Validation Report

Report for:

PT. Wirajaya Packindo

Validation of CDM project for

Installation of Waste Heat Recovery Steam

Boiler at Wirajaya Packindo

LRQA Reference

Date

Work carried out by

Work verified by

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

: ENQ/2607/11/IRE

Version 02.14

: 04/12/2012

: Ankush Jain

Cholid Bafagih

Hikmat Wijaya

M. Nursyam

: Ketan Deshmukh

Brahim Abdullah

Michiaki Chiba

Date: 04/12/2012

Page 1 of 92

Revision 0.9, 07 November 2012

Contents

1

Executive Summary ............................................................................................ 3

2

Introduction ......................................................................................................... 5

3

4

2.1

Objective ................................................................................................................ 6

2.2

Scope...................................................................................................................... 6

2.3

GHG Project Description ....................................................................................... 6

Methodology........................................................................................................ 6

3.1

Review of documents ............................................................................................ 6

3.2

Site Visit and Follow-up interviews ...................................................................... 7

3.3

Resolution of clarification and corrective action requests................................. 8

3.4

Internal quality control .......................................................................................... 8

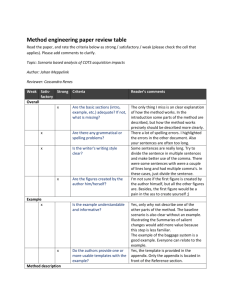

Validation protocol and conclusions ................................................................ 8

4.1

Approval ................................................................................................................. 9

4.2

Participation requirements.................................................................................... 9

4.3

Project design document ...................................................................................... 9

4.4

Project description .............................................................................................. 10

4.5

Baseline and monitoring methodology .............................................................. 10

4.6

Additionality of a project activity........................................................................ 12

4.7

Monitoring Plan.................................................................................................... 13

4.8

Local stakeholder consultation .......................................................................... 13

4.9

Environmental impacts ....................................................................................... 13

4.10

Summary of Changes .......................................................................................... 13

5

Comments by parties, stakeholders and NGOs ............................................. 14

6

Validation Opinion ............................................................................................ 15

7

Appendices........................................................................................................ 16

7.1

Appendix A: Letter of approval for the project by the host and investing

country DNA .................................................................................................................... 16

7.2

Appendix B: List of documents reviewed .......................................................... 16

7.3

Appendix C: List of persons interviewed........................................................... 18

7.4

Appendix D: How due account has been taken to the public input made to the

validation requirements .................................................................................................. 19

7.5

Appendix E: Certificate of Appointment ............................................................ 20

7.6

Appendix F: Validation Protocol and findings log............................................. 21

No distribution without permission from the client or responsible organisational unit

Limited distribution

Unrestricted distribution

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date: 04/12/ 2012

Page 2 of 92

Revision 0.9, 07 November 2012

1

Executive Summary

Lloyd’s Register Quality Assurance Limited has been contracted by PT. Wirajaya

Packindo representing the project participants (PP), to undertake validation of the

proposed project activity “Installation of Waste Heat Recovery Steam Boiler at

Wirajaya Packindo”. The validation has been performed through a process of

document review based on the project design document, Version 1 dated 20/10/2011

initially submitted for validation and the subsequent revisions, follow-up interviews with

the stakeholders, resolution of outstanding issues and issuance of the validation report.

The project activity is recovery of waste heat in the existing gas turbine system to

generate steam. The project activity involves installation of a waste heat recovery

boiler which utilises the waste heat and natural gas as supplementary fuel to generate

steam. The steam otherwise would have been generated from the existing coal based

boilers. The project activity reduces the GHG emissions from recovery of waste heat

and using lower GHG natural gas as fossil fuel.

The fulfilment of the requirements as set forth in Article 12 of the Kyoto Protocol of the

United Nations Framework Convention on Climate Change (UNFCCC), the modalities

and procedures for a CDM (CDM M&P) and relevant decisions of the Conference of

the Parties, serving as meeting of the Parties to the Kyoto Protocol (COP/MOP) and

the Executive Board of the CDM (CDM-EB) have been evaluated and conformance to

the validation requirements were confirmed based on the given information. A risk

based approach was taken to conduct the validation and corrective action requests

(CARs) and clarifications (CLs) were raised for relevant actions by the PP.

The validation team has found through the validation process 4 CARs and 6 CLs.

The PP has taken actions and submitted to LRQA the revised PDD and supporting

evidence. The validation team is of the opinion that the proposed project activity as

described in the project design document Version 5.5 dated 04/12/2012 meets all the

relevant UNFCCC requirements for the CDM, as well as the host country’s national

requirements and if implemented as designed, is likely to achieve the emission

reductions and contribute to the sustainable development of the host country. LRQA

therefore requests the registration of “Installation of Waste Heat Recovery Steam

Boiler at Wirajaya Packindo” to the CDM Executive Board as a CDM project activity.

Lloyd’s Register Quality Assurance Ltd

Hiramford

Middlemarch Office Village

Siskin Drive

Coventry CV3 4FJ

United Kingdom

LRQA Reference: ENQ/2607/11/IRE

Registered office:

Lloyd’s Register

71 Fenchurch Street

London EC3M 4BS

United Kingdom

Date: 04/12/2012

Page 3 of 92

Lloyd's Register Quality Assurance Ltd, its affiliates and subsidiaries and their respective officers, employees or

agents are, individually and collectively, referred to in this clause as the ‘Lloyd's Register Group’. The Lloyd's

Register Group assumes no responsibility and shall not be liable to any person for any loss, damage or expense

caused by reliance on the information or advice in this document or howsoever provided, unless that person has

signed a contract with the relevant Lloyd's Register Group entity for the provision of this information or advice and

in that case any responsibility or liability is exclusively on the terms and conditions set out in that contract.

MSBSF43847

Revision 0.9, 07 November 2012

Abbreviations

AE

BE

CARs

CDM

CDM-EB

CDM M&P

CDM PS

CDM VVM

CDM VVS

CERs

CLs

COP/MOP

DEHSt

DNA

DOE

EF

EIA

EPC

ERPA

FAR

GHG

GSP

IPCC

IRR

ISO

KP

kW / kWh

LE

LoA

LR

LRQA

MW / MWh

NCV

NGO

NPV

ODA

PDD

PE

PP

tCO2e

UNFCCC

Applicant entity

Baseline emissions

Corrective action requests

Clean development mechanism

Executive board of clean development mechanism

Modalities and procedures for a clean development mechanism

CDM Project Standard

CDM Validation and Verification Manual

CDM Validation and Verification Standard

Certified emission reductions

Clarification requests

Conference of the Parties serving as meeting of the Parties to the

Kyoto Protocol

German Emission Trading Authority

Designated national authority

Designated operational entity

Emission factor

Environmental impacts assessment

Engineering, Procurement and Construction

Emissions reduction purchase agreement

Forward action requests

Greenhouse gas

Global stakeholders’ consultation process

Intergovernmental panel on climate change

Internal rate of return

International Standards Organisation

Kyoto Protocol of the United Nations Framework Convention on

Climate Change

Kilowatt / Kilowatt hour

Leakage emissions

Letter of approval

Lloyd’s Register

Lloyd’s Register Quality Assurance Limited

Mega watt / Mega watt hour

Net calorific value

Non governmental organization

Net Present Value

Official development aid

Project design document

Project emissions

Project participant

Tonnes of carbon dioxide equivalent

United Nations Framework Convention on Climate Change

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 4 of 92

Revision 0.9, 07 November 2012

2

Introduction

The project participant (PP) represented by PT. Wirajaya Packindo has contracted with

Lloyd’s Register Quality Assurance Limited (LRQA) to undertake validation of the

proposed project activity “Installation of Waste Heat Recovery Steam Boiler at

Wirajaya Packindo”. This report summarise the findings of the validation process that

has been conducted on the validation requirements of the CDM.

The validation has been undertaken by the team formed of the qualified personnel of

LRQA as follows:

Ankush Jain

LRQA India

Cholid Bafagih

LRQA Indonesia

Hikmat Wijaya

M. Nursyam

Ketan Deshmukh

Brahim Abdullah

Michiaki Chiba

LRQA Indonesia

External expert

LRQA Ltd.

External expert

LRQA Ltd.

Team Leader,

CDM Lead Validator

Team member,

CDM Validator,

Host country expert

Trainee

Sector expert

Technical reviewer

Sector expert to technical reviewer

Decision maker

Personnel being engaged in a CDM project validation are qualified based on the

established procedures of LRQA to assure the resource requirements satisfy all the

requirements of competence criteria for an AE/DOE under CDM (CDM-Accreditation

Standard for Operational Entities Version 04.0). LRQA is designated as an operational

entity and holds the full responsibility of decision-making regarding the validation, in

line with the accreditation requirements of the CDM-EB. The certificate of appointment

of the team personnel is attached to this report.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 5 of 92

Revision 0.9, 07 November 2012

2.1

Objective

Validation is the process of an independent third party evaluation of a project activity

on the basis of the PDD, against the requirements of the CDM as set out in Article 12

of the Kyoto Protocol, the CDM M&P, subsequent decisions made by the COP/MOP

and CDM-EB, and other rules applicable to the proposed project activity including the

host country’s legislation and its specific requirements for sustainable development.

The validation follows the requirements of the current version of the CDM validation

and verification standard (CDM VVS) and the CDM Project Standard (CDM PS) to

ensure the quality and consistency of the validation work and the report.

2.2

Scope

The scope of validation is an independent and objective review of the project design.

Review of the PDD is conducted against the requirements of the Kyoto Protocol, the

CDM M&P and relevant decisions of the COP/MOP and the CDM-EB. LRQA follows a

risk-based approach in the validation focusing on the identification of significant risks

for project implementation and generation of CERs. Validation is not meant to provide

any consulting towards the PP, however, the corrective actions requests (CARs) and

clarifications (CLs) might provide input for improvement of the project design. A

validation conclusion shall become final subject to the decision maker’s review by

LRQA Ltd.

2.3

GHG Project Description

The Project activity is recovery of waste heat from the existing turbine of capacity

12MW (15MW under International Standards Organisation (ISO) conditions) to

produce steam. The project activity involves installation of a new waste heat recovery

boiler. The waste heat recovery boiler will also use natural gas as supplementary fuel

to produce steam required for the manufacturing process of paper. Prior to the project

activity the steam demand was met through the existing coal fired boilers. The

existing coal fired boilers will be used as stand by for meeting steam demand in

emergency situations. The project activity reduces the GHG emissions from the

recovery and utilisation of waste heat and use of lower GHG fossil fuel.

The estimated GHG emission reductions are 56,427 tCO2e per annum. The emission

reduction has been estimated based on the designed efficiency, emission factor based

on IPCC and average annual working days.

3

Methodology

3.1

Review of documents

The validation is performed primarily based on the review of the project design

document (PDD) and the other supporting documentation.

The PDD Version 1 dated 20/10/2011 was initially reviewed. LRQA requested the PP

to present supporting information and documents relating to the project design and

such additional information and documents were also reviewed by LRQA.

Through the process of the validation, the PDD and the supporting documents of the

same were evaluated to confirm the actions taken by the PP to the CARs and CLs

issued by LRQA. The documents reviewed by LRQA are listed in Appendix B. LRQA

reviewed the final version of the PDD version 5.5 dated 04/12/2012 to confirm that all

changes agreed had been incorporated.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 6 of 92

Revision 0.9, 07 November 2012

3.2

Site Visit and Follow-up interviews

A site visit and follow-up interviews with the stakeholders were conducted as detailed

in the schedule as below:

Date

Location/

Address

Tangerang,

Banten,

Indonesia

Party

Interviewed

PT. Wirajaya

Packindo

Subjects Covered

13/12/2011

Tangerang,

Banten,

Indonesia

Local

stakeholders

Ankush Jain

Cholid Bafagih

Hikmat Wijaya

M. Nursyam

14/12/2011

Local

Environment

Protection

Bureau,

Tangerang

PGN Office,

Jakarta,

Indonesia

BPLHD

1. Invitation letters issued to local

stakeholders

2. Representation by stakeholders

in stakeholders’ consultation

meeting

3. Minutes of meeting –

comments, action taken

4. Employment generation due to

the project activity

5. Discussion on land ownership

and transaction procedures

6. Views on the project activity

7. Any other issues of

stakeholders’

8. Interview local stakeholders

1. EIA

2. Other statutory requirements

3. Clearances required

4. Views on project activity

Gas supplier

1. General overview about the

project

2. Gas pricing and supply

scenario

Ankush Jain

Cholid Bafagih

Himkat Wijaya

M. Nursyam

Tangerang,

Banten,

Indonesia

PPs

Consultant

1. Discussion on project and

timelines

2. Closing meeting

Ankush Jain

Cholid Bafagih

Himkat Wijaya

M. Nursyam

13/12/2011

14/12/2011

14/12/2011

1. Project description, boundary

and technology

2. Applied project technology and

industrial good practices.

3. Monitoring plan.

4. Record keeping

5. Emergency preparedness

6. Data collection and archiving

7. Training and internal audits

8. Legal requirements

9. Environmental impacts of the

project activity

10. Local stakeholders

consultation

Team Members

on Site

Ankush Jain

Cholid Bafagih

Himkat Wijaya

M. Nursyam

Ankush Jain

Cholid Bafagih

Himkat Wijaya

M. Nursyam

A full list of persons interviewed is shown in Appendix C.

For details of all the findings of the desk review and site visit, please refer to the

Validation Protocol and Findings in Appendix F.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 7 of 92

Revision 0.9, 07 November 2012

3.3

Resolution of clarification and corrective action requests

LRQA applies the risk based approach aimed at focusing on high risk issues to the

validation results while not omitting any part of the mandatory processes.

Findings identified in the process are indicated under the titles corrective action

requests (CARs) and clarification requests (CLs) and forward action requests (FARs).

CARs and CLs require the PP to take relevant actions. Criteria for judging items as

CAR or CL are as follows:

Corrective action request (CAR):

• the project participants have made mistakes that will influence the ability of the

project activity to achieve real, measurable additional emission reductions

• the CDM requirements have not been met, or

• there is a risk that emission reductions cannot be monitored or calculated.

Clarification request (CL):

• information is insufficient or not sufficiently clear to determine whether the

applicable CDM requirements have been met.

FARs are to be raised to highlight issues related to project implementation that require

review during the first verification of the project activity. FARs do not relate to CDM

requirements for registration.

CARs and CLs are to be resolved or closed out if the PP modifies the project design,

rectifies the PDD or provides adequate additional explanations or evidence that

satisfies the concerns. If this is not completed, the project activity cannot be

recommended for registration to the CDM Executive Board.

For details of the nature of the issues raised, the nature of the responses provided, the

means of validation of such responses and the resulting changes in the PDD or

supporting annexes please refer to the Validation Protocol and Findings in appendix F.

3.4

Internal quality control

A technical review by a qualified person independent from the validation team and a

review by an authorized decision maker were conducted before the submission of the

validation report to the PP and before requesting the registration of the project activity.

4

Validation protocol and conclusions

This section provides an overview of the validation activities undertaken by LRQA

in order to arrive at the final validation conclusions and opinion. It includes

general conclusions based on the Clean Development Mechanism Validation and

Verification Standard (CDM VVS) version 03.0. Further details in relation to each

element of the protocol and each finding are shown in the Validation Protocol and

Findings – Appendix F.

The protocol is structured based on the main validation requirements as follows:

• Approval by the Parties involved

• Participation requirements

• Project design document

• Project description

• Baseline and monitoring methodology

o Applicability of the selected methodology

o Project boundary

o Baseline identification

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 8 of 92

Revision 0.9, 07 November 2012

Algorithms and/or formula used to determine emission reductions

Additionality of a project activity

o Prior consideration of the CDM

o Identification of alternatives

o Investment analysis

o Barrier analysis

o Common practice analysis

• Monitoring plan

• Local stakeholder consultation

• Environmental impacts.

o

•

4.1

Approval

A CDM project shall be approved by the Parties involved.

The host Party of the proposed project is Indonesia. Indonesia ratified the Kyoto

Protocol on 28/07/2004. The Designated National Authority (DNA) is National

Committee on Clean Development Mechanism. The information of the DNA has been

confirmed by the validation team against the relevant information on the UNFCCC

CDM website (http://cdm.unfccc.int/DNA/index.html). A letter from approval from the

host country, reference number B074/KNMPB/032012 has been received. This letter

of approval confirms the contribution of the project activity “Installation of Waste Heat

Recovery Steam Boiler at Wirajaya Packindo” to the sustainable development of

Indonesia.

The Annex I Party is Germany. Germany ratified the Kyoto Protocol on

31/07/2002. The DNA is German Emission Trading Authority (DEHSt). The

information of the DNA has been confirmed by the validation team against the

relevant information on the UNFCCC CDM website

(http://cdm.unfccc.int/DNA/index.html). A letter from approval from the Annex I

Party dated: 01/08/2012, reference number E1.6-18410-0403/100 has been

received.

For details relating to this section, please refer to the Validation Protocol in

Appendix F.

4.2

Participation requirements

PT. Wirajaya Packindo is a private entity having its registered office in Indonesia.

KfW is a private entity having its registered office in Germany.

The contact details of the PPs are correctly provided in Annex 1 of the PDD.

Participation in the project activity of the PPs has been ٛ authorized, as confirmed in

the LoAs issued by the Parties concerned. The team confirmed that no entities other

than the ٛ authorized entities are indicated as project participants in the PDD.

For details relating to this section, please refer to the Validation Protocol in Appendix

F.

4.3

Project design document

The PDD was checked and confirmed as complete against the Guidelines for

completing the project design document form for small-scale CDM project, Version 01.

A valid form of the F-CDM-SSC-PDD is used that is the current form under CDM VVS

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 9 of 92

Revision 0.9, 07 November 2012

track as available on the UNFCCC-CDM website.

For details relating to this section, please refer to the Validation Protocol in Appendix

F.

4.4

Project description

The Project activity is recovery of waste heat from the existing gas turbine to generate

steam in a recycled-paper production factory owned by PT Wirajaya Packindo in

Indonesia. The project activity involves installation of a new waste heat recovery

boiler which utilises waste heat from the gas turbine and natural gas as

supplementary fuel. The steam required for the paper manufacturing process in the

existing line and planned new production line would have been generated from the

existing coal fired boilers. In the project scenario, the existing coal fired boilers will be

kept as stand by for emergencies. The project activity will reduce GHG emissions by

utilisation of waste heat and use of natural gas as fuel.

The details on the location of the project activity was confirmed as Karawaci SubDistrict, Regency of Tangerang, Desa Koang Jaya, Banten Province, Indonesia as

given in the section A.4.1 of the PDD. The geographic coordinates of the project

activity were confirmed as Latitude 106° 37’18.80’’ East and Longitude 6°12’14.03’’

South.

LRQA confirms that the project description included in the PDD is accurate and

complete. This description provides the reader with a clear understanding of the

precise nature of the project activity and the technical aspects of its implementation.

The project description was validated by document review including PDD and

supporting project documentation, official information of the host country and sector

information as publicly available, interview, and the on site visit.

Sustainable development

The host Party’s DNA confirmed the contribution of the project activity to the

sustainable development of the host Party.

Small scale CDM criteria

The project activity recovers and utilises waste heat from the existing gas turbine. The

project activity, therefore, is characterised as ‘Type III’ activity. Validation team

confirms from the review of PDD and its supporting documents, sectoral expertise and

on site visit that emission reductions from the project activity will not cross 60,000

tCO2e/annum every year throughout the crediting period.

Validation team confirms from the interview of the PP that it does not intend to change

the project design.

For details relating to this section, please refer to the Validation Protocol in Appendix F.

4.5

Baseline and monitoring methodology

Applicability of the selected methodology to the project activity

The project activity applied the approved baseline and monitoring methodologies:

AMS-III.Q. “Waste energy recovery (gas/heat/pressure) projects”, Version 4.0.

This version of the methodology is valid from 29/04/2011 and currently having an

“active” status.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 10 of 92

Revision 0.9, 07 November 2012

LRQA confirms unambiguously that the selected methodology is applicable to this

project activity. The project applicability was confirmed against each condition in the

approved methodology selected. Appendix F includes the list of each applicability

condition, the steps taken to validate each one and the conclusions about its

applicability to the proposed project activity.

For details relating to this section, please refer to the Validation Protocol in Appendix F.

Project boundary

The project boundary has been validated through documentation review on the overall

design document, EIA report, quotation and contract with equipment supplier, interview

and field survey that included the waste heat recovery system, gas turbine generator,

and paper mill where steam will be used. This information was substantiated via cross

check with the information obtained from the public sources by the validation team.

Through the processes taken, the validation team confirmed that the identified project

boundary, the selected sources and the gases were justified for the project activity and

they meet the requirements of the approved methodology.

Baseline identification

The baseline scenario identified in the PDD has been assessed against the

requirements in the approved methodology AMS-III.Q. “Waste energy recovery

(gas/heat/pressure) projects”, Version 4.0. LRQA can confirm that the procedure

included in this methodology to identify the most reasonable baseline scenario, has

been correctly applied.

The steps taken to assess the baseline identification are described in the Validation

protocol in Appendix F.

LRQA confirms that:

-

-

All the assumptions and data used by the project participants are listed in the PDD,

including their references and sources;

All documentation used is relevant for establishing the baseline scenario and

correctly quoted and interpreted in the PDD;

Assumptions and data used in the identification of the baseline scenario are

justified appropriately, supported by evidence and can be deemed reasonable;

Relevant national and/or sectoral policies and circumstances are considered and

listed in the PDD;

The approved baseline methodology has been correctly applied to identify the most

reasonable baseline scenario and the identified baseline scenario reasonably

represents what would occur in the absence of the proposed CDM project activity.

Algorithms and/or formula used to determine emission reductions

LRQA has confirmed that the steps taken and the equations applied to calculate

project emissions and baseline emissions and emission reductions comply with the

requirements of the approved methodology AMS IIIQ version 4.0.

The steps taken to assess the algorithms and/or formula used to determine emission

reductions are described in the Validation protocol in Appendix F.

LRQA confirms that:

•

•

•

All assumptions and data used by the project participants are listed in the PDD,

including their references and sources;

All documentation used by project participants as the basis for assumptions and

source of data is correctly quoted and interpreted in the PDD;

All values used in the PDD are considered reasonable in the context of the

proposed CDM project activity;

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 11 of 92

Revision 0.9, 07 November 2012

•

•

4.6

The baseline methodology has been applied correctly to calculate project emissions,

baseline emissions, leakage and emission reductions;

All estimates of the baseline emissions can be replicated using the data and

parameter values provided in the PDD.

Additionality of a project activity

The project additionality was demonstrated by the PP using the Guidelines on the

demonstration of additionality for small-scale project activities (Version 09.0).

Prior consideration of CDM

The start date of the project activity is 01/08/2011 based on the date of signing

Engineering, Procurement and Construction (EPC) contract with PT. Indoturbine. The

start date was confirmed from the review of EPC contract with PT. Indoturbine. The

start date was confirmed in accordance with the Glossary of CDM terms, Version 07.0.

The start date of the project activity was after 02/08/2008. Prior consideration of the

project was demonstrated through notification made to the DNA of Indonesia and

UNFCCC secretariat on 20/07/2011. Validation team confirmed the prior consideration

through the list of notifications available at UNFCCC website, Filled prior consideration

form dated: 18/07/2011, email submitted to UNFCCC dated: 20/07/2011 and

confirmation email received from the Indonesian DNA dated: 25/07/2011.

The steps taken to assess the prior serious consideration of the CDM are described in

the Validation protocol in Appendix F.

Identification of alternatives

The list in the Validation Protocol – Appendix F section 6.b, shows the alternatives

given in the PDD, and clearly states how LRQA has validated whether these

alternatives are credible and complete.

It is the opinion of LRQA that the list of alternatives provided in the PDD are credible

and complete considering the technology and circumstances of the proposed Project

activity as well as the investor business.

Investment analysis

The Investment analysis option has been used to demonstrate the additionality of the

proposed project activity. LRQA confirms that the PDD provides evidence that this

project activity would not be the most economically or financially attractive alternative.

The PPs have shown that the project activity is additional by demonstrating that the

financial returns of the proposed CDM project activity would be insufficient to justify the

required investment.

For assessing the additionality of this project activity LRQA has complied with the

latest version of the “Guidelines on the Assessment of Investment Analysis” as

provided by the CDM Executive Board and with other relevant guidance including the

latest guidelines on plant load factors “Guidelines for the reporting and validation of

plant load factors”.

For details about the validation of the parameters used in the financial calculations and

assessment of the benchmark applied, please refer to the Validation protocol in

Appendix F.

LRQA confirms that the underlying assumptions for the investment analysis are

appropriate and that the financial calculations are correct.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 12 of 92

Revision 0.9, 07 November 2012

4.7

Monitoring Plan

The PDD includes a Monitoring Plan based on the approved monitoring methodology

AMS III Q version 4.0.

LRQA confirms that the Monitoring Plan described in the PDD complies with the

requirements in the Monitoring Methodology and that the PPs will be able to apply

this Monitoring Plan following the monitoring arrangements described in it.

For details about the validation of the Monitoring Plan, please refer to the Validation

protocol in Appendix F.

4.8

Local stakeholder consultation

The PPs invited Local Stakeholders to comment on the proposed project activity on the

5/10/2011 before the publication of the PDD on the UNFCCC website. The local

stakeholder consultation meeting was held in Club House Modernland and Country

Golf, Tangerang and the following persons and entities attended this meeting.

-

Local people

Chief of village

Local authorities

The representatives of Local official agencies of Environment (BLHD

The representatives of PT. SEML’s management and staff

KfW representative

LRQA confirms that the stakeholder consultation process targeted stakeholders and

was appropriate for identifying stakeholders’ opinions about the project and collecting

their views.

For details about the steps taken to assess the adequacy of the Stakeholder

consultation, please refer to the Validation protocol in Appendix F.

4.9

Environmental impacts

LRQA has confirmed that the PPs have undertaken an environmental impact

assessment as required by the host country.

The PPs have submitted documentation to LRQA on the analysis of the environmental

impacts of this project activity in line with paragraph 37 (c) of the CDM modalities and

procedures.

For details about the document review and determination of whether the PPs have

undertaken the analysis of environmental impacts, please refer to the Validation

protocol in Appendix F.

4.10 Summary of Changes

Significant changes made to the original PDD published for Global Stakeholder

Consultation Process are summarised below. The PDD version 1 dated 20/10/2011

was modified and several changes occurred due to the result of validation process.

The PDD version 5.5 dated 04/12/2012 includes all these changes.

For details about the results of the responses to CARs and CLs, discussions on

revisions to project documentation and the detailed changes to the PDD coming from

the validation process, please refer to the Validation Findings Log in the Validation

Protocol in Appendix F.

Item

Description

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Value in PDD

Value in PDD

GSP

RfR

CAR/CL

Page 13 of 92

Revision 0.9, 07 November 2012

Item

Value in PDD

Value in PDD

GSP

RfR

CAR/CL

1.

Emission factor of the coal was corrected

based on CAR 02

92.80 tCO2/TJ

89.50 tCO2/TJ

CAR 02

2.

NPV was increased due to correction in

depreciation and interest calculations.

-4.03

USD

-1.35

USD

CL 05

3.

Monitoring plan was revised

NA

NA

CAR 03

4.

PP has removed the methodology AMS.II.D

based on the finding and clarification from

UNFCCC (SSC_582)

PP has changed the PDD from CDM-VVM

track to CDM-VVS track

NA

NA

CL 04

NA

NA

NA

5.

5

Description

Million

Million

6.

PP has revised the baseline efficiency of coal

boiler from the designed to most

conservative

value

in

the

applied

methodology

78%

100%

NA

7.

Based on the use of correct emission factor

of coal and conservative baseline efficiency

of coal boilers the ex-ante emission reduction

estimate were decreased

70,593

tCO2/annum

56,427

tCO2/annum

CAR 02

Comments by parties, stakeholders and NGOs

In line with the requirement of the Procedures for Processing and Reporting on

Validation of CDM project activities, the PDD is to be made publicly available for 30

days subject to confidentiality provisions agreed with the PP, to enable comments to

be received from Parties, stakeholders, and UNFCCC accredited NGOs on the

validation and registration requirements.

