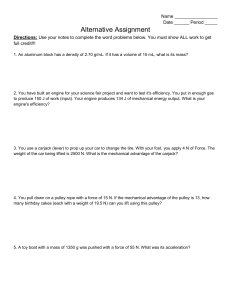

Automatic Scooter Engine The CYLINDER/PISTON The cylinder, cylinder-head and piston are some of the most important components in the engine. The upward stroke of the piston draws in the fuel/air mixture from the carburettor and the downward stroke of the piston transfers this mixture up to the cylinder head, the power created by the explosion in the cylinder head (combustion chamber) is transferred to the engine via the crankshaft and connecting rod. The design, material and shape of these components are critical to achieve the desired performance. The upper part of the piston with the help of the piston rings has to provide a gas tight seal within the cylinder. The position of the piston and the size / shape and position of the cylinder ports, control the flow of gas through the cylinder. The CARBURETTOR The carburettor is the control for the engine. It feeds the engine with a mixture of air and petrol in a controlled volume that determines the speed, acceleration and deceleration of the engine. The carburettor is controlled by a slide connected to the throttle cable from the handlebar twist grip which adjusts the volume of air drawn into the engine. A system of fixed holes (jets) and, adjustable needles control the volume of fuel (petrol) to match the volume of air. The ratio of fuel and air the carburettor delivers can be changed by selecting different jets and adjusting the position of the needles. Sometimes but not very often, the manufacturers restrict the speed of the scooter for certain countries by fitting a reducing washer to the entrance of the carburettor. Adjustments Although the carburettor is set by the manufacturer, it is sometimes necessary to make adjustments to match the characteristics of the engine. These are: 1- Tick-over, this controls the speed of the engine when the twist grip is closed to stop the engine from stalling. 2- Mixture screw, this controls the volume of fuel that enters the engine when accelerating from a low engine speed. 3- The height of the float and float needle controls the amount of fuel available in the the carburettor. If the float needle becomes worn it may cause the carburettor to leak and overflow. 4- Height of slide needle, controls how quickly the needle is lifted from the main jet, to allow the fuel to pass through the jet. 5- Size of the main jet, selecting a main jet with a different size hole will effect the volume of fuel it will pass. For example when a new exhaust is installed or a custom air filter it is likely that a higher ratio of fuel to air will be necessary and therefore a main jet with a larger hole will be required. THE EXHAUST The exhaust has a very important role in the performance of a two stroke engine. The design of the exhaust is critical to achieve the maximum power. Following combustion in the cylinder head the burnt gases are discharged through the exhaust port and they expand into the shaped chamber of the exhaust. The shape, size and length of this chamber are critical to the efficiency of the system. At the end of the chamber, there is a tapered outlet into the silencer. This tapered outlet creates a reverse pulse, back to the cylinder which is timed to reach the exhaust port at the moment the piston passes it and closes it off. This reverse pulse helps to ensure that none of the incoming fuel/air mixture escapes and the maximum is retained in the cylinder for combustion. It is common for the scooter manufacturers to restrict the speed of the scooter for certain countries by tack welding a washer or small restrictor to the entrance of the exhaust or at the exit to the silencer, these can usually quite easily be removed. Sometimes another way for the manufacturers to restrict the scooters speed is for them weld an extra piece of pipe some 15 or 20 cm long to the outside of the exhaust lead in pipe, again a performance increase will be experienced if this is removed, and weld over the hole it leaves. Each exhaust is designed and tuned to achieve maximum performance with a specific engine. 1 - the exhaust evacuates the burnt combustion gases 2 - the exhaust reduces the sound from the combustion chamber 3 - the exhaust is tuned to improve the efficiency of the port timing. The Variator The variator is like a continuously variable drive system to give the optimum gear ratio between the engine and the rear wheel. This enables the engine to work at the best speed in comparison to the rear speed. The variator works upon the ratio of the diameter of the front and rear drive belt pulleys. Both front and rear pulleys are an assembly of moving plates. When viewed from the side, one plate is convex and the other is concave. At low engine speed, the plates of the front pulley are pushed apart by the tension of the belt as it forces itself between the plates. At the same time, the plates in the rear pulley are pushed together by the spring beneath the