obviously there are degrees of "firmness", and so with concrete and tarmac for example only steel base plates would be provided. These base plates will have the vertical standards sitting directly upon them. In less firm situations e.g. on soil, a base plate May 2008 261 is used again, but this time it will be positioned upon a timber "sole board" which has an effect similar to a ski, since it spreads the load. Ties A tie links the scaffold to a building. These are used to prevent the scaffold moving towards or away from the structure or building. Scaffolds can be very high, narrow structures which can be very unstable if not tied. They also give lateral strength to the standards. Bracing A tube and coupler scaffold is a "pin jointed" framed structure. Pin jointed structures must be broken down into triangles. The scaffold may move in two planes forwards and backwards, and left to right. Therefore, both facade and ledger bracing must be provided. Ledger bracing is that bracing which runs between the ledgers in a dog-leg fashion from the front to the back of the scaffold. Facade bracing runs diagonally along the face (or facade) of a structure. Standards These are the vertical tubes which transmit the loading down to the ground. It is important that joints are staggered, and should be positioned as near to the ledgers as is possible. They should always be stood upon a minimum of a base plate, as well as a sole board for soft ground. 2. Putlog scaffold This type of scaffolding is less common, and is primarily seen in the house building or house renovating sector since it is used in the brick or block walls. The scaffold relies on the wall for part of its structural strength. Putlog scaffolds should normally be restricted to one working platform. May 2008 262 Putlog inserted into wall There is no ledger bracing. Such ledger bracing will normally be fitted on alternate pairs of standards. It should be connected using load bearing couplers to either standards or ledgers. and will run the full height of the scaffold starting at the base plate. There is no inner line of standards, these have been replaced by the use of putlogs. Other than these two main differences both types of scaffold are essentially the same, and must include; Facade bracing Facade bracing must be provided for all scaffolds. Like ledger bracing it should be connected using load bearing couplers. Such bracing must be connected either as a zig-zag from top to bottom, between a pair of standards or as a continuous sloping tube. Ties A tie links the scaffold to a structure, and is provided to resist the pull and push movements of the scaffold and to provide extra stability. There are a variety of different methods; Through ties - these are where the tube passes through an opening, and bears on the inside face of the wall. Reveal ties - this is where a tube is wedged between two opposite surfaces, using a reveal pin to make all necessary jacking adjustments. Expanding eye bolts - these are drilled and screwed into the face of the structure in order to provide anchorages. Box ties – these are where a ‘box’ is put around part of a structure and secured to the scaffold. Working Platform A working platform is made by laying scaffold boards across the putlogs. Each board requires a minimum of three supports. The width of the working platform will be decided by the type of work being undertaken. For example it would be five boards wide for general work, including bricklaying, and four boards wide for plastering. Scaffold boards must never be painted since this could disguise any defect with the board. Toe boards Toe boards should be fixed to the inside of the standards on all open edges of the working platform. Their purpose is twofold; May 2008 263 1. to prevent materials falling from the working platform. 2. to prevent injured persons from rolling off the platform. They must be accompanied by two guard rails, an upper and an intermediate guard rail, or an upper guard rail and a brick guard. A top and intermediate guard rail would be used where it was not expected that materials or equipment would be likely to topple over the toe board. An upper guard rail and brick guard would be used where materials or equipment was likely to fall through the gap between the upper guard rail and toe board. Either system would be suitable to prevent a person accidentally falling. Guard rails The purpose of these two guard rails are to act as a handrail, and a fixed barrier to prevent a worker falling off the platform whilst standing or bending over. If a guard rail is removed for access of materials, then it must be replaced as soon as practicable. Signage Scaffolds partially constructed or dismantled, must be sign-posted, and access blocked. Access and Egress Access and egress is normally provided by ladders or staircases. Any ladder used must be tied into the structure, and when this is done it is now deemed to form part of the scaffolding structure, and should be included on the regular scaffold inspections, which must be formally recorded as follows; before being taken into use for the first time. after any substantial alteration or dismantling. after any event likely to have weakened its strength or stability e.g. high winds or heavy rain. every seven days. MOBILE SCAFFOLDS AND TOWERS These structures are not in themselves specific mentioned in C(HSW)R., however, they are always either a place of work, or a working platform which require access and egress. Therefore, they fall fully within the requirements of the Regulations. The precise requirements are further expanded upon by HSE Guidance Note GS 42. May 2008 264 Mobile towers may be; prefabricated system-built tube and coupler Note that to be mobile such towers will have lockable wheels at each corner of the tower. It is the responsibility of the worker on the tower to remove all equipment and materials prior to their moving the tower themselves from below. Under no circumstances should the tower be moved with workers, materials or equipment still on the working platform. They are available from many manufacturers, and are made out of either steel or aluminium. Mobile scaffolds are commonly used for painting and simple maintenance jobs at height. They have one working platform which will be accessible by either an internal staircase or an internal ladder. The working platform is normally rectangular in plan. The working platform must conform to the standards that are laid down for all scaffolds e.g. toeboards and guard rails. If a tower is to be free standing (that is, not tied into the structure), then the manufacturers instruction leaflet should detail the maximum safe height to which the tower can safely be erected. There is however, a general rule of thumb that is used, and this is as follows; Alloy towers Steel Outdoors 3 xb Indoors 3.5 x b 3.5 x b 4 xb Where “b” is taken to be the narrowest base dimension. This narrowest base dimension may be extended by the use of outriggers. May 2008 265 The discrepancy in ratios between steel and alloy is due to the steel being of greater weight (mass) so it is inherently more stable. Furthermore, the discrepancy between indoor and outdoor ratios is due to the effect of the wind in outdoor situations. Mobile Tower Scaffold Checklist Always be methodical - either start from the ground up, or the platform down! Is the tower sited on firm, level ground Are the locking wheel brakes in good working order Is internal safe access and egress provided? Is the working platform complete, and in good condition? Are toe boards in position? Are guard rails in position? Is the tower within the maximum base to height ratio? If not, is the tower securely tied into the structure? WORK ON ROOFS Roof work contributes substantially to the number of serious and fatal accidents every year. Most of these accidents could have been avoided with careful Risk Assessment, and equipment that is readily available. As a high risk activity, it is important that roof work is pre-planned by competent personnel, with a high regard to the construction of the safety equipment required, and the nature of the work, which can vary from actual roof construction, to the maintenance of guttering. Safe systems need to be established and followed. Safety Precautions. During roof work safe working conditions must be provided, which will vary according to the activity. Edge Protection. 1- Handrail 2- Toeboards 3- Through Tie Again the type of edge protection will depend on the type of roof and the activity being carried out. May 2008 266 Fragile Roofs Falls through fragile roofs are a major cause of fatal accidents. The appearance of some roofs are mis-leading and although may look alright on the outside, they could be seriously affected by process’s on the inside. Safety signs must be displayed and roof ladders or crawl boards must be used. The angle of the roof and the work being carried out will affect the type of equipment required, but when working on or passing over the roof the users weight must be evenly distributed by the crawling boards, and the practice of walking on the purlins is very dangerous, and, contrary to popular belief, not safe. Working near to fragile roofs suitable guard-rails must be provided. Flat roof A flat roof is one with a slope of less than 10 0 , and edge protection must be provided. Sloping roofs A pitch of more than 100 is classed as a sloping roof. Edge protection and roof ladders are required LIGHTWEIGHT STAGING OR TRESTLE SCAFFOLDS Many of the general rules for the safe use of ladders and scaffolds also apply to the use of lightweight staging or trestle scaffolds. In addition the following points should be considered; Trestle scaffolds are intended for light work of short duration. They consist of two or more trestles (of either the folding type of the fixed telescopic steel type), supporting scaffold boards or proprietary staging to form a working platform. The platform should be of adequate strength, and without any defects or damage. All lightweight staging should be marked with the maximum permitted distributed loading. This is best done by specifying the number of persons, and their tools and equipment, which can be on it at any one time. Normally the working platform shall not be less than 600mm wide, in exceptional circumstances, where it is not reasonably practicable to achieve the 600mm working platform, a lesser width platform may be permissible only if it is used in conjunction with fall arrest equipment. May 2008 267 General Guidelines Trestles must always be set on firm, level ground and always be in the fully opened position Only one tier is permitted when folding supports are used. Guard rails, barriers and toe-boards are required on all working platforms from where there is a significant risk of a fall. Guard rails may be either a top or main guard rail plus a mid guard rail, or a top guard-rail plus a substantial barrier e.g. a brick guard. The top main guard rail should be positioned at least 950mm above the level of the platform. The mid or intermediate guard-rail should be set at approximately halfway between the toeboard and the top guard-rail. Any barrier used instead of a mid guard-rail must be of substantial construction and completely cover the opening between the top guard-rail and the toe-board. It must be securely fixed on the inside of any standards or ledgers used, or otherwise prevented from being displaced. If a guard-rail is removed to allow access of materials, it must be replaced as soon as practicable. Any scaffold boards used on trestles as a working platform must be of consistent length and of equal thickness. CONSTRUCTION (HEAD PROTECTION) REGULATIONS 1989 Introduction Workers are killed and many others seriously injured in the construction industry every year as a result of head injuries. However if you wear a safety helmet your chances of being seriously hurt are greatly reduced. Wearing one could save your life. As always personal protective equipment (PPE) is always the last line of defence. Wherever possible other measures to reduce or control the risk should be adopted first, e.g. provide brick guards, keep scaffolds free of loose material, securely tie suspended loads The Construction (Head Protection) Regulations 1989 require suitable head protection to be provided and worn WHEN THERE IS A SIGNIFICANT RISK OF HEAD INJURY. This may be from falling materials or knocking into things such as low scaffolds. Safety helmets MUST be worn in designated 'hard hat' areas. Only turban wearing Sikhs are exempt from these requirements. Selection of head protection Head protection will be considered suitable for the purposes of the Regulations if: 1. it protects the wearer against the risk of head injury; May 2008 268 2. 3. 4. it conforms to the appropriate British Standard for safety helmets (NB 'bump caps' should not normally be used on site as they do not afford adequate protection against falling objects); it is suitable for the work or activity carried out by the wearer; and it is adjustable to provide a good fit. Helmets come in a variety of designs and it is important that the right type of helmet is provided for the task in hand. Some for example, are made with a reduced peak and may be more suitable for those on site who spend a lot of their time looking upwards, e.g. surveyors or scaffolders. Similar helmets have also been designed for use in the roofing industry. If the helmet is going to be worn by someone who has to bend forward, e.g. steel fixers and groundworkers, or where there is a risk of the helmet being blown off, a chin strap should be provided and used. Helmets can also be worn on top of other head coverings (e.g. paper liners, hoods, etc) provided a suitable fit is maintained. On many sites workers may also be required to wear additional ppe e.g. hearing or eye protection, so careful selection is required to avoid compatibility problems. Duties of employers and those in control of construction work If you are an employer you must provide your employees with head protection when it is required and maintain and replace it whenever necessary. If you are IN CONTROL OF A SITE, e.g. as a main/principal contractor, the Regulations allow you to make RULES governing when and where safety helmets should be worn. These rules then apply to EVERYONE on site, and that includes visitors such as architects, delivery drivers and utility workers. These rules should be in writing and be brought to the attention of all those who may be affected by them so that everyone knows when and where head protection should be worn. Duties of employees and the self-employed Employees must wear their safety helmets properly and as directed by their employer or comply with rules made by the person in control of the site. They should take care of their helmets, not misuse them and report any defects or problems. The self-employed must provide their own head protection, if not provided on site. They must wear it when there is a risk of head injury, when directed to do so by someone in control or to comply with rules made by the person in control of the site. They must also maintain and replace the head protection, whenever necessary. Storage and use of helmets Safety helmets should be periodically checked for damage, such as cracks, serious scratches and dents, and replaced whenever necessary. In any event they should be replaced at intervals recommended by the manufacturer (this may typically be after two years of use, but it could be more frequent than this). May 2008 269 They should not be used for any other purpose and should be kept in a locker or in a dry and cool place out of direct sunlight at the end of each working day. Do not use the chin strap to hang up the helmet. Provision for visitors to a site Other people who visit a site as a part of their job and are at