The PDD was made publicly available in line with the requirements of the procedure

for the period of 29/10/2011 to 27/11/2011 as per

http://cdm.unfccc.int/Projects/Validation/DB/SY7X21Y5CMMDJDGCAL596JSNKSDP9

N/view.html

No comment was received during this period.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 14 of 92

Revision 0.9, 07 November 2012

6

Validation Opinion

LRQA has undertaken the validation of the proposed project activity “Installation of

Waste Heat Recovery Steam Boiler at Wirajaya Packindo” based on the requirements

of CDM as set out in Article 12 of the Kyoto Protocol, the CDM M&P, the present

annex, subsequent decisions made by the COP/MOP and CDM-EB, and the other

rules applicable to the proposed project activity including the host country’s legislation

and its specific requirements for sustainable development.

The Project activity is recovery of waste heat from the existing gas turbine. The project

activity involves installation of a new 50TPH waste heat recovery boiler. The waste

heat recovery boiler recover the waste heat from the existing gas turbine of capacity 12

MW (15MW under ISO conditions) and it uses natural gas as supplementary fuel. The

steam generated from the waste heat recovery boiler will replace it from the existing

coal fired boilers. The project activity will reduce GHG emissions from the utilisation of

waste heat and use of natural gas.

To arrive at the final validation conclusions and opinion, LRQA carried out review of

project documents, assessment of compliance with and application of the approved

baseline and monitoring methodology as well as the approved methodological tools,

field survey and physical on site assessment of the project site and interviewing the

local stakeholders.

Through the validation process, the validation team identified 4 CARs and 6 CLs. The

PP has taken action on the raised issues and submitted to LRQA the revised PDD and

other supporting evidence.

The validation team is of the opinion that the proposed project activity conforms to all

the relevant UNFCCC requirements for the CDM as well as the host country’s national

requirements, and if implemented as designed, is likely to achieve the validated

emission reductions of 56,427 tCO2 and contribute to the sustainable development of

the host country. Therefore, LRQA requests the registration of “Installation of Waste

Heat Recovery Steam Boiler at Wirajaya Packindo” to the CDM Executive Board as a

CDM project activity.

Decision Maker

Michiaki Chiba

Climate Change Manager – Asia & Pacific

04/12/2012

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 15 of 92

Revision 0.9, 07 November 2012

7

Appendices

7.1

Appendix A: Letter of approval for the project by the host and

investing country DNA

Letter of Approval from Indonesia dated 06/03/2012

Letter of Approval from Germany dated 01/08/2012

7.2

Appendix B: List of documents reviewed

Category A documents (documents prepared by the PP)

• PDD Version 1 dated 20/10/2011

• PDD Version 2 dated 23/02/2012

• PDD Version 3 dated 30/03/2012

• PDD Version 04.0.0 dated 29/05/2012

• PDD Version 05.0.0 dated 16/07/2012

• PDD Version 05.1.0 dated 20/07/2012

• PDD Version 05.1.1 dated 07/08/2012

• PDD Version 05.2 dated 27/09/2012

• PDD Version 5.3 dated 05/10/2012

• PDD Version 5.4 dated 29/10/2012

• PDD Version 5.5 dated 04/12/2012

• Spreadsheet for IRR calculation, Version 01 dated 20/10/2011

• Spreadsheet for IRR calculation, Version 02 dated 23/02/2012

• Spreadsheet for IRR calculation, Version 03 dated 16/07/2012

• Emission reduction spreadsheet, Version 01 dated 20/10/2011

• Emission reduction spreadsheet, Version 02 dated 29/05/2012

• Emission reduction spreadsheet, Version 03 dated 16/07/2012

• Emission reduction spreadsheet, Version 04 dated 07/08/2012

• Emission reduction spreadsheet, Version 04.1 dated 27/09/2012

• Mass and Energy balance spreadsheet dated 07/08/2012

• Overall design documents for project Installation of Heat Recovery Steam Boiler at

Wirajaya Packindo

• Gas turbine manufacturer’s specifications

• Contract with HRSG supplier and EPC contractor between PT Wirajaya Packindo

and PT. Indoturbine dated 01/09/2011

• ERPA term sheet between PT Wirajaya Packindo and KfW dated 12/08/2011

• Sustainