A Novel Machine Learning Technique for

Online Health Monitoring of High-speed Trains

LINHAO ZHANG, YIQING NI, SIUKAI LAI

and SHENGGUO WANG

ABSTRACT

To ensure the operation safety and ride comfort of high-speed trains, a combination of

smart sensory systems and intelligent identification models for online condition

monitoring and assessment is highly desired. During routing operations, various

dynamic responses induced by the wheel-rail interaction can cause severe wheel

defects. The deterioration of train wheels, normally classified as “out-of-roundness”

(OOR), can seriously threaten the operation safety and cause catastrophic derailment

events. Conventional model-based prognostic methods often require an in-depth

understanding of the wheel-track system to develop favorable mathematical models

that are rather cumbersome. To complement the deficiencies of model-based

prognostic approaches, the use of data-driven methods has been increasingly applied

to various engineering fields. This research introduces a random forest (RF)-based

method for online condition prediction and monitoring of train wheels. The RF-based

method is a novel machine learning technique that possesses good stability and high

accuracy for data classification with less parameter adjustment in modeling processes.

A crucial step for the successful implementation of the RF-based technique is the data

mining process to extract valuable feature information from the raw data. Therefore,

the Teager-Kaiser energy operator (TKEO) and the wavelet packed decomposition

(WPD) technique are integrated together for feature extraction in this work. The

optimized feature subsets can thus be employed in the presented data-driven model for

the online health monitoring of high-speed train wheels.

_____________

Lin-Hao Zhang, Department of Civil and Environmental Engineering, The Hong Kong

Polytechnic University, Hung Hom, Kowloon, Hong Kong, P.R. China.

Yi-Qing Ni, Department of Civil and Environmental Engineering, and Hong Kong Branch of

National Rail Transit Electrification and Automation Engineering Technology Research Center,

The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong, P.R. China.

Siu-Kai Lai, Department of Civil and Environmental Engineering, The Hong Kong Polytechnic

University, Hung Hom, Kowloon, Hong Kong, P.R. China.

Sheng-Guo Wang, College of Engineering, University of North Carolina at Charlotte, Charlotte,

NC 28223-0001, USA.

349

INTRODUCTION

High-speed railway (HSR) is currently deemed as an environmentally friendly

mode of transport that can bring greatly beneficial for a huge volume of people to

strengthen social networks and business activities. Wheelsets of a high-speed train act

as one of crucial components, any deterioration poses a significant threat to the service

life and running quality. Wheel defects are generally known as “out-of-roundness”

(OOR), such as wheel flats, wheel spalling, corrugation and polygonization, which can

cause severe damages on both tracks and vehicle components [1, 2].

To maintain desirable safety, comfort and economic trips of high-speed trains, it is

therefore needed to draw more attention to the health status of wheelsets. In the

literature, there are plenty of research studies on the performance assessment of

wheelsets. Conventional inspection techniques (e.g., wheel impact load detector

(WILD)) are suitable for a large number of wheel inspections, but it is often one-off.

Besides, various wheel-rail interaction models have been proposed to investigate the

dynamic responses of wheels and rail structures due to the presence of wheel defects

[3, 4]. Nevertheless, the assumptions and simplifications adopted in the model-based

approaches can greatly affect the level of accuracy and effectiveness in fault detection.

In recent years, the data-driven methods based on monitoring data emerge as an

alternative way for long-term assessment of high-speed trains [5, 6].

This paper proposes a novel strategy to combine smart sensory systems and

intelligent identification models for online health monitoring of high-speed trains. The

random forest (RF)-based prognostic method that possesses good stability and high

accuracy for data classification is employed. In the present study, the monitoring data

were acquired from an on-board sensing system, which was installed on an in-service

high-speed train before and after the wheel lathing procedure (i.e., a process making

out-of-round wheels perfectly round again in a depot). Since the information hidden

behind the measured data is crucial to identify the health status of train wheels, the

Teager-Kaiser energy operator (TKEO) and the wavelet packed decomposition

(WPD) technique are integrated together for feature extraction before implementing

the RF-based method.

RF-BASED METHODOLOGY FOR CONDITION ASSESSMENT

This section presents the major procedures to implement the RF-based method for

online condition assessment of train wheels. It consists of three phases, namely (i) the

data pre-processing with a moving window, (ii) the feature extraction in both timedomain and frequency-domain, and (iii) the construction of a RF model. Each of them

is discussed in the subsequent sub-sections in detail.

Data Pre-processing with Moving Window

To effectively identify the operational performance of wheels by using the online

monitoring data, a fixed-size moving window is used to extract various sub-datasets

from the original signals. The raw data processed by the moving window at time 𝑡𝑘

can be compacted into a matrix form as

350

𝑚1 (𝑡𝑘 )

𝑚1 (𝑡𝑘+1 )

𝐌𝐤 (𝐭) =

⋮

[𝑚1 (𝑡𝑘+𝑁𝑤 )

𝑚2 (𝑡𝑘 )

𝑚2 (𝑡𝑘+1 )

⋮

𝑚2 (𝑡𝑘+𝑁𝑤 )

𝑚𝑁𝑠 (𝑡𝑘 )

⋯

⋯ 𝑚𝑁𝑠 (𝑡𝑘+1 )

𝑁𝑝

, 𝑘 = 1, … , 𝑁 (1−𝑄)

𝑤

⋱

⋮

⋯ 𝑚𝑁𝑠 (𝑡𝑘+𝑁𝑤 )]

(1)

where 𝑁𝑠 is the number of sensors deployed on the high-speed train, 𝑁𝑝 is the number

of sampling points and 𝑁𝑤 is the number of measurements within each moving

window. 𝑄 denotes the overlap degree of the window along the column. In each time

step 𝑡𝑘 , 𝑚𝑖 (𝑡𝑘 ) is the i-th sensor data at time 𝑡𝑘 , the data segment 𝐌𝐤 (𝐭) represents

the running condition of train wheels within the moving time window at time segment

𝑡𝑘 .

To dig out the information of the original signals, the TKEO is used to transfer the

data into a TK time domain and gains the following amplitude modulated signals as in

(2) with the description in (6),

𝑎𝑁𝑠 (𝑡𝑘 )

⋯

𝑎1 (𝑡𝑘 )

𝑎2 (𝑡𝑘 )

⋯ 𝑎𝑁𝑠 (𝑡𝑘+1 )

𝑎1 (𝑡𝑘+1 ) 𝑎2 (𝑡𝑘+1 )

𝑁𝑝

(2)

𝐀 𝐤 (𝐭) =

, 𝑘 = 1, … , 𝑁 (1−𝑄)

𝑤

⋱

⋮

⋮

⋮

[𝑎1 (𝑡𝑘+𝑁𝑤 ) 𝑎2 (𝑡𝑘+𝑁𝑤 ) ⋯ 𝑎𝑁𝑠 (𝑡𝑘+𝑁𝑤 )]

The statistical approaches are then employed for feature exaction as presented in

Table I. Along with other features extracted from a frequency-domain by using the

WPD method and the Sperling index, the feature matrix is then expressed as

𝑁𝑝

𝐅(𝐭 𝒌 ) = [𝑓1 (𝑡𝑘 ) 𝑓2 (𝑡𝑘 ) ⋯ 𝑓𝑁𝑣 (𝑡𝑘 )], 𝑘 = 1, … , 𝑁 (1−𝑄)

(3)

𝑤

where 𝑁𝑣 is the number of features extracted at each time segment.

