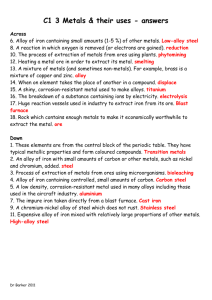

TBS /CHEMISTRY 10C /Online Course by Online Course • Enter the online meeting • Make your pen or pencils ready Subject: METALS Objective: Extraction of METALS from its ORE Rules Online Course • Teacher will control who will talk or share something • Teacher will control your microphone(mute or unmute) • Whenever teacher gives you control of mouse and keyboard ; please use it responsibly • Lessons are recorded by teacher; behave responsibly 1 TBS /CHEMISTRY 10C /Online Course by Earth Curst Subject: METALS Ore: Rocks that contains valuable minerals in it. Objective: Extraction of METALS from its ORE Extraction Methods of Metals from Ore • The position of the metal on the reactivity series influences the method of extraction. • Those metals placed higher up on the series (above carbon) have to be extracted using electrolysis. • Metals lower down on the series can be extracted by heating with carbon. Iron oreHametite Extraction of Metals from Ore Al ore Bauxite • The Earth’s crust contains metals and metal compounds such as gold, iron oxide and aluminium oxide. • When found in the Earth, these are often mixed with other substances like rocky. • i) ii) To be useful, the metals have to be extracted from their ores through processes such as Electrolysis using a blast furnace or by reacting with more reactive material.(CARBON) • The extraction of metals is a reduction process. • Unreactive metals do not have to be extracted as they are often found as the uncombined element as they do not easily react with other substances GOLD –SILVER-Platinium ... Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel 2 TBS /CHEMISTRY 10C /Online Course by Steps of extraction Subject: METALS Objective: Extraction of METALS from its ORE BLAST FURNACE –Extraction of iron from Hametite by carbon Raw Materials: Iron Ore (Haematite), Coke, Limestone and Air:called charge are mixed together and fed into the top. Hot air is blasted into at the bottom Step3: ZONE3 : Temp: 600 oC Carbon Monoxide (the reducing agent) reduces the Iron (III) Oxide Molten iron flow down collect at the bottom where it is tapped off: Main rxn Fe2O3 (s) + 3CO (g) → 2Fe (III) + 3CO2 (g) Oxisdising A Reducing A Pure iron waste gas Step2: ZONE2 : Temp: 1000 oC high temperatures in the furnace carbon dioxide reacts with coke to form carbon monoxide: CO2 (g) + C (s) → 2CO (g) ( less oxygen or no oxygen here) rises up Step1: ZONE1: Temp: 1900 oC Coke is an impure carbon burns in the hot air to form carbon dioxide. This is a strongly exothermic reaction:Very High Temp C (s) + O2 (g) → CO2 (g) rises up H o t a i r r i s e s M o l t e n i r o n f l o w s Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel Function of LimeStone to remove impurities in the ore. Silicon Dioxide Calcium Carbonate in decomposes to form calcium Oxide: CaCO3 (s) → CaO (s) + CO2 (g) The Calcium Oxide reacts with the Silicon Dioxide which is an impurity in the Iron Ore, to form Calcium Silicate. This melts and collects as a molten slag ,floating on top of the molten Iron which is tapped off separately: CaO (s) → SiO2 (s) + CaSiO3 (I) 3 TBS /CHEMISTRY 10C /Online Course by Steps of extraction Subject: METALS Objective: Extraction of METALS from its ORE Making Steel and Arranging Carbon percentage • • • • Extracted Iron is not pure completely . Its Called -pig iron-Cast iron- 4% Carbon + 96% iron Cast-pi-iron is basicly STEEL but some impurities in it. BUT 4% Carbon is too much , its brittle steel • We have to get rid of excess Carbon and • impurities such as; Sulfur, Silicon dioxide, Phosphorus . Normally we added LimeStone in the blast furnace, but we cant not get rid of all them. There are still some impurities. BASIC OXYGEN PROCESS –Tilt Furnace(mixing Furnace) Oxygen gas is added to molten pig-cast iron Pieces of scrap steel is added Excess carbon is decreased by C (s) + O2 (g) → CO2 (g) Excess Sulfur is decreased by S (s) + O2 (g) → SO2 (g) They left tilt furnace as a gas CaO is added to get rid of Silica and Phosphorus CaO(s) + SiO2 (g) → CaSiO3 (s) They are collected as a slag on at the top of molten iron According to needs, Chromium and Manganese ,tungsten or other metals are added for different types of alloys. Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel 4 TBS /CHEMISTRY 10C /Online Course by Steps of extraction of Zinc • Zinc blende This is mainly zinc sulfide, ZnS. • First it is roasted in air,giving zinc oxide and sulfur dioxide: • zinc sulfide + oxygen zinc oxide + sulfur dioxide 2ZnS (s) + 3O2 (g) 2ZnO (s) + 2SO2 (g) i) Using carbon monoxide : ZnO (s) + CO (g) Zn (s) + CO2 (g) The final mixture contains zinc and a slag of impurities. The zinc is separated by fractional distillation. (It boils at 907°C.) ii Using electrolysis But zinc oxide has a very high melting point (1975°C), and is insoluble in water! Instead, it is dissolved in dilute sulfuric acid (made from the sulfur dioxide produced in the roasting stage). Zinc oxide is a base, so it neutralises the acid, giving a solution of zinc sulfate. This undergoes electrolysis, and zinc is deposited at the cathode: Zn2 + (aq) + 2e 2 Zn (s) (reduction) The zinc is scraped off the cathode, and melted into bars to sell. In fact most zinc is extracted by electrolysis, because this gives zinc of very high purity. Cadmium and lead occur as impurities in the zinc blende, and these metals are recovered and sold too. • Extraction of Copper • Ore: Copper pyrites CuFeS2 , it can be also found as pure • Mainly Electrolysis is used. Subject: METALS Objective: Extraction of METALS from its ORE Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel 5 TBS /CHEMISTRY 10C /Online Course by Steps of extraction of Zinc • Extraction of Copper • Ore: Copper pyrites CuFeS2 , it can be also found as pure • Mainly Electrolysis is used. Subject: METALS Objective: Extraction of METALS from its ORE Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel 6 TBS /CHEMISTRY 10C /Online Course by Subject: METALS Objective: Extraction of METALS from its ORE Keywords Blast furnace Ore Hametite Carbon Carbonmonoxide Slag Steel Alloy Extraction Reduction Oxidation Objective Define Ore Define iron ore Extraction of iron at Blast furnace Making Steel 7 TBS /Science 8 /Online Course Subject: Energy Objective: Comparision of Renewable and NONrenawable energy resources Keywords QUIZ TIME Go to your google class See the online Quiz Complete it on time. You have 10-15 minutes to complete it. Energy Fuel FossilFuel Renewable NonRenewable Solar Wind Nuclear Biofuel Objective 8