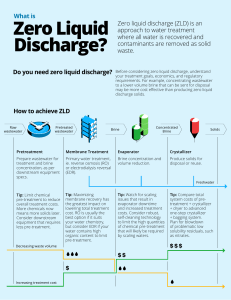

Feature Article BR EN T AL S PAC H AN D G R A HAM J U BY Cost-Effective ZLD Technology for Desalination Concentrate Management LIQUID DISCHARGE TECHNOLOGY ILLUSTRATES THE POTENTIAL FOR AFFORDABLE USE AT DESALINATION PLANTS ACROSS THE COUNTRY IN THE FORTHCOMING AWWA MANUAL OF PRACTICE M69. I ncreasing demand for freshwater resources among a variety of beneficial uses (i.e., municipal, agricultural, industrial, and environmental) is straining available supplies to an unprecedented degree. In the United States, competition for these supplies was intensified by the recent multiyear droughts that afflicted California, Texas, and the desert Southwest. Consequently, the use of alternative, lower-quality sources, such as brackish groundwater, saline surface water, and recycled wastewater, are rapidly becoming integral potential components of long-term water supply portfolio planning. Nearly all of these alternative supplies require desalination; however, in many areas, particularly inland locations, concentrate management options may be limited because of the lack of a suitable receiving body, environmental regulations, and/or permitting restrictions. In these cases, the use of zero liquid discharge (ZLD) technology can overcome all of these barriers. ALSPACH & JUBY | JANUARY 2018 • 110:1 alspach_npr.indd 37 | JOURNAL AWWA Layout imagery by Shutterstock.com artists: XONOVETS, teamplay A FRESH LOOK AT ZERO 37 12/11/2017 4:32:24 PM With the demand for desalination at a historic level that continues to trend upward, expanded funding for ZLD research has yielded a number of novel and innovative approaches. Although these new approaches have significantly reduced the cost of ZLD, many are boutique strategies with applicability that is limited to specific concentrate water quality characteristics, thus benefitting only a small subset of desalination facilities. By contrast, the more conventional ZLD approach—the combination of brine concentrators and crystallizers—is not constrained by water quality and can be deployed to treat concentrate of almost any quality. The primary limitation of conventional ZLD has been very high life cycle costs, which are largely attributable to substantial specific energy requirements. As a result, despite recent advances and a growing need for versatile, more environmentally friendly concentrate management options, the mainstream adoption of conventional ZLD has remained elusive. However, a fresh examination of conventional ZLD demonstrates that in some cases the process can be applied at costs that are comparable to other alternative sources of supply, such as desalinated seawater. potential for affordable use at desalination plants across the country. OVERVIEW OF ZLD The concept of ZLD represents the complete (or near complete) elimination of liquid waste from a water treatment residuals stream. For desalination processes, ZLD further concentrates the highly saline liquid residuals stream, ultimately generating solids or dense slurries that can be transported offsite for disposal or recycling. However, the idea of ZLD is not exclusive to desalination; surface water treatment plants (i.e., those treating lowsalinity sources) with advanced residuals management can likewise achieve ZLD, albeit using much different processes. Because the literature may not clearly make this distinction, and because ZLD associated with low-salinity water treatment is generally much more economical and therefore more common, it is important to understand the context in which the term is applied. For the purposes of this article, the discussion of ZLD is limited to desalination applications. Because there is no formal definition of the concept, what constitutes ZLD is somewhat fluid; therefore, With the demand for desalination at a historic level that continues to trend upward, expanded funding for ZLD research has yielded a number of novel and innovative approaches. This article, which is adapted from the forthcoming AWWA Manual of Practice M69: Inland Desalination and Concentrate Management, discusses the results of this examination in detail. Focusing on implementation, operations, and economics, the objective of this article is to enhance the practical understanding of conventional ZLD throughout the industry and demonstrate the 38 alspach_npr.indd 38 ALSPACH & JUBY | JANUARY 2018 • 110:1 there is no widely recognized threshold recovery beyond which a desalination plant constitutes a ZLD facility. Accordingly, the literature may represent plants operating at recoveries near 98.5% as using ZLD or nearZLD. However, accomplishing nearly 100% recovery is not necessarily a rigorous prerequisite for ZLD, as some water may be incorporated into the final hydrated solids or thickened slurries. In such examples, the plant does not discharge any strictly liquid residuals, although technically 100% recovery is not attained. In any case, the ZLD label is less important than achieving the goal of eliminating the discharge of liquid residuals. There are two primary advantages associated with eliminating liquid discharge. The first advantage is maximizing the yield of treated/desalinated water. The second advantage is providing a means of concentrate management for cases in which there are no other viable options. The benefit of increasing treated water production could be a significant consideration in any location, potentially driven by issues of water rights, the cost of developing new sources, the availability of additional supplies, procuring land for new treatment facilities, and other factors. However, the utility of ZLD is particularly acute for inland desalination locations, which often have fewer concentrate management alternatives than coastal regions. For example, • an inland area may lack a suitable receiving body for desalination concentrate; • the concentrate water quality may not permit discharge to any existing receiving bodies; • there may be a lack of a centralized wastewater collection system for discharge, or if such infrastructure is present, the municipal effluent discharge permit may not allow for higher salinity flows; • water quality, geology, and/or regulations may limit deep well injection; and • the evaporation rate and/or availability of land acreage for storage ponds may be insufficient to accommodate the concentrate flow. If all of these conditions are true, then ZLD may be the only alternative for concentrate management and thus the only means of enabling the use of desalination treatment. Unlike most other concentrate | JOURNAL AWWA 12/11/2017 4:32:39 PM management strategies, conventional ZLD (defined for the purposes of this work as the combination of a brine concentrator and crystallizer) can be deployed almost anywhere and has relatively few environmen­ tal, regulatory, or practical limita­ tions that restrict feasibility; how­ ever, the cost may be prohibitive. Conventional ZLD treatment. Con­ ceptually, ZLD can be con­sidered as a series of two progressive treatment steps, including advanced concentra­ tion followed by solids generation. Although these two steps may not necessarily be distinct, depending on the specific processes used, the underlying concept is useful for understanding ZLD treatment. Accordingly, the discussion of ZLD treatment in this article focuses on the combination of brine concentra­ tors (advanced concentration) and crystallizers (solids generation). While there may be many varied approaches to achieving ZLD, the combination of brine concentrators and crystallizers has the important advantage of not being limited by water quality. For example, Locke et al. (2015) describe a groundwater desalination plant owned by the City of Palm Coast, Fla., that achieves ZLD by applying a combination of precipitative softening, ultra­ filtration, sludge thickening, and dewatering to its reverse osmosis (RO) concentrate. However, the suc­ cessful implementation of this tech­ nique is predicated on a raw water supply with relatively low total dis­ solved solids (TDS) levels composed predominantly of hardness. This same approach would not be suit­ able for the concentrate of a seawater desalination plant, consisting largely of sodium and chloride that do not readily precipitate. By contrast, the coupling of brine concentrators and crystallizers can accomplish ZLD with almost any saline supply, inde­ pendent of TDS concentrations or the relative proportion of its con­ stituent dissolved solids. The literature contains numer­ ous descriptions of both brine FIGURE 1 Process schematic for a typical brine concentrator Feed brine Concentrated brine Steam vapor Distillate/condensate Vent Deaerator Feed tank Heat exchanger Feed pump Distillate tank Distillate pump Brine evaporator Mechanical vaper compressor Recirculation pump © General Electric Company. All rights reserved. Reprinted with permission. Use of this image does not signify endorsement by General Electric Company. con­centrators and crystallizers that include detailed process discussions (Ciszewski 2015, Yallaly 2015, Juby et al. 2008, Mickley 2006). The respective descriptions that follow provide a concise general overview of brine concentrator and crystallizer technology, focusing on the points most critical from a planning-level perspective. Although these descrip­ tions are framed in the context of employing RO as a primary desalina­ tion process, this assumption does not necessarily limit the dis­cussion from applying to the use of brine concen­ trators and crystallizers to reduce or eliminate the concentrate of other desalination technologies. Brine concentrators. Unlike RO, which employs pressure-driven membrane separation to accomplish desalination, brine concentrators use mechanical vapor compression technology to separate water from dissolved solids via thermal evapo­ ration. A process schematic for a typical brine concentrator is shown in Figure 1. The influent “feed brine” shown in Figure 1 represents the concentrate from a primary RO process. Acid may be added to the brine concen­ trator feed to lower the pH, thereby converting bicarbonate to dissolved carbon dioxide, which is subse­ quently removed in the deaerator in order to prevent corrosion. The stripping of carbon dioxide also removes alkalinity from the system, thus reducing the potential for cal­ cium carbonate scaling onto heat transfer surfaces, which reduces effi­ ciency. It is also common to seed cal­ cium sulfate crystals into the recircu­ lated brine slurry (shown in Figure 1 as the red “concentrated brine” pipe ALSPACH & JUBY | JANUARY 2018 • 110:1 | JOURNAL AWWA alspach_npr.indd 39 39 12/11/2017 4:32:59 PM TABLE 1 Influence of feed TDS and maximum concentrated brine effluent TDS on brine concentrator recoverya,b Brine Concentrator Feed TDS mg/L Brine Concentrator Recovery at a Maximumc Concentrated Brine Effluent TDS mg/L % 200,000 mg/L 250,000 mg/L 300,000 mg/L 97.5 98.0 98.3 5,000 10,000 95.0 96.0 96.7 20,000 90.0 92.0 93.3 30,000 85.0 88.0 90.0 40,000 80.0 84.0 86.7 50,000 75.0 80.0 83.3 TDS—total dissolved solids aAssumes brine concentrator distillate TDS of 10 mg/L brine concentrator recoveries are independent of feed flow. limited by assumed scaling potential bCited cAs loop driven by the recirculating pump) to serve as precipitation nuclei, preventing scaling by facilitating crystal growth. Scale inhibiting chemicals are also routinely added to the feed to control silica and other sparingly soluble species. The “distillate/condensate” flow in Figure 1 is the treated water produced by the brine concentrator, and TDS concentrations are typically below 10 mg/L. If a brine concentrator is used as the first step in a ZLD process (as is the case in this discussion), then the bleed flow from the concentrated brine shown in Figure 1 (red pipe and arrow at the bottom right) serves as the crystallizer feed flow. TDS levels in this residuals stream generally vary from approximately 180,000 to 250,000 mg/L depending on the scaling potential of This facility employs both brine concentrator (two units at right) and crystallizer (one unit at left) processes. Photo credit: ©General Electric Company. All Rights Reserved. Reprinted with permission. Use of this image does not signify endorsement by General Electric Company. 40 alspach_npr.indd 40 ALSPACH & JUBY | JANUARY 2018 • 110:1 the constituent dissolved solids; concentrations can potentially be increased to ~300,000 mg/L by incorporating a softening pretreatment process. Water recovery across the brine concentrator (i.e., the percent of influent feed flow that is converted to distillate) varies with the feed TDS concentration and its associated scaling potential. These influences are demonstrated in Table 1, which shows the brine concentrator recovery at feed TDS levels ranging from 5,000 to 50,000 mg/L for each of three cases in which the effluent “concentrated brine” (as referenced in Figure 1) is limited to 200,000 mg/L, 250,000 mg/L, and 300,000 mg/L, respectively, as a result of scaling. As indicated by these example cases, feed water with lower TDS and less scaling potential (i.e., higher TDS limits in the “concentrated brine” effluent) results in higher brine concentrator recoveries. It is im­portant to underscore that the recoveries shown in Table 1 are for the brine concentrator process only; if a brine concentrator and crystallizer are used as successive steps in a ZLD treatment process, the overall combined recovery is assumed to be effectively 100% (i.e., an insignificant volume of liquid residuals). Although the context of this discussion is the combination of brine concentrators and crystallizers as “conventional ZLD” that can be applied largely independent of feed water chemistry and flow, the use of a crystallizer is not always a prerequisite for producing crystalline solids for disposal. If the flow of concentrated brine from the brine concentrator is sufficiently low, discharge to a lined evaporation pond may be feasible (potential limitations of land area and evaporation rate notwithstanding). Brine concentrator specific energy consumption typically ranges from 60 to 90 kW·h/1,000 gal of water recovered (i.e., treated water flow), with higher degrees of concentration (e.g., targets of 200,000 versus | JOURNAL AWWA 12/11/2017 4:33:19 PM 250,000 versus 300,000 mg/L, and so on) requiring more energy per unit volume (Ciszewski 2015, Juby et al. 2008, Mickley 2006). By contrast, seawater desalination using RO (SWRO) typically requires 10–15 kW·h/1,000 gal of permeate. It is important to underscore that SWRO and brine concentrators are not functionally equivalent; the former is a primary desalination process that produces concentrate on the order of about 70,000 mg/L, while the latter would be applied to the SWRO concentrate and yield a residuals stream with TDS levels roughly two to four times higher. This comparison is provided only to illustrate the large increase in specific energy necessary to achieve concentrated solutions significantly higher than those produced by a primary desalination process. The values for brine concentrator specific energy consumption provided in this discussion assume the use of electric power and do not reflect the contribution of any available waste heat or other thermal advantage. Aside from the high energy requirements, the disadvantages of brine concentrators are primarily associated with operations and maintenance (O&M). In addition to the system complexity, brine concentrators respond more slowly to flow changes than a primary RO process, thus necessitating appropriately sized equalization tanks for the feed flow (as illustrated in Figure 1). Moreover, a supply of steam is necessary for brine concentrator start-up, including after every maintenance event, both complicating and extending the duration of the start-up process relative to many other treatment technologies. This steam may be provided by a dedicated boiler or supplied by another steam-generating process onsite (e.g., in the case of co-location with an applicable industrial manufacturing or power facility). Brine concentrator O&M challenges can be especially problematic for potable water treatment system operators who may not FIGURE 2 Process schematic for a typical crystallizer Feed brine Concentrated brine Steam vapor Distillate/condensate Crystallizer vapor body Brine heater Mechanical vapor compressor Recirculation pump © General Electric Company. All rights reserved. Reprinted with permission. Use of this image does not signify endorsement by General Electric Company. have experience with the complex thermal desalination systems that are uncommon in municipal applications outside of the Middle East. Thus, a rigorous operator training program is essential. Aesthetic concerns may also be a drawback, depending on the location of the Crystallizers. Like brine concentrators, crystallizers use mechanical vapor compression to desalinate highly concentrated brines, generating a slurry of solids. A process schematic for a typical brine concentrator is shown in Figure 2. Continuing through the treatment train of a Conceptually, ZLD can be considered as a series of two progressive treatment steps, including advanced concentration followed by solids generation. treatment facility. Because brine concentrators (and crystallizers) bear more resemblance to industrial equipment (see the photograph on page 40) than typical drinking water treatment plant processes, public acceptance may be an important consideration. conventional ZLD treatment scheme, the “feed brine” shown in Figure 2 is the concentrated residuals stream produced by the brine concentrator. Because the primary purpose of the crystallizer is to produce precipitated solids, neither acid nor scale inhibitors ALSPACH & JUBY | JANUARY 2018 • 110:1 | JOURNAL AWWA alspach_npr.indd 41 41 12/11/2017 4:33:35 PM crystallizer operating costs is shown in Table 2. The higher flows associated with RO concentrate would also substantially affect the capital cost of a crystallizer process, as the required capacity would be approximately an are used for pretreatment; however, antifoaming agents may be added. Concentrate from a primary RO process could also be treated with a crystallizer without a preceding brine concentrator, although the costs If the feed water has high concentrations of species that more readily precipitate out of solution, the specific energy requirements will be lower. order of magnitude higher than would be the case for a treatment train that included brine concentration before crystallization. Water quality can also have an influence on the specific energy requirements for crystallizers. If the feed water has high concentrations would be much greater due to the extremely high specific energy requirements, which can range from about 180 to 250 kW·h/1,000 gal (Ciszewski 2015, Mickley 2006). An example of the influence of the higher RO concentrate flows (versus brine concentrator residuals flows) on TABLE 2 Example of influence of flow on crystallizer operating costs Crystallizer Specific Energy Crystallizer Requirement Feed Flow kW·h/1,000 gal mgd Feed Water 200 Brine concentrator residualsc Primary RO concentrate Annual Energy Usagea 106 kW·h Annual Energy Costb $ 0.1 7.3 730,000 1 73 7,300,000 RO—reverse osmosis aAssumes bAssumes continuous operation $0.10/kW·h brine, as depicted in Figure 2 cConcentrated TABLE 3 Sample ZLD treatment cost summary Capital Cost O&M Cost Case Capacityb mgd millions of $ $/gpd millions of $/year ZLD-1 1.0 41.11 41.11 7.05 19.11 10.63 29.12 ZLD-2 0.5 28.38 56.77 3.78 20.29 6.25 34.25 ZLD-3 0.25 21.53 86.13 2.16 23.67 4.04 44.24 ZLD-4 0.125 16.64 133.11 1.28 28.07 2.73 59.87 $/1,000 millions $/1,000 gal of $/year gal Source: Juby et al. 2008 (for “Brine B”) O&M—operations and maintenance, ZLD—zero liquid discharge aAmortization bAssumes 42 alspach_npr.indd 42 Total Amortized Costa over 20 years at a 6% annual interest rate 100% recovery (i.e., ZLD feed flow = ZLD treated water flow) ALSPACH & JUBY | JANUARY 2018 • 110:1 of species that more readily precipitate out of solution, the specific energy requirements will be lower; however, significant concentrations of highly soluble species such as nitrate salts require more energy per unit volume of distillate produced. Also, as discussed in conjunction with brine concentrators, the 180–250 kW·h/1,000 gal range for crystallizer specific energy consumption provided in this discussion is a conservative estimate for planning purposes that assumes the use of electric power and does not reflect the contribution of any available waste heat or other thermal advantage. The “distillate/condensate” flow in Figure 2 is the treated water produced by the crystallizer, and TDS concentrations are typically 30–50 mg/L, a range that is somewhat higher than brine concentrator distillate (Ciszewski 2015). The recovery of the crystallizer process is effectively 100% (i.e., the volume of liquid waste is insignificant), although this includes the use of a centrifuge to dewater the solid slurry residual stream (i.e., the “concentrated brine” in Figure 2) to produce crystalline solids for landfilling or beneficial use (if feasible). The centrate generated by centrifuge is typically returned to the crystallizer feed flow (not shown in