Feature Extraction Strategies

TIME-DOMAIN FEATURES: TKEO

The TKEO [·] was first proposed by Kaiser [7]. It has good adaptability and high

time resolution without complicated signal transform procedures and any band-pass or

low-pass filtering. It is defined as

(4)

[𝑥(𝑡)] = [𝑥̇ (𝑡)]2 − 𝑥(𝑡)𝑥̈ (𝑡)

where 𝑥(𝑡) and 𝑥̈ (𝑡) are the first and second time derivatives of the original signals,

respectively. In terms of a discrete time, it can be expressed as

(5)

[𝑥(𝑛)] = 𝑥(𝑛)2 − 𝑥(𝑛 + 1)𝑥(𝑛 − 1)

where only three sampling points are required for energy computation at each time

instant. To capture the variation of signals in the form of energy fluctuation, DESA-1

is employed to estimate the amplitude modulated signals [8]:

|𝑎(𝑛)| =

[𝑥(𝑛)]

[𝑥(𝑛)] + [𝑥(𝑛 + 1)]

}

4[𝑥(𝑛)]

2

1 − {1 −

(6)

𝑓(𝑛) = arccos {1 −

[𝑦(𝑛)] + [𝑦(𝑛 + 1)]

}

4[𝑥(𝑛)]

(7)

√

where 𝑦(𝑛) = 𝑥(𝑛) − 𝑥(𝑛 − 1) . Functions 𝑎(𝑛) and 𝑓(𝑛) are, respectively, the

amplitude modulated signals and the instantaneous frequency-modulation signals.

351

After that, the statistical measures are applied for feature extraction as shown in Table

I below.

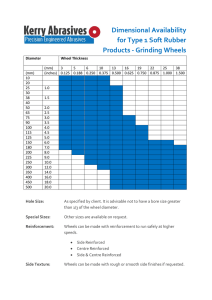

FREQUENCY-DOMAIN FEATURES: WPD AND SPERLING INDEX

Two frequency-domain techniques are used to extract features in this work. The

WPD method can evaluate the variation of energy by decomposing the original signals

into 2𝑁 bands [9]. In Figure 1, a significant change is observed when comparing the

power spectral density (PSD) of the acceleration on the axle box acquired before and

after the wheel lathing process. Similarly, the variation of energy at the second band

(4.88 Hz – 9.77 Hz) can be obviously found by the WPD technique. This is well

consistent with the available results [10], in which the vibration frequencies ranging

from 5 Hz to 10 Hz are mainly caused by the wheel-rail contact bouncing at two sides

of abrasion concave due to wheel defects. Hence, the energy value of the second

frequency band obtained by the WPD technique is selected as a feature in RF

modeling.

In addition, the vibration-based Sperling index, relating to the subjective comfort

feeling of passengers with objective physical variables, is selected as a feature to

reflect the running status of train vehicles [11]. The details are presented in Table II.

(a)

(b)

Figure 1. Acceleration on the axle box before and after lathing: (a) original signals in PSD; (b)

corresponding energy values in WPD.

Label

ME

RM

SF

SK

TABLE I. SUMMARY OF TIME-DOMAIN FEATURES.

Expression

Specification and illustration

1 𝑁

Mean value of the amplitude of TK

𝑚 = ∑𝑖=1 𝑥𝑖

𝑁

signals.

Root mean square is also known as a

1

𝑥𝑟𝑚𝑠 = √ ∑𝑁

𝑥2

quadratic mean.

𝑁 𝑖=1 𝑖

1

Shape factor refers to a value that is

|𝑥 |

𝑓 = 𝑥𝑟𝑚𝑠 ⁄ ∑𝑁

𝑁 𝑖=1 𝑖

affected by the shape of waveforms.

Skewness measures the asymmetry of

3

the probability distribution of a real1

1

(𝑥 − 𝑚)3 ⁄[√ ∑𝑁

(𝑥 − 𝑚)2 ]

𝑠 = ∑𝑁

valued random variable around its

𝑁 𝑖=1 𝑖

𝑁 𝑖=1 𝑖

mean value.

352

1

1

𝑁

𝑁

KU

𝑁

4

2

𝑘 = ∑𝑁

𝑖=1(𝑥𝑖 − 𝑚) ⁄[ ∑𝑖=1(𝑥𝑖 − 𝑚) ]

CF

𝑐 = max(𝑥) /𝑥𝑟𝑚𝑠

Kurtosis is a descriptor for the shape of

a probability distribution by different

quantifying ways.

Crest factor is the measure of a

waveform to show the ratio of the peak

value to the effective value.

2

TABLE II. SUMMARY OF FREQUENCY-DOMAIN FEATURES.

