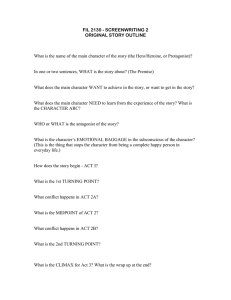

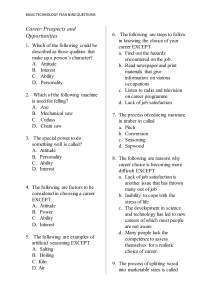

Capital University of Science & Submitted to Sir Saqib Amir Technology Performed by: Usama Farooq BME183126 Afaq Khalid BME183123 Talha Zeb BME183127 Waleed Usman BME183124 Manufacturing a pen holder on a lathe machine This Monday, 22nd October 2018 Objectives: 1. 2. Learn and practice various machine operations like facing, drilling, center drilling, turning, taper turning, and parting. Carry out this experiment safely. Materials Required: Workpiece material: Brass rod Workpiece size: 19mm diameter and 80mm length Required Shape: Tools/Parts of Machine Used (Some of the pictures given below): 1. Three Jaw Chuck 2. Spanner 3. Vernier Calipers 4. 5. 6. Parting tool Tap set Center drill 7. 8. 9. 10. 11. Two drills having diameters 4mm and 10mm Turning tool Taper turning attachment Bench vice File set Machine operations list: 1. 2. 3. 4. 5. 6. Facing the stock end Center drilling Turning cylindrical surfaces Taper turning Threading Parting the extra part Procedure Outline: 1. Get a Brass rod 2. 3. 4. 5. 6. Grip the piece Facing operation Drilling the center of the rod Various turning operations Taper turning Procedure (detailed): Before starting, have an extensive look at the drawing so it is clear for us what and how to design. First of all bring an alloy rod e.g.: steel, brass, brass, etc. In this case, brass was used. Its diameter should be approximately 19-20mm. Measure it using a Vernier Calipers. It should have a length for about 80mm. Check this using a scale or meter rule. Grip the rod tightly in the three jaw chuck and upto the point where the operation has to be done. Fix the cutting tool in a right position. Now we are ready to perform the first machine operation. Facing of the rod done for a few seconds. Drill at the center of rod using the 4mm drill bit to mark a reference point by supporting it by the dead center on the tailstock. Start turning on a trial basis to get a better idea. Then final turning of the rod has to be done upto 15mm. Now check again and again the diameter by using the Vernier Calipers, either it is upto 15mm or not. Our requirement was to apply turning to the whole piece so we removed and placed again to perform it on the remaining side. Attach the 10mm drill bit at the dead center on the tailstock and drill the object up 10mm diameter. According to figure, we performed turning again upto 12mm but left the 1mm part of length so that we can have a tip. Measure this using a Vernier Calipers again. Detach the object from the lathe machine. Now, carefully check the dimensions using relevant measuring tools e.g.: Vernier Calipers, scale, meter rule, etc. This is because we will move to the most important operation of this machine. Next, we need to perform taper turning which gives the actual shape to the object according to the figure. Taper turning was done at an angle of 7 degrees upto 16.5 mm to obtain a conical shape. Then fix the object in the bench vice. Last but not the least, use the metric tap set of M5 size for threading the drill diameter upto 4mm. Finally, we have successfully able to manufacture a pen holder using the lathe machine! Safety Precautions: 1. 2. 3. 4. 5. 6. 7. 8. 9. Wearing an overall suit (the very first and the most important part before starting any mechanical workshop experiment). Listen to the instructor carefully to get the directions. Critically study the parts of lathe machine before using it. Make sure that the chuck is securely tightened onto the lathe spindle. Wear safety goggles. While the machine is running, do not come near to the prime mover (motor) or the moving rubber belt. Do not be on the left side of the person who is using the lathe machine. Let the user operate the machine himself. Never perform things quickly or be too lazy. Keep a balance. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Do not daydream while using the machine. Remove the chuck key immediately after using. First start the machine, then pull the lever towards yourself for performing an operation. While finishing an operation, push the lever before turning of the machine. Avoid the sharp edges to the newly performed object. Do not wear the student card while working on the machine. Stop the machine first when removing the object from the chuck. Beware operation performed object would be hot, so be careful while touching it. Don’t cut the object completely through when turning between centers. Do not grasp or touch chips or turnings with your fingers, but get rid of them using a blunt instrument. It is safer to turn off the lathe before clearing chips than to leave it running. Turn the chuck by hand before turning on the power to be sure there is no binding or clearance problem. Stop the machine before taking the measurements. Before cleaning the lathe, remove the tools from the tool post and tailstock. 21. 22. Overall Suit: