2016 Con Study on a feeding circuit model formulated to use multipurpose solvers for multi-train simulators

advertisement

Study on a Feeding Circuit Model Formulated to

Use Multipurpose Solvers for Multi-Train

Simulators

Ryosuke Murata

Masafumi Miyatake

Graduate School of Electrical and Electronics Engineering

Sophia University

Tokyo, Japan

Email: m-ryosuke@eagle.sophia.ac.jp

Sophia University

Department of Engineering and Applied Sciences

Tokyo, Japan

Email: miyatake@sophia.ac.jp

Takashi Akiba

Power and Industrial Systems R&D Center, Toshiba

Corporation

Tokyo, Japan

Abstract— Reduction of energy consumption is one of the

recent key topics in railway sector. There are many investigations

such as SiC devices, permanent magnet motors, onboard and

stationary energy storage and reversible substations to absorb

regenerative braking, energy efficient driving and traffic

management. Multi-train simulators play an important role in

evaluating the effect of these countermeasures. In the simulator,

power feeding circuit must be modeled to calculate the energy

consumption with high accuracy. There are some literatures of

modeling and solving feeding circuits, however most of them

linearized some nonlinear but important characteristics of trains

and substations. We have also proposed a methodology of precise

modeling and solving power feeding circuits of railway systems

implemented in the multi-train simulator. The methodology is

flexible and characterized by the special node numbering and

introduction of ‘tie nodes’ which is solvable by multipurpose

solvers. In this paper, we analyze the solvability of the

methodology and introduce the virtual ‘tie nodes’ to decrease

errors of circuit equation if the distance of two nodes is very near.

The criterion whether the virtual tie node should be used or not is

finally analyzed.

Keywords—multi-train traffic simulation, energy efficiency, DC

electrification, feeding circuit, solver.

I. INTRODUCTION

In the recent decades, demand growth in public transport

systems has increased rapidly. Reduction of energy

consumption is one of the recent key topics in railway sector.

Most urban mass transit systems require DC traction power

supply to energize their rail vehicles[1]. There are many

investigations such as SiC devices, Permanent Magnet

Synchronous Motors (PMSMs), onboard and stationary energy

storage and reversible substations to absorb regenerative

braking, energy efficient driving and traffic management.

Multi-train simulators play an important role in evaluating

the effect of these countermeasures. In the simulator, power

feeding circuit must be modeled to calculate the energy

978-1-5090-0814-8/16/$31.00 ©2016 IEEE

Masahiro Tajima

Railway & Automotive System Division, Toshiba

Corporation

Kanagawa, Japan

consumption with high accuracy. There are many literatures of

modeling and solving feeding circuits[1]-[10], however, most

of them linearized some nonlinear but important

characteristics of trains and substations. Only a few literatures

deal with enough realistic nonlinear characteristics of trains

and substations.

We have also proposed a methodology of precise modeling

and solving power feeding circuits of railway systems

implemented in the multi-train simulator[11]. Our

methodology is suitable for rapid implementation because it is

flexible and characterized by the special node numbering and

introduction of ‘tie nodes’ which is solvable by multipurpose

solvers.

One of the features of the feeding circuits is that the

topology is often reconfigured as a train moves. Therefore, our

simulator checks the topology and derives the conductance

between adjacent nodes calculated by the multiplication of the

conductivity and the node distance. However, when a train

exists very near from a substation in a snapshot, the

conductance between the adjacent nodes is quite large. The

unbalanced node conductance often influences on the error of

our calculation and finally difficulty in convergence.

This paper describes the method to settle this problem. We

analyze the solvability of the methodology and introduce the

virtual ‘tie nodes’ to decrease errors of circuit equation if the

distance of adjacent two nodes is very near. We also

investigate the criterion whether the virtual tie node should be

used or not.

II. MODELING METHOD

A. Feeding model

Regenerative braking of rail vehicles is commonly used in

these days for higher energy efficiency by transferring

regenerative energy of a braking train to an accelerating train.