Expression

Specification and illustration

𝑛

The calculation of energy by the

2

2

WPD technique using the

𝐸 = ∫|𝑆𝑁𝑗 (𝑡)| 𝑑𝑡 = ∑|𝑥𝑗𝑘 |

acceleration data [12].

𝑘=1

Label

EN

0.1

𝑛

𝑊=

(𝑊110

+

𝑊210

+

⋯ 𝑊𝑛10 )0.1

SI

𝑊 = 7.08 [

= (∑ 𝑊𝑖10 )

𝑖=1

0.1

𝐴2𝑖

𝐹(𝑓𝑖 )]

𝑓𝑖

The Sperling index is a specific

indicator relating to the subjective

comfort feeling of passengers with

the objective physical variables of a

running vehicle [13].

RF-based Classification

Random forest (RF) model is an ensemble learning technique for classification. It

has good stability and is not sensitive to noise. As shown in Figure 2, the basic

rationale of a RF model combines a plenty of individual classifier decision trees and

allows them to vote for the most favorite class to achieve a high level of accuracy [14].

Three major steps for the implementation of this RF classification technique are

presented as follows:

Step 1: Data subset generation for training.

The feature matrix 𝐅(𝐭) is employed as the original input dataset in the RF.

Making use of a bagging process, 𝑘 training sub-datasets are randomly

selected from the original 𝐅(𝐭) dataset. Due to the selection with

displacements and no deletion of the sampling data, other unused data

consisted of the out-of-bag (OOB) datasets are used to estimate the accuracy.

Step 2: Growth of classifier trees.

Unlike conventional decision trees, the RF technique does not require using

any pruning techniques to gain high performance. It randomly selects a fixedsize (𝑚) of split features from 𝐅(𝐭). Then, the inherent Gini index is used to

decide the best feature in the division of each splitting node for growing trees.

Step 3: Selection of the most popular class.

The margin function in RF assists the selection of a right class. Finally, the RF

technique counts the number of times for the appearance of the samples at the

same terminal classification node and then votes for the best classification.

353

Figure 2. Architectural hierarchy of a RF classification model.

ILLUSTRATIVE APPLICATION

As aforementioned, an on-board sensing system was installed on an in-service

high-speed train. Both piezoelectric and optical fiber sensors were used to

continuously collect various types of data, including acceleration, strain, temperature

and sound data, from the trailer bogie, axle box and interior car floor of the train [15].

According to Tables I and II, 𝑁𝑣 (= 21) features are extracted from the raw data and

they are recorded in the matrix columns 𝐅(𝐭) = [𝑓1 (𝑡), 𝑓2 (𝑡), … 𝑓𝑁𝑣 (𝑡)]. In this study,

the moving window, having a width of 100s and a 75% overlap degree, is employed.

To validate the effectiveness of the proposed RF-based prognostic technique, the

monitoring data acquired from the train before and after the wheel lathing process are

used. At each time segment 𝑡𝑘 , 𝐅(𝐭 𝐤 ) is stuck with a classification tag that can be used

to represent the status of train wheels.

TABLE III. CLASSIFICATION ACCURACY (%) WITH DIFFERENT SPLIT FEATURES.

m Split feature(s) selected for RF modeling and prediction (k = 2000, Nv’ = 10)

Category

m=1

2

3

4

5

6

7

8

9

10

Class 1

99.83

99.72

99.65

99.55

99.55

99.51

99.38

99.27

99.27

99.13

Class 2

97.96

97.96

98.10

98.14

98.14

98.21

98.14

98.10

98.10

97.96

Average

98.90

98.84

98.88

98.85

98.85

98.88

98.83

98.74

98.69

98.55

(Note: Nv’ is the number of features extracted from the elimination work (i.e., the selection of relative

important features from the original matrix F(t) according to the Boruta feature selection; Class 1 is for

the estimate accuracy of the well-behaved statue of wheels, and Class 2 is for the estimate accuracy of

the out-of-round wheels.)

TABLE IV. CLASSIFICATION RESULTS OF THE OPTIMIZED RF MODEL.

