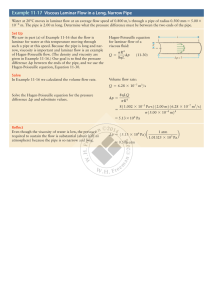

Multiphase flow Gas-liquid General - multiphase flow Multiphase flow includes all combinations which have at least two phases: solid, liquid or gaseous. Multiphase flow is common in many industries, and mostly in the petrochemical industry. Particularly important are the pipelines that transport gas and oil from oil rigs. Example Nam Con Son pipeline in Vietnam. Transports gas and condensate from the Lan Tay gas production platform in Block 6.1, 370 km offshore south eastern Vietnam, to an onshore gas processing terminal and a 28 km-long onshore pipeline to customers. Benefits of two-phase flow: 3 no extraction on the platform, except water separation; easier and cheaper, only one pipeline. General Multiphase flow combinations: Gas-Liquid Solid-Liquid Solid-Gas Liquid-Liquid Two-phase flow (Gas-Liquid) G-L 5 Two-phase flow G-L The presence of the gas phase during the flow of the liquid alters the properties of the original single-phase liquid flow. This is a result of interaction of the two phases, and various physical properties of each phase. The gaseous phase generally flows faster than liquid, so there would be a different ratio of phases through the cross-section of the pipe over time. 6 Two-phase flow G-L Both phases can flow in turbulent or laminar regime. Turbulent two-phase flow begins at the lower value of the Reynolds number than single-phase flow (Re = 2320). In the two-phase flow it is considered that the flow is turulent if Re > 1000. WHY? The second phase is always disturbing steady linear motion of the liquid. 7 Horizontal flow patterns Different velocity ratio of the gaseous and liquid phase forms various types of two-phase flow. Horizontal flow gas liquid Plug flow Bubble flow Stratified flow Wavy flow 8 Slug flow Annular flow Mist flow Horizontal flow patterns Bubble flow Low flow rate of gas. Bubbles of gas appear in the upper part of the pipe. Stratified flow Low velocity of the liquid and gas. The fluid of higher density is always at the bottom of the pipe. Fluids are separated into layers, and the interfacial area is flat. Wavy flow 9 Fluids are separated into layers. Due to an increase in gas velocity it makes waves on the liquid surface. Horizontal flow patterns Plug flow It occurs after the bubble flow when the velocity of the liquid is reduced, and the gas flow rate is increased. Gas bubbles merge into larger and form the so-called plugs that flow in the upper part of the pipe . Slug flow 10 Gaseous phase flows much faster than liquid which causes the waves that rise to the upper wall of the pipe. Very unstable flow which can cause damage to the pipeline . Horizontal flow patterns Annular flow Kapljevina struji uz stijenku cijevi stvarajući prsten, a plin i raspršena kapljevina u središnjem dijelu cijevi. It occurs by increasing the flow velocity of the gas phase. Liquid flows along the wall of the pipe, creating a ring, and gas with a dispersed liquid flows in the central part of the pipe. Mist flow 11 The highest content and velocity of the gas phase. Due to the high gas velocity liquid is dispersed into tiny droplets. Vertical flow patterns Vertical flow gas flow rate increases gas liquid Bubble flow Plug flow Churn flow 12 Wispyannular flow Annular flow Flow patterns The energy and momentum transfer between gas and liquid phase depends on the geometry of the system, interfacial area and two-phase flow regime/pattern. For example, the pressure drop or the amount of heat transferred will vary for bubbly flow (gas dispersed in a liquid) and the annular flow (liquid along the wall, the gas in the middle). This leads to different models that describe mass transfer, as well as momentum and energy transfer. The most important task at the two-phase flow is precisely predict flow regime as well as the characteristics of the fluid that may lead to transitional areas . 13 Flow pattern/regime maps Method of displaying results of the visual determination of the flow patterns. Charts with fluid velocities of flux of both phases on axes. When all values are recorded, lines representing the boundaries between different forms of flow are drawn into the chart. 