Most electrified lines in urban areas use DC parallel feeding

system. Since there are some substations as well as trains in the

feeding circuit, the size of the circuit to be solved becomes so

large and complicated. The circuit calculation of the network

with these elements becomes more important besides energy

calculation of a single train. This makes the circuit analysis

difficult and complicated.

Our methodology uses the concept of ‘tie nodes’ in order to

represent the nodes are connected with wires whose resistance

is neglected. It acts as a constraint in changing voltages of

these nodes simultaneously. The tie nodes are flexible because

they can be set at any places in the circuit topology of the

snapshot. The places of some tie nodes are represented by the

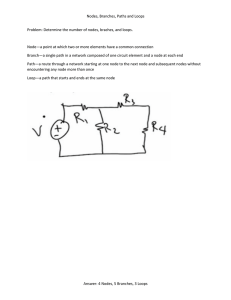

‘tie matrix’. The feeding model can be described as a feedingnetwork in Fig.1. It makes easier modeling and calculation to

express a feeding circuit with substation, train and tie nodes in

a feeding-network. By the tie node representation, nodes

connecting information is divided into the information of nodes

in different voltages and the information of nodes in the same

voltage. It enables to get an expression of Kirchhoff’s current

law in three steps. The first step is to make node current

equations disabling connections between the tie nodes. The

second step is to select the equations of the tie node from all

equations. The last step is to merge the selected equations

together in order to consider current flow among tie nodes

connected each other.

Construction of feeding circuit model is basically the same

in case of large change of a feeder topology. Without the

concept of the tie nodes, it is needed to modify the circuit

topology thoroughly every time in change of a feeding system.

Since only the feeder conductance between adjacent nodes is

considered taking the topological feature of the power feeder

into account, the values of the conductance is given by a vector,

not a matrix. If an element of the conductance vector is 0, it

means that the adjacent nodes are physically separated. For

example, in Fig.1, a conductance between nodes 7 and 8 is 0. A

connection between train and feeding-line is considered as a

point, regardless of train length. Resistance per unit length of

feeders, trolley wires and rails were merged to the resistance in

feeders. Substations and trains are considered as be grounded,

namely 0 [V]. Inductance and capacitance of feeding circuit is

neglected because transient response time is much faster than

the time step of this simulator.

Fig.1. Feeding circuit network model

B. Substation Model

A substation current model is represented by a function

( ) where i and V mean current and voltage, respectively.

With a typical characteristic of a diode substation like Fig. 2

represented with a no-load substation voltage

, a rated

voltage and current and , a substation current is given by

Eq. (1) where max( , ) is a function to choose bigger one of a

and b. This mathematical expression has enough flexibility to

introduce some advanced technologies; e.g. the expanded ( )

up to negative current is used for regenerative inverters or a

PWM substation, and V-I characteristics of each State of

Charge (SOC) controlled by the charge-discharge controller are

used for an energy storage system.

Fig.2. Voltage- Current characteristic of a substation

=

(

0

−

≥ 0)

(otherwise)

(1).

C. Train Model

A train current model is represented by a function ( , )

where i, V and n mean current, voltage and notch that

represents the acceleration/deceleration command by a driver

or Automatic Train Operation (ATO), respectively. In this

paper, induction motors driven by inverters are assumed to be

equipped on trains. There are two types of motor

characteristics of a train; motoring and regenerative braking

characteristics. Each of them is divided into three regions;

constant torque region, constant power region, and high-speed

region, depending on velocity. A motoring characteristic is

and

are given with Eq. (2). In

depicted in Fig. 3, where

the motoring constant torque region, load-compensating

device adjusts tractive effort in proportion to the train weight

dependent on the number of passengers in order to keep the

same acceleration. In the motoring constant power region,

tractive effort is changed in inverse proportion to the voltage.

Therefore a train current is represented by a function

( , , , ). A regenerative brake characteristic is similar to

and used in the

a motoring characteristic; the value of

braking can be different from that used in the accelerating.

Some types of motor drive systems divided into two regions

except for constant braking power region can be modeled as

=

. When voltage of a regenerating train exceeds

voltage limit, train current is squeezed (regenerative squeezing

control, Fig. 4) for protection of onboard apparatus. In order to

get constant deceleration of a train corresponding to a selected

notch, a mechanical brake is added to a regenerative brake. If

a regenerative brake is reduced by the squeezing control, a

mechanical brake should be increased. When train weight W,

voltage V, velocity v and a notch n are given, current i,

regenerative braking current when all braking power is

, regenerative braking current before

provided with it

and current after squeezing are given with Eq.

squeezing

(3)-(8) where min( , ) is a function to choose smaller one

from a and b.

Fig.3. Speed-traction characteristic of a train

Fig.4. Squeezing of regenerative current characteristic

=

=

(2)

Motoring

=

⎧

⎪

⎨

⎪

⎩

∙

, Constant Torque Region

∙

, Constant Power Region

∙

, High Speed Region

Regenerative Braking

=

∙

=

⎧

⎪

⎨

⎪

⎩

= max

= max( ,

Coasting

=0

(4)

∙

, Constant Torque Region

∙

, Constant Power Region

∙

(5)

, High Speed Region

, min max

)

(3)

,

,0

(6)

(7)

(8)

subject to

: rated voltage of train

: rated weight of train driving/braking

: notch

: velocity at end of constant torque region

: velocity at end of constant power region

: rated tractive effort at velocity 0 [km/h]

: brake tractive effort of weight W (

< 0)

η: motor and main circuit efficiency

: start voltage of squeezing regenerative current

: end voltage of squeezing regenerative current

: maximum regenerative current at under start voltage

of squeezing of regenerative current (F < 0)

Because auxiliary current is P/V where P is auxiliary

power, P/V is added to the main circuit current i calculated

already to get total current of a train. After calculating

current i, traction F is calculated according to weight and

voltage (Eq. (9)). Braking traction is obtained by F which

is decided by a selected notch and weight W (Eq. (10)).

=

∙ ∙

=

(9)

(10)

III. FEEDING-CALCULATION METHOD

Fig. 5 shows a flow of feeding-calculation. A flow mainly

consists of three steps; pre-process, optimization process

(feeding-network calculation using an optimization function)

and post-process. In the pre-process, node numbers are

allocated to each of trains, substations and tie positions (1)

based on inputs, and a network model of the feeding circuit is

generated with nodes and edges (2) as a conductance vector

and a tie matrix. It is permitted to allocate consecutive numbers

to disconnected nodes such as a down line and up line. In the

optimization process, node voltages (converged results) are

obtained by feeding-network calculation. First, currents of

feeders, trains and substations with non-linear characteristics as

stated in the last chapter are calculated (3, 4) using initial

values of each node voltage. Essentially, the converged result

at the previous snapshot is used as initial values. Then, sum of

square of current equation’s error is calculated (5) according to

Kirchhoff’s circuit laws. Sum of square of voltage errors

between nodes in ties (positions in same voltage) is also

calculated (6). An objective function (8) is composed of a

weighted sum (7) of sums (5) and (6) (Eq. (11)). A nonlinear-

minimization program is solved by converged calculation until

a value of the objective function becomes small enough to be

judged it has converged, number of iteration is over a limit, or

decrement of the objective function is too small. Because it is

difficult to obtain converged results (voltages) analytically,

approximate solution is applied to solve the program using an

optimization function of a multipurpose solver. This is one of

the proposals to formulate the model with applying the

multipurpose solver for easy implementation. In the postprocess, currents of trains and substations are calculated using

the converged values of node voltages. The non-linear

characteristics and states of each train and substation are

considered in current calculation of trains and substations. The

characteristics and states should be expressed by voltagecurrent formulas and conditional branches.

minimize

=Σ {

+

+ ∙Σ {

}

−

−

}

(11)

subject to

: sum of squared errors of circuit equations

: point of contract

α: weight of the voltage error

: combination of tie connected nodes

, : voltages of tie nodes that should be identical

Fig.5. Flow of feeding-calculation

Parameter

V

v

F

V

I

TABLE 1. Train characteristic parameters

Value

Parameter

1500[V]

W

50[km/h]

V

156[kN]

F

1750[V]

V

-1600[A]

Η

IV. SIMULATION & RESULT

We consider the case with the very short node distance. For

example, if a train is running very near to a substation, the

conductance between them is divergent. Therefore, the

calculation is difficult to find the solution with small errors of

the circuit equations. The ‘virtual tie node’ is used as the way

to settle this problem. It is possible to make two nodes with

small distance the same voltages by using the virtual tie nodes.