work on operations or works to which the regulations apply, will require head protection to be provided by their employers e.g. surveyors, architects etc. The regulations do not require head protection to be provided to people not undertaking construction work, for example, people delivering goods to a site or prospective house purchasers. However, in order to comply with general duties under section 3 of the Health and Safety at Work etc Act 1974, employers and self-employed people engaged in construction work should require visitors to wear suitable head protection if there is a foreseeable risk of head injury. Working Over Water When any works are being carried out which necessitates personnel working at heights above water the following precautions are to be taken. Any works over water should be subject to the company "Permit to Work" system A fence or barrier must be provided to any structure or scaffold where there is a risk of persons falling from such structures into water Where an independent electrically or mechanically operated hoist or cradle is used a competent operator must be provided, or sufficient training be given in its use. Some means of communication is to be provided for use in an emergency Any hoist/cradle is to be checked, maintained and inspected/examined as per manufacturers or statutory requirements. Warning signs/notices are to be displayed There is to be adequate lighting for the whole of the period of work. Lighting must be adequate for night work and must illuminate the immediate surrounding water surface. A buoyancy aid, of a tested and approved pattern, is to be worn by all personnel working over water Suitable rescue equipment, for example a boat, boathook, lifebelt or lifeline is to be in position and checked as serviceable before works are permitted to commence. The use of any electrical equipment is to be strictly controlled and steps are to be taken to ensure that leads are not long enough to touch the water. All equipment should be connected to lines to prevent their accidental dropping into water causing possible electric shocks etc. All personnel are to be instructed as to means of raising alarm and rescue drills The Site Supervisor, or a nominated person, is to make regular and frequent checks on numbers of personnel working. Any works over water are to be carried out by a minimum of two persons, no lone workers are permitted. Special care must be taken in fog, snow or rain, when extra checks are to be made by the site supervisor May 2008 270 8.3: EXCAVATIONS Introduction Every year, many people are killed and many more seriously injured around the world when working in excavations. Excavation work has to be properly planned, managed, supervised and carried out to prevent accidents. Wherever reasonably practicable employers should eliminate the need for excavation work by use of ‘trenchless techniques’ such as thrust boring and directional drilling. The selection of any trenching method is a critical decision. If the wrong choice is made there are no good results. If the selection is too conservative at bid time, the project will be awarded to another contractor. If the choice is too aggressive, then the job faces cost overruns and potential safety problems. Hazards which may be present around excavations buried services falls of persons/equipment and materials into the excavation collapse of the sides collapse of adjacent structures water ingress into the trench wall can cause the bank to become unstable. Slow seepage usually does not cause a trench to become unstable. If it is not practicable or possible to lower the water table enough to trench, then shoring may be necessary. contaminated ground toxic and asphyxiating atmospheres mechanical hazards Risk Assessment Before digging any excavations it is a legal requirement to conduct a suitable and sufficient risk assessment, which should consider the following factors; depth; soil type: the nature of the soil(s) through which the excavation will proceed. Battering can be made in most soil conditions where ground water can be handled. The exceptions are oozing mud, which is really a viscous fluid, and running clean sand, which may not stand on a slope. type of work: the required size and depth of the excavation or trench; depth and flow potential of any groundwater present; use of mechanical equipment; overhead obstructions: Power lines, bridges and trees can create major problems for crane and backhoe operations. These low overheads can hamper or prevent piledriving operations. proximity of structures- type of building, and foundation details. proximity of roadways - will rail loads and vibrations affect the excavation? site traffic - do lorries or site plant pass close to the excavation? stored near the excavation -spoil heaps: is the excavated material going to be stored next to the excavation? construction materials: are there to be quantities of bricks, imported fill etc. presence of the public e.g. excavations in footpaths weather etc. May 2008 271 Make sure the necessary equipment needed such as trench sheets, props, baulks (railway sleepers) etc, is available on site before work starts. Excavation collapse Where the risk assessment indicates no significant risk of collapse, then nothing need be done to prevent collapse. However, where such a risk does exist consideration needs to preventing the sides and the ends from collapsing by; battering them to a safe angle or supporting them with timber, sheeting or proprietary support systems. In such cases never work ahead of the support. Remember that even work in shallow trenches can be dangerous. You may need to provide support if the work involves bending or kneeling in the trench. Battering Open cut by sloping the trench walls (battering) is the first choice. Shoring is selected when this is not reasonably practicable. So where there is sufficient room, battering can be used in almost any soil condition. Generally a sloped open cut excavation is the most cost and schedule effective method of trenching. When the trench is very deep and/or expensive backfill materials are required, then a vertical cut at the toe of the slope supported by shoring may be effective. Ground water and weak lower layers may force partial shoring or flattening of the excavation slopes. Support Systems 1. Trench Boxes Trench and manhole boxes are generally the first choice for the rapid shoring of trench runs in non-urban environments. • Used for linear shoring of trenches generally up to 4m wide x 6m deep in reasonable ground conditions. • Not recommended in waterlogged ground. • Used in multiples to continuously support a length of trench. • Available in a wide variety of sizes and weights and usually comprise a base box, typically around 2.5m high, and up two top extension boxes. • Although rubber tyred 180 degree excavators can handle the smaller "backhoe" type boxes, generally a 360 degree excavator is required, particularly as large pulling forces can be required to extract boxes in cohesive ground. • Larger 4m high boxes can weigh over 4 tonnes. • Where manholes are to be constructed within the trench run, necessitating a local widening of the trench, a special type of trench box is recommended. These are called "manhole" boxes and are commonly available in 2.5m, 3m, 3.5m and 4m panel lengths. The panels of a manhole box incorporate typically 0.5m long return sections at each end. These ‘shoulders’ provide additional support and protection in the widened section of trench. The panels are strutted apart by identical struts to those used in a Trench box. May 2008 272 2. Drag Boxes (shields) Used for short-term protection of the work force in non-urban environments typically for pipeline installation. • Generally used as a single unit to support trenches up to 4m wide x 4m deep in good stable ground conditions. • They are available up to 7.5m long and the larger drag boxes are very heavy and can weigh in excess of 6 tonnes. • They are designed to be pulled or dragged through the trench by the excavator as work proceeds. • They are not suitable in urban environments. • Drag boxes are intended to provide a secure working area for operatives rather than providing an effective means of preventing ground movement, hence they are often referred to as "shields". • Operatives should ensure they enter the trench within the area protected by the shield – not from front or rear, where protection is not present. 3. Slide Rail Systems A specialist linear shoring system where positive ground support is required. • These are specialist linear shoring systems comprising posts, sliding panels and struts. • When assembled the system forms a continuous line of support and can be used to support trenches typically up to 7m wide x 7m deep in most types of ground conditions. • The advantages of these systems over 'box' systems is that much greater trench depths and widths can be shored with greater strut clearance for pipe installation, whilst reducing potential settlement inducing ground movement. • However, greater skill and larger plant is required to install this equipment, for example, a 40 tonne excavator. 4. Vertical Shore Vertical shores can be rapidly installed to provide short-term intermittent support of relatively shallow trenches in good ground conditions. • A hydraulically operated intermittent system comprising of vertical aluminium rails strutted apart by two hydraulic rams. • They are used for short-term support of relatively narrow/shallow trenches, typically up to 2m wide x 2m deep. • The units are designed for manual installation from outside the trench, being activated by a manual hand pump. • In suitable ground the units are installed typically at 1.2m horizontal centres along the trench. • If there is any doubt about the stability of the ground between the supports, a system that provides full support should be selected. • The trench must be pre-dug to depth prior to installing the unit; therefore they are only suitable for use in stable, nonwater bearing ground conditions. 5. SHEET PILING Sheet piles can be readily rented for short term and the system will weigh about ½ of a slide rail system. The tight sheets are very effective in helping to control ground water. The main draw back of sheet piles is they will not easily accommodate utilities and obstructions. The May 2008 273 soil must be fairly soft because the piles are easily damaged by obstructions and ground that resists driving at more than 10 blows per foot. Sometimes a vibro hammer will effectively drive sheet pile where an impact hammer will cause damage. One advantage of sheet piles is that they can form a watertight barrier to control ground water. Where sheets must be installed in hard ground, a dig and drive is usually required to eliminate pile damage and splitting interlocks. Sheet pile will easily cantilever 15 feet and the pile length will be slightly shorter than a soldier pile. Sheet pile shoring advantages: This method provides positive trench wall support. Excavation and backfill quantities are minimized. Access to the trench is maximized. A minimum of right of way is needed. Sheet pile shoring disadvantages: The piles are expensive to buy or rent and install. Additional equipment and material at the site congest the work site. Additional crew operations of install and extract can cause logistic delays. Trench production is often slowed to the rate of shoring installation. The installation and extraction can cause undue noise and vibration pollution, especially if impact pile hammers are used. The installation and extraction process can cause surface settlement in uncompacted soils. The shoring design usually requires a professional engineer stamp. The soil conditions must be fairly soft or the sheets will be damaged while being driven. Any underground obstruction more than a few inches in size can damage the pile by bending and splitting the interlocks. Underground utilities will often prevent the effective use of sheet pile shoring. 6. Waler Frames Waler frames and sheeting provide a very versatile means of supporting medium sized trenches, giving very positive ground support, particularly in urban environments. • These are hydraulically operated frames, installed horizontally for two-sided trench support. • A waler frame comprises two fixed lengths; aluminium or steel rails strutted apart by a pair of hydraulic rams. Longer rails can incorporate a centre strut for additional strength. • Waler frames are used in conjunction with steel trench sheets, to form a system of trench support. • This type of system can be used to support trenches generally up to 4m wide x 6m deep in all types of ground conditions. • In trenches greater than 3.5m deep, or if ground conditions are poor, or if surcharge loading are likely to be high e.g. adjacent to buildings, it is advisable to have the system designed by a qualified engineer to determine the strength and spacing requirement. • The relatively small weight and versatility of the system makes it ideal for use in urban environments where underground services and obstructions are likely to be encountered. • The need to pitch and drive trench sheets can result in a longer installation period than with a 'box system'. May 2008 274 • Very positive support to the surrounding ground is provided by the hydraulic installation forces exerted by the pressurised waler frames. 7. Bracing Frames / Manhole Braces For smaller excavations where support is required on all 4-sides, manhole braces and trench sheeting provide the safest, quickest and most economical solution for positive earth support. Heavy duty frames can provide support for larger excavations and cofferdams. • These are hydraulically operated frames that provide support on 4- sides, used for supporting smaller relatively shallow excavations and shafts. • The frames comprise four individual telescopic legs, usually of steel construction. The legs can be either single or double acting; that is, the latter type can be both expanded and retracted hydraulically. • "Manhole brace" is the generic term for frames used in excavations up to 6m square x 6m deep. • A series of manhole brace frames are used in conjunction with trench sheeting to support the depth of the excavation. • Positive support to the surrounding ground is provided by the hydraulic forces exerted on installation by the pressurised manhole brace legs. • Heavy-duty bracing legs are available in lengths exceeding 20m; however, these would generally need to be combined with cross-strutting for greater strength and reduce deflection. • With these systems it is essential that a qualified and experienced engineer design the supporting systems. Most proprietary shoring equipment suppliers can offer a design service. • Due to the length and weight of individual leg components, installation is usually carried out leg by leg at reduced excavation levels, unlike manhole braces that are generally installed as a frame. 