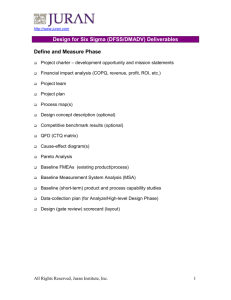

Chapter 5 Quality By Design to Increase Sales Strategic Vs. Operational Planning Strategic quality planning is the process of establishing long-range customer-focused goals and defining the approach to meeting these goals (Chapter 2). Operational quality planning focuses on the product and process with middle management. The Juran Trilogy The quality planning process is a dual hatchery: • A benign hatchery produces new, useful quality plans. • A malignant hatchery produces new alligators. To stop the production of new alligators requires shutting down that malignant hatchery. J.M. Juran (1992) Proposed Changes Cause • Planning is being done by amateurs • Planning is focused on the little Q • Planning is done without participation of those who are impacted Remedy • Train the armatures to be professionals • Enlarge focus to Big Q • Require participation Proposed Changes (Cont.) Cause • Planning is done by use of empirical methods • Plans are transferred to operations without proof of process capability Remedy • Adopt modern systematic methods • Require proof of process capability The Need for Structure Structured Quality Planning Unstructured Quality Planning Phases Around the Spiral J.M. Juran (1992) The Road Map 1. Define the opportunity • Identify the opportunity • Define the target customers • Set goals with respect to market, customer, quality, financials, and performance. • Establish the product team to lead and complete the project. • Construct high-level flow of product production and use. • Identify all customers, internal and external. 2. Discover customers’ needs • Plan how to discover customer needs: e.g., market research, customer complaints, competitive evaluations • Collect information on customer needs in their language • Analyze and prioritize customer needs. 3. Design the product • Select high-level product features and goals (functional design). • Develop detailed product features and goals. • Optimize product features and goals. • Finalize the product design. 4. Develop the process • • • • • • • Collect known baselines. Select general process design. Identify high-level process features and goals. Develop detailed process features and goals. Optimize process features and goals. Establish initial process capability. Finalize the process design. Develop process controls • • • • • Identify control subjects. Develop feedback loops. Develop control plans. Establish audit. Demonstrate process capability and controllability. 5. Deliver results • Plan for transfer to operations. • Implement plan. • Validate transfer. Structured Planning Techniques • Quality Function Deployment (QFD) • Design for Six-Sigma (DFSS) Quality Function Deployment • QFD is the result of the early work by Dr. Akao in Japan (1972). • It provides a structured method for translating customer needs into design features. • Some times referred to as the “House of Quality” • The method utilizes a series of interlocking matrices that translate customer needs into product and process features. • Each matrix includes customer wants and needs on the rows and the design features on the columns. • The intersecting cell between a column and a row is used to record the strength of the relationship between the need and the design feature. • The foundation of the house contains benchmarks or target values. • The matrix is topped by a triangular roof, which shows how the design features are related among themselves. • Knowledge of these relationships helps in alerting the designer to changes that may occur in other features while making changes to one of them. House of Quality Interrelationships Technical Requirements (How?) Customer Requirements (What?) Relationship matrix Benchmarking or Targets (How much?) Customer requirement priorities (Why?) Competitive evaluation Building the House of Quality 1. Identify customer requirements. 2. Identify technical requirements. 3. Relate customer requirements to the technical requirements. 4. Conduct an evaluation of competing products or services. 5. Evaluate technical requirements and develop targets. 6. Deploy the “Hows” in one house to the “Whats” in the next. The QFD Process Technical requirements Product features process features Control features QFD benefits companies through improved communication and teamwork between all constituencies in the value chain, such as between marketing and design, between design and manufacturing, and between purchasing and suppliers. Design for Six Sigma • DFSS is a method of bringing order to the design process. • It is focused on creating new or modified designs that are capable of significantly higher levels of performance (six sigma). DFSS Methodologies • DFSS can be carried out using a number of methodologies. These include: • Identify-Design-Optimize-Validate (IDOV) • Define-Measure-Explore-DevelopImplement (DMEDI) • Define-Measure-Analyze-Design-Verify (DMADV). The DMADV Methodology Define Phase: Define project goals and customer requirements. Deliverables: • Established design project • Project charter • Project plan • Initial business case Measure Phase: Measure and determine customer needs and specifications (CTQs) Deliverables: • Prioritized list of customer needs • Prioritized list of CTQs • Current baseline performance Analyze Phase: Analyze options for meeting customer needs. Deliverables: • Design alternatives • Selected high-level design • Results of design capability/risk analysis • Best-fit design • Detailed design requirements Design Phase: Develop optimal and detailed functional design requirements Deliverables: • Optimized design parameters • Prediction model • Optimal tolerance and settings • Detailed functional design • Results of design verification tests (DVT) Verify Phase: Ensure that the new design can be manufactured and supported within the required quality. Deliverables: • Manufacturing verification test results • Control plans • Final project report