0

References

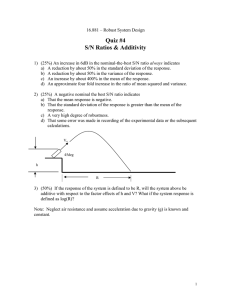

ISBN 978-86-900284-2-9

10 11 12 13 14 15 16 17 18 19 20 21

[...]

9

9 Measurement uncertainty

8

8 Tests and functions fitting

7

7 Variances

In front of you is the Companion with

concisely described subjects that are

indispensable in all measurements.

The Companion consists of about

minimal and sufficient set of concepts

and methods required to compute a

measurement result and its

measurement uncertainty. The text is

in the form that enables direct

applications in computations, manual

or spreadsheet, and in writing

software.

6

6 Outlines of the statistics

5

5 Measurement standards and

calibrations

The essence of measurement is the

same in all areas. The purpose of

this publication is to be a companion

to people dealing with

measurements, that is experiments or

observations, from production to

research, from physics and chemistry

to biology and medicine. The

publication is also intended for

students.

4

4 Measurement results, accuracy

and errors

Goran Kostić

3

3 Devices for measurement

2

2 Measurements

From a shop floor to the fundamental

sciences, statistical analysis of

results of repeated measurements is

required. The purpose of the

analysis is to determine the value of

a measured quantity, as well as the

accuracy of the determined value. It

is requested that accuracy is

described by the standard

measurement uncertainty to enable

traceability and ensure computing of

the confidence level and the

confidence interval.

1

1 Quantities and units of

measurement

From the Preface

Goran Kostić

Chapters

THE NEW SI E-BOOK ON CONCEPTS AND

COMPUTATIONS IN MEASUREMENTS

Goran Kostić

PAGES FROM:

Metrology

Companion

To buy this book, click www.symmetry.rs.

Leskovac, 2019

CONTENTS

CONTENTS 5

Abbreviations 12

Letter symbols 13

Greek alphabet 14

PREFACE 15

INTRODUCTION 19

PART I FUNDAMENTALS OF MEASUREMENTS 21

1 QUANTITIES AND UNITS OF MEASUREMENT 23

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

1.19

1.20

1.21

Measurable quantity 23

Quantities of the same kind 23

System of quantities 24

Base quantity 25

Derived quantity 26

Ordinal quantity 26

Dimension of a quantity 27

Unit of measurement 28

Base unit of measurement 29

Derived unit of measurement 29

Coherent unit of measurement 29

Value of a quantity 30

Numerical value of a quantity 31

Conventional value of a quantity 31

Reference value 31

Constant 32

Quantity equation 34

Numerical value equation 34

Unit equation 35

Conversion factor between units 35

System of units 36

1.21.1 SI base units 37

1.22 Off-system unit of measurement 41

Kostić • 2019 • Metrology Companion

5

1.23 Decimal units of measurement 41

1.24 Binary unit of measurement 42

1.25 Expressing the value of a quantity in the SI 43

2 MEASUREMENTS 51

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

Measurement 51

Metrology 51

Measurand 52

Principle of measurement 52

Method of measurement 52

Measurement procedure 53

Robustness of procedure 53

Standard operating procedure 53

Standard measurement procedure 54

Qualification and validation 55

Validation of measurement procedure 55

Accreditation and certificate 57

About design of experiment 58

Mathematical model 59

2.14.1 Examples 59

2.15 Simulation 60

3 DEVICES FOR MEASUREMENT 61

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

3.16

3.17

6

Device for measurement 61

Indicating measuring instrument 62

Material measure 62

Measuring chain 63

Measuring system 63

Nominal value 64

Indication of a device for measurement 64

Indication interval 65

Measuring interval 65

Response function 65

Measuring transducer 66

Sensor 66

Detector 66

Measurement signal 66

Resolution 67

Sensitivity 67

Response time 67

Kostić • 2019 • Metrology Companion

3.18

3.19

3.20

3.21

3.22

3.23

3.24

3.25

3.26

3.27

3.28

3.29

3.30

3.31

3.32

3.33

3.34

3.35

3.36

3.37

Limit of detection 68

Limit of quantification 68

Dynamic interval 68

Dead interval 69

Hysteresis 69

Influence quantity 69

Blank indication 69

Stability 70

Selectivity 70

Transparency 70

Operating conditions 71

Reference operating conditions 71

Limiting conditions 71

Gauging of a device for measurement 72

Error of indication of a device for measurement 72

Datum error of a device for measurement 72

Zero error of a device for measurement 72

Bias of a device for measurement 73

Intrinsic error of a device for measurement 73

Accuracy class 73

3.37.1 Examples 73

3.38 Type approval of a device for measurement 74

3.39 Verification of a device for measurement 74

4 MEASUREMENT RESULTS, ACCURACY AND ERRORS 75

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

4.16

Measurement result 75

Accuracy 75

Absolute error 76

Relative error 77

Random error 78

Systematic error 78

Combined error 79

4.7.1 Example 79

Limits of error 80

Outlier 80

Correction 81

Precision of measurement results 82

Repeatability of measurement results 82

Reproducibility of measurement results 82

Rounding of number 83

Truncation of digits 84

Significant digits 84

Kostić • 2019 • Metrology Companion

7

5 MEASUREMENT STANDARDS AND CALIBRATIONS 85

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

Measurement standard 85

Reference material 86

Primary measurement standard 88

Secondary measurement standard 88

International measurement standard 88

National measurement standard 89

Transfer measurement standard 89

Reference measurement standard 89

Working measurement standard 89

Relativistic effects on the values of standards 90

Calibration 91

Calibration report 92

PART II STATISTICAL ANALYSIS OF MEASUREMENT RESULTS 93

6 OUTLINES OF THE STATISTICS 95

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

6.15

6.16

6.17

6.18

6.19

6.20

6.21

6.22

6.23

8

About statistical analysis 95

Statistical analysis of results of repeated measurements 97

Probability 98

Random variable 99

Dependent variable and independent variable 100

Correlated variables 100

Sample 101

Maximum likelihood value 102

Best estimate 102

Biased evaluation 103

Distribution of a variable 104

Normal distribution 106

Means 108

Mode 110

Median 111

Arithmetic mean 112

Experimental arithmetic mean 114

Indicators of dispersion of values 115

Natural Deviation 116

Experimental standard deviation 118

Deviation of the arithmetic mean 121

Deviation of the standard deviation 122

Standard deviation from a median, range and sample size 124

Kostić • 2019 • Metrology Companion

6.24 Degrees of freedom 125

6.24.1 Examples 126

6.25 Effective degrees of freedom 127

6.25.1 Example 127

6.26 Degrees of freedom from the deviation of the standard

deviation of the arithmetic mean 128

6.26.1 Example 128

6.27 Confidence level and confidence interval 129

6.27.1 Example 131

6.28 Standard deviation and its degrees of freedom from the level

and interval of confidence and sample size 131

6.29 T- distribution 133

6.30 Uniform distribution 136

6.31 Triangular distribution 138

6.32 U-distribution 140

6.33 Lognormal distribution 142

6.34 Chi-square distribution 144

6.35 F-distribution 145

6.36 Indicator of asymmetry of a distribution 146

6.37 Indicator of peakedness of a distribution 147

6.38 Histogram 148

6.38.1 Example 150

6.38.2 Example 151

6.39 Convolution 152

6.40 Filtering 154

6.41 Operations on distributions and central limit theorem 155

6.42 Monte Carlo simulation 158

6.42.1 Example of estimate of a value and its statistical

parameters 162

6.42.2 Example of estimate of a length of gauge block and

its statistical parameters 166

The contents continues on the next page.