8. Hydraulic or mechanical struts Hydraulic or mechanical struts are generally used for high axial load propping applications such as cross strutting to supporting frames or horizontal or raking support to pile caps. • These are hydraulically or mechanically operated telescopic members used for supporting high axial loads such as is generated in cross-strutting applications, corner or ‘knee’ bracing or in raking support to pile caps. • Proprietary equipment is available up to 250 tonnes axial load capacity. • Each strut or strut assembly incorporates a hydraulic adjustment/ pressurising facility or means of mechanical adjustment. Hydraulic struts are usually double acting, i.e. pump both in and out. • This type of equipment is usually modular incorporating fixed length extension sections for greater versatility. Some units are able to incorporate cruciform pieces to facilitate strutting in both directions • Struts assemblies are available in unsupported lengths exceeding 25m, • It is essential that a qualified and experienced engineer design these supporting systems. Most proprietary shoring equipment suppliers can offer a design service. Materials falling into excavations. Do not store spoil or other materials close to the sides of excavations. The spoil may fall into the excavation and the extra loading will make the sides more prone to collapse. Make sure the edges of the excavation are protected against falling materials. Provide toe boards where necessary. Wear a hard hat when working in excavations. May 2008 275 People and vehicles falling into excavations. Take steps to prevent people falling into excavations. If the excavation is 2 m or more deep, provide substantial barriers, e.g. guard rails and toe boards. It may be possible to utilise the spoil as an effective barrier so long as it is sited well away from the excavation. Keep vehicles away from excavations wherever possible. Use brightly painted baulks or barriers where necessary. Where vehicles have to tip materials into excavations, use stop blocks to prevent them from over-running. In the case of trench sheeting this can extend beyond ground level and again form a suitable barrier. People being struck by plant Keep workers separate from moving plant such as excavators. Use baulks to physically separate passing traffic from pedestrians wherever reasonably practicable. Where this is not possible use safe systems of work to prevent people being struck. This may involve the use of banksmen, mirrors on plant, turning circles and reversing alarms. Plant operators should be competent, and all staff should be wearing hi-viz jackets. Undermining nearby structures Make sure excavations do not affect the footings of scaffolds or the foundations of nearby structures. Walls may have very shallow foundations, which can be undermined by even small trenches. Decide if the structure needs temporary support before digging starts. Surveys of the foundations and the advice of a structural engineer may be needed. Avoiding underground services The majority of accidents involving underground services are caused by the failure to locate the position of cables and pipes before excavation, or by the subsequent failure to take all reasonably practicable precautions whilst the excavation is in progress. Look around for obvious signs of underground services, e.g. valve covers or patching of the road surface. Use locators to trace any services. Mark the ground accordingly. Make sure that the person supervising excavation work has service plans and knows how to use them. Everyone carrying out the work should know about safe digging practices and emergency procedures. Digging should be carried out alongside the service, rather than directly above it. Final exposure of the service should be by horizontal digging. The use or proprietary ‘air-knife’ operated by compressed air is recommended to expose the buried services. Access Safe means of getting into and out of an excavation must be provided. The provision of a good standard of access is also important for emergency use should it be necessary to vacate an excavation quickly due to flooding, build-up of fumes, etc. Emergency arrangements need to address how an injured person, unable to use a ladder access, will be recovered. Additionally by providing good ladder access or other safe ways of getting in and out of the excavation, the risk of accidental collapse is minimised. Any such ladder should project a minimum of 1 metre above ground level. Climbing in and out of an excavation using walings and struts must be prohibited. Fumes Exhaust fumes can be dangerous. Do not site petrol or diesel-engined equipment such as generators or compressors in, or near the edge of, an excavation unless fumes can be ducted May 2008 276 away or the area can be ventilated. In such situations the excavation should now be treated as a confined space. Protecting the public Fence off all excavations in public places to prevent pedestrians and vehicles falling into them. Where children might get onto a site out of hours, take precautions (e.g. backfilling or securely covering excavations) to reduce the chance of them being injured. Supervision A competent person must supervise the installation, alteration or removal of excavation support. People working in excavations should be given clear instructions on how to work safely. Inspecting excavations A competent person must inspect excavations: - At the start of each shift before work begins - After any event likely to have affected the strength or stability of the excavation; - after any accidental fall of rock, earth or other material. The competent person who must then prepares a written report must provide a copy of the report within 24 hours to the person on whose behalf the inspection was carried out. A copy of this report must be kept for a minimum of three months from the date of completion. Stop work if the inspection shows the excavation to be unsafe. May 2008 277 A Typical Inspection Form Legal requirements Health and Safety at Work etc Act 1974 Management of Health and Safety at Work Regulations 1999 Provision and Use of Work Equipment Regulations 1998 Construction (Design and Management) Regulations 2007 May 2008 278 Definitions Battering - sloping the trench banks to a safe angle Trench Box - i.e. rigid frame designed to protect persons from collapsing soil. Sometimes incorrectly referred to as a ‘drag box’. Trench boxes are modular whilst drag boxes are not. Soldier pile and lagging shoring – are slide rail systems consisting of drilled or driven Hpile with wood or steel plates Sheet piling shoring – i.e. Interlocking steel piles Modular shoring – is commercial slide rail systems of panels, piles and struts. Aluminium Hydraulic Shoring: A pre-engineered shoring system comprised of aluminium hydraulic cylinders (cross braces) used in conjunction with vertical rails (uprights) or horizontal rails (walers). This system is designed specifically to support the sidewalls of an excavation and prevent cave-ins. Benching: A method of protecting employees from cave-ins by excavating the sides of an excavation to form one or a series of horizontal levels or steps, usually with vertical or near vertical surfaces between levels. Cohesive Soil: Soil that remains in clumps when excavated. Competent Person: One who is capable of conducting a “suitable and sufficient” risk assessment by identifying existing or predictable hazards in the surroundings of working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorisation to take corrective measures to eliminate them. Also a person who is responsible for conducting the visual and recorded inspections. Cross braces: The horizontal members (struts) of a shoring system installed perpendicular to the sides of an excavation, the ends of which bear against either uprights or walers. Excavation: Any man-made cut, cavity, trench or depression in an earth surface, formed by earth removal. Granular Soil: Soil that breaks up easily and does not stay in clumps. Hazardous Atmosphere: An atmosphere by reason of being explosive, flammable, poisonous, corrosive, oxidizing, irritating, oxygen- deficient, toxic or otherwise harmful, may cause death, illness or injury. Protective System: A means of protecting employees from cave-ins. Protective systems include support systems (shoring), benching systems, shield systems (trench boxes) and other systems that provide the necessary protection. Shield: A structure that is able to withstand the forces imposed on it by a cave-in and thereby protect employees within the structure. Shields can be permanent structures or can be designed to be portable and moved along as work progresses. Shields can be either premanufactured or job built. Shields used in trenches are usually referred to as “drag boxes”. May 