14 Flow pattern/regime maps aL – cross sectional area of the pipe occupied by liquid vL – liquid velocity VL a L vL vs A surface velocity of the liquid 15 Flow pattern/regime maps Baker diagram – flow in horizontal pipe 1 2 G L W A W L L W 1 2 3 W L ṁG,A, ṁL,A– flux, gas and liquid, kg m-2 s-1 – density, kg m-3 – surface tension, N m-1 – viscosity, Pa s G – gas A – air at 20 °C and 101 325 Pa L – liquid W – water at 20 °C 16 Flow pattern/regime maps Hewitt-Roberts diagram – flow in vertical pipe 17 Pressure drop models Homogeneous Gas-Liquid Models Separated Flow Models Fenomenological Models 18 Homogeneous Gas-Liquid Models The simplest method for calculating the pressure drop is to find mean values of fluid properties (density, viscosity, etc.) and then calculating the pressure drop as it is a single-phase systems. Assumption: both phases have the same velocities. The biggest problem is the calculation of the viscosity of the two-phase system. McAdams method 19 Homogeneous Gas-Liquid Models Properties of two-phase system: 1 TP x G 1 x L VTP x VG (1 x ) VL 1 TP x G 1 x x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s TP – two-phase system G – gas L – liquid L Mean values of two-phase system are introduced into Darcy-Weissbach equation: 2 v TS p 1 l TS d 2 20 Separated Flow Models Assumptions: Each phase occupies a certain cross sectional area of the pipe. There may be differences in the phase velocities. There are numerous models proposed in the literature, but the simplest is considered the "classical" LockhartMartinelli method (1949) According to this method, the total pressure drop is obtained by the pressure drop in one phase multiplied by Lockhart-Martinelli multiplier, . p 2 p L l TP l L 21 p 2 p G l TP l G Separated Flow Models Lockhart-Martinelli multiplier depends on Martinelli parameter X. Martinelli parameter is calculated from the pressure drop of each phase: p l L X p l G 22 0,5 mL, A L G X mG, A G L 0,5 Separated Flow Models Lockhart-Martinelli multiplier is calculated according to: C 1 1 2 X X 2 L G2 1 C X X 2 23 Kapljevina Plin Oznaka C Turbulent Turbulent tt 20 Laminar Turbulent vt 12 Turbulent Laminar tv 10 Laminar Laminar vv 5 Separated Flow Models Lockhart-Martinelli multiplier 24 Review of methods McAdams McAdams – Homogeneous Gas-Liquid Model 1 x 1 x 1 L TP Find viscosity and density for TP. Reynolds number and friction factor (64/Re or Moody diagram) Re G x G 1 x L mtotal,A d TP muk v A TP Pressure drop: 1 v 2 TP p l TP d 2 25 TP x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s ṁtotal,A – total flux, kg m-2 s-1 ṁtotal – total mass flow rate, kg s-1 TP – two-phase system G – gas L – liquid Review of methods Lockhart-Martinelli McAdams Reynolds number and friction factor of each phase. ReL – Separated Flow Model mtotal,A 1 x d L ReG mtotal,A x d x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s ṁtotal,A – total flux, kg m-2 s-1 ṁtotal – total mass flow rate, kg s-1 TP – two-phase system G – gas L – liquid G Find flow regime for each phase. Re < 1000 – laminar; Re > 2000 – turbulent mL, A L G X m G, A G L Calculate X Find L ili G (equation, chart) 26 0,5 L2 1 C 1 X X2 G2 1 C X X 2 Review of methods Lockhart-Martinelli McAdams Calculate pressure drop of a single phase: 1 vL2 L p L l L d 2 – Separated Flow Model 2 1 mG,A p G l G d 2 G Calculate pressure drop for two-phase flow p 2 p L l TP l L 27 x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s ṁtotal,A – total flux, kg m-2 s-1 ṁtotal – total mass flow rate, kg s-1 TP – two-phase system G – gas L – liquid Moody diagram Laminar flow 5x10– 4 Absolute roughness depends on material and surface characteristics. (Tables) 2x10– 4 Complete turbulence 5x10– 5 Smooth Pipe Reynolds number, Re 28 5x10– 6 relative roughness, e/d friction factor, Transition region Equations Mass balance x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s ṁtotal,A – total flux, kg m-2 s-1 ṁtotal – total mass flow rate, kg s-1 TP – two-phase system G – gas L – liquid mtotal mL mG mL 1 x muk mG x muk Velocity vL vG 29 1 x mtotal 1 x mtotal,A A L x mtotal x mtotal,A A G G L Equations Reynolds number ReL 1 x mtotal d 1 x mtotal,A 4 1 x mtotal A L Pressure drop 2 1 mL,A p L l L d 2 L 30 L d L x – mass content of gas (1-x) – mass content of liquid – viscosity, Pa s ṁtotal,A – total flux, kg m-2 s-1 ṁtotal – total mass flow rate, kg s-1 TP – two-phase system G – gas L – liquid