Kostić • 2019 • Metrology Companion

9

7 VARIANCES 171

7.1

7.2

7.3

7.4

7.5

7.6

Natural variance 171

Experimental standard variance 173

Evaluations of grouped results 175

Experimental standard covariance 176

7.4.1 Example of compution of the standard covariance 179

7.4.2 Example of compution of the standard covariance of

the means 180

Standard correlation coefficient 181

Combined variance 183

7.6.1 Example of the combined variance of an evaluation of

resistance of electrical circuit element and the

maximum possible variance of this variance 191

7.6.2 Example of the combined variance of an evaluation of

length of a gauge block and the maximum possible

variance of this variance 193

7.6.3 Example of the combined variance of pH value 198

7.6.4 Example of the combined variance of resistance of

resistors in a series 199

8 TESTS AND FUNCTIONS FITTING 203

8.1

Detection of outliers 203

8.1.1 Example 205

8.2 Fitting 206

8.3 Method of the least sum of squares 206

8.3.1 Example 209

8.4 P-value 212

8.5 Goodness-of-fit test 213

8.6 Estimating the type and parameters of a distribution 215

8.7 Pearson chi-square test for the goodness of fit of

distributions 217

8.7.1 Example 221

8.8 Shapiro-Wilk test for normality of a population 223

8.8.1 Example 225

8.9 White noise test 230

8.10 Analysis of variance (ANOVA) 231

8.10.1 Example 233

8.11 Transformation of a variable 236

8.11.1 Example 237

10

Kostić • 2019 • Metrology Companion

9 MEASUREMENT UNCERTAINTY 239

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

Measurement result and its uncertainty 239

Type A standard measurement uncertainty 241

Type B standard measurement uncertainty 242

9.3.1 Example 243

9.3.2 Example 245

Combined standard measurement uncertainty 247

Expanded standard measurement uncertainty 248

Relative standard measurement uncertainties 249

Evaluations from non-normally distributed results 249

Expressing the standard measurement uncertainty 251

Expressing the standard measurement uncertainty when

corrections are not applied 252

General guidance on reporting a measurement result 253

Procedure for estimating the measurement result and

associated data 254

Example of calibration of a thermometer 256

9.12.1 The measurement problem 256

9.12.2 Least squares fitting 256

9.12.3 Standard uncertainty of the predicted correction

addend 259

9.12.4 Elimination of the correlation between the slope and

the intercept point 260

Resistance, reactance and impedance, computed from the

same component measurement results 261

9.13.1 The measurement problem 262

9.13.2 Mathematical model of the measurement 262

9.13.3 Final results and their standard uncertainties,

standard covariances and standard correlation

coefficients - approach a 263

9.13.4 Final results and their standard uncertainties,

standard covariances and standard correlation

coefficients - approach b 263

Metrological traceability 268

9.14.1 Example 269

REFERENCES 271

Kostić • 2019 • Metrology Companion

11

Preface

From a shop floor to the fundamental sciences, statistical analysis of

results of repeated measurements is required. The purpose of the

analysis is to determine the value of a measured quantity, as well as the

accuracy of the determined value. It is requested that accuracy is

described by the standard measurement uncertainty to enable traceability

and ensure computing of the confidence level and the confidence interval.

The essence of measurement is the same in all areas. The purpose of

this publication is to be a companion to people dealing with

measurements, that is experiments or observations, from production to

research, from physics and chemistry to biology and medicine. The

publication is also intended for students.

In front of you is the Companion with concisely described subjects that

are indispensable in all measurements. The Companion consists of about

minimal and sufficient set of concepts and methods required to compute

a measurement result and its measurement uncertainty. The text is in the

form that enables direct applications in computations, manual or

spreadsheet, and in writing software.

The manner of presentation is encyclopedic. However, the order of

presentation allows reading the text as a book or textbook. It seems that

the form of encyclopedias is suitable for expert writings because it

facilitates understanding of relations among concepts that make the

essence of every exact knowledge.

Most of this text is a terminologically consistent and compliant

synthesis of international recommendations and regulations, articles and

encyclopedic texts. References are given in brackets.

Special attention was paid to the definitions of terms and their

consistent use. Most of the terms are according to the second and third

editions of the International vocabulary of metrology (see [VIM 2] and

[VIM 3]) which was issued by the Joint Committee for Guides in Metrology

(JCGM). These glossaries were not applied when it was thought that they

do not correspond to what they should express, or that there are far better

terms. Any such exceptions from the glossaries are noted with the

references.

Kostić • 2019 • Metrology Companion

15

The second part of the Companion, regarding statistical analysis of

measurement results, is the basis for computation of the standard

measurement uncertainty. It is intended for anyone involved in the

analysis of the measurement results.

The chapter on the standard measurement uncertainty is according to

the instructions published by the JCGM in the Guide to the expression of

uncertainty in measurement (see [GUM]).

The level and interval of confidence of the measurement result can be

considered as a purpose of determination of all measurement errors. An

accurate evaluation of the level and interval of confidence is enabled by

the standard measurement uncertainty of a traceable value. In this

Companion, the traceability is described in the short, but comprehensive

text given at the end of the section concerning measurement uncertainty.

At the end of the Preface, attention is drawn to the following viewpoint

expressed in [GUM]. “The evaluation of uncertainty is neither a routine

task nor a purely mathematical one; it depends on detailed knowledge of

the nature of the measurand and of the measurement. The quality and

utility of the uncertainty quoted for the measurement result therefore

ultimately depend on the understanding, critical analysis, and integrity of

those who contribute to the assignment of its value.”

All equations in the Companion are for the coherent units.

The following marking is used in the Companion.

● Bold fonts are used for terms when defined.

● The abbreviated terms that may be used are provided next to the

terms, in parentheses, when this will not lead to confusion.

● Underlined text is linked to detailed explanations of a concept which

underlined text indicates. A “see...” is also linked to a reference.

● Equations, tables and figures are marked with the number of the

chapter, then by a point, and subsequently by their order number in the

chapter.

● A blue text needs special attention.

For the help in the creation of the Companion, I wish to thank to

engineer Siniša Hristov, professor Dr Gligorije Perović, Dr Walter Bich,

professor Dr Dragić Banković, professor Dr Vesna Jevremović and

Dr Emina Krčmar. To my longtime colleague, engineer Zlatko Sudar, I am

grateful for comments which have led to an improved text.

16

Kostić • 2019 • Metrology Companion

I am grateful to professor Ljiljana Sudar and professor Dr Živomir

Petronijević for their efforts and valuable remarks of the trial readers.

Thanks to Ljiljana D. Kostić for her trust and material support.

This Companion was created as a part of the development project of

measurement and control equipment, which is in progress in the

laboratory for development of electronic products, Symmetry, based in

Leskovac, Serbia.

This is an updated e-edition that comes after the fundamental revision

of the International System of Units (SI) as well as one English and two

Serbian editions.

Please send comments to the symmetry@ptt.rs.

Leskovac, 15th August 2019

Goran Kostić

Kostić • 2019 • Metrology Companion

17

Introduction

The measurements are essential for human activity - from the trade to

the fundamental sciences.

International trade has been one of the important reasons for the

establishment of the International Bureau of Weights and Measures

(BIPM). The Bureau contributes to the reduction of technical barriers to

trade, ensuring that measurements and tests carried out in different

countries are considered equivalent.

Scientists create their theories on a basis of measurement results

which are for them facts about the material world, true within limits of

measurement errors.

The International System of Units was conceived after ancient

discussions of European scientists about the need for a new system of

measurement. The first proposal of a unified system of units, based on

the metre (metric) and decimal, was made as early as 1670 by Gabriel

Mouton, a priest from Lyon, France. That system replaced national and

regional variants that made scientific and commercial communication

difficult. The first decimal metric system was established in France in

1799 as an important fruit of the French Revolution. The world became

metric in early 1993 when the International System of Units (SI) became

primary in the USA government institutions.

The current SI has emerged as perhaps the most significant revision

of the SI. This revision was voted at the 26th General Conference on

Weights and Measures (CGPM) in November 2018. The current

definitions of SI base units are fundamentally different from those

previously used. Now, the seven SI base units are defined using only

seven “defining constants” whose values are taken as exact. The

definitions are published in the 9th edition of the SI Brochure and are

applied from 20th May 2019.

The International Bureau of Weights and Measures was created by

the Metre Convention signed in Paris on 20th May 1875. The Convention

was amended in 1921 and has remained the basis of the international

agreement on measuring units until now. The original signatories of the

Convention were representatives of 17 States, and on 15th August 2019,

there were 60 Member States of the Convention and 42 Associates of the

Kostić • 2019 • Metrology Companion

19

CGPM. Since its establishment, the headquarters of Bureau is in Sevres

near Paris.

The purpose of Bureau is to ensure worldwide unification of

measurements in order to enable traceability of measurement results to

the International System of Units. Therefore the task of Bureau is to:

● “represent the worldwide measurement community, aiming to

maximize its uptake and impact

● be a centre for scientific and technical collaboration between the

Member States, providing capabilities for international measurement

comparisons

● be the coordinator of the worldwide measurement system, ensuring

it gives comparable and internationally accepted measurement results.”

The Bureau operates under the exclusive supervision of the

International Committee for Weights and Measures (CIPM) which itself

comes under the authority of the General Conference on Weights and

Measures. The International Committee and the General Conference was

established by the Metre Convention, at the same time as the Bureau.

By harmonizing and providing complete coverage of all areas, the

International System of Units is an outstanding tool of the modern

sciences and practices that created it.

[SI] Appendix 4. Part 2, 1.1, PP 117 [Britannica] [NIST]

20

Kostić • 2019 • Metrology Companion

1 Quantities and units of measurement

1.1 Measurable quantity

Measurable quantity (quantity) is a property of a body, a

substance, or a phenomenon, that may be distinguished qualitatively

and determined quantitatively.

Quantity is not a body, a substance or a phenomenon.

Quantity is independent of measurement and system of quantities.

The term quantity may refer to a quantity in a general sense (length,

time, mass, temperature...) or to a value of a particular quantity (the

length of a given rod, the electric resistance of a given wire, a number of

entities...).

[VIM 2] 1.1 [VIM 3] 1.1 [Sonin] 2.3

1.2 Quantities of the same kind

Quantities of the same kind are quantities whose values may be

added or subtracted, but that it has a physical representation.

Examples. The addition of values of all forms of energies, such as the

amount of heat, kinetic energy and potential energy, has a physical

representation. Thus, all forms of energies, are quantities of the same

kind. A value of energy and a value of moment of force have the same

dimension but there is no physical representation of addition or

subtraction of their values, so those quantities are not of the same kind.

In a given system of quantities:

- quantities of the same kind have the same dimension

- quantities of the same dimension are not necessarily of the same kind

- quantities of the different dimension are always of a different kind.

Quantities of the same kind are grouped into categories of

quantities. Examples of the categories of quantities are:

- thickness, circumference, wavelength

- heat, work, energy.

[Quinn] [VIM 2] 1.1 Notes [VIM 3] 1.2, 1.7

Kostić • 2019 • Metrology Companion

23

1.4 Base quantity

Base quantity, together with other base quantities of a system of

quantities, enables obtaining derived quantities.

The selected base quantity always has a physical representation so

that it may be realized using its definition.

A base quantity is a property for which the following mathematical

operations are defined in physical terms: comparison, addition,

subtraction, multiplication by a quantity of dimension one and division by

a quantity of dimension one. Each of these operations is performed on

physical properties of the same kind and yields a physical property of that

kind. Each of these physical operation obeys the same rules as the

corresponding mathematical operation for pure numbers, that is,

quantities of dimension one. This makes possible to describe the physical

properties by the language of mathematics.

The choice of a set of base quantities is somewhat arbitrary. However,

for the selected base quantities it must be possible to define the

operations previously specified. It is preferred that the base quantities of a

set are mutually independent. The set may be minimal, or somewhat

larger, than one out of which it is possible to obtain all necessary derived

quantities.

Example. The base quantities may be: the length, mass, area, speed

and force. A shape and color cannot be base quantities because they

lack acceptable addition.

Things from nature can be described only by comparison with the

several well-known things among which are the base quantities.

[Sonin] 2.2, 2.1, 2.8 [SI] 2

Kostić • 2019 • Metrology Companion

25

1.21 System of units

System of units is formed by the base units, the derived units and

equations that define relations between these units.

International System of Units, SI, is based on the International

System of Quantities. The General Conference on Weights and Measures

recommends the SI.

SI coherent units are formed only by seven SI base units (base

units of the SI) and twenty-two SI coherent derived units.

The complete set of SI units (SI units, or units of the SI) is formed

by SI coherent units and SI decimal units.

The complete set of SI units is not coherent.

The complete set of SI units is divided into the class of SI base units

and the class of SI derived units.

The definitions of seven SI base units are provided in Table 1.1 and

described in the following section 1.21.1.

Out of seven SI base units, in almost all areas are used: metre,

kilogram and second. The other four units are used to define derived

units that are specific to particular areas:

● ampere, for electrical and magnetic units

● kelvin, for heat units

● mole, for units of chemistry and molecular physics

● candela, for light units.

The SI coherent derived units with special names and symbols are

listed in Table 1.2. These special names and symbols may be used in

combination with the names and symbols for base units and for other

derived units to express the units of other derived quantities.

The “SI Brochure” [SI] recommends using the complete set of SI units

and only in particular circumstances (to satisfy the needs of commercial,

legal, or specialized scientific interests) non-SI units listed in Table 1.3.

When the non-SI unit is used, it is recommended to define the non-SI

unit in terms of the SI units.

By harmonizing and providing complete coverage of all areas, the SI is

an outstanding tool of the modern sciences and practices that created it.

[Sonin] 2.7 [SI] 2, 3, 4, in which “decimal multiples and sub-multiples of SI units” is

used instead of “SI decimal units”

36

Kostić • 2019 • Metrology Companion

1.21.1 SI base units

Seven SI base units are defined using only the seven defining

constants. The values of defining constants were fixed after being

identified as the best estimates at the time just before the decision on the

revision of the SI. In this way the SI is scaled to the seven physical

constants of high reproducibility, and these constants become exact. See

Figure 1.1 and Table 1.1. The reference definitions of base units are

published in the SI Brochure, see [SI].

The current definitions of SI base units have brought important benefits.

The most important are: 1) a large number of physical constants become

either exactly known or known with higher accuracy; 2) values of quantities

that are much smaller or much larger than the base units can be measured

with unreduced accuracy; 3) liberation of mass metrology from the unit

based on the mass standard which is undoubtedly changing with time; 4)

the Josephson effect and Hall effect can be used to directly realize the SI

definitions of most electrical units; 5) the definition of the kelvin does not

make reference to a water having the defined isotopic composition.

Some of the consequences of the current definitions are that the following

constants are not exactly known, and must be measured: 1) the magnetic

constant, the electric constant and the characteristic impedance of a vacuum;

2) the temperature of triple point of water; 3) the molar mass of carbon 12.