2008 279 Shoring: A structure such as a metal hydraulic, mechanical or timber shoring system that supports the sides of an excavation, and which is designed to prevent cave-ins. Support System: A structure such as underpinning, bracing or shoring which provides support to an adjacent structure, underground installation or the sides of an excavation. Trench: A narrow excavation made below the surface of the ground. Uprights: The vertical members of a trench shoring system placed in contact with the earth. Wales: The horizontal members of a shoring system placed parallel to the excavation face whose sides bear against the vertical members (uprights) of the shoring system May 2008 280 PAST EXAMINATION PAPERS May 2008 281 MOCK EXAMINATION.001 Paper IGC 1 THE MANAGEMENT OF INTERNATIONAL HEALTH AND SAFETY Section 1 This section contains one question. The marks for each part of the question are shown in brackets. You are advised to spend approximately half an hour on it. 1. (a) Identify the possible consequences of an accident to: (i) the injured workers; (ii) their employer. (3) (3) (b) Identify the direct and indirect costs to the employer of accidents at work. (8) (c) Outline the actions an enforcement agency may take following an accident at work. (6) Section 2 This section contains ten questions and you are advised to spend approximately 90 minutes on it. The marks for each question or part of a question are shown in brackets. 2. Outline how two organisations who share the same workplace can work together to ensure that good health and safety standards are achieved. (8) 3. Outline what should be considered when undertaking a risk assessment for young persons who are to be employed in the workplace. (8) 4 (a) Identify THREE types of emergency in the workplace which require the evacuation of workers. (3) (b) Explain why it is important to develop workplace procedures for emergency situations.(5) 5 Outline the key elements of a health and safety management system. (8) 6 (a) Give TWO reasons why visitors to a workplace might be at greater risk of injury than workers. (2) (b) Identify the precautions to be taken to reduce the risk of injury to visitors to the workplace. (6) 7. Outline the immediate and longer term actions that should be taken following an accident at work that caused serious injury to a worker. (6) 8. Outline the main features of: (a) a health and safety inspection; (4) (b) a health and safety audit. (4) 9 List the ways in which a manager could involve workers in the improvement of health and safety in the workplace. (8) 10. (a) Explain, using an example, the meaning of the term ‘risk’. (4) (b) Outline the key steps of a risk assessment. (4) (a) Outline why it is important for an organisation to set health and safety targets. (2) (b) Identify health and safety targets that an organisation may set. (6) 11. May 2008 282 MOCK EXAMINATION.002 PAPER IGC 2 CONTROL OF INTERNATIONAL WORKPLACE HAZARDS Section 1 This section contains one question. The marks for each part of the question are shown in brackets. You are advised to spend approximately half an hour on it. 1. (a) Outline the factors that may affect the risk from manual handling in relation to: (i) the task; (ii) the load. (iii) the individual (iv) the working environment (4) (4) (4) (4) (b) Outline a good manual handling technique that could be used when lifting a box weighing 12.5 kg. (4) Section 2 This section contains ten questions and you are advised to spend approximately 90 minutes on it. The marks for each question or part of a question are shown in brackets. 2. Outline FOUR types of engineering control that may be used to reduce noise in the workplace, giving a practical example of EACH. (8) 3. Outline the issues that should be considered by an organisation when developing a system for the safe collection and disposal of its waste. (8) 4 (a) Outline ways of segregating pedestrians and vehicles in the workplace. (4) (b) Outline ways of reducing the risk to pedestrians when segregation is not practicable. (4) 5 Outline a range of checks that should be made to ensure electrical safety in an office environment. (8) 6 (a) Outline the principles of the following types of machine guard: (i) fixed guard (ii) interlocked guard (2) (2) (b) Identify TWO advantages and TWO disadvantages of a fixed machine guard. (4) Identify the ways in which accidents may be prevented when using portable ladders as a means of access. (8) (a) Define the meaning of the term ‘hazard’. (2) (b) Outline the main hazards that may be present during the demolition of a building. (6) (a) Describe the differences between acute and chronic health effects. (4) (b) Identify the factors that could affect the level of harm experienced by a worker exposed to a toxic substance. (4) (a) In relation to the classification of fires, give an example of a material(fuel) that falls within EACH of the classes A, B, C and D. (4) 7 8. 9 10 (b) Identify TWO methods of heat transfer AND explain how EACH method contributes to the spread of fire. (4) 11 May 2008 a) List possible health effects of working outside in extreme heat created by the sun. (4) (b) Outline control measures that could be used to minimise the effects of the sun on construction workers. (4) 283 MOCK EXAMINATION.003 Paper IGC 1 THE MANAGEMENT OF INTERNATIONAL HEALTH AND SAFETY Section 1 This section contains one question. The marks for each part of the question are shown in brackets. You are advised to spend approximately half an hour on it. 1. Following a significant increase in accidents, a health and safety campaign is to be launched within an organisation to encourage safer working by employees. (a) Outline how the organisation might ensure that the nature of the campaign is effectively communicated to, and understood by, the employees. (8) (b) Other than poor communication, describe the organisational factors that could limit the effectiveness of the campaign. (12) Section 2 This section contains ten questions and you are advised to spend approximately 90 minutes on it. The marks for each question or part of a question are shown in brackets. 2. Outline reasons for maintaining good standards of health and safety within an organisation.(8) 3. 4 Outline the key areas that should be addressed in the ‘arrangements’ section of a health and safety policy document. (8) (a) Explain why it is important for an organisation to set targets in terms of its health and safety performance. (2) (b) Outline SIX types of target that an organisation might typically set in relation to health and safety. (6) 5 Employers have a requirement placed upon them under health and safety to involve their employees. (i) Explain the difference between ‘consulting’ and ‘informing’ (2) (ii) Outline the health and safety matters on which employers must consult their employees. (6) 6 Outline the main health and safety issues to be included in an induction training programme for new employees. (8) 7 Outline ways in which the health and safety culture of an organisation might be improved (8) 8 With respect to the management of risk within the workplace: (i) Explain the meaning of the term ‘hierarchy of control’. (ii) 9 10 11 May 2008 (2) Outline, with examples, the standard hierarchy that should be applied with respect to controlling health and safety risks in the workplace. (6) (a) Explain, using an example, the meaning of the term ‘risk’. (2) (b) Outline the factors that should be considered when selecting individuals to assist in carrying out risk assessments in the workplace. (6) Outline the immediate and longer term actions that should be taken following a serious injury accident at work. (8) List the written information that is likely to be examined during a health and safety audit. (8) 284 MOCK.004 Paper IGC 1 THE MANAGEMENT OF INTERNATIONAL HEALTH AND SAFETY Section 1 This section contains one question. The marks for each part of the question are shown in brackets. You are advised to spend approximately half an hour on it. 1. (a) An organisation has seen an increase in the number of accidents at work. Give reasons why this increase in accidents might have occurred. (4) FOUR (b) Explain why workers may not follow the instructions they have been given. (4) (c) Outline how the organisation might improve its health and safety performance to accidents. reduce (12) Section 2 This section contains ten questions and you are advised to spend approximately 90 minutes on it. The marks for each question or part of a question are shown in brackets. 