Classifier

RF

Identification accuracy of the wheel conditions (k = 1500, m = 6)

Well-behaved

Out-of-round

Overall

99.62%

98.21%

98.91%

354

0.4

0.2

0.0

-0.2

Dim 2 2

Dimension

Classification 1

Classification 2

-0.4

-0.2

0.0

Dimension 1

0.2

0.4

Dim 1

Figure 3. A metric multi-dimensional scaling representation for the online monitoring data of the inservice high-speed train.

Two metric parameters, the number of trees (𝑘) and the split number of features

(𝑚), are required for RF modeling. In this work, 𝑘 is set as 1500 since the generation

error converges as the number of trees increases in accordance with the “Strong Law

of Large Numbers” [16]. To ensure the robustness and reduce the data processing load,

the Boruta feature selection (BFS) as one of the powerful RF-based importance

measures [17] is used to estimate the significance of features, it can also rearrange the

sequence of elements in 𝐅(𝐭). Finally, the first 10 important features (𝑁𝑣′ = 10) in

𝐅𝐵𝐹𝑆 (𝐭) are considered for RF modeling based on a convergence study.

Table III shows the influence of the number of split variables (𝑚) on the classifier

accuracy as the tree number 𝑘 is equal to 2000. The best performance of the RF model

to recognize classification 1 (i.e. well-behaved statue of wheels) reaches to 99.83%

when 𝑚 is set to 1. Similarly, the RF model using 6 split features (𝑚 = 6) can well

identify the second classification (i.e. out-of-round wheels) with an accuracy of

98.21%. Regarding of the average classifying accuracy, the RF models employing 1, 3

and 6 split features can achieve the relative higher values (98.88% – 98.90%) when

comparing to other cases. It is worth noting that the identification accuracy of the outof-round wheels (class 2) should be paid more attention since the wheel defects can

affect the running safety of high-speed trains. From a modeling perspective, the

number of 𝑚 (>1) is preferred to balance the tree strength and the correlation among

trees in a RF structure. Therefore, the RF model trained by defining 1500 trees (𝑘 =

1500), 6 split variables (𝑚 = 6) and 𝐅𝐵𝐹𝑆 (𝐭) with 𝑁𝑣′ = 10 is selected as the optimal

one for condition assessment of the train wheels. In this research, 50% of the collected

data are randomly selected for RF modeling, and the rest samples (5676 sets) are used

to test the model performance. In Table IV, the proposed method can effectively

identify the out-of-round wheels (class 2) with an accuracy of 98.21%, and the average

recognition accuracy is up to 98.91%. The metric multi-dimensional scaling results

from the optimized RF model are illustrated in Figure 3. It is observed that the features

to characterize the same condition of the wheels are clustered well and each cluster is

clearly separated.

355

CONCLUSIONS

Operation safety is always of paramount importance for high-speed trains. The

quality of train wheels is a dominant safety factor whose deterioration can seriously

cause catastrophic derailment events. It is motivated to exploit innovative techniques

for online condition assessment of high-speed trains. The use of data-driven

approaches based on online monitoring data paves an effective avenue to trace the

health status of high-speed trains. This paper presents a novel RF-based strategy that

combines with both TKEO and WPD techniques for real-time condition monitoring of

train wheels. The RF technique possesses good stability and involves less parameter

adjustment in classification. In RF modeling, the moving window technique is used to

realize the fast and continuous status identification. The feature extraction that digs out

the useful information contained in the raw data is a crucial step for the successful

implementation of the RF-based method for online health monitoring of high-speed

trains. An illustrative example is provided herein, and the test results show that the RF

model can achieve an excellent performance for the identification of out-of-round

wheels.

ACKNOWLEDGEMENTS

The work described in this paper was supported by the funding from the

Innovation and Technology Commission of Hong Kong SAR Government (Grants

No. K-BBY1 and 1-BBYJ) to the Hong Kong Branch of Chinese National Rail

Transit Electrification and Automation Engineering Technology Research Center.

Prof. Sheng-Guo Wang appreciates the Fulbright award program and HK PolyU

support to his work as a US Fulbright-PolyU senior scholar of 2016-2017 at the HK

PolyU.