The current definitions of SI base units are fundamentally different from

those previously used. However, as it was the case in the past revisions

of the SI, the transition to the current definitions was realized without

noticable impact on daily life, while the measurements based on previous

definitions of the units remain valid within their measurement uncertainties.

Figure 1.1. The SI

base units are defined

using the set of only

seven defining

constants whose values

are taken as exact.

Each base unit is

defined, either, through

the corresponding

constant from the set, or

through the constant

from the set and other

base units that are also

defined through the

constants from that set.

Kostić • 2019 • Metrology Companion

37

1.25 Expressing the value of a quantity in the SI

A numerical value of a quantity and unit symbol are printed in upright

typeface. The numerical value always precedes the unit symbol, and a

space is always used to separate the number from the unit symbol. The

only exceptions, in which no space is left between the number and the unit

symbol, are the unit symbols for plane angle: degree, °, minute, ’, and second, ”.

A prefix symbol precedes the unit symbol without a space, and it is

considered as a new inseparable unit symbol, as well as mathematical entity.

A numerical value of a quantity with a unit symbol is regarded as the

product, and they are treated using the ordinary rules of algebra.

One must neither use the plural of a unit symbol, nor the period after a

symbol except at the end of a sentence.

A prefix symbol, formed by placing together two or more prefix

symbols, are not permitted. This also applies to prefix names.

A prefix symbol and a prefix name will not be used with the following

symbol and name of the units of time: min, minute; h, hour; d, day.

No space or hyphen is used between the prefix name and the unit

name. The combination of prefix name plus unit name is a single word.

In an expression, only one unit is used. An exception is in expressing

the values of time, and of plane angles, using non-SI units. However, for

plane angles it is generally preferable to divide the degree decimally, except

in fields such as navigation, cartography, astronomy, and in expressing

very small angles. Example, one would write 22.20° rather than 22° 12’.

Unit symbol is never qualified by further information about the property

of the quantity. Extra information on the property of the quantity should be

attached to the quantity symbol, and not to the unit symbol. Example,

U max = 50 V, but not U = 50 Vmax.

In forming products and quotients of unit symbols the normal rules of

algebraic multiplication or division apply. Multiplication must be indicated

by a space or a half-high dot (⋅). Division is indicated by a horizontal line

(――), by a solidus (/), or by negative exponents. When several unit symbols

are combined, care should be taken to avoid ambiguities, for example by

using brackets or negative exponents. To remove ambiguities, a solidus

without brackets, must not be used more than once in a given expression.

Among the base units of the SI, the kilogram is the only whose name

and symbol, for historical reasons, includes a prefix (“k”). Symbol and

name for the decimal unit of mass are formed by attaching prefix symbol

to the unit symbol “g”, and prefix name to the unit name “gram”. Example,

−6

10 kg is written as 1 mg, not as 1 µkg.

[SI] 3, 5

Kostić • 2019 • Metrology Companion

43

Table 1.2 SI coherent derived units with special names and symbols

[SI] 2.3.4

Expressed

in terms

of other

SI units

SI derived quantity

Special

name of

SI unit

Special

symbol

for SI

unit

plane angle

radian

rad

m · m −1 = 1

solid angle

steradian

sr

m2 · m − 2 = 1

frequency

hertz

Hz

s−1

force

newton

N

kg · m · s − 2

pressure, stress

pascal

Pa

N / m2

kg · m−1 · s−2

energy, work, amount of heat

joule

J

N·m=

W·s

kg · m2 · s − 2

power, radiant flux

watt

W

J/s

kg · m2 · s − 3

coulomb

C

F·V

A·s

volt

V

W/A

kg · m2 · s−3 · A−1

ohm

Ω

V/A

kg · m2 · s−3 · A−2

electric conductance

siemens

S

A/ V

kg · m · s · A

electric capacitance

farad

F

C/V

kg · m · s · A

electric charge, amount of

electricity

(electric) potential difference,

electromotive force, voltage,

(electric) tension

electric resistance

electric inductance

henry

Expressed in

terms of SI

base units

−1

−2

−1

3

−2

2

2

4

−2

2

−2

H

Wb / A

kg · m · s · A

kg · m2 · s−2 · A−1

magnetic flux

weber

Wb

V·s=

T · m2

magnetic flux density,

magnetic induction

tesla

T

Wb / m2 =

N / (A · m)

kg · s − 2 · A−1

Celsius temperature

degree

Celsius

°C 4)

K 4)

K 4)

luminous flux

lumen

lm

cd · sr

m · m · cd = cd

illuminance

lux

lx

lm / m2

m − 2 · cd

activity referred to a radionuclide

(ionizing radiation) absorbed

dose, specific (imparted)

energy, kerma

(radiation) dose equivalent

becquerel

Bq

gray

Gy

J / kg

m2 · s − 2

sievert

Sv

J / kg

m2 · s − 2

catalytic activity

katal

kat

2

−2

s −1

mol · s −1

4)

The units °C and K are equal only when expressing temperature difference or

width of temperature interval. The numerical value of a Celsius temperature expressed

in degrees Celsius is related to the numerical value of the thermodynamic temperature

expressed in kelvins by the relation: t [°C] = T [ K] − 273.15. [SI] 2.3.1 The kelvin

44

Kostić • 2019 • Metrology Companion

2 Measurements

2.1 Measurement

Measurement is a determination of a value of a quantity by its

comparison with the known value of the quantity.

The value of a quantity may be measured with very high accuracy

except perfect.

The following are necessary for measurement: a specification of

measurand, a description of measurement procedure and a device for

measurement.

Measurement does not apply to nominal properties. Examples: sex of

a human being; ISO two-letter country code; the sequence of amino acids

in a polypeptide...

[Sonin] 2.3 [GUM] 3.1.1 [VIM 2] 2.1 [VIM 3] 2.1, 1.30 Examples

2.2 Metrology

Metrology is the science of measurements.

Metrology includes all theoretical and practical aspects of

measurements, whatever the measurement accuracy and field of

application.

Legal metrology is the part of metrology relating to measurements

specified in the law.

The scope of legal metrology commonly includes:

● protection of the interests of individuals and enterprises

● protection of national interests

● protection of public health and safety, especially those related to the

environment and medical services

● meeting the requirements for commerce and trade.

[VIM 2] 2.2 [VIM 3] 2.2 [VIML] 1.03

Kostić • 2019 • Metrology Companion

51

2.3 Measurand

Measurand is a particular quantity subject to measurement.

The requested accuracy determine how many details should be given

in a specification of a measurand. For example, if the length of a

nominally one-metre long steel bar is to be determined to micrometre

accuracy with relative error of about 5 · 10 − 6, its specification should

include the temperature and pressure of the environment in which is the

bar.

[VIM 2] 2.6 [VIM 3] 2.3 [GUM] 3.1.3

2.4 Principle of measurement

Principle of measurement (or measurement principle) is a

phenomenon serving as the basis of a measurement.

Example: the thermoelectric effect applied to a measurement of

temperature.

[VIM 2] 2.3 [VIM 3] 2.4

2.5 Method of measurement

Method of measurement (or measurement method) is a concept of

applying the principle of measurement.

Primary method of measurement (or primary measurement

method, primary method) is a method having the highest metrological

qualities, whose procedure is completely explained and described, and

for which the combined standard uncertainty traceable to the SI units is

determined.

Primary ratio method is a method used to determine a quotient of

value of measurand and value of measurement standard (where both

values are of the same kind).

Primary direct method (primary method) is a method in which a

value of measurand and values of used measurement standards, are of

different kind.