Since less error is expected in the calculation, the effect of the

virtual tie nodes is evaluated by comparing the errors between

with and without it against various distances between the

nodes. If the virtual tie nodes are used, these nodes are

connected regardless of the distance between them.

The problem to minimize the sum of squared errors of circuit

equations in (11) was implemented on MATLAB by using the

nonlinear optimization solver ‘fmincon’ of the Optimization

Toolbox.

A. Relation of distance and error

We assume the feeding circuit model of a snapshot of a

commuter line as illustrated in Fig. 6 in order to consider the

relevant condition of applying the virtual tie node. There are

three substations, 24 trains on the double-track layout. The

trains are located with the same distance of 3,000 [m] to

eliminate the influence of uneven distribution as the initial

condition. The location of the substations is in the middle of

the adjacent trains, namely the distance of a train and a

substation is 1,500 [m].

Value

200[ton]

75[km/h]

-194[kN]

1800[V]

0.9

We consider the case with the very short node distance. For

example, the distance between a train and a substation is

virtually changed between 20[m] and 100[m]. We consider

two cases of node pairs: #3 and #4, and #7 and #8. In this case,

the conductance is divergent. Therefore, the calculation is

difficult to find the solution with small errors of the circuit

equations. The ‘virtual tie node’ is used as the way to settle

this problem. It is possible to make two nodes with small

distance the same voltages by using the virtual tie nodes #10

and #11. Fig.7 shows relation between the distance and sum of

squared error of the circuit equation in each case of 3-4 and 78. In the case with the virtual tie nodes, since the two nodes

are virtually connected regardless of the distance, only one

value is indicated in each graph in Fig.7. Generally, if the

error of using the virtual tie nodes is lower than that without it,

this technique contributes to reduce errors. The experimental

result so far shows that the error is increasing when the train is

approaching to a substation without setting the tie nodes. On

the other hand, it is found that setting the virtual tie nodes can

prevent error increasing by setting tie node. However,

increased tendency of the error depending on the distance is

different in the states of the feeding circuit as drawn in Fig.7.

For example, in case of node #3-4 in Fig. 6, node #3-4 should

be tied when the distance was less than 60 [m] between nodes.

But in case of node #7-8, node #7-8 should be tied when the

distance was less than 99 [m] between nodes.

If some minor exceptions with extremely large error can be

neglected, we can find the rough criterion that the virtual tie

nodes should be used if the distance between adjacent train

and substation is less than 50 [m].

Legend: Red arrow: Accelerating train, Black arrow: Coasting train, Blue arrow: Decelerating train.

Fig.6. Assumed double-track model with three substation and 24 trains.

Fig.7. Relation of distance during node, error and using tie nodes in case of node #3-4 and #7-8

B. Typical railway model

Taking the previous results into account, the idea is applied

to a realistic railway line with multiple snapshots in order to

demonstrate the idea of the virtual tie node. A typical Japanese

double-track urban railway line with 10 stations between A

and J and 3 substations was assumed as Fig.8 in order to

ascertain computational error to decrease by simulation.

Timetables for both directions composed of mixed local and

rapid trains are drawn in Figs 9 and 10. The rapid trains

connect A and J stations without stopping intermediate

stations. There are passing loops in E and G for the rapid

trains to pass the local trains. The speed profiles of local and

rapid trains are plotted in Fig. 11.

Simulation was performed for 30 minutes between 8:00 and

8:30, the morning peak time, with one-second increments

(1800 snapshots). The number of nodes of each snapshot is 17

and 21 that depend on the train positions. The computation

time for each snapshot is about 0.3 [s] in this case study.