Figure 2). Crystallizers have many of the same disadvantages as brine concentrators, including operational complexity, the need for a supply of steam for each system start-up, and aesthetics. Crystallizers also respond relatively slowly to flow changes, and although not shown in Figure 2, equalization storage is likewise recommended for the crystallizer feed flow. Residuals management. Although a true ZLD treatment scheme does not generate liquid residuals, the process does produce solids (or a highly concentrated solid slurry) that must be properly managed for either beneficial use or disposal. Because these solids may contain significant levels of regulated metals or other contaminants, it is important to conduct a | JOURNAL AWWA 12/11/2017 4:33:52 PM hazardous waste characterization. Solids that cannot be recycled for beneficial use should be directed to a landfill (or similar facility) that is appropriately permitted to receive the residuals in accordance with their charac­terization. ZLD residuals are typically transported by truck, and the cost of this transportation, as well as the comprehensive cost of residuals management, must be incorporated into any economic analysis of ZLD. Any economic advantage from beneficial use would also be a factor in this analysis. Sample RO treatment cost summary at 80% recovery TABLE 4 Capacity Case Feed mgd Permeate mgd Concentrate mgd Capital Costa $/gpd O&M $/1,000 gal Total Amortized Costb $/1,000 gal Costa RO-1 5 4 1 0.58 0.30 0.44 RO-2 2.5 2 0.5 0.80 0.40 0.59 RO-3 1.25 1 0.25 1.11 0.60 0.87 RO-4 0.625 0.5 0.125 1.54 0.70 1.07 O&M—operations and maintenance, RO—reverse osmosis aAdapted from Bergman and Elarde 2003 (escalated to 2008 dollars) over 20 years at a 6% annual interest rate bAmortization COST CONSIDERATIONS Cost comparison and normalization. As previously discussed, the specific energy consumption for both brine concentrators and crystallizers is much higher than for seawater desalination, which is among the most energy-intensive processes used in potable water treatment. These substantial energy requirements translate into high ZLD treatment costs. Examples of ZLD costs for systems with four different capacities are summarized in Table 3, which is adapted from a 2008 US Bureau of Reclamation (USBR) study, Report No. 149 in the series prepared under the Desalination and Water Purification Research and Development Program (Juby et al. 2008). The costs in Table 3 include both brine concentrators and crystallizers, and 100% recovery is assumed such that the feed and treated water flows are equivalent; capital costs were amortized over 20 years at a 6% annual interest rate. The ZLD costs in USBR Report No. 149 include landfilling solids at $50/ton; this cost could increase if testing determines that the crystallized solids constitute a hazardous waste. As shown in Table 3, amortized ZLD unit costs range from approximately $30–$60/1,000 gal over capacities spanning 1 mgd down to 0.125 mgd. For the purposes of comparison, AWWA M61 (Desalination of Seawater) cites amortized unit costs for SWRO that vary from approximately $2.50/1,000 gal–$5/1,000 gal TABLE 5 Sample combined treatment cost summary for RO + ZLD at 80% RO recovery Case Capacitya mgd Capital Cost $/gpd O&M Cost $/1,000 gal Total Amortized Costb $/1,000 gal RO-1 → ZLD-1 5.0 8.68 4.10 6.18 RO-2 → ZLD-2 2.5 11.99 4.46 7.32 RO-3 → ZLD-3 1.25 18.11 5.21 9.54 RO-4 → ZLD-4 0.625 27.85 6.17 12.83 O&M—operations and maintenance, RO—reverse osmosis, ZLD—zero liquid discharge aAssumes flow) 100% recovery over the treatment plant (i.e., feed flow = RO permeate flow + ZLD distillate bAmortization over 20 years at a 6% annual interest rate over a very wide range of capacities (AWWA 2011). Even at unit costs that are double these figures (i.e., $5–$10/1,000 gal), SWRO— one of the most expensive water shown in Table 4. The example costs in this table are adapted from Bergman and Elarde (2003), who developed best-fit curves of cost figures from operating desalination Utilities evaluating ZLD may opt to rely on performance-based equipment specifications rather than detailed mechanical and process design conducted by a third party. treatment processes—is much less expensive than ZLD. The difference in costs is even more pronounced for the desalination of brackish water, which is more characteristic of inland locations, as plants. For the purposes of comparison with the ZLD costs published in USBR Report No. 149, the costs in Table 4 are escalated to 2008 dollars (as applicable) and amortized using similar terms (i.e., 20 years at 6% ALSPACH & JUBY | JANUARY 2018 • 110:1 | JOURNAL AWWA alspach_npr.indd 43 43 12/11/2017 4:34:08 PM Sample RO + ZLD treatment cost comparison at 80% RO recovery TABLE 6 RO System ZLD System Combined Treatment Case Permeate Flow mgd Total Amortized Costa $/1,000 gal Distillate Flow mgd Total Amortized Costa $/1,000 gal Treated Water Production mgd Total Amortized Costa $/1,000 gal RO-1 → ZLD-1 4.0 0.44 1.0 29.12 5.0 6.18 RO-2 → ZLD-2 2.0 0.59 0.5 34.25 2.5 7.32 RO-3 → ZLD-3 1.0 0.87 0.25 44.24 1.25 9.54 RO-4 → ZLD-4 0.5 1.07 0.125 59.87 0.625 12.83 RO—reverse osmosis, ZLD—zero liquid discharge aAmortization over 20 years at a 6% annual interest rate. interest). The cases shown in Table 4 are designed to align with those in Table 3, such that the concentrate of case RO-1 becomes the feed to the ZLD-1 case. A recovery of 80% was used for the example RO systems, which were assumed to be treating brackish water with a TDS concentration similar to the raw water supply used to generate the ZLD costs in USBR Report No. 149: ~2,300 mg/L treated with RO, with the concentrate feeding the ZLD process. A comparison of the amortized unit costs in Tables 3 and 4 indicates that ZLD treatment is roughly 1 to 2 orders of magnitude more expensive than typical brackish water Sample RO treatment cost summary at 90% recovery TABLE 7 Capacity Permeate mgd Concentrate mgd Capital Costa $/gpd O&M Costa $/1,000 gal Total Amortized Costb $/1,000 gal Case Feed mgd RO-1A 5.0 4.5 0.5 0.55 0.25 0.38 RO-2A 2.5 2.25 0.25 0.76 0.35 0.53 RO-3A 1.25 1.125 0.125 1.05 0.60 0.85 O&M—operations and maintenance, RO—reverse osmosis aAdapted from Bergman and Elarde, 2003 (escalated to 2008 dollars) over 20 years at a 6% annual interest rate bAmortization TABLE 8 Sample RO + ZLD combined treatment cost summary at 90% RO recovery Case Capacitya mgd Capital Cost $/gpd O&M Cost $/1,000 gal Total Amortized Costb $/1,000 gal RO-1A → ZLD-2 5.0 6.17 2.29 3.77 RO-2A → ZLD-3 2.5 9.30 2.68 4.90 RO-3A → ZLD-4 1.25 14.26 3.35 6.75 O&M—operations and maintenance, RO—reverse osmosis, ZLD—zero liquid discharge aAssumes flow) 100% recovery over the treatment plant (i.e., feed flow = RO permeate flow + ZLD distillate bAmortization 44 alspach_npr.indd 44 over 20 years at a 6% annual interest rate ALSPACH & JUBY | JANUARY 2018 • 110:1 desalination using RO. The figures in Table 4 are not intended as precise estimates of RO costs, but rather representative figures for the purposes of illustration; even significant but reasonable variation of the total amortized costs for RO in Table 4 will not render these costs comparable with those for ZLD shown in Table 3. Cost comparisons such as these are common in literature discussing ZLD, and they are valid for illustrating the starkly higher expense of ZLD treatment. However, this exercise is not a truly equitable comparison, given that the unit costs for ZLD and RO are normalized for the flows treated by each process—distillate and permeate, respectively. In practice, an inland desalination facility employing ZLD for concentrate management would have both RO and ZLD processes, and the total cost of treatment (i.e., RO + ZLD) should be normalized by the total treated water flow (i.e., RO permeate + ZLD distillate). The impact of properly accounting for the capital, operating, and total amortized costs of a combined RO (from the example cases in Table 4) and ZLD (from the example cases in Table 3) is shown in Table 5. The total amortized costs of RO (from Table 4), ZLD (from Table 3), and combined RO + ZLD (Table 5) systems are summarized in Table 6 for direct comparison. Although the total amortized costs for the | JOURNAL AWWA 12/11/2017 4:34:31 PM combined treatment are generally an order of magnitude higher than for RO alone, they are also roughly an order of magnitude less expensive than ZLD alone. Because minimizing the flow to the ZLD process can significantly reduce treatment costs, the impact of increasing RO recovery in a combined RO + ZLD system can have a substantial financial impact. Tables 7, 8, and 9 replicate Tables 4, 5, and 6, respectively, assuming the RO recovery has been increased from 80 to 90%. Thus, the RO-1 system concentrate flow changes from 1 to 0.5 mgd (case RO-1A), which then aligns with ZLD flow in case ZLD-2. The RO-2 concentrate flow decreases from 0.5 to 0.25 mgd (case RO-2A), which aligns with the ZLD flow in case ZLD-3. Likewise, the RO-3 concentrate is reduced from 0.25 to 0.125 mgd (case RO-3A), aligning with the ZLD flow in case ZLD-4. (Because the cost data provided in USBR Report No. 149 are for discrete and specific flows, there is no companion ZLD example for the case in which the RO-4 system concentrate decreases by half.) Note that this example of increasing the RO recovery to 90% neglects the resulting change in concentrate salinity. Although the TDS levels in the RO concentrate would roughly double in cases in which the recovery was increased from 80 to 90% (i.e., halving the concentrate flow while assuming a constant 100% salt rejection for the purposes of illustration), the impact on ZLD treatment costs due to this change in salinity would be very small relative to the influence of the de­creased flow; however, both the decreased recovery is substantial, reducing the total amortized unit cost of treated water by 30 to 40% for the examples cases shown. Overall, this analysis underscores three important points to Because minimizing the flow to the ZLD process can significantly reduce treatment costs, the impact of increasing RO recovery in a combined RO + ZLD system can have a substantial financial impact. flow and increased TDS would result in lower ZLD treatment costs. The influence of increasing the recovery of a primary RO process from 80 to 90% is summarized in Table 10, including the respective total amortized costs and the percent cost reduction associated with the recovery increase. These examples are not representative of installed facilities making adjustments to increase RO recovery from 80 to 90%; in these cases the capacity of the ZLD system would be oversized by a factor of two, skewing the capital costs. Instead, this example illustrates the comparison of options in the planning stage and the impact on total amortized cost if 90 versus 80% primary RO recovery can be achieved in conjunction with a ZLD system sized appropriately for each case. As shown in Table 10, the impact of increased understand about conventional ZLD systems (i.e., the combination of brine concentrators and crystallizers). (1) Economies of scale are significant. As illustrated in Table 3, economies of scale significantly affect the unit cost of water produced by a ZLD system. This impact likewise heavily influences the unit cost of desalinated water in a combined RO + ZLD system, as summarized in Table 10. Thus, to the extent that larger capacity systems are feasible and affordable (i.e., within budget), it is economically advantageous to maximize the size of a planned RO + ZLD desalination plant. (2) Maximizing primary RO recovery is important for ZLD affordability. For a given total available flow of water (e.g., the rights to 5 mgd of a brackish water supply), it is economically advantageous to Sample RO + ZLD treatment cost comparison at 90% RO recovery TABLE 9 RO System Case Permeate Flow mgd ZLD System Total Amortized Costa $/1,000 gal Distillate Flow mgd Total Amortized Costa $/1,000 gal Combined Treatment Treated Water Production mgd Total Amortized Costa $/1,000 gal RO-1A → ZLD-2 4.5 0.38 0.5 34.25 5.0 3.77 RO-2A → ZLD-3 2.25 0.53 0.25 44.24 2.5 4.90 RO-3A → ZLD-4 1.125 0.85 0.125 59.87 1.25 6.75 RO—reverse osmosis, ZLD—zero liquid discharge aAmortization over 20 years at a 6% annual interest rate ALSPACH & JUBY | JANUARY 2018 • 110:1 | JOURNAL AWWA alspach_npr.indd 45 45 12/11/2017 4:34:49 PM TABLE 10 Comparison of RO + ZLD combined treatment costs at 80 and 90% RO recovery RO + ZLD at 80% RO Recovery Treated Water Capacitya 5.0 Case Total Amortized Costb $/1,000 gal RO-1 → ZLD-1 6.18 RO + ZLD at 90% RO Recovery Case Total Amortized Costb $/1,000 Unit Cost Reduction % RO-1A → ZLD-2 3.77 39 2.5 RO-2 → ZLD-2 7.32 RO-2A → ZLD-3 4.90 33 1.25 RO-3 → ZLD-3 9.54 RO-3A → ZLD-4 6.75 29 RO—reverse osmosis, ZLD—zero liquid discharge aAssumes 100% recovery over the treatment plant (i.e., feed flow = RO permeate flow + ZLD distillate flow) over 20 years at a 6% annual interest rate bAmortization maximize primary RO permeate flow (e.g., 4.5 versus 4 mgd) and minimize the flow to the ZLD pro­ cess (e.g., 0.5 versus 1 mgd). (3) The unit costs of seawater de­­ salination and inland desalination with ZLD treatment are roughly comparable. The properly amor­ tized unit costs of RO + ZLD treat­ ment summarized in Table 7 are on the same order of magnitude as the $2.50–$5/1,000 gal figures indi­ cated for SWRO in AWWA’s M61 Desalination of Seawater (2011), as suppliers, these utilities do have the economically com­parable alterna­ tive of brackish water desalination in combination with ZLD treat­ ment. The latter case is limited only by the accessibility of brackish water supplies, not by either pro­ hibitively disproportionate econom­ ics or the lack of a viable concen­ trate management strategy. Other cost considerations. Because of the large specific energy con­ sumption (kW·h/1,000 gal) associ­ ated with both brine concentrators The specific energy consumption for both brine concentrators and crystallizers is much higher than for seawater desalination, which is among the most energy-intensive processes used in potable water treatment. previously discussed, and they com­ pare very well for the RO + ZLD cases at 90% RO recovery. Account­ ing for the RO + ZLD system econ­ omies of scale, as demonstrated by the declining amortized unit cost trends with increasing treated water capacity shown in Table 10, larger RO + ZLD systems would likely compare even more favorably with SWRO. Thus, although SWRO is not an option for inland water 46 alspach_npr.indd 46 ALSPACH & JUBY | JANUARY 2018 • 110:1 and crystallizers, the unit price of energy ($/kW·h) exerts a substantial influence on the cost of desalination for cases in which conventional ZLD treatment is used for concentrate management. Likewise, for these same cases, because of the high unit cost of treating water using ZLD (as shown in Table 3, expressed as $/1,000 gal), minimizing the ZLD flow can significantly reduce the overall cost of desalination. Thus, as applied to a primary RO process, minimizing the concentrate (i.e., ZLD feed) flow reduces both the required ZLD capacity and the associated energy expended, result­ ing in lower capital and operating costs, respectively. Although ZLD capital costs are not sensitive to changes in water quality, the operating cost is influ­ enced by the concentrations of both TDS and relative levels of the con­ stituent components making up the TDS. For example, in comparing two cases in which ZLD feed flows are similar, the flow with the higher TDS requires less concentration, reducing the specific energy consumption, which in turn lowers the cost. In terms of constituent dissolved solids, greater proportions of highly soluble species will increase the specific energy necessary to accomplish ZLD treatment; nitrates are among the most notable of these soluble species. The economy of scale associated with ZLD treatment is demonstrated in Table 3, with higher unit costs for smaller capacity systems. Thus, in terms of the cost per unit volume of water produced, larger ZLD systems are more economical than small facil­ ities. However, the economy of scale is limited by the size of discrete brine concentrator and crystallizer units for which components can be trans­ ported; currently this limit is achieved for ZLD systems with a capacity in the range of ap­­proximately 1,000 to | JOURNAL AWWA 12/13/2017 8:25:17 AM 1,200 gpm (Ciszewski 2015). Beyond this limit, larger-capacity ZLD systems consist of increasing numbers of discrete treatment units (i.e., rather than larger units), negating further economies of scale. INSTALLATIONS AND INSTITUTIONAL KNOWLEDGE Although ZLD treatment is used in many industrial applications, at present there is only one known municipal water treatment in­s tallation in the United States using a brine concentrator to treat the residuals from a primary RO process, and the concentrated brine is directed to an evaporation pond; there are no known municipal applications of crystallizer treatment. Thus, institutional knowledge regarding ZLD remains extremely limited in the potable water and reuse sectors. However, despite the dearth of municipal installations, the two processes described as conventional ZLD in this paper (i.e., brine concentrators and crystallizers) are proven technologies that are well understood. Consequently, utilities evaluating ZLD may opt to rely on performance-based equipment specifications rather than detailed mechanical and process design conducted by a third party. In addition, because of the complexity of ZLD systems, the use of contract operation may be a strategic consideration. SUMMARY AND CONCLUSIONS Although the conventional ZLD combination of a brine concentrator and crystallizer is an expensive option for concentrate management, it offers several critical advantages that broadly enhance the viability of desalination for treating alternative water resources: • Feasible deployment virtually independent of concentrate water quality • Lack of environmental and regulatory permitting constraints that inhibit many other concentrate management options • Overall costs (including primary RO + ZLD) roughly comparable to seawater desalination However, unlike SWRO, the use of RO in conjunction with ZLD is potentially accessible for utilities in nearly any location, whether coastal or inland. Thus, a potable water purveyor at any inland location with a saline source of supply could employ RO to augment its portfolio of resources at a cost no more significant than that associated with the desalination of seawater that is available to its coastal counterparts. ABOUT THE AUTHORS Brent Alspach (to whom correspondence may be addressed) is director of applied research at Arcadis, 2175 Salk Ave., Ste. 130, Carlsbad, CA 92008 USA; brent.alspach@arcadis.com. He is an AWWA Water Quality & Technology Division trustee and chair of the AWWA 2018 International Symposium on Potable Reuse. He also serves on the Opflow editorial advisory board and is the 2014 recipient of AWWA’s Golden Spigot award. Alspach is also the sitting president of the American Membrane Technology Association. Graham Juby is senior project manager with Carollo Engineers in Costa Mesa, Calif. https://doi.org/10.5942/jawwa.2018.110.0005 REFERENCES AWWA, 2011 (1st ed.). Manual of Water Supply Practices M61: Desalination of Seawater. AWWA, Denver. Bergman, R.A. & Elarde, J.R., 2003. The Cost of Membrane Softening and Desalting for Municipal Water Supplies. Proc. AWWA Membrane Technology Conference, Atlanta. Ciszewski, D., 2015. Personal communications, February–April. Global commercial and process engineering leader, GE Water & Process Technologies, Feasterville-Trevose, Pa. Juby, G.; Zacheis, A.; Shih, W.; Ravishanker, P.; Mortazavi, B.; & Nusser, M.D., 2008. Evaluation and Selection of Available Processes for a Zero-Liquid Discharge System for the Perris, California, Ground Water Basin, Report No. 149. US Bureau of Reclamation Desalination and Water Purification Research and Development Program, Washington. Locke, P.; Greiner, F.; Popko, R.; & Cooke, N., 2015. ZLD Process Utilizes Ultrafiltration to Achieve 98.5% RO Recovery. Proc. American Membrane Technology Association/AWWA Membrane Technology Conference, Orlando, Fla. Mickley, M.C., 2006. Membrane Concentrate Disposal: Practices and Regulation, Report No. 123. USBR Desalination and Water Purification Research and Development Program, Washington. Yallaly, B., 2015. Vice-president, Carollo Engineers Inc. Personal communication. AWWA RESOURCES • Consider Brackish Groundwater Supplies for Desalination. Maliva, R.G.; Manahan, W.S.; & Guo, W., 2014. Opflow, 40:2:22. Product No. OPF_0079602. • Forward Osmosis: Novel Desalination of Produced Water and Fracturing Flowback. Coday, B.D. & Cath, T.Y., 2014. Journal AWWA, 106:2:E55. Product No. JAW_0079287. • Seawater Desalination: New Challenges Mark a Changing Landscape. Alspach, B., 2010. Opflow, 36:6:14. Product No. OPF_0071997. These resources have been supplied by Journal AWWA staff. For information on these and other AWWA resources, visit www.awwa.org. Journal AWWA welcomes comments and feedback at journal@awwa.org. ALSPACH & JUBY | JANUARY 2018 • 110:1 | JOURNAL AWWA alspach_npr.indd 47 47 12/11/2017 4:35:23 PM