[BIPM] [NIST]

52

Kostić • 2019 • Metrology Companion

3 Devices for measurement

3.1 Device for measurement

Device for measurement is a device, or combination of devices,

designed for measurement.

The device for measurement may be a measuring instrument or a

measuring transducer. A measuring instrument is an indicating

measuring instrument or a material measure. A material measure is: a

reference material, weight, volume measure, gauge block, standard

electric resistor, standard signal generator...

Devices for measurement arranged in approximate order of increasing

complexity are: a part, material measure, reference material, measuring

transducer, measuring instrument, measuring chain, measuring system,

measuring installation.

Device for measurement is periodically checked, or qualified, by a

user or a recognized laboratory. The checks determine whether an error

of a device for measurement, in operating conditions, is within a specified

interval and whether it will be within this interval in future.

[VIM 2] 4 introduction, 4.1, 4.3, 4.6, 4.2 [VIM 3] 3, 3.1, 3.7, 3.3, 3.6

Figure 3.1. A measuring transducer and a measuring installation. Left:

an ion-selective probe for concentration of sodium measurement

(Thermo Scientific). Right: a highly automated measuring installation, 18 m

long, for biochemical analysis in a hospital laboratory (Roche Diagnostics).

Kostić • 2019 • Metrology Companion

61

3.2 Indicating measuring instrument

Indicating measuring instrument is a measuring instrument

providing an output signal that contains information about the value of a

measurand.

Examples: a thermometer, micrometer, electronic balance, barograph.

Displaying measuring instrument (or meter) providing an output

signal in visual form.

Recording measuring instrument provides a record of its indication

as an output signal.

[VIM 2] 4.6 [VIM 3] 3.3

3.3 Material measure

Material measure (measure) is a device for measurement intended

to supply, or reproduce, one or more known values of a quantity.

Examples: a weight, volume measure, gauge block, standard electric

resistor, standard signal generator, reference material.

An indication of a material measure is its assigned value.

An error of a material measure is the error of the indication of the

material measure.

End gauge is a material measure which supplies one known value.

Example. A length end gauge has the form of: parallelepipeds

(gauge block), pins, blades, plugs, rings, snaps.

Go - no go gauge consists of two end gauges which determine

whether a value of a measurand is within an interval given by the end

gauges.

[VIM 2] 4.2, 3.2 Note 3, 5.20 Note 3 [VIM 3] 3.6, 4.1

62

Kostić • 2019 • Metrology Companion

4 Measurement results, accuracy and

errors

4.1 Measurement result

Measurement result (or result of measurement, or estimated

value) is a value assigned to a measurand on the basis of one or more

results of measurements.

A measurement result is obtained in the manner specified in the

description of the measurement procedure: ● taking a result of a single

measurement (or particular result), ● computing the arithmetic mean of

the results of repeated measurements, ● taking the value that appears

most often in the results of repeated measurements (that is, taking the

mode), ● computing on the basis of a functional relationship between the

value of a measurand and component values (or component results,

or component variables, or component quantities, or input

quantities, or components) on which the value of the measurand

depends...

Results of repeated measurements of the same quantity are represented

by the random variable which is characterized by statistical parameters.

A complete measurement result includes information about its accuracy.

[VIM 2] 3.1 [GUM] [VIM 3] 2.9

4.2 Accuracy

Accuracy of a value is a qualitative concept which indicates a

closeness of this value to a reference value.

Accuracy of a measurement result (accuracy) is a qualitative

concept which indicates a closeness of this measurement result to a

value of the measurand.

Accuracy of a measurement result is determined in the manner

specified in the description of the measurement procedure.

Kostić • 2019 • Metrology Companion

75

Accuracy of a measurement result depends on errors which are

classified into the two groups. The first group is random errors, whose

influence on the final measurement result can be reduced by increasing

the number of repeated measurements and then computing the arithmetic

mean of the measurement results. The second group is systematic errors,

whose influence on the final measurement result can be reduced by

applying certain correction.

A complete measurement result includes information about its

accuracy. However, if inaccuracy is considered to be negligible for the

intended purpose, the information about accuracy may be omitted. In

many fields, the ordinary way of expressing a measurement result does

not include the information about accuracy.

In order to enable the use of one measurement result and its accuracy

as component values of another measurement result and its accuracy,

the information specified in 9.10 General guidance on reporting a

measurement result should be provided.

Results of repeated measurements of the same quantity are

represented by the random variable which is characterized by statistical

parameters. The description of the accuracy of the result of repeated

measurements is its standard measurement uncertainty.

The term precision should not be confused with accuracy.

[VIM 2] 3.5 [VIM 3] 2.13, 2.15, 2.9 Note 2 [GUM] 3.2

4.3 Absolute error

Absolute error (error, or difference, or divergence) of a value is

given by formula:

ABSOLUTE_ERROR = VALUE – REFERENCE_VALUE.

(4.1)

VALUE = REFERENCE_VALUE + ABSOLUTE_ERROR

(4.2)

REFERENCE_VALUE = VALUE – ABSOLUTE_ERROR

(4.3)

ABSOLUTE_ERROR =

= SYSTEMATIC_ERROR + RANDOM_ERROR

(4.4)

In practice, the conventional value is used as the reference value.

The value and its absolute error have the same dimension.

76

Kostić • 2019 • Metrology Companion

5 Measurement standards and calibrations

5.1 Measurement standard

Measurement standard (standard, or etalon) is a device for

measurement intended to realize, reproduce or define the value of a

quantity to serve as a reference in measurements.

Examples: a Kibble balance (or a watt balance); 1 kg mass standard;

100 Ω standard resistor; standard ammeter; caesium frequency standard;

hydrogen reference electrode; reference solutions of cortisol, in human

serum, with specified concentration.

Figure 5.1. Left: a Kibble balance in the International Bureau of

Weights and Measures. Among other things, the balance is used for

measuring a 1 kg mass standard with the combined standard

measurement uncertainty of 2 · 10 − 8. The measurements are performed

through the Planck constant, gravitational acceleration, velocity, plus

electromagnetic quantities, and represent the realization of the definition

of the kilogram. Right: a Josephson voltage standard used for driving a

stable current through the coil of the above-mentioned Kibble balance

using a standard resistor. (Courtesy of the BIPM.) [BIPM]

Kostić • 2019 • Metrology Companion

85

Intrinsic measurement standard (intrinsic standard) is based on an

inherent and reproducible phenomenon in nature. Examples: the speed of

light in vacuum; the elementary charge; a triple-point-of-water cell as a

standard of temperature; a Josephson array as a voltage standard; a

quantum Hall effect as a standard electric resistor.

Collective standard (or ensemble of standards) is a set of

standards that, through their combined use, constitute a standard.

Group standard is a set of standards that, individually, or in

combination, provide a sequence of values of quantities of the same kind.

Table 5.1 presents the most accurate standards, or measurements, of

the base quantities and their approximate combined standard

measurement uncertainties.

[VIM 2] 6.1 [VIM 3] 5.1 in which the associated measurement uncertainty of a

measurement standard is required, 5.10

5.2 Reference material

Reference material, RM, is material with homogeneous, stable and

accurately defined properties used as a reference in measurements.

Reference material may be a pure or mixed: gas, liquid or solid.

Examples: a solution used in calibration of measuring instruments for

chemical analyses; a color chart; a fish tissue containing a specified mass

concentration of dioxin.

Certified reference material, CRM, is the reference material

accompanied by a certificate specifying the values of the material

properties and traceable standard measurement uncertainty of these

values.

Example. Human serum accompanied by a certificate specifying the

value of the concentration of cholesterol and the associated traceable

standard uncertainty.