REFERENCES

1.

2.

3.

4.

5.

6.

7.

8.

Johansson, A., and Nielsen, J. C. 2003. “Out-of-round railway wheels—wheel-rail contact forces

and track response derived from field tests and numerical simulations,” Proc. Instit. Mech. Eng.,

Part F: J. Rail Rapid Transit, 217(2): 135-146.

Barke, D. W., and Chiu, W. K. 2005. “A review of the effects of out-of-round wheels on track and

vehicle components,” Proc. Instit. Mech. Eng., Part F: J. Rail Rapid Transit, 219(3): 151-175.

Nielsen, J. C., and Oscarsson, J. 2004. “Simulation of dynamic train–track interaction with statedependent track properties,” J. sound vib., 275(3-5): 515-532.

Alexandrou, G., Kouroussis, G., and Verlinden, O. 2016. “A comprehensive prediction model for

vehicle/track/soil dynamic response due to wheel flats,” Proc. Instit. Mech. Eng., Part F: J. Rail

Rapid Transit, 230(4), 1088-1104.

Ni, Y. Q., Liu, X. Z., Zhao, W. Z., and Liang, S. L. 2015. “Outlier Detection in Sensor-assisted

Online Ride Comfort Assessment of High-speed Trains,” Proceeding of the 10th International

Workshop on Structural Health Monitoring, Stanford, California, USA.

Zhang, L. H., Wang, Y. W., Ni, Y. Q., and Lai, S. K. 2018. “Online condition assessment of highspeed trains based on Bayesian forecasting approach and time series analysis,” Smart Struct. Syst.,

21(5), 705-713.

Kaiser, J. F. 1990. “On a simple algorithm to calculate the 'energy' of a signal,” Proc. Int. Conf.

Acoust., Speech, Signal Process., Apr. 1990, pp. 381-384.

Kvedalen, E. 2003. “Signal processing using the Teager Energy Operator and other nonlinear

operators,” PhD thesis, University of Oslo, 2003.

356

9.

10.

11.

12.

13.

14.

15.

16.

17.

Ekici, S., Yildirim, S., and Poyraz, M. 2008. “Energy and entropy-based feature extraction for

locating fault on transmission lines by using neural network and wavelet packet decomposition,”

Expert Syst. Appl., 34(4), 2937-2944.

Huang, Z. W., Cui, D. B., Du, X., and Jin, X. S. 2013. “Influence of deviated wear of wheel on

performance of high-speed train running on straight tracks,” J. China Railw. Soc., 35(2), 14-20.

Zhou, J., Goodall, R., Ren, L., and Zhang, H. 2009. “Influences of car body vertical flexibility on

ride quality of passenger railway vehicles,” Proc. Instit. Mech. Eng., Part F: J. Rail Rapid Transit,

223(5), 461-471.

Zhou, Q., Zhou, H., Zhou, Q., Yang, F., and Luo, L. 2014. “Structure damage detection based on

random forest recursive feature elimination,” Mech. Syst. Signal Process., 46(1), 82-90.

China National Bureau of Standards 1985, Railway Vehicles Specification for Evaluation of

Dynamic Performance and Accreditation Test, GB5599, Beijing, China.

Breiman, L. 2001. “Random forests,” Mach. Learn., 45(1), 5-32.

Wang, X., Ni, Y. Q., Zhang, L. H., and Sun, Q. 2016. “Understanding of dynamic interaction of an

in-service high-speed train via on-board monitoring,” Presented at the 1st International Workshop

on Structural Health Monitoring for Railway System, October 12-15, 2016.

Rodriguez-Galiano, V. F., Ghimire, B., Rogan, J., Chica-Olmo, M., and Rigol-Sanchez, J. P. 2012.

“An assessment of the effectiveness of a random forest classifier for land-cover classification,”

ISPRS J. Photogramm. Remote Sens., 67, 93-104.

Kursa, M. B., and Rudnicki, W. R. 2010. “Feature selection with the Boruta package,” J. Stat.

Softw., 36(11), 1-13.

357