Compared the criteria of distance, the sum of squared errors

of every circuit equations were calculated to evaluate the

computational error. The result is shown in the TABLE 2. The

number of snapshots with error value less than 100 is the

largest when the virtual tie is set where the distance between

adjacent nodes is less than 100 [m]. Therefore virtual tie node

is effective if it is set the link between a train and a substation

less than 100 [m]. On the other hand, there are still some

snapshots with large errors even if the virtual tie nodes are

properly given. The error must be reduced if the convergence

conditions of the optimization solver are adjusted. However, it

should be noted that the error and computation time has a

trade-off relationship.

12000

Distance[m]

10000

8000

6000

4000

2000

0

8:00:00

Fig.8. Arrangement of stations and substations

8:15:00

Time [h:mm:ss]

8:30:00

Horizontal line: position of three substations

Fig.9. Train timetable for downward direction from A to J

70

12000

60

Speed[km/h]

Distance[m]

10000

8000

6000

4000

50

Local

Train

Rapid

Train

40

30

20

10

2000

0

0

8:00:00

8:15:00

0

8:30:00

2500

Time [h:mm:ss]

5000

7500

Distance[m]

10000

Fig.11. Local and rapid train’s speed profile for one direction

Fig.10. Train timetable for upward direction from J to A

TABLE 2. Computing error of each criteria of distance to make virtual tie node

with virtual Tie where the distance between adjacent nodes are

without

the value shown below

number of snapshots with

virtual

error

values E

shown

on the

right

≤ 100㻌

Tie

30m

50m

75m

100m

125m

150m

300m

930

1099

1134

1134

1134

1130

1125

1084

100 <

≤ 1000㻌

200

190

152

153

158

159

155

168

1000 <

≤ 10000㻌

173

124

125

123

121

120

128

149

497

387

325

389

529

390

733

387

933

391

1093

392

1214

399

1637

283

412

532

654

748

807

1004

42

117

201

279

345

407

633

241

295

331

375

403

400

371

10000 < 㻌

using virtual Tie

(a) error values less than

without virtual Tie

(b) error values more than

without virtual Tie

(a)-(b)

Fig.12. One of the snapshots of railway circuit (Time 8:28:20)

Node

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Sum of Squared

Errors E

TABLE 3. Voltage and current solution and error value of Fig12

Virtual Tie condition

Virtual Tie condition

Without virtual Tie

50m or less

150m or less

V[kV]

Cur[kA]

V[kV]

Cur[kA]

V[kV]

Cur[kA]

1.5930

0

1.5931

0

1.5931

0

1.5934

-0.1992

1.5931

-0.2064

1.5931

-0.2074

1.5926

0

1.5927

0

1.5931

0

1.5848

0

1.5883

0

1.5885

0

1.5772

-0.6841

-0.4881

-0.4871

1.5837

1.5838

1.5772

0

0

0

1.5837

1.5837

1.5759

0

1.5804

0

1.5805

0

1.5723

-0.8302

-0.9066

-0.9064

1.5698

1.5698

1.5723

0

0

0

1.5698

1.5698

1.5725

0

1.5703

0

1.5703

0

1.5885

0

1.5924

0

1.5923

0

1.5892

0

1.593

0

1.5928

0

1.5897

0

1.5932

0

1.5931

0

1.5904

0

1.5898

0

1.5898

0

1.5915

0

1.5860

0

1.5860

0

1.5923

0

1.5837

0

1.5837

0

1.5449

1.6004

1.5501

1.6004

1.5501

1.6004

1.5609

0

1.5697

0

1.5698

0

2753.2

Fig. 12 shows a snapshot in the simulation. Since most

trains don’t consume/regenerate energy in this situation, we

choose this snapshot for easy consideration of the error.

Three cases of different virtual tie application are

considered. The solved node voltages and currents are

tabulated in TABLE 3. The significant difference of the

results is the node voltages between 2 and 3. Although the

node must have unneglectable voltage difference, the virtual

tie is applied in the last case shown in the right row of

TABLE 3. This increases the error E. Of course, no virtual

tie leads to huge error.

V. CONCLUSION

In this paper we introduce the already proposed circuit

model and newly proposed concept of the ‘virtual tie nodes’

to reduce the calculation error in some specific circuit

topology. The criterion of using the virtual tie node is

derived.

We simulated various snapshots with more realistic traffic

situation to verify the efficacy of our proposal. We

implemented the new circuit model to the multi-train

simulator with more realistic train timetable and speed

profiles. As a result of the simulation, we showed that

virtual tie node introduced by this paper is effective.

Our future work is to balance the computation error and

time. We need to compare different optimization solvers,

0.12421

0.21297

adjust convergence conditions, introduce some heuristic rule

for the initial conditions, etc.

ACKNOWLEDGMENT

This work was supported by the Adaptable and Seamless

Technology Transfer Program through Target-driven R&D

(A-STEP) of Japan Science and Technology Agency (JST),

Japan. Products names (mentioned herein) may be

trademarks of their respective companies.

REFERENCES

[1]

[2]

[3]

[4]

[5]

Thanatchai Kulworawanichpong, “Multi-train modeling and

simulation integrated with traction power supply solver using

simplified Newton–Raphson method”, Journal of Modern

Transportation, Volume 23, Issue 4, pp 241-251, 2015.

C.J. Goodman and L.K. Siu, “DC Railway Power Network Solutions

by Diakoptics”, Railroad Conference, Chicago, pp.103-110, 1994

P.Grube, F.Nunez and A.Cipriano, “An event-driven simulator for

multi-line metro systems and its application to Santiago de Chile

metropolitan rail network”, Simulation Modelling Practice and

Theory, Volume 19, Issue 1, pp.393–405, 2011.

D'Avanzo, S., Iannuzzi, D., Murolo, F., Rizzo, R. and Tricoli, P., “A

Sample Application of Supercapacitor Storage Systems for Suburban

Transit”, Electrical Systems for Aircraft, Railway and Ship

Propulsion (ESARS), 19-21 October 2010, IEEE, pp. 1-7, 2010.

Xia, H., Chen, H., Yang, Z., Lin, F. and Wang, B., “Optimal Energy

Management, Location and Size for Stationary Energy Storage

System in a Metro Line Based on Genetic Algorithm”, Energies,

Vol.8, No. 10, pp. 11618-11640, 2015.

[6]

[7]

[8]

Fazel, S.S., Firouzian, S. and Shandiz, B.B., “Energy-Efficient

Emplacement of Reversible DC Traction Power Substations in Urban

Rail Transport through Regenerative Energy Recovery”, International

Journal of Railway Research, Vol.1, No.2, pp. 11- 22, 2014.

Á. J. López-López, R. R. Pecharromán, A. Fernández-Cardador, A. P.

Cucala, “Assessment of Energy-saving Techniques in Direct-currentelectrified Mass Transit Systems”, Transportation Research Part C,

Vol.38, pp.85-100, 2014.

Z. Tian, P. Weston, S. Hillmansen, C. Roberts and N. Zhao, “System

Energy Optimisation of Metro-transit System using Monte Carlo

Algorithm”, IEEE International Conference on Intelligent Rail

Transportation, Birmingham, 2016.

[9]

Takagi, R., “Energy Saving Techniques for the Power Feeding

Network of Electric Railways”, IEEJ Transactions on Electrical and

Electronic Engineering, Vol.5, No.3, pp. 312-316, 2010.

[10] Takagi, R., “Preliminary Evaluation of the Energy-saving Effects of

the Introduction of Superconducting Cables in the Power Feeding

Network for DC Electric Railways Using the Multi-train Power

Network Simulator”, IET Electrical Systems in Transportation,Vol. 2,

No.3, pp. 103-109, 2012.

[11] M. Miyatake, T. Akiba, M. Tajima and M. Tsuda, “Methods of

Modeling and Calculation of a Feeding Circuit for Evaluating Energy

Efficiency and Operational Robustness by Train Traffic Simulation”,

STECH 2015, No. 1A11, pp.1-11, Chiba, 2015.