[NIST] [VIM 2] 6.13, 6.14 [VIM 3] 5.13, 5.14

86

Kostić • 2019 • Metrology Companion

Table 5.1 The most accurate standards, or measurements, of the

base quantities, state in 2019 [BIPM] [Newell 2014] [NIST]

[SI realization]

Quantity

Conditions

Absolute

standard

uncertainty

Relative

standard

uncertainty

time

The best of primary standards which

realizes the SI second in the BIPM.

1 · 10−16 s

1 · 10 − 16

The length of the cubic unit cell edge

of pure 28Si (5.431 · 10 −10 m)

measured using interferometry.

3 · 10 −18 m

5 · 10 − 9

A steel gauge block of the length of

100 mm measured using optical

interferometry.

10 nm

1 · 10 − 7

The Earth-Moon separation

(376 203 km) measured by a laser

and a retroreflector on the Moon.

1 mm

3 · 10 −12

A mass of single atom (an order of

magnitude of 10 − 25 kg) through

frequency measurements of photons

during absorption or emission of that

atom.

ca 10−33 kg

2 · 10 − 9

A 1 kg weight measured on a Kibble

balance.

20 µg

2 · 10 − 8

electric

current

Generating a current up to 10 mA

using a Josephson voltage standard

and a Hall standard resistor.

< 6 · 10

thermodynamic

temperature

−155 °C to 30 °C measured using the

relative primary acoustic gas

thermometry in the NPL.

< 1 mK

amount of

substance

The number of atoms in a single

crystal of 1 kg of the pure 28Si

(2.153 · 10 25 atoms) using volumetric

and interferometric measurements.

4 · 10

atoms

2 · 10 − 8

luminous

intensity

The light source, from 10 − 3 cd to

10 4 cd, directly measured with a

standard photometer.

2 · 10 − 6 cd

to 20 cd

2 · 10 − 3

length

mass

Kostić • 2019 • Metrology Companion

−12

A

17

6 · 10 −10

for kelvin

scale

< 7 · 10 − 3

87

6 Outlines of the statistics

6.1 About statistical analysis

Statistical methods are used to determine the representative value of

an investigated property for a group of elements. The elements within the

group can have significantly different values of the property.

Evaluation (or estimation, or “statistic”) is a value estimated by the

statistical method.

Population is a group of all elements for which we determine the

representative value of a property by the statistical method. The

population has a finite or infinite number of elements.

Figure 6.1. The example of four samples of values which yield: the

equal arithmetic means of variables x and y, the equal deviations of x, the

same linear regression function obtained by the method of least

squares... [Anscombe]

Kostić • 2019 • Metrology Companion

95

The investigated property of a population is determined by the

statistical method usually on a basis of a sample of the population that

truly represents the population. The sample truly represents the

population when a number of its elements is sufficiently large and when

the elements are randomly selected from the population.

In order to prove that the conclusions drawn from the sample are with

a certain probability valid for the population can be proved by

goodness-of-fit tests.

In order to reduce the possibility of errors in statistical analysis, data

graph should be necessarily considered. The graph provides an overview

of qualitative features of data. The diagrams in Figure 6.1 demonstrate

the importance of graphical presentation and visual analysis of data.

A property of a population determined by a statistical method is the

property of a large number of elements of that population. On a basis of

statistical evaluation, we can determine only the probability that a

particular element of a population has a certain property.

Statistics is subjective; statisticians try to explain or predict the

material world through arbitrary, but reasonable way, using probability

theory, mathematics and common sense.

Unlike the statistics, probability theory for a fully defined problem gives

a unique and a reproducible solution. Probability theory is the algebra of

inductive reasoning. (Boolean algebra is the algebra of deductive

reasoning.)

Statistical methods are among the most widespread quantitative

methods, with important applications in almost all human activities.

[Njegić] 1.1., 1.2. [Ivković] II.1 [Britannica] Probability theory [Drake] 7-1, 7-6

[Lazić] I, 1.2 [Anscombe]

96

Kostić • 2019 • Metrology Companion

6.2 Statistical analysis of results of repeated

measurements

The purpose of statistical analysis of results of repeated

measurements of a particular quantity is to determine the best estimated

value of the quantity. And also, to determine an interval about the best

estimated value which, with requested probability, encompass a true

value of the quantity.

Normally, for the best estimated value of the quantity is taken the

maximum likelihood value of this quantity.

The results of repeated measurements most often have normal

distribution because the central limit theorem is most often valid. In the

case of normal distribution, and after correction for all significant

systematic errors, the maximum likelihood value of the quantity is an

arithmetic mean of the results of measurements.

For the normal distribution, the interval:

ARITHMETIC_MEAN ± DEVIATION_OF_THE_ARITHMETIC_MEAN

is the interval in which a true value of the quantity is with the probability of

0.68.

[GUM] 3, 4

Kostić • 2019 • Metrology Companion

97

6.24 Degrees of freedom

Degrees of freedom, ν, of an evaluation estimated from a sample of

size n is given by formula (6.64). The R is a number of evaluations

estimated from this sample and used to estimate this evaluation. See

also 6.24.1 Examples.

ν=n–R

(6.64)

The least possible sample size is 1, and from this sample it is possible

to estimate an evaluation of the degree of freedom equal to 1.

Evaluations with the degrees of freedom equal to 1 have the greatest

possible dispersion. The dispersion is reduced by increasing the sample

size, that is, the degrees of freedom, so the degrees of freedom is the

indicator of reliability of an evaluation. The degrees of freedom of an

evaluation is equal to the number of elements of the sample above the

least number of elements necessary to compute the evaluation, plus, 1.

The degrees of freedom defined by (6.64) gives a value which is a

parameter of different distributions. For example, a sample from population

with the normal distribution, for which (6.64) gives a degrees of freedom ν,

has the T-distribution with parameter “degrees of freedom” equal to ν. Also,

the standard uncertainty, for which (6.64) gives a degrees of freedom ν,

has the T-distribution with parameter “degrees of freedom” equal to ν.

If for a sample from a population with the normal distribution, is known

its standard deviation s, and a degrees of freedom of this deviation, ν,

formula (6.65) gives half-width of confidence interval, Δ, for a confidence

level of an interval, P. The coefficient k is the coverage factor which can

be determined from the relation among P, ν and k listed in Table 6.3 for

the T-distribution. Formula (6.65) is derived from (6.77).

Δ = k·s

(6.65)

The degrees of freedom enables accurate computation of a level and

interval of confidence, even in the case of small sample size.

The quantities Δ and k from (6.65) can be used as an expanded

standard measurement uncertainty and its coverage factor.

Without giving a general definition, the concept of the degrees of

freedom first started to use Sealy Gosset (“Student”) in 1908 and Ronald

Fisher in 1915. Since then, the concept is based on an incomplete theory.

A particular problem is the computation of the degrees of freedom.

[Njegić] 5.6. [GUM] 4.2.6, G.3.2, G.3.3, G.6.4 [Eisenhauer]

Kostić • 2019 • Metrology Companion

125

6.27 Confidence level and confidence interval

Confidence level (or level of confidence, or coverage probability)

is a probability that a value of variable is from a specified interval.

Confidence interval (or interval of confidence, or two-sided

confidence interval, or coverage interval) is the interval which has the

specified probability that the value of variable is from it. Confidence

limits are the limits of confidence interval.

The number of measurement results is from a particular interval. The

probability that the result is from mentioned interval is equal to the

quotient of the number of results from mentioned interval, and the total

number of results. The mentioned interval is the confidence interval. The

mentioned probability is the confidence level.