2. Outline when a health and safety policy would require review. (8) 3. Explain how two organisations who share the same workplace can work together to ensure good health and safety standards are achieved. (8) (a) Outline the rights of workers in respect of health and safety at work. (4) (b) Outline the responsibilities of workers in respect of health and safety. (4) Outline design features which may increase the likelihood of errors and violations occurring in the workplace. (8) (a) Define the term ‘hazard’. (2) (b) Define the term ‘risk’. (2) (c) Identify FOUR means of hazard identification that may be used in a workplace. (4) Describe , with the use of workplace examples, the principles of a general ‘hierarchy of control’ for risk reduction. (8) Outline the main features of: (a) a health and safety inspection; (4) (b) a health and safety audit. (4) 9 Outline the benefits to an employer of conducting accident investigations. (8) 10. (a) Explain why it is important for an organisation to consult with its workers on health and safety issues. (4) (b) Describe how the arrangements for consultation with workers may be made more effective. (4) Identify the factors to be considered to ensure the health and safety of persons who are required to work on their own away from the workplace. (8) 4 5 6 7 8. 11. May 2008 285 MOCK EXAMINATION.005 PAPER IGC 2 CONTROL OF INTERNATIONAL WORKPLACE HAZARDS Section 1 This section contains one question. The marks for each part of the question are shown in brackets. You are advised to spend approximately half an hour on it. 1. (a) Outline the factors to be considered when carrying out a manual handling risk assessment in respect of the: (i) the load. (4) (ii) the individual (4) (b) Give FOUR types of injury which may be caused by the incorrect manual handling of loads. (4) (c) Give TWO examples of how a manual handling task might be avoided. (2) (d) Outline a good handling technique that could be adopted by a worker required to lift a load. (6) Section 2 This section contains ten questions and you are advised to spend approximately 90 minutes on it. The marks for each question or part of a question are shown in brackets. 2. Identify the main hazards associated with excavation work on construction sites. (8) 3. Outline the electrical safety checks that the user should carry out on a portable electrical sander before using it. (8) 4 A maintenance worker regularly uses a hand held grinder, exposing him to external vibration. (a) Identify the symptoms that the worker may experience due to this exposure. (2) 5 6 7. 8. 9 10. 11. May 2008 (b) Outline SIX control measures that can be used to reduce exposure to vibration. (6) Fork-lift trucks operating in a busy environment. Describe suitable measures that the employer could take to reduce the risk of collision with workers. (8) (a) Identify FOUR mechanical hazards associated withy the use of mechanical hazards. (4) (b) Outline the precautions to be taken to minimise the risk of injury to operators of pedestal drills. (4) Outline the factors that may reduce the effectiveness of a local exhaust ventilation (LEV) system. (8) (a) Explain, using a suitable sketch, the significance of the fire triangle. (2) (b) Outline the main hazards that may be present during the demolition of a building. (6) (a) Identify THREE forms of biological agent. (3) (b) State THREE possible routes of entry into the body for a biological agent. (3) (c ) Give TWO appropriate control measures that can be taken to reduce the risk of exposure to a biological agent. (2) (a) Identify TWO types of ionising radiation. (4) (b) Explain the main principles of control for ionising radiation. (4) List the factors that should be considered when using a mobile elevated working platform (MEWP). (8) 286 NEBOSH INTERNATIONAL NATIONAL GENERAL CERTIFICATE CANDIDATE BRIEFING SHEET The course The course follows the syllabus as laid down by NEBOSH. It covers 3 main units or areas: IGC 1 Management of Safety and Health IGC 2 Controlling workplace hazards IGC 3 Practical inspection However, this is not the order in which it is presented by BSS, because there is considerable overlap, and scope for integration of elements from all three areas. So the programme you will follow is designed to impart the knowledge required in a logical, compact and interesting way. The course will also not follow the order set out in your manual because we aim to achieve a mix of both ‘heavy’ and ‘light’ subjects each day in order to achieve maximum attention and enjoyment for yourselves. Examinations The examinations are closed book and undertaken as follows: NEBOSH sets and marks the two written examination papers, covering units IGC 1 and IGC 2 of the syllabus. Each paper contains eleven questions. One 20 mark question, main question and ten, short answer, 8 mark questions. The time allowed for each paper is two hours and candidates are required to answer ALL questions. However, for students where english is not their first language, there will be an additional time allowance of 25% for special consideration, subject to NEBOSH approval for all three unit assessments- see below, special consideration section. IGC 3, the practical assessment unit, is set and marked by British Safety Services, and is moderated by NEBOSH. It requires the candidate to make an unaided inspection of health and safety at a real workplace and to prepare a report for management. This practical exercise is a pass or fail, requiring the student to achieve a minimum 60%. Candidates awarded less than 60% in IGC 3 will be referred in this part of the overall assessment. Examination and result grades Performance indicators The pass mark for each unit may vary accordingly to pre-determined criteria but is normalised to 45% for the written papers (IGC1 & IGC2) and 60% for the practical application unit (IGC3). Candidates who are successful in an individual unit will be issued with a Unit Certificate, normally within 8 weeks of the issue of the result notification. This will show a pass grade only. Qualification grading When candidates have been awarded a Unit Certificate for all three units (i.e. have achieved a Pass in IGC1, IGC2 and IGC3), the marks for all three units are added together and a final grade is awarded as follows: Pass 150 - 179 marks Credit 180 - 209 marks Distinction 210 marks or more Qualification certification Once a candidate has achieved at least a Pass grade in all three units and the overall qualification grade awarded, a qualification parchment will be issued, normally within 10 weeks of the issue of the result notification. Once the result of the third completed unit has been issued the candidate has one month from the date of issue of that result to either: Inform NEBOSH in writing of their intention to re-sit a successful unit for the purposes of improving a grade or; submit an Enquiry About Result (EAR) request – contact the BSS office for further details. Candidates who fail to do this will be issued with a qualification parchment and will be deemed as having completed the award. May 2008 287 Unit re-sits If a candidate’s performance in any unit component is lower than a pass, candidates may re-register for each unit or the whole qualification at a later date if they so wish. Candidates may re-sit just the unit/s in which they have been unsuccessful