automatic clutch. Behind the moving plate of the front pulley, there are weight rollers, these are thrown towards the outside edge of the variator by centrifugal force, as the rotation speed of the engine / variator increases. When the weight rollers move towards the outside of the variator, the inside plate is forced together with the outer plate and this moves the drive belt towards the outside of the pulley. This effectively makes the diameter of the front pulley larger. As the belt moves out on the front pulley, the tension in the belt is increased, which overcomes the spring pressure holding the two plates together in the rear pulley. The belt moves towards the center of the rear pulley, which effectively makes the diameter of the rear pulley smaller. In this way, the ratio between the two pulleys is changed and therefore, the speed ratio between the engine and rear wheel is changed. It is common for the scooter manufacturers to restrict the speed of the scooter by fitting a spacer washer under the variator. This restricts the amount the variator is allowed to open. if removed the belt is allowed to go further out into the pulley. FINAL DRIVE ASSEMBLY The final drive assembly drives the rear wheel; this is a combination of shafts and gears that determine the speed of the wheel in relation to the speed of the engine. In standard form the ratio is set to allow the engine to turn at an optimum speed according to the wheel speed. If the performance of the engine is improved it is possible to change the gears in the final drive assembly for a new ratio. Aprilia sr 50cc The Differences Developed from the air-cooled motors with horizontal cylinders, these engines have had a number of changes over the years. The major changes concern the transmission parts: the rear pulley, the clutch diameter and the rear pulley diameter changed around 1996/7, but apart from cosmetic differences and the use of a disc brake on the rear, the motors are basically the same. Derestricting Derestriction usually involves removing the restricter from the front variator, removing the washer from the exhaust and cutting the front pipe 90° elbow off and rewelding. When derestricted by these methods the top speed is around 50 to 55mph on the speedo. Exhaust The usual way of improving performance after derestricting is to fit a better exhaust. The LeoVinci Handmades and the Giannelli NRX exhausts give a good boost in power, but with a narrow powerband they can give the transmission problems if roller weights are not spot-on for the individual motor. The exhausts with wider more flexible powerbands are the Giannelli Sport Cee and the LeoVinci SP3. These give good performance but at lower RPM than the NRX and Handmade pipes. They are better suited to the 70cc kits for road use where a gear kit is to be fitted. Because the RPM is lower with these exhausts potential engine wear is reduced. Further Improvements Like most Yamaha automatic motors, the transmission allows large variations in RPM, so using aftermarket springs, variators, and a torque driver pulley will benefit performance. The use of a 70cc cylinder kit with a larger carb and a gear kit will give another boost in performance, the increase depending on what other parts are fitted - around 8 to 9bhp is achieved with the basic performance parts and around 10 to 11bhp with the aluminium MHR kit from Malossi and the W-port aluminium kit from Polini. These higher performance kits will benefit from the race spec transmissions that Malossi make under the wide-range transmission format, which must be fitted and used as complete sets. The cast-iron basic cylinder kits such as those made by DR, Top Performance, Malossi and Polini can use 17.5mm, 21mm or 22mm carbs, but the more expensive larger carbs only give a small power increase over the 17.5mm when used with the cast-iron cylinders. When aluminium cylinders are used the larger carbs become more beneficial. Any of the cylinder kits will run on any of the carbs, including the standard one, but like everything else it depends on performance required and budget. Ignition Standard ignition retards above 10,000rpm, so some combinations of parts require an uprated CDI. Use either a straight replacement without a rev limiter or one with retarding ignition timing to suit performance motors with higher compression. Crank If an uprated crank is desired then race cranks are available to use the standard 10mm small end or 12mm small end, swapping the piston in the kit to suit. The 12mm small end is the stronger and better option, especially with aluminium kits and high-revving exhausts. Reed Petals and Blocks Uprated carbon fibre petals are available to fit the original reed block or a complete Malossi or DR reed block assembly fitted with carbon petals. There are carbon fibre reed petals to fit the standard reed block that will improve performance and there are replacement reed valve blocks with carbon petals to replace the original. Our experience of replacing the block has shown that it only becomes beneficial with high-revving motors. When thinner 0.25mm or 0.3mm petals are used the better cushioning effect of these blocks increases the life of the petals. In general, the thinner the petals the more susceptible to fraying edges they are. 0.3mm for road engines is a good compromise. Airbox All the engine units have rubber inlet tubes feeding into the airbox to reduce noise. Removing this trumpet will allow more air to enter the airbox and into the engine more freely, but it’s not just a matter of removing it. The carb main jet must be increased considerably and the needle lifted to provide more fuel. For example, a 17.5mm carb with a 70cc kit and exhaust on a standard airbox requires the main jet in the 75-80 range, but with the rubber inlet removed the main jet is in the 88-90 range. With a 22mm carb and the inlet rubber fitted the main jet is 75, but without the inlet rubber it is 88-90. Failure to use the correct main jet will cause damage to the motor. Gearing The standard motors are geared fairly high. With the choice of parts giving different operating RPM the overall gearing can sometimes be left the same or up-geared to increase the top speed. Between DR, Polini and Malossi we have a range of gearing available from +10% to +60%. It is always worthwhile trying to match the gearing to the power output and motor configuration correctly. Being geared lower wastes speed and increases wear at top speed. Gearing too high gives the clutch and drive belt a harder time than necessary when moving off. Contrary to popular belief, once the motor is operating on the pulleys at peak RPM the overall gearing used does not affect the acceleration. The transmission just uses a different part of the pulley’s diameters. We normally use the manufacturer’s recommendation for gearing but occasionally better results are obtained with a different set-up. Yamaha/Minarelli Style Motors (As used in some Aprilia, Italjet, Malaguti, Beta, Benelli, MBK, Motron, Yamaha scooters etc.) The Yamaha engines are in three types, two air-cooled and one watercooled, all made under license by Minarelli in Italy and supplied to a number of manufacturers. The oldest was originally used in the Yamaha BWS. It has an upright cylinder and the carb feeding through a reed valve into the rear of the cylinder barrel. The later engine unit was originally used in the Yamaha Jog, which has a similar layout to the BWS motor, but has a horizontal not vertical cylinder with the carb feeding into the crankcase not the cylinder. This motor was originally air-cooled and for the last few years has been available in watercooled form. Up until recently the motors were all drum brake at the rear with either 10" or 13" wheels. Now the latest models are available with a disc brake on the rear. These water and air cooled motors had an update in 1995/96 when the transmission clutch and rear pulley system was revised. All the restricted motors are restricted by a spacer between the front pulleys, restricters in the exhausts (not always) and a rev limiter built into the CDI unit. The rev limiter can be disconnected on early motors by disconnecting one wire. On later motors (’96 onwards) there was an increase in the number of manufacturers using the latest CDI units, which must be replaced to remove the rev limiter. These replacement CDI units can have standard ignition timing or variable ignition timing with no rev limiter (which is useful when higher states of tune are used). One of the problems with all these engine units is that the RPM varies greatly as the pulleys change diameter, and that the standard transmission spring will not cope with 70cc power outputs without obtaining belt slip at low speeds. The easiest way to help both these problems is to use an aftermarket variator and rear pulley spring to enhance transmission performance. The rear half of the rear pulley can be changed so that RPM change is reduced to a minimum as the pulleys change diameter. This rear pulley half is referred to as a torque driver pulley. The higher state of tune aluminium MHR or race cylinders with race expansions can beneficially use the race/fast-road transmission set-up, which uses a matched rear pulley assembly and variator and a special drive belt. The only extra part required is a clutch assembly to obtain a complete transmission system. If an exhaust is used with a cylinder that between them generates a wider powerband then the only transmission part required is an uprated rear spring so that belt slip is eliminated. The most popular aftermarket exhausts are those supplied by LeoVinci in several different styles: Sito Plus Standard-looking box with enhanced performance. Does not usually require any transmission modifications on a standard bike. It is a useful way of obtaining a bit of extra power when replacing a standard box. SP3 This is a standard style box but it increases performance by around 20% on air-cooled and 10% on water-cooled motors. It is supplied with rollers to fit the standard transmission parts. Navigator Latest style box from LeoVinci. Gives more performance than the SP3 and is supplied with rollers and sometimes clutch springs. Not as good as the handmade exhaust. Handmade Exhaust Gives 35/40% power increase on air-cooled and around 25% on watercooled motors. This comes with rollers and clutch springs so that the transmission works in the right range. These exhausts are all very reliable, improving both top speed and acceleration. Malossi do two exhausts. One is a road exhaust called Wild Lion which is not normally used as the LeoVinci gives the same performance at a cheaper price. The other is a race expansion which is extremely expensive but will not work with the centre stands and is designed to work with MHR replica and MHR race cylinders. Polini do a range of exhausts but the basic two systems are covered by LeoVinci. The race box is cheaper than the Malossi version but again is designed for their cylinders and will not clear a stand. They do a road expansion chamber that suits the 70cc kits very well, the cast-iron and aluminium road units from both Malossi and Polini. It is slightly dearer than the LeoVinci carbon fibre handmade, but works at a lower RPM range than the LeoVinci, which means it suits the MHR and aluminium kits better when used on the road. The clutches are available in two and three shoe types. Aftermarket springs are available to alter the biting point to tune the transmission. On higher states of tune where enough slip cannot be generated by the springs, aftermarket clutches are available that have a choice of springs and lighter shoes to give more adjustment. The ultimate clutches are Polini speed clutches and Malossi delta clutches. These have a choice of springs and spring positions and movable weights to allow the clutch to work with any motor from standard to full race. Cylinder kits are available in several formats, basically cast-iron with or without cylinder heads, road aluminium with cylinder head and race aluminium with cylinder head. The race and MHR motor can run at RPMs that will increase stress on the crankshaft so that it becomes advisory to change them. Race crankshafts are available from Malossi and Polini that are good for 16,000rpm, well above what road motors should be built to run at - so are extremely reliable. They are available with a small end to take 10mm standard gudgeon pin size or 12mm to suit different pistons that are available to fit the cylinder kits. The12mm gudgeon pin further improves reliability on high states of tune. If you are going to use MHR or MHR-Replica type cylinders and have a performance crankshaft that uses the 12mm type crank then get the cylinder with the 12mm piston kit. The engine units use autolube but the pump is not connected to the throttle, so the oil delivery is dependable on engine RPM only. When using tuned motors you must use fully synthetic two-stroke oil to avoid problems with lubrication, and if MHR or race cylinders are used either add extra oil in the petrol or remove the autolube and use oil at 3% with the petrol. Carbs come in a lot of different sizes; the standard carb is 12mm. For road use 17.5mm is large enough, but MHR or aluminium cylinder kits with expansion chambers will benefit from larger carbs - 22mm is popular. Some motors have auto chokes and some cable chokes - carbs can be supplied with either. There are also 19 and 21mm carbs listed by Malossi and Polini that are cable choke only. To raise the overall gearing there are several types of gear kit available, with different numbers of teeth to suit the various models. The best option is to use the gear kit recommended by the kit manufacturer to obtain a balance between power and gearing. It is becoming more popular to use these motors for racing in Italy, so there are special cylinders and crankshafts for motocross and race use that must use the appropriate crankshaft, exhaust and transmission parts. The operating RPM is between 13,000 and 14,000rpm, and although very powerful the wear rate for road use is not acceptable. The life of some components in race use is as little as 10 hours and a full engine rebuilt of crankshaft and bearings is required every 25 hours of use to ensure reliability! At the normal sub-10,000rpm of the road motor, reliability is excellent if good two-stroke oil is used and the carburation is set up correctly to avoid overheating. As with all tuned motors, you need to decide what end result you require and select the appropriate components to give you this. For example, if only a limited increase in performance is required, this could be achieved by using an exhaust on a standard cylinder or a road cylinder kit with the standard exhaust. If you need large increases in top speed you have to upgear the transmission with a suitable gear kit and then find the power to obtain this top speed. If you need any advice on what mix of bits and pieces you require to obtain the desired level of performance then please contact the shop. New Wide-Range Pulley System for Race Engines Malossi Transmission System for Aprilia-Benelli-Italjet-Malaguti-MBK-Yamaha When MHR and MHR Replica cylinders are used with race or race style exhausts systems they create a narrow power band that the original pulley systems cannot cope with. Normal aftermarket pulleys use a standard rear pulley half and drive belt size. The latest pulley system uses a wider belt and larger diameter pulleys to increase the operating range of the pulley system. Together with revised pulley angles, it allows even highly tuned race engines to stay in the working power range. However, although the parts are similar to or the same as some previously listed components, they are not compatible with standard components and must be used as a complete system. Relying on its leadership in the field of automatic scooter transmissions, Malossi has extended its technological skills to the new automatic transmission for competition scooters with Minarelli and Yamaha engines. This new transmission has been designed and tested on engines ready for scooter cross and racing competition, demonstrating excellent reliability and extremely high levels of performance. This new system hinges on the new rear torque driver Rear Pulley System that has two pulleys with a much larger diameter than the original and the very latest technological specifications. The larger diameter of these pulleys allows one to have a greater velocityratio range compared to the original pulleys that have a notably smaller external diameter. Malossi engineers have also taken particular care in realising this pulley right down to the smallest detail, using special materials and a particular type of thermochemical treatment that ensures exceptional surface hardness and therefore excellent wear and abrasion resistance. In order to fully exploit the range of the new torque driver unit and the power ratings currently offered by competition machines, a new Malossi notched Kevlar Belt has been introduced with larger cross section and revised length to ensure maximum performance under all running conditions. To complete the renewal of the transmission system and take full advantage of its exceptional specifications, the Multivar variable-speed drive has also been upgraded by fitting it with new tracks for the rollers and a new hub. This new variable-speed drive represents the evolution of the previous generations, the result of many years experience on the race circuit and the currently available CAD-CAM technology that allows top-level specifications to be obtained. The combination of these new components creates a perfect cocktail that will allow you to savour the taste of victory. The new Malossi system must be fitted AS A WHOLE Available for: Aprilia Sr 94, Sr Replica, Sr Netscaper, Sr Stealth, Sr Racing, Sr WWW; Benelli 491 Gt, 491 Sport, K2 (air cooled and liquid cooled), Italjet Dragster; Malaguti F12 Phantom, F15 Firefox; Mbk Booster, Booster Next Gen., Flipper, Nitro, Ovetto, Rocket; Yamaha Aerox, Bws, Bws Next Gen., Neo's, Spy, Zuma Variable-Speed Drive 51 9725 Kevlar Belt 61 9713 Rear Pulley System 61 9733 Peugeot Air/Water Cooled 50cc Scooters Peugeot Elyseo, Trekker, Vivacity, Speedfight, Buxy & Squab Scooters These motors are basically identical except for water-cooled cylinders and water pump driven from the flywheel right-hand side of the motor, replacing the fan on the air-cooled engine and approximately 10% higher gearing in the water-cooled motors. Derestricting Despite the many differences in the bodywork and exhaust styling, they are all restricted in the same way : 1. By the exhaust being fitted with a resonant tube (a blind pipe attached to the front pipe) that should be cut off and welded up. This improves power and rev-on. 2. By a gearing restrictor in the variator body. This takes the form of a large diameter plate next to the roller drive plate in the rear of the front pulley. It just requires removal of the variator body cover and removal of the plate and reassembly. If these derestrictions are done correctly the differences shown in the dyno curves will be apparent. Fitting a 70cc Cylinder Kit Dyno graph showing the different stages carried out on the same Peugeot 50cc scooter We would normally fit a slightly larger main jet, approximately size 76/78 if size 72/74 was originally fitted. To improve power output further the next stage is to fit a 70cc cylinder kit. These are available very cheaply for the air-cooled and water-cooled motors. The DR air-cooled cylinder kit comes complete with a size 80 main jet for the carb and fits using the original head. Power is improved as shown on the dyno graph. Exhausts Compared to the standard exhausts most aftermarket exhausts will give more power, but not necessarily more RPM. So you can have the effect of obtaining more acceleration and less top speed compared to a derestricted motor. This is not such a bad result, as fitting a gear kit will increase the top speed whilst engine revs stay lower than with those exhausts that obtain extra speed for extra high RPM. Also, the Peugeot motors are not that smooth when revved very highly, and we prefer to obtain the power at lower engine RPM and then fit a gear kit if higher top speed is wanted. If a 70cc cylinder kit is used then a lower revving exhaust and a gear kit will make vibration less apparent, which is preferable. For maximum power on 50’s use a LeoVinci Handmade ZX or Giannelli NRX expansion exhaust. For mid-range power use a Giannelli Sport Cee exhaust or a Tecnigas expansion exhaust. Carburettor When more power is required then a larger carb and better reed block is necessary. The Malossi carb kit comes with adapters to fit to the original manifold and is 19mm in size. It also converts to a manual choke. The transmission will not cope without uprating. The belt slip becomes more noticeable with the extra power, so the fitting of an aftermarket front pulley and Kevlar belt, preferably with the torque driver rear pulley half, will give improved engine response and better acceleration through the midrange by reducing RPM variation in the engine. The water-cooled motors are approached the same way as the air-cooled. All of the motors have a very poor inlet manifold/reed block design and the power outputs achieved are not as good as with other engine makes. It will always be worthwhile to clean out any casting flaws and to match the inlet port carefully to improve air flow in this area. The use of the DR reed cage assembly which changes from 3 small to 2 large reed petals is recommended for all states of tune. Peugeot Speedfight, Trekker & Elyseo 100 Tuning Guide Parts for these machines are slowly becoming available from European manufacturers. The biggest single improvement you can make is by fitting one of the exhaust systems. To see the difference look at the Dynojet graph below comparing the standard exhaust with an aftermarket Giannelli Freeway exhaust. The larger 21mm carb kit from Malossi improves this again, but the major change is the exhaust. There are also some improved transmission parts available that extend the range. We will provide Dynojet graphs showing the use of these parts as soon as we have them available. With the exhaust fitted the power output is so much improved that the 100 is even more under-geared than standard and can usefully do with gearing 20-25% higher. As soon as we have chance to check out the internals we will sort one out but I’m sure the Italian aftermarket parts manufacturers will have something available soon. Gilera DNA 50cc Scooters Introduction The initial assumption with the Gilera DNA 50 scooter is that it is just a water-cooled version of the Hiper2 motor in the Zip 2000 Kat. But the 14 inch rear wheel, the crankcase length and the gear box layout are not the same as used in earlier Piaggio 50cc automatics. The gear transfer box in the DNA motor is now accessed by unbolting the case area from behind the rear wheel. (Previously this was part of the main crankcase and was accessed through a cover under the rear transmission pulley.) The DNA is restricted in the usual way for Piaggio and Gilera scooters - a washer in the front pulley (actually two) and a resonant pipe on the exhaust, the effects of which can be seen in the dyno curve below. A main jet increase is needed when derestricting. The problem with any tuning using the catalysed standard exhaust is that the exhaust gas analyser machines that measure the CO content are not accurate, which makes it difficult to confirm what jetting changes are required when engine modifications are made with the standard exhaust. So, when derestricting using the standard exhaust leave the air inlet snorkel and brass washer in the carb in place, and fit a 60 main jet. Derestricting a UK Spec DNA 50 First remove the two nylon washers in-between the front pulley halves. Remove the exhaust front pipe resonant tube (blind-ended tube) and weld over the hole. Rejet the carb with a larger main jet (standard is 56). Piaggio recommend using a 58, but we prefer a 60. Additional Performance The next step is to fit an aftermarket exhaust system. We have found that the LeoVinci Handmade ZX gives an excellent boost in performance when fitted with the appropriate carb and transmission modifications (see Dynojet graph 1 above). The standard DNA carb has the usual "Hyper2" brass washer in the inlet area. When this washer and the rubber air inlet snorkel into the air filter box are removed, the carb needs rejetting with a larger main jet and pilot jet. We used 36-38 pilot (standard is 32) and 74-76 main jet (standard is 56) when we fitted a LeoVinci ZX exhaust system. With this setup power is up to around 6.5bhp, compared to 3bhp when restricted and 5bhp when derestricted. The transmission rollers need optimising (5 to 5.5g) and stronger clutch springs need to be used (or an aftermarket clutch fitted). If you are going to use a 70cc cylinder kit, the increased power at low RPM means that the standard clutch does not need modifying. To increase the performance further fit a 70cc cylinder kit, a gear kit and transmission pulleys (Malossi front pulley and torque driver rear pulley half). Because the standard carb is 17.5mm this is large enough for road tuned engines. Malossi make both cast-iron and aluminium MHR replica cylinders. The latest Malossi cylinders have smaller spigots so that they can be fitted into the smaller Hyper 2 crankcase area.The MHR cylinder is more powerful. This is what we used to obtain graph 2 below. DR cylinders have a larger bore at 48.0mm and the normal spigot size, so if a DR cylinder is used the crankcase will need altering to remove the antitamper crankcase ‘bulges’. Other cylinder makes will need checking for suitability. The latest Malossi front pulley and torque driver rear pulley improve the transmission quality so that the engine RPM remains more consistent throughout the speed range and therefore maximises the acceleration. This Gilera DNA 50 tuning guide should be read in conjuction with the Hyper 2 tuning guide Honda X8R, SFX and X8BR Tuning Guide The Honda X8R, SFX and X8BR scooters are restricted by a rev limiter in the CDI, a washer in the exhaust system and a restricted variator that limits gearing. The washer in the exhaust front pipe is easily dealt with - just grind out the spot welds and remove it. The original CDI has two rev limiters built in, one at 7,500rpm and one at 9,250rpm. The standard motor runs at 7,000rpm at peak power. The CDI can be modified to remove the 7,500 rev limiter. If the cylinder and exhaust remain standard then this is okay, as by the time the motor hits the 9,250 rev limit power output is more than halved compared to power at 7,000. The front pulley variator has restricted movement. The easiest way to fix this is to replace the variator assembly. Either a cheaper replacement unit or, if further tuning is envisaged, a Malossi or Polini unit. The variator, CDI and exhaust modifications will give an increase in speed from 30 to 33mph up to 42 to 45mph. The power of the motor from the exhaust modifications rise from 3.5 to 5bhp, giving enough power at 50cc to go to 50mph. There is a modified Bali gear kit we do that is a 15% raise in gearing that gears the 50 to the right level to achieve this. If a 70cc kit is to be used the higher gearing from Malossi or Polini is more sensible and increases the top speed potential to over 60mph on the standard exhaust and 70mph on aftermarket exhausts. If a higher revving exhaust or cylinder kit is to be used aftermarket CDI are available that have programmable rev limiters to set to the RPM you wish or bypass it completely. With aftermarket exhausts (LeoVinci or Giannelli) that will give power above the Honda 9250 rev limit. It is desirable to fit a CDI that will allow engine operation above 10,000rpm to obtain full performance. There are Malossi cast-iron and aluminium MHR 70cc cylinders available. The road cast-iron cylinder with a suitable exhaust and carb kit will give over 8.5bhp at the rear wheel. The MHR kit will give over 10bhp. Both will work with the standard exhaust, but an aftermarket exhaust gives best results. In order to achieve maximum increase in performance with the 70 kit - a larger carburettor is necessary. Malossi do a 19mm carb. In order to maximise acceleration the transmission can be improved by the use of a torque driver rear pulley half, which minimises engine RPM changes. When high gearing and higher revving cylinders and exhausts are used acceleration from standstill can be improved by use of clutches that can generate more slip. The Malossi fly clutch is the road version. The Delta clutch is the full race unit that has adjustable springs and weight positions as well as a choice of springs. For most road engines stronger springs for the standard clutch or the fly clutch are adequate. For the ultimate road tune a full circle crankshaft with race spec conrod and big end bearing is available. This allows modification to be made that allows 13,000rpm to be used reliably for race work. To summarise: Derestrict or change exhaust Derestrict or change CDI Change front variator Fit raised gearing to suit 50 or 70cc Fit 70cc kit, cast-iron or aluminium Fit larger carb kit Fit torque driver rear pulley to improve transmission quality on high revving tuned motors Fit race crankshaft Disclaimer: We can not be held responsible for and damage caused by alterations to your motorcycle/scooter this is intended for information use only.