Chapter

TEN

Moment-Distribution Method

10.1 Introduction

The moment-distribution method was originally presented by

Prof. Hardy cross in 1930 and is considered one of the most

important contributions ever made to the structural analysis

of continuous beams and rigid frames.

The moment-distribution is a method of successive

approximations that may be carried out to any desired degree

of accuracy. Essentially, the method begins by assuming

each joint of a structure is fixed. Then, by unlocking and

locking each joint in succession, the internal moments at the

joints are distributed and balanced until the joints have

rotated to their final or nearly final positions.

243

Chapter Ten

10.2 General Principles and Definitions

Before developing the procedures of the moment-distribution

method, it is necessary to adopt a sign convention and define

the various terms used in the analysis.

Sign Convention

In applying the moment-distribution method, we will adopt

the same sign convention as used previously for the slopedeflection method: Clockwise moments that act on member

ends are considered positive, whereas counterclockwise

moment are negative.

Fixed-End Moments (F.E.Ms)

The moments at the fixed end of a loaded member are called

fixed-end moments. These moments can be determined from

Table (9.1) of the preceding chapter, depending upon the

type of loading on the member.

Member Stiffness Factor (kij)

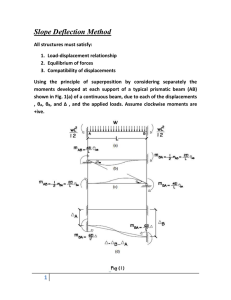

Consider a prismatic beam AB, which is hinged at end A and

fixed at end B, as shown in Fig. (10.1-a). If we apply a

moment M at the end A, the beam rotates by an angle θ at the

hinged end A and develops a moment MBA at the fixed end

B, as shown in the figure. In Chapter 9 we related M to θ

using the conjugate beam method. This resulted in Eq. (9.6),

that is,

242

Moment-Distribution Method

MBA=carryover

moment

M=applied

moment

θ

(a)

B

A

L

EI=constant

M=applied

moment

A

B

θ

(b)

L

EI=constant

Real beam

M/EI

(c)

A'

RA'

B'

L

Conjugate beam

RB'

Figure (10.1)

The term

is referred to as the stiffness factor at A and can be defined as

the moment that must be applied at the end A of the member

to cause a unit rotation (

) at A.

244

Chapter Ten

Now, suppose that the far end B of the beam is hinged,

as shown in Fig. (10.1-b). The relationship between the

applied moment M and the rotation θ of the end A of the

beam can be determined by using the conjugate beam

method, as illustrated in Fig. (10.1-b), that is

This expression indicates that the stiffness factor of the

member at A for this case is

Thus it may summarized that the stiffness factor of a member

ij at the end i is given by

if far end j of member is fixed

(10.1)

if far end j of member is hinged

(10.2)

Carry-Over Moment (C.O.M.)

Let us considered again the hinged-fixed beam in Fig. (10.1a). When a moment M is applied at the hinged end A of the

beam, a moment MBA develops at the fixed end B, as shown

in the figure. The moment MBA is termed the carryover

moment. It was shown in Chapter 9 that:

243

Moment-Distribution Method

(Eq. 9.6)

and

(Eq. 9.7)

or

(10.3)

This equation indicates that, when a moment of magnitude M

is applied at one end of a beam, one-half of the applied

moment is carried over to the far end, provided that the far

end is fixed. Note that the direction of the carryover moment,

MBA, is the same as the applied moment, M.

When the far end of the beam is hinged, as shown in

Fig. (10.1-b), the carry over moment MBA is zero. Thus we

can express the carryover moment as

{

(10.4)

The ratio of the carryover moment to the applied

⁄

moment (

is called the carryover factor of the

member. It represents the fraction of the applied moment M

that is carried over to the far end of the member. Thus we can

express the carryover factor (COF) as

{

(10.5)

243

Chapter Ten

Distribution Factor (D.F)

When an external moment is applied to a joint of a structure

where two or more members meet, an important question that

arises is how to distribute this moment among the various

members connected at that joint. Consider the joint B show

in Fig. (10.2-a) at which three members meet, and suppose

that a moment M is applied to this joint, causing it to rotate

by an angle θ. To determine what fraction of the applied

moment M is resisted by each of the three members

connected to the joint, we draw the free-body diagram of

joint B as show in Fig. (10.2-b). By considering the moment

equilibrium of joint B (that is, ∑

), we have

C

M

A

θ

θ

B

M

θ

MBC

MBA

B

MBD

(a)

(b)

D

Figure (10.2)

243

Moment-Distribution Method

or

(10.6)

The moments at the ends B of the members can be expressed

in terms of the joint rotation θ and the stiffness factor k of the

members, Eqs. (10.1) and (10.2), as

(10.7)

(10.8)

(10.9)

Substituting these equations into Eq. (10.6), we obtain

(

or

∑

where ∑

(10.10)

and represents the sum of the

stiffnesses of all the members connected to joint B. From Eq.

(10.10) we can write

(10.11)

∑

The above equations, Eqs. (10.7) to (10.9), can now be

written as

∑

∑

243

Chapter Ten

∑

⁄∑ ,

The ratios

⁄∑ , and

⁄∑

indicate the

portions of the moment M that are resisted by members BA,

BC, and BD, respectively. The ratio ⁄∑ for a member ij is

termed the distribution factor (D.F) of the member and it will

be given the symbol d, that is

∑

(10.12)

The distribution factor for a member is thus equal to the

stiffness of the member divided by the sum of the stiffnesses

of all members meeting at the joint.

10.3 Procedure for Analysis

The procedure for the analysis of structures by the momentdistribution method can be summarized as follows:

1.

The joints on the structure should be identified.

2.

Compute the fixed-end moments. Assuming that all the

free joints are clamped against rotation, evaluate for

each member, the fixed-end moments due to the

external loads and support settlements (if any) by using

the fixed-end moment expressions given in Table (9.1)

of Chapter 9.

3.

Calculate the distribution factors. The stiffness factors

for each member of the structure at the joints should be

243

Moment-Distribution Method

calculated. Using these values the distribution factors

can be determined from Eq. (10.12). Remembering that

the distribution factor is zero for a fixed end and one for

an end roller or hinged support. The sum of all the

distribution factors at a joint must equal 1.

4.

Balance the moments at all the joints that are free to

rotate by applying the moment-distribution process as

follows:

a. At each joint, evaluate the unbalanced moment and

distribute it to the members connected to the joint.

The distributed moment at each member end rigidly

connected to the joint is obtained by multiplying the

negative of the unbalanced moment by the

distribution factor for the member end.

b. Carryover one-half of each distributed moment to the

opposite (far) end of the member.

c. Repeat steps (4-a) and (4-b) until either all the free

joints are balanced or the unbalanced moments at

these joints are negligibly small.

5.

Determine the final

member end moments by

algebraically summing the fixed-end moment and all the

distributed and carryover moments at each member end.

If the moment distribution has been carried out

correctly, then the final moments must satisfy the

233

Chapter Ten

equations of moment equilibrium at all joints of the

structure that are free to rotate.

6.

Compute member end shearing forces and axial forces

by considering the equilibrium of the members of the

structure.

7.

Determine support reactions by considering the

equilibrium of the joints of the structure.

8.

Draw the shearing force, axial force, and bending

moment diagrams.

Example 10.1: Draw the bending moment diagram for the

beam shown in Fig. (10.3) by using the moment-distribution

method.

Solution:

First of all the joints are numbered. We have three joints, 1,

2, and 3, which divide the beam into two members.

Fixed-End Moments:

By assuming that joints 1, 2, and 3 are fixed (or locked), we

calculate the fixed-end moments at the ends of each member

due to the external loads, Fig. (10.3-b). By using Table (9.1)

in Chapter 9, we obtain for member 1-2

kN.m

233

Moment-Distribution Method

38 kN

18 kN/m

(a)

1

I

2

3

2m

2m

2I

6m

38 kN

18 kN/m

(b)

1

2

6m

3

38 kN

18 kN/m

(c)

4m

2

2

1

3

+35 kN.m

(d)

2

Unbalanced moment=+35 kN.m

(e)

1

3

2

Carryover moment

Distributed moments

Carryover moment

M12=-54-10=-64 kN.m M21=+54-20=+34 kN.m M32=+19-7.5=+11.5 kN.m

38 kN

18 kN/m

(f)

1

2

M23=-19-15=-34 kN.m

Figure (10.3)

3

233

Chapter Ten

-64

+

_

-34

+

_

(g)

- -11.5

(+B.M. on compression side

-B.M. on tension side)

Figure (10.3) Continued

kN.m

and for member 2-3

kN.m

kN.m

Distribution Factors:

We must determine the distribution factor at the two ends of

each member. Using Eq. (10.1) the stiffness factors at these

ends are

(

(

(

(

232

Moment-Distribution Method

The distribution factor can then be determined for the ends of

member by using Eq. (10.12). At joint 1 and 3, the

distribution factor depends on the member stiffness factor

and the stiffness factor of the fixed support (wall). Since in

theory it would take an infinite size moment to rotate the wall

one radian, the wall stiffness factor is infinite. Thus for joints

1 and 3 we have

and for member ends connected at joint 2 we have

⁄(

⁄(

)

)

Note that the sum of the distribution factors at each joint

must always equal 1.

Balancing Joint 2:

There is a

kN.m fixed-end moment at end 2 of member

(1-2), whereas the end 2 of member (2-3) is subjected to a

kN.m fixed-end moment. Thus the unbalanced moment

UM2 at joint 2 is, Figs. (10.3-c) and (10.3-d)

kN.m

234

Chapter Ten

To balance joint 2, we will apply an equal, but opposite

moment of

kN.m to the joint and allow it to rotate

freely. As a result, portions of this moment are distributed in

members (2-1) and (2-3) in accordance with the distribution

factors of these members at the joint. Specifically, the

distributed moment D.M21 in member (2-1) is

(

kN.m

and that D.M23 in member (2-3) is

(

kN.m

The distributed moment at end 2 of member (2-1)

induces a carryover moment at the far end 1 (Fig. 10.3-e),

which can be determined by multiplying the distributed

moment by the carryover factor of the member. Since joint 1

is fixed, the carryover factor is . Thus the C.O.M at end 1 of

member (1-2) is

(

kN.m

These results are shown in Fig. (10.3-e).

In this particular case only one cycle of moment

distribution is necessary, since no further joints have to be

balanced (or unlocked) to satisfy joint equilibrium.

The final member end moments are obtained by

algebraically summing the fixed-end moment and all the

233

Moment-Distribution Method

distributed and carryover moments at each member end. The

results are depicted in Fig. (10.3-f) and the bending moment

diagram is shown in Fig. (10.3-g).

Since the process of moment distribution, as explained

above, is both long and cumbersome, it is usually convenient

to carry out the analysis in tabular form as shown in Table

(10.1).

Table (10.1)

Joints

1

Members connected to

joint

Distribution factors

Members

12

21

23

32

D.Fs.

0

4/7

3/7

0

Fixed-end moments

F.E.Ms.

-54 +54 -19

Distributed moments

D.Ms.

-20

Carryover moments

C.O.Ms.

-10

Final End

Moments

-64 +34 -34 +11.5

2

3

+19

-15

-7.5

Example 10.2: Draw the bending moment diagram for the

beam shown in Fig. (10.4) by using the moment-distribution

method.

Solution:

Fixed-End Moments:

From Table (9.1) in Chapter 9

233

Chapter Ten

80 kN

(a)

24 kN/m

2

2I

6m

8m

1

3

3I

I

4

6m

6m

+120

+

-28.295

(b)

-93.437 +108 kN.m

_

+

-18.850

_

_

(+B.M. on compression side

-B.M. on tension side)

_

-9.528

Figure (10.4)

kN.m

kN.m

kN.m

kN.m

there is no load on member (3-4)

Stiffness Factors:

From Eq. (10.1),

233

Moment-Distribution Method

Distribution Factors:

From Eq. (10.12),

fixed end

⁄(

⁄(

⁄(

)

⁄(

)

fixed end

Starting with the fixed-end moment, the moments at joints 2

and 3 are balanced and distributed simultaneously. These

moments are then carried over simultaneously to the

respective ends of each member. The resulting moments are

again simultaneously distributed and carried over. The

process is continued until the resulting moments are

diminished an appropriate amount. The resulting moments

are found by summation. The complete analysis is shown in

Table (10.2).

The bending moment diagram is shown in Fig. (10.4-b)

233

Chapter Ten

Table (10.2)

Joints

1

Members

12

21

23

32

34

43

D.Fs.

0

1/3

2/3

3/4

1/4

0

F.E.Ms.

-30

+90

-72

+72

0

0

D.Ms.

0

-6

-12

-54

-18

0

C.O.Ms.

-3

0

-27

-6

0

-9

D.Ms.

0

+9

+18

+4.5

+1.5

0

C.O.Ms.

+4.5

0

+2.25

+9

0

+0.75

D.Ms.

0

-0.75

-1.5

-6.75

+2.25

0

C.O.Ms.

-0.375

0

-3.375

-0.75

0

-1.125

D.Ms.

0

+1.125

+2.25

+0.562

+0.188

0

C.O.Ms.

+0.562

0

+0.281

+1.125

0

+0.094

D.Ms.

0

-0.094

-0.187

-0.844

-0.281

0

C.O.Ms.

-0.047

0

-0.422

-0.094

0

-0.241

D.Ms.

0

+0.141

+0.281

+0.070

+0.024

0

C.O.Ms.

+0.071

0

+0.035

+0.145

0

+0.012

D.Ms.

0

-0.012

-0.023

-0.108

-0.036

0

C.O.Ms.

-0.006

0

-0.054

-0.012

0

-0.018

Final End

Moments

-28.295

+93.410

-93.464

+18.844

-18.855

-9.528

Average

2

3

93.437

4

18.85

10.4 Hinged or Simple Supports at Ends

The analysis of structures, that are hinged or simply

supported at one or more ends, can be considerably

simplified by using Eq. (10.2) to calculate the stiffness

233

Moment-Distribution Method

factors for members adjacent to the hinged or simple end

supports. Also, the joints at the hinged or simple end

supports are balanced only once during the moment

distribution process, after which they are left unclamped so

that no moment can be carried to them as the interior joints

of the structure are balanced.

Example 10.3: Draw the bending moment diagram for the

beam shown in Fig. (10.5). By using the moment-distribution

method.

constant.

80 kN

24 kN/m

(a)

1

5m

3

2

1.25 m 1.25 m

+75 kN.m

-52.5

+

_

-45

_

(b)

+50

+

0

(+B.M. on compression side

-B.M. on tension side)

Figure (10.5)

Solution:

Fixed-End Moments:

From Table (9.1),

kN.m

233

Chapter Ten

kN.m

kN.m

kN.m

Stiffness Factors:

From Eq. (10.1),

From Eq. (10.2),

From Eq. (10.1),

Distribution Factors:

fixed end

⁄(

)

⁄(

)

hinged end

The process of moment distribution is conducted in Table

(10.3), and the bending moment diagram is shown in Fig.

(10.5-b). The final end moments on the last line of Table

233

Moment-Distribution Method

(10.3) are obtained by algebraically summing the modified

fixed-end moment and all the distributed and carryover

moments at each member end (that is each column).

Table (10.3)

Joints

1

2

3

Members

12

21

23

32

D.Fs.

0

2/5

3/5

1

F.E.Ms.

-50

+50

-25

+25

Balance joint (3)

-25

C.O.Ms.

Modified F.E.Ms.

-12.5

-50

D.Ms.

C.O.Ms

Final End

Moments

+50

-37.5

-5

-7.5

-2.5

-52.5

0

0

+45.0

-45.0

0

10.5 Structures with Cantilever Overhangs

Sometimes, a structure may have a cantilever overhang at

one or more ends, Fig. (10.6). In such a case, the bending

moment at end A of the overhanging portion will be due to

the load over this portion and will remain constant,

irrespective of the moments on the other portions of the

structure. Since the overhanging portion AB does not

contribute to the rotational stiffness of joint A, the

distribution factor for its end A is zero. Thus, joint A in Fig.

(10.6-b) can be treated as a simple end support in the

233

Chapter Ten

analysis. The moment at end A of the cantilever, however

does affect the unbalanced moment at joint A, Figs. (10.6-a

and -b) and must be included along with the other fixed-end

moments in the analysis.

P

w

P

w

A

B

A

(a)

B

(b)

Figure (10.6)

Example 10.4: Draw the bending moment diagram for the

beam shown in Fig. (10.7) by using the moment-distribution

method.

constant.

Solution:

Fixed-End Moments:

From Table (9.1),

there is no load on member (1-2)

kN.m

kN.m

kN.m

232

Moment-Distribution Method

30 kN

10 kN/m

(a)

2

1

3

4m

9m

6m

4

(a) Continuous beam

M34=-30*4=-120 kN.m

(b)

30 kN

3

4

30 kN

(b) Statically determinate cantilever portion

-27.5

+13.75

(c)

+27.5

+120

10 kN/m

-120

30 kN

3

4

2

1

(c) Final end moments

+101.25 kN.m

+

-120

_

-27.5

_

(d)

+

+13.75

(d) Bending moment diagram

(+B.M. on compression side

-B.M. on tension side)

Figure (10.7)

Stiffness Factors:

From Eq. (10.1),

From Eq. (10.2),

_

234

Chapter Ten

From Eq. (10.1),

Distribution Factors:

From Eq. (10.12),

fixed end

⁄(

)

⁄(

)

hinged end

Table (10.4) shows the moment distribution process.

Table (10.4)

Joints

1

Members

12

21

23

32

34

D.Fs.

0

2/3

1/3

1

0

F.E.Ms.

0

0

-67.5

+67.5

-120

+52.5

0

+120

-120

2

3

Balance joint (3)

C.O.Ms.

Modified F.E.Ms.

+26.25

0

D.Ms.

C.O.Ms

0

-41.25

+27.5

+13.75

+13.75

Final End Moments +13.75

0

+27.5

-27.5

+120

-120

233

Moment-Distribution Method

10.6 Moment Distribution

Sidesway

for

Frames:

No

The procedure for the analysis of frames without sidesway is

similar to that for the analysis of continuous beams presented

in the preceding sections. However, unlike the continuous

beams, more than two members may be connected to a joint

of a frame. In such cases, care must be taken to record the

computation in such a manner that mistakes are avoided.

Example 10.5: Draw the bending moment diagram for the

frame shown in Fig. (10.8) by using the moment-distribution

method.

Solution:

Fixed-End Moments:

From Table (9.1),

kN.m

kN.m

there is no load on member (2-4)

kN.m

kN.m

kN.m

233

Chapter Ten

2 kN/m

3

2I

4

5

2I

10 m

I

I

1

2

8000.99

40 kN

10 m

(a)

30 m

+225

+

30 m

-205.7

-186.2

_ _

+225

-116 -115.9 _

-19.3 _

+200 +

(b)

-92.1

_

- -9.6

(+B.M. on compression side

-B.M. on tension side)

Figure (10.8)

kN.m

Stiffness Factors:

From Eq. (10.1),

From Eq. (10.2),

+

233

Moment-Distribution Method

From Eq. (10.1),

Distribution Factors:

From Eq. (10.12),

fixed end

⁄(

)

⁄(

)

fixed end

⁄(

⁄(

⁄(

)

)

)

hinged end

Moment Distribution:

The moment distribution process is carried out in Table

(10.5). The table, which is similar in form to those used

previously for the analysis of continuous beams, contains one

column for each member end of the frame. Note that the

columns for all member ends, which are connected to the

same joint, are grouped together, so that any unbalanced

233

Chapter Ten

moment at the joint can be conveniently distributed among

the members connected to it. Care must be taken when

carrying over moments from one end of the member to the

other. In this frame, no moment can be carried over from end

1 to end 3 of member (1-3) and from end 2 to end 4 of

member (2-4), because joints 1 and 2, which are at fixed

supports, will not be released during the moment distribution

process.

Table (10.5)

Joints

1

Members

13

31

34

43

45

D.Fs.

0

0.429

0.571

0.4

F.E.Ms.

-100

+100

-150

+150

3

4

2

5

42

24

54

0.3

0.3

0

1

-150

0

0

+150

Balance

joint 5

-150

C.O.Ms.

Modified

F.E.Ms.

-75

-100

D.Ms.

C.O.Ms.

+150

-225

0

+21.45

+28.55

+30

+22.5

+22.5

+15

+14.275

-8.565

-5.71

-2.855

-4.283

+1.630

+1.713

+0.857

+0.815

-0.489

-0.326

-0.163

-0.244

-116.0

+186.2

-6.435

-3.218

D.Ms.

C.O.Ms.

-150

+10.725

D.Ms.

C.O.Ms.

+100

+1.225

+0.613

D.Ms.

-0.368

C.O.Ms.

-0.184

Final End

Moments

-92.1

+115.9

0

0

+11.25

-4.283

-4.283

-2.142

+1.285

+1.285

+0.643

-0.244

-0.244

-0.122

-205.7

+19.3

+9.6

0

233

Moment-Distribution Method

The bending moment diagram is shown in Fig. (10.8-b)

Example 10.6: Draw the bending moment diagram for the

frame shown in Fig. (10.9) by using the moment-distribution

method.

36 kN

64.8 kN/m

2

1

(a)

2I

3

5m

I

4

5m

1.5 m

+202.5 kN.m

+

_

-162

-81

-54 _

_

(b)

-27 _

(+B.M. on compression side

-B.M. on tension side)

- -13.5

Figure (10.9)

Solution:

Fixed-End Moments:

233

Chapter Ten

From Table (9.1),

there is no load on member (2-4)

kN.m

kN.m

kN.m

Stiffness Factors:

From Eq. (10.1),

Distribution Factors:

From Eq. (10.12),

⁄(

)

⁄(

)

fixed end

fixed end

Using these data, the moment distribution is carried out in

Table (10.6). The bending moment diagram is shown in Fig.

(10.9-b).

233

Moment-Distribution Method

Table (10.6)

Joints

2

3

4

Members

21

24

23

32

42

D.Fs.

0

1/3

2/3

0

0

F.E.Ms.

+54

0

-135

+135

0

D.Ms.

0

+27

+54

+27

+13.5

+162

+13.5

C.O.Ms

Final End

Moments

+54

+27

-81

10.7 Analysis of Frames with Sidesway

Frames

that

are

nonsymmetrical

or

subjected

to

nonsymmetrical loading have a tendency to sidesway, or

deflect horizontally. An example of one such case is shown

in Fig. (10.10-a). Here the applied load P will create unequal

moments at joints B and C such that the frame will deflect an

amount Δ to the right. Since the deformations are assumed to

be small, the joints B and C displace by the same amount, Δ,

as shown in Fig. (10.10-a).

The moment distribution analysis of such a frame, with

sidesway, is carried out in two parts. In the first part, the

sidesway of the frame is prevented by adding an imaginary

roller to the structure, as shown in Fig. (10.10-b). External

loads are then applied to this frame, and member end

moments are computed by applying the moment-distribution

233

Chapter Ten

process in the usual manner. With the member end moments

known, the restraining force (reaction) R that develops at the

imaginary support is evaluated by applying the equations of

equilibrium.

Δ

P

P

Δ

B

C

A

D

(a) Actual frame

M moments

R

R

B

C

B

C

A

D

A

D

(b) Frame with sideway (c) Frame subjected

prevented

to R

M0 moments

MR moments

δ

δ

Q

(d) Frame subjected to an arbitrary

translation δ (MQ moments)

Figure (10.10)

In the second part of the analysis, the frame is subjected

to the force R, which is applied in the opposite direction, as

shown in Fig. (10.10-c). The moments that develop at the

member ends are determined and superimposed on the

moments computed in the first part to obtain the member end

232

Moment-Distribution Method

moments in the actual frame. If M, M0, and MR denote,

respectively, the member end moments in the actual frame,

the frame with sidesway prevented, and the frame subjected

to R, then we can write

(10.13)

A question that arises in the second part of the analysis

is how to determine the member end moments MR that

develop when the frame undergoes sidesway under the action

of R. Since the moment-distribution method cannot be used

directly to compute the moments due to the known lateral

load R, we employ an indirect approach in which the frame is

subjected to an arbitrary known joint translation δ caused by

unknown load Q acting at the location and in the direction of

R, as shown in Fig. (10.10-d). From the known joint

translation, δ, we determine the relative translation between

the ends of each member, and we calculate the member

fixed-end moments. These moments are distributed by the

moment-distribution process to determine the member end

moments MQ caused by the yet unknown load Q. Once the

member end moments MQ have been determine, the

magnitude of Q can be evaluated by the application of

equilibrium equations.

With the load Q and the corresponding moments MQ

known, the desired moments MR due to the lateral load R can

234

Chapter Ten

now be determined easily by multiplying MQ by the ratio

, that is,

( )

(10.14)

By substituting Eq. (10.14) into Eq. (10.13), we can express

the member end moments in the actual frame as

( )

(10.15)

This method of analysis is illustrated by the following

example.

Example 10.7: Draw the bending moment diagram for the

frame shown in Fig. (10.11) by using the momentdistribution method.

constant.

Solution:

Fixed-End Moments:

From Table (9.1),

there is no load on member (1-2)

kN.m

kN.m

there is no load on member (3-4)

Stiffness Factors:

233

Moment-Distribution Method

40 kN

2

3

5m

(a)

7m

4

1

3m

4m

40 kN

R

2

3

(b)

4

1

M21=+24

kN.m 2

M34=-24

kN.m 3

(d)

(c)

5m

7m

M43=-12.2

kN.m 4

M12=+12.1

kN.m 1

Δ

R

2

3

R=2.08 kN

Δ

3

2

4

4

(e)

1

kN

(f)

kN

1

Figure (10.11)

233

Chapter Ten

M21=+34.5

kN.m 2

(g)

M12=+42.3

kN.m 1

Q

M34=+45.4

kN.m 3

(h)

7m

(i)

5m

M43=+71.7

kN.m 4

Figure (10.11) Continued

From Eq. (10.1),

Distribution Factors:

From Eq. (10.12),

fixed end

⁄(

)

⁄(

)

⁄(

)

⁄(

)

fixed end

Moment-Distribution Method

233

Moment-Distribution, Part I:

In this part of the analysis, the sidesway of the frame is

prevented by adding an imaginary roller at joint 2, as shown

in Fig. (10.11-b). The moment-distribution of the fixed-end

moments due to the applied external load 40 kN is then

performed, as shown in Table (10.7), to determine M0

member end moments.

To evaluate the restraining force R that develops at the

imaginary roller support, we first calculate the shears at the

lower ends of the columns (1-2) and (3-4) by considering the

equilibrium of the free bodies of the columns shown in Figs.

(10.11-c) and (10.11-d). Next, by considering the equilibrium

of the horizontal forces acting on the entire frame (Fig.

(10.11-e)), we determine the restraining force R. From Fig.

(10.11-c),

∑

+

kN

From Fig (10.11-d),

∑

+

kN

From Fig (10.11-e),

∑

+

kN

233

Chapter Ten

Table (10.7)

Joints

1

Members

12

21

23

32

34

43

D.Fs.

0

1/2

1/2

0.417

0.583

0

F.E.Ms.

0

0

-39.2

+29.4

0

0

+19.6

+19.6

-12.3

-17.1

-6.2

+9.8

+3.1

-4.1

-2.1

+1.6

+1.1

-0.7

-0.4

+0.6

+0.2

-0.3

-0.2

+0.1

-24.1

+24.1

D.Ms.

C.O.Ms

+3.1

+1.6

D.Ms.

C.O.Ms

+1.1

+0.6

D.Ms.

C.O.Ms

Final End

Moments

3

+9.8

D.Ms.

C.O.Ms

2

+0.2

+0.1

+12.1

+24

4

-8.6

-5.7

-2.9

-0.9

-0.5

-0.3

-0.2

-24

-12.2

Note that the restraining force acts to the right, indicating that

if the roller would not have been in place, the frame would

have swayed to the left.

Moment-Distribution, Part II:

Since the actual frame is not supported by a roller at joint 2,

the frame will be subjected to a lateral load

kN at

joint 2 in the opposite direction (that is, to the left), as shown

in Fig. (10.11-f). Here the joints 2 and 3 are temporarily

restrained from rotating, and as a result the fixed-end

moments at the ends of the columns are determined by the

Eq. (9.12) in Chapter 9, as

233

Moment-Distribution Method

Thus,

Here Δ is unknown and the method to conduct the analysis is

to assume a value for Δ or one of the fixed-end moments.

This assumed value will correspond to unknown load Q

instead of R.

Assuming,

kN.m, then

from which

kN.m

The positive sign is necessary since the moment must act

clockwise on the column for deflection Δ to the left. The

foregoing fixed-end moments are distributed by the usual

moment-distribution process, as shown in Table (10.8), to

determine the MQ moments caused by unknown load Q.

To evaluate the magnitude of Q, we first calculate the

shearing forces at the lower ends of the columns by

considering their equilibrium and then apply the equation of

233

Chapter Ten

equilibrium in the horizontal direction to the entire frame.

From Fig. (10.11-g),

Table (10.8)

Joints

1

Members

12

21

23

32

34

43

D.Fs.

0

1/2

1/2

0.417

0.583

0

F.E.Ms.