Generally, there is more than one coverage interval for a specified

probability. Shortest confidence interval of a variable is a confidence

interval with the narrowest width among all coverage intervals having the

same coverage probability. In the case of unimodal distribution, the

shortest confidence interval is to the left of the mode and to the right of

the mode. Unless otherwise indicated, the confidence interval means the

shortest confidence interval.

A confidence level, P, of a variable x with a probability density function

f(x), for confidence interval [a, b], is given by (6.76). With (6.76) there is a

graphical example for the normal distribution.

P = P(a ≤ x ≤ b ) =

b

f( x ) ⋅ d x

(6.76)

a

For a variable with the normal distribution, it can be computed an

arithmetic mean x , and standard deviation of the mean, s. For a requested

confidence level, P, a confidence interval can be given in the form of:

[ x − k ⋅ s , x + k ⋅ s ] or simplified x ± k ⋅ s .

(6.77)

In the case of the normal distribution, the coefficient k can be determined

from function (6.78) which gives the relation between P and k. The

values in Table 6.2 are obtained from (6.78).

P(k ) =

2

⋅

π

k

0

1

k2

2

⋅ dk

(6.78)

e

The coefficient k is called the coverage factor. Product k · s is a

half-width of confidence interval (or one-sided confidence interval).

Kostić • 2019 • Metrology Companion

129

A standard deviation of a variable with the normal distribution is a

half-width of a confidence interval of the variable at the confidence level

(of the interval) equal to 0.6827.

One or more measurement results, from a population with the normal

distribution, have the T-distribution. For details and about levels and

intervals of confidence, see 6.29 T-distribution.

The level and interval of confidence of the measurement result can be

considered as a purpose of all determinations of measurement errors.

[Ivković] PP 79, PP 81, PP 17 [GUM] 7.2.4, G.3.2, G.5.3, G.1.4

Table 6.2 For the normal distribution, N(x): relations between the

confidence level, P, and coverage factor k

P

0.079 7

0.100 0

0.158 5

0.200 0

0.300 0

0.382 9

0.400 0

0.500 0

0.600 0

0.682 7

0.700 0

0.800 0

0.850 0

0.900 0

0.950 0

0.954 5

0.970 0

0.980 0

0.990 0

0.995 0

0.997 3

0.998 0

0.999 0

0.999 9

0.999 99

0.999 999

130

k

0.100

0.126

0.200

0.253

0.385

0.500

0.524

0.675

0.842

1.000

1.036

1.282

1.440

1.645

1.960

2.000

2.170

2.326

2.576

2.807

3.000

3.090

3.291

3.891

4.417

4.892

Kostić • 2019 • Metrology Companion

6.38 Histogram

The sample of values can be splitted into disjoint subintervals of equal

widths (or cells, or bins). The histogram is the graphic representation of

a number of the values that fall into each of the subintervals.

The histogram is made in the following way. First, split a part of the

horizontal axis which contains the values from the sample into disjoint

subintervals of equal width, see Figure 6.14 b). Then draw rectangles

whose bases overlap subintervals on the horizontal axis and whose

heights are proportional to the number of values that fall into the

subinterval of their base.

The histogram appearance is significantly affected by the subintervals

width and their position along the axis. The limits of subintervals can be

determined according to the following two recommendations.

a) If we make the histogram for a sample with a small number of

possible discrete values, the subintervals should be chosen so that each

discrete value corresponds to one subinterval. This is the case in

Example 6.38.1, in which 8033 discrete measurement results have one of

16 possible discrete values, out of which only 5 values are distinguished

by the number of appearances. Histograms, such as in this case, are

bases for reliable estimating.

b) If we make the histogram for a sample with a large number of

possible values, subintervals width and position in the horizontal axis can

be determined as follows.

If the n values in the sample have the normal distribution and n is

larger than about 25, the optimal subinterval width w, is given by formula

(6.116) with the parameter C = 3.5. The standard deviation of values in

the sample is denoted by s. This formula is derived from the criterion of

the minimum of integrated mean squared error (IMSE).

w = C⋅

s

3

n

(6.116)

If the values in the sample do not have the normal distribution, and n

is larger than about 25, based on the experience we can also recommend

using (6.116) with C = 2.

In the case of discrete values, it is necessary to round the subintervals

width so that each subinterval contains the same number of possible values

(that is, round subintervals width to an integer multiple of a resolution).

148

Kostić • 2019 • Metrology Companion

The limits of subintervals should be chosen so that more of the values

are around the middle of subintervals.

In the histograms described in b), it is classified the case in Example

6.38.2, in which 78 discrete measurement results have one of 30 possible

values. This example shows how the subintervals width affects the

histogram appearance.

In most statistical software a default subinterval width and position are

not optimal.

The height of a rectangle of a histogram is proportional to the

probability that values fall into the subinterval of the rectangle base, so

the histogram is the variation of the probability density function.

By visual inspection of the well-made histogram, we can estimate the

following properties of the distribution: a type; a mode; an existence of

outliers; a dispersion of values; an existence of several maximums; a

symmetry; and a peakedness. The lack of an evaluation based on the

histogram is subjectivity.

The approximate arithmetic mean of n values represented by a

is given by formula (6.117) derived from (6.19). The bi is a

histogram, x,

number of values in a subinterval with the middle xi .

x ≈

1

1 n

⋅ (b1 ⋅ x1 + b2 ⋅ x2 + ... + bn ⋅ xn ) =

⋅ bi ⋅ xi

n

n i =1

(6.117)

[Britannica] Statistics [Perović, communication] [Scott] [Hristov, communication]

Kostić • 2019 • Metrology Companion

149

6.40 Filtering

Filtering is a procedure to reduce random differences of values in a

sequence.

Filtering is most often performed by averagings. Moving average filtering

uses the convolution, it is simple and optimal to reduce random differences

of values in a sequence. This filtering retains sharp changes but gives the

wrong idea about values and widths of peaks in the sequence. These

disadvantages are worsened by decreasing a bandwidth of the filtering.

In Figure 6.17 there is an

example of filtering by using the

convolution. The weight

function (that is, window) is the

Chebyshev type sequence with

seven coefficients (that is,

points) scaled so that their sum

equals to one. (The moving

average filtering using the

weight function with equal

coefficients.) Filtering is applied

to the fluctuating discrete

measurement results. These

results with the corresponding

histogram are also shown in

Figure 6.15.

In addition to averaging,

filtering is also implemented by

fitting. Savitzki - Golay

filtering uses local polynomial

fitting across a moving window

within the values in the

sequence. The polynomial is

often of the fourth degree, and

it is fitted by the method of least

squares. Such filtering tends to

preserve the values and widths

of peaks in the sequence. See

[Savitzky].

[Savitzky]

[Hristov, communication] [Guiñón]

154

Figure 6.17. Filtering of the

sequence of discrete measurement

results by using the convolution: a) the

Chebyshev type weight function, b)

the sequence of discrete

measurement results and c) the

convolution of these two functions.

[Hristov, communication]

Kostić • 2019 • Metrology Companion

6.41 Operations on distributions and central limit theorem

When a die is thrown, each number from 1 to 6 comes up with equal

probability. The probability function of these numbers, P(x1), is uniform

and discrete, and it is represented pictorially in the following figure.

Think about the probabilities to happen values which are the sum of

two numbers obtained from two tosses of a die. The possible values of

the sum are 2 to 12. There is only one way of making 2, two ways of

making 3, etc. See the following picture. The sum 7 is the most probable

because it can be achieved in the greatest number of ways.

The random variable x1 , which assume values obtained from tosses of

the die, has the uniform and discrete probability function. The random

variable x2 , whose values are the sum of the two numbers obtained from

two tosses of the die, has the triangular and discrete probability function.

As an example, using the properties of probability, we can compute the

probability that the sum of x2 is 5:

P(x2 = 5) = P[(4 1) (3 2) (2 3) (1 4)] =

= P(4 1) + P(3 2) + P(2 3) + P(1 4) =

= P(4) · P(1) + P(3) · P(2) + P(2) · P(3) + P(1) · P(4) =

2

= 4 · (1/6) = 4/36 = 1/9.

We see that P(x2 = 5) can be written as P( x2 = 5) =

4

P(5 − i ) ⋅ P(i ),

i =1

which is the convolution of discrete function P with itself. Based on previous

example, we can determine the probability function of the x2 , P2 (x2 ):

1/ 6, x1 = 1, 2, ..., 6

P1 ( x1 ) =

0 ≥ x1 ≥ 7

0,

P 2 ( x2 ) =

∞

P1 ( x2 − i ) ⋅ P1 (i ) = P1 ( x2 ) ∗ P1 ( x2 ).

i = −∞

Kostić • 2019 • Metrology Companion

155

Analogous to the previous discrete probability functions, we can

determine the probability function of the sum of variables with continuous

probability functions. See [Osgood] 3.6.6.

For discrete and for continuous probability density functions the

following applies. The probability density function of a sum of two

independent random variables is the convolution of the probability density

functions of those two variables. That is, if f is the probability density

function, and if x1 and x2 are independent variables, then:

f (x1 + x2 ) = f (x1 ) * f (x2 ).

(6.127)

From the example in Figure 6.18, we can see the following. The sum

of two independent variables, with the uniform distributions of the same

width, has a triangular distribution. Approximately normal distribution has

the sum of the variable with the triangular distribution and variable with

the uniform distribution, as well as the sum of variables with normal

distribution and variable with the uniform distribution. The example in

Figure 6.18 shows how from chaotic differences of variables the normal

distribution emerges necessarily which suggests the central limit theorem.

Central limit theorem states that a sum of independent variables,

with any distributions, approaches the normal distribution as a number of

the variables increases, but if there is no variable with multiple times

greater differences than other differences. See [Osgood] 3.7 and 3.10.

[Osgood] 3.6, 3.7, 3.10 [Box 2005] PP 28

156

Kostić • 2019 • Metrology Companion

Figure 6.18. The variable x1 in

time, its distribution and the

distributions of the sums of

independent variables xi with the

distributions as x1.

Kostić • 2019 • Metrology Companion

157

6.42 Monte Carlo simulation

Monte Carlo simulation, MCS (or Monte Carlo method, MCM) is

used to estimate a value by performing mathematical model computations

for a large number of combinations of input values.

The combinations of input values are chosen so that intervals of

interest are simulated as uniformly as possible and at enough points. The

input values can be a sequence of numbers represented in the diagrams

below, each with one hundred pairs of the: a) equidistant numbers x and y,

b) numbers with the uniform distributions, c) numbers with quasi-random

distributions, d) numbers with the normal distributions and e) linearly

correlated numbers with the normal distributions.

Input numbers with quasi-random distributions are suitable when a

model has many variables and depends strongly on some of the

variables. If with such model we use numbers with other distributions, and

with the same total number of points, we obtain significantly poorer

resolution per variable. See [Sobol].

The Monte Carlo simulation is for computer implementation.

In the metrology, in order to simulate values of component quantities,

input values produce number generators for given best estimated

component quantities and distributions of these evaluations. The

simulated input values must have all parameters of a distribution equal to

parameters of a distribution of simulated evaluation, including possible

correlation. This simulation truly represents a measurement procedure.

The simulation can be used to:

● determine a distribution of evaluations of measurand

● determine a confidence interval of evaluation

● determine the best estimated value of measurand

● determine a standard measurement uncertainty of this evaluation

● determine the degrees of freedom of this uncertainty

● determine sensitivity coefficients

● to validate procedures according to the GUM.

158

Kostić • 2019 • Metrology Companion

The Monte Carlo simulation applies if the conditions to use the primary

procedures according to the GUM are not fulfilled, or if it is unclear whether

they are fulfilled. The simulation can also be applied if the condition to use

the convolution is not fulfilled (the condition is uncorrelated input values).

The simulation is commonly used in the following cases:

● linearization of a model of measurement is not satisfactory

● it is inconvenient to provide partial derivatives for a model of

measurement

● a model of measurement is too complex

● distribution functions of input values are highly skewed

● standard measurement uncertainties of input values are not roughly

equal

● a distribution of output values departs appreciably from the normal

distribution

● an output value and its standard measurement uncertainty are

roughly equal.

Conditions for application of the Monte Carlo simulation:

● the possibility of computing a sufficiently large number of Monte

Carlo trials

● in the neighborhood of the best estimated input quantities the model

of measurement is continuous (not necessarily the derivatives of the model)

● if for output values an arithmetic mean and deviation exist

● if the confidence interval is to be determined:

- the cumulative distribution function of output values is continuous

and strictly increasing

- the probability density function of output values is continuous over

an interval for which it is larger than zero, it is unimodal and it is strictly

increasing, or zero, to the left of the mode and strictly decreasing, or zero,

to the right of the mode.

The primary advantages of the Monte Carlo simulation:

● it is not necessary to determine partial derivatives of a model of

measurement

● the simulation gives the distribution of output values

● the simulation has broader applicability than the procedures

according to the GUM

● the same kind of simulation results and results of procedures

according to the GUM.

Kostić • 2019 • Metrology Companion

159

Estimate of a value of a quantity and its statistical parameters can be

performed by the Monte Carlo simulation in the following steps.

1) Specify the input data: a model of measurement and component

quantities with their parameters.

2) Determine the required number of Monte Carlo trials, that is, sets of

input values, M. This number depends on the requested accuracy of the

4

simulation results and on distributions of input values. Often satisfies 10

6

to 10 trials.

3) Produce by number generators M sets of randomly ordered input

values with appropriate distributions and possible correlations. See

Example 6.42.1 and [GUM-S1].

4) For each set of input values from 3), by the use of a model of

measurement, compute the model output value, ym (m = 1, 2, ..., M ).

5) From the M model output values, the histogram is obtained in the

usual way according to 6.38 Histogram.

6) The best estimated value of a quantity is obtained by:

● using the model of measurement and other input data - if the input

values have symmetric distributions with approximately equal

measurement uncertainties which are relatively small in relation to the

means of input values, or

● if the input values do not have distributions as in the preceding

clause - based on the distribution of the model output values, and

according to 6.9 Best estimate.

7) When n results of repeated measurements of component quantities

are simulated, the M output values are divided into J = M / n groups with

the n values.

8) The maximum likelihood value of the standard deviation of the

value obtained from the n results of repeated measurements is computed

in the usual way from (6.56) so that the standard deviation of all M values

is divided by n . This deviation is the combined standard measurement

uncertainty of the mean of n results of repeated measurements. (The

standard deviation of all M values is approximately equal to the average

(that is, arithmetic mean) of the deviations of the n values within the groups.)

9) For each group with the n values, the standard deviation of the mean

of the group is computed in the usual way from (6.56). See Table 6.4.

10) For all J groups, the deviation of the standard deviations of the

mean of the group, from 9), is computed in the usual way from (6.49).

See Table 6.4.

11) For all J groups, the standard deviation of the means of the group is

computed in the usual way from (6.49). See Table 6.4.

160

Kostić • 2019 • Metrology Companion

12) The degrees of freedom of the standard deviation from 8) is

approximately computed from (6.75), using the deviation of the standard

deviations of the mean of the group from 10) and the standard deviation

of the means of the group from 11). See Table 6.4.