providing that they re-sit within 5 years of the sitting of the first successful unit. Candidates should take this to mean from the result declaration date for their first successful unit. Aims and objectives of course to: confirm existing knowledge improve competence and confidence in undertaking duties of your job successfully undertake examinations enjoy the course Method: formal presentations videos and slides practical exercise, and group work site visits private study Private study Each day you will be given private study, to practise exam type questions, learn what NEBOSH mean by certain action words, and confirm understanding. Private study will be taken in by course tutors, marked and returned. This private study is not mandatory and does not account for any of the examination marks. However, it is strongly recommended that it is done, since there is a marked difference between those students who do attempt the private study and those who do not! Your role Ask questions Participate Private study Handout The handout is yours to keep and use as a reference book, but we do recommend that you make notes of your own. This will aid your memorising the information, help understanding and prepare your hand for writing for 2 and a half hours at a time in the examinations at the end of the course! Group work Why ? To exchange ideas, and confirm understanding General The International General Certificate is intended for candidates who are not based in the UK, since it does not cover UK law. The principles of achieving high standards of health and safety are the same regardless of any local legal requirements anywhere in the world. It is these principles, and the practices that follow them, that form the basis of the International Certificate. International. Technical and other standards (ILO Codes of Practice, for instance) will receive emphasis in the syllabus, where relevant. In other cases, UK requirements and practices may be assumed to represent ‘good practice’ and reference may be made in this respect to UK Approved Codes of Practice and relevant guidance. We will undertake a mock exam of the practical during the course. Special Consideration Where a candidate may be disadvantaged in the examination and/or the practical application unit due to English not being their first language, where deemed reasonable and appropriate by NEBOSH, may be allowed reasonable adjustments to help to compensate for such a disadvantage. This is normally an extra 25% time allowance in order to be able to refer to a paper (not electronic) dictionary. Exam technique and key words At every examination, a number of candidates - including very capable ones - perform less well than they might because of poor examination technique. It is therefore strongly recommended that you attempt all the home study, in order to get practice at answering both essay type questions and short answer questions. The BSS team will mark all submitted private study, and make individual comments concerning content, exam technique and time discipline. This last matter time, is important, because the International Certificate is a very condensed set May 2008 288 of examinations, and candidates must learn how to budget their time according to the number of marks allocated to questions (and parts of questions) as shown on the paper. Sometimes candidates may not pay full attention to the action verb in each question. To help to emphasise their importance action verbs are highlighted in bold type on Certificate examination question papers. The most commonly used ones are: Define: provide a generally recognised or accepted definition, e.g. Define the term ‘target organ’ within the context of occupational health. Describe: give a word picture, e.g. Describe the body’s respiratory defence mechanisms against atmospheric dust. Explain: give a clear account of, or reasons for, e.g. Explain the meaning of the term ‘perception’. Identify select and name, e.g. Identify TWO respiratory conditions related to exposure to asbestos. List provide a list without explanation, e.g. List EIGHT types of mechanical hazard commonly associated with machinery Outline: give the most important features of (less depth than either explain or describe, but more depth than ‘list’) e.g. Outline the methods that may be used to assess an organisation’s health and safety performance. Sketch: provide a simple line drawing using labels to identify specific features, e.g. Sketch an example of a machine or process with an ‘running nips’ hazard together with a suitable guard which will make it safe to use. State: a less demanding form of ‘define’, or where there is no generally accepted, recognised definition e.g. State the objectives of active monitoring. It is essential to pay proper attention to the action verb. Candidates will inevitably miss marks if the question asks for an ‘outline’ and only a ‘list’ is given. Equally, if a ‘list’ is required, candidates who write out an explanation will be wasting time, as no extra marks will be gained, when that lost time could be spent more profitably elsewhere on the paper. Mnemonics Some candidates find it easier to construct a speedy and logical answer to exam questions by utilising mnemonics, so in order to assist such candidates we use a series of mnemonics which you might wish to begin memorising for future use, both during and after the course: Risk Management: ACME IITS: Information, instruction and training Benefits of good health and safety management: HEL Manual Handling Strategy: AAA First Aid Assessment: DANNIELS Factors in a Manual Handling Assessment: LITE Safety Signs: SWMPF Functions- Safety Rep: RIICI Confined Spaces: ACME Functions of a Safety Committee: MIST Hazards: PEME Matters for consultation: MITAC Ergonomics: PEMEO Requirements for equipment & PPE: SUMRIC Machinery hazards: ENTICE P Machinery Guarding: FIAT Hierarchy Of Controls: ERIC PD Hierarchy for guarding of dangerous parts of machinery: FOSPI Noise reduction strategy: RIP RIP Noise reduction techniques: AIIDS May 2008 289 Assessor’s marking sheet INTERNATIONAL GENERAL CERTIFICATE UNIT IGC 3 – International health and safety application Candidate name ______________________________________________ Candidate number I ________________ Examination centre ________________________________________________________________________________ Date of practical assessment ____ / ____ / ____ Name of assessor ______________________________________ Maximum marks available Assessor’s marks NEBOSH moderated (if applicable) Observations 1 Range of issues identified 5 2 Number of hazards identified 20 3 Identification of immediate, medium and long term actions 10 4 Suitability of remedial action / time scales 20 Report to management 5 Selection of topics for urgent management action 10 6 Consideration of cost implications 5 7 Identification standards 8 Presentation of information 10 9 Effectiveness in convincing management to take action 15 of possible breaches of international TOTAL MARKS Outcome: SATISFACTORY (60% or more) 5 100 UNSATISFACTORY (less than 60%) please do not write in this box Date assessed _____ / _____ / _____ Assessors signature _________________________________ Date received by programme organiser _____ / _____ / _____ Date received by NEBOSH (if applicable) _____ / _____ / ___ May 2008 290 INTERNATIONAL GENERAL CERTIFICATE Candidate’s observation sheet Unit IGC3 – International health And safety practical application Sheet number of _____ Candidate name _____________________________________ Candidate number I _______________ Place inspected ______________________________________ Date of inspection __ / __ / ___ _ Observations List hazards, unsafe practices and good practices Priority / risk Actions to be taken (if any) Time scale List all immediate and longer-term actions required (immediate, 1 week, etc) (H, M, L) 291 2008:nebosh\courses\IGC\handoutIGCv1 Revision 1 :14/04/08