+50

+50

0

0

+98

+98

-25

-25

-40.9

-57.1

-20.5

-12.5

+10.3

+5.2

+2.6

+5.2

-1.3

-2.2

-1.1

-0.7

+0.6

+0.3

+0.2

+0.3

-0.1

-0.1

-0.05

-0.05

-34.4

-45.5

D.Ms.

C.O.Ms

-12.5

D.Ms.

C.O.Ms

+10.3

+5.2

D.Ms.

C.O.Ms

-1.3

-0.7

D.Ms.

C.O.Ms

+0.6

+0.3

D.Ms.

C.O.Ms

Final End

Moments

∑

2

-0.1

-0.05

+42.3

+34.5

+

kN

From Fig. (10.11-h),

∑

+

kN

From Fig. (10.11-i),

3

4

-28.6

+7.3

+3.7

-3

-1.5

+0.4

+0.2

-0.2

-0.1

+45.4

+71.7

233

Moment-Distribution Method

∑

+

kN

which indicates that the moments MQ in Table (10.8) are

caused by a lateral load

kN. Since the moments

are linearly proportional to the magnitude of the load, the

desired moments MR due to the lateral load

kN

must be equal to the moments MQ multiplied by the ratio

⁄

⁄

.

Actual Member End Moments:

The actual member end moments, M, can be determined by

Eq. (10.15). Thus

kN.m

kN.m

(

kN.m

(

kN.m

kN.m

kN.m

10.8 Analysis of Multistory Frames

The forgoing procedure can be extended to the analysis of

structures with several independent joint translations.

Consider the two-story frame shown in Fig. (10.12-a). This

233

Chapter Ten

P3

P3

Δ2

P1

P1

F

R2

E

E

P4

P4

Δ1

P2

R1

P2

D

C

C

A

δ1

F

C

D

B

(b) Frame with sidesway

prevented

M0 moments

(a) Actual frame

M moments

E

D

A

B

δ2

Q21

F

Q12

D

C

A

B

(c) Frame subjected to

known translation δ1

(MQ1 moments)

Q22

E

Q11

A

F

B

(d) Frame subjected to

known translation δ2

(MQ2 moments)

Figure (10.12)

structure has two independent joint translations, the sidesway

Δ1 of the first story and the displacements Δ2 of the second

story. The moment-distribution analysis of this frame is

carried out in three parts. In the first part, the sidesway of

232

Moment-Distribution Method

both floors of the frame is prevented by adding imaginary

rollers at the floor levels, as shown in Fig. (10.12-b).

Member end moments M0 that develop in this frame due to

the external loads are computed by the moment-distribution

process, and the restraining forces R1 and R2 at the imaginary

supports are evaluated by applying the equations of

equilibrium. In the second part of the analysis, the lower

floor of the frame is allowed to displace by a known amount

δ1 while the sidesway of the upper floor is prevented, as

shown in Fig. (10.12-c). The fixed-end moments caused by

this displacement are computed and distributed to obtain the

member end moments MQ1. With the member end moments

known, the forces Q11 and Q12 at the locations of the roller

supports are determined from the equilibrium equations.

Similarly, in the third part of the analysis, the upper floor of

the frame is allowed to displace by a known amount δ2, as

shown in Fig. (10.12-d), and the corresponding member end

moments MQ2, and the forces Q12 and Q22, are evaluated. The

member end moments M in the actual frame are determined

by superposition of the moments computed in the three parts

as

(10.16)

In which c1 and c2 are the constants whose values are

obtained by solving the equations of superposition of

horizontal forces at the locations of the imaginary supports.

234

Chapter Ten

By superimposing the horizontal forces shown in Figs.

(10.12-a) to (10.12-d) at joints D and F, respectively, we

obtain

By solving these equations simultaneously, we obtain the

values of the constants c1 and c2, which are then used in Eq.

(10.16) to determine the desired member end moments, M.

The analysis of multistory frames by the momentdistribution method is quite tedious and time consuming.

Therefore, the analysis of such structures is performed on

computers using the matrix formulation of the displacement

method.

Problems

10.1 through 10.4: Determine the reactions and draw the

shearing force and bending moment diagrams for the beams

shown in Figs. P9.1 to P9.4 by using the moment-distribution

method.

10.5 through 10.7: Determine the member end moments for

the frames shown in Figs. P9.6, P9.7, P9.9, and P9.10 by

using the moment-distribution method.