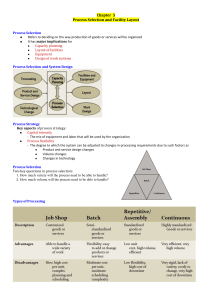

Process Selection and Facility Layout Copyright © 2015 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. You should be able to: LO 6.1 LO 6.2 LO 6.3 LO 6.4 LO 6.5 LO 6.6 LO 6.7 LO 6.8 LO 6.9 Explain the strategic importance of process selection and the influence it has on the organization and its supply chain Name the two main factors that influence process selection Compare the four basic processing types Explain the need for management of technology List some reasons for redesign of layouts Describe product layouts and their main advantages and disadvantages Describe process layouts and their main advantages and disadvantages Solve simple line-balancing problems Develop simple process layouts 6-2 Process selection Refers to deciding on the way production of goods or services will be organized It has major implications for Capacity planning Layout of facilities Equipment Design of work systems LO 6.1 6-3 Two key questions in process selection: 1. How much variety will the process need to be able to handle? 2. How much volume will the process need to be able to handle? Job Shop Batch Repetitive LO 6.2 Continuous 6-4 Repetitive/ Assembly Job Shop Batch Description Customized goods or services Semistandardized goods or services Standardized goods or services Highly standardized Goods or services Advantages Able to handle a wide variety of work Flexibility; easy to add or change products or services Low unit cost, high volume, efficient Very efficient, very high volume Disadvantages Slow, high cost per unit, complex planning and scheduling Moderate cost per unit, moderate scheduling complexity Low flexibility, high cost of downtime Very rigid, lack of variety, costly to change, very high cost of downtime LO 6.3 Continuous 6-5 Process technology and information technology can have a profound impact on: Costs Productivity Competitiveness LO 6.4 6-6 1. Inefficient operations High cost Bottlenecks 2. 3. 4. 5. 6. 7. 8. Accidents or safety hazards Changes in product or service design Introduction of new products or services Changes in output volume or product mix Changes in methods or equipment Changes in environmental or other legal requirements Morale problems LO 6.5 6-7 Product layout Layout that uses standardized processing operations to achieve smooth, rapid, high-volume flow Raw materials or customer Material and/or labor Station 1 Material and/or labor Station 2 Material and/or labor Station 3 Station 4 Finished item Material and/or labor Used for Repetitive Processing Repetitive or Continuous LO 6.6 6-8 Process layouts Layouts that can handle varied processing requirements LO 6.7 Dept. A Dept. C Dept. E Dept. B Dept. D Dept. F Used for Intermittent processing Job Shop or Batch 6-9 Fixed Position layout Layout in which the product or project remains stationary, and workers, materials, and equipment are moved as needed 6-10 Line balancing The process of assigning tasks to workstations in such a way that the workstations have approximately equal time requirements Goal: Obtain task grouping that represent approximately equal time requirements since this minimizes idle time along the line and results in a high utilization of equipment and labor Why is line balancing important? 1. It allows us to use labor and equipment more efficiently. 2. To avoid fairness issues that arise when one workstation must work harder than another. LO 6.8 6-11 Cycle time The maximum time allowed at each workstation to complete its set of tasks on a unit Cycle time also establishes the output rate of a line Operating time per day Cycle time Desired output rate Operating time per day Output rate Cycle time LO 6.8 6-12 The required number of workstations is a function of Desired output rate Our ability to combine tasks into a workstation Theoretical minimum number of stations N min t Cycle time where N min theoretica l minimum number of stations t Sum of task time s LO 6.8 6-13 The main issue in designing process layouts concerns the relative placement of the departments Measuring effectiveness A major objective in designing process layouts is to minimize transportation cost, distance, or time LO 6.9 6-14 In designing process layouts, the following information is required: 1. 2. 3. 4. 5. 6. LO 6.9 A list of departments to be arranged and their dimensions A projection of future work flows between the pairs of work centers The distance between locations and the cost per unit of distance to move loads between them The amount of money to be invested in the layout A list of any special considerations The location of key utilities, access and exit points, etc. 6-15