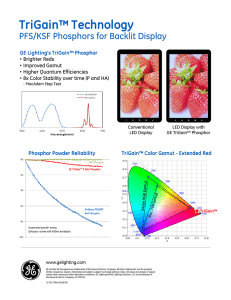

IMPLEMENTATION OF PHOSPHOR SEDIMENTATION TO REDUCE THERMAL INSTABILITY ISSUE OF WHITE LED ABSTRACT In general lighting application, white Light Emitting Diode (LED) usually exposed to an extreme operating temperature of above 90 °C. It is well known that spectral characteristics of white LED are dependent on the temperature, causing thermal effects on the luminous flux and the color-shift of white LED become a critical application checkpoint to be addressed by white LED manufactures. Thus, this study aims to minimize the thermal stability issue affecting white LED luminescence during operation by introducing phosphor sedimentation process. The luminescence properties of blue LED chip samples, yellow YAG:Ce3+ phosphor samples, red Sr2Si5N8:Eu2+ phosphor samples and assembled white LED samples were initially characterized at varying temperatures to understand the seriousness of the luminescence properties thermal instability issue of both LED materials and assembled LED. The efficiency of gravitational phosphor sedimentation (GPS) and centrifugal phosphor sedimentation (CPS) were then compared to determine the best approach to sediment phosphor particles. Finally, the temperature varied luminescence properties and the reliability of LED samples after implementing phosphor sedimentation were investigated to understand the impact of introducing phosphor sedimentation. Computational fluid dynamics (CFD) thermal simulation was also applied in this study to understand the temperature distribution of the LED with no phosphor sedimentation (NPS) and full phosphor sedimentation (FPS) during operation to validate the hypotheses based on experimental data. The results show that CPS method has greater efficiency to sediment the phosphor particles compared to GPS method, and this i method just requires ~60 seconds to fully sediment the phosphor particles with 10 rps of centrifugation. Moreover, the results show that the color coordination is more stable, the rate of luminous flux degradation is reduced by around 3.0 %, and the color rendering index (CRI) shift is reduced by around 0.35 % as temperature increases from 25 °C to 95 °C after implementing phosphor sedimentation process. The results also show that the degradation of luminous flux and color coordination is not significantly influenced by phosphor sedimentation in steady state life test (SSLT). In conclusion, the thermal instability issue of white LED in terms of color-shift, luminous flux degradation, and CRI shift can be improved by introducing phosphor sedimentation process without causing any reliability drawbacks. These improvements are mainly due to the heat generated by phosphor particles during operation can be dissipated effectively throughout a high thermal conductivity substrate after phosphor sedimentation. Hence, the phosphor temperature of LED with FPS is lower during operation as validated with the thermal simulation, which reduces the thermal quenching and color-shift effects of phosphor particles in LED with FPS at high temperature. These improvements are practically significant and are valuable to the LED manufacturing companies that intend to survive against fierce competition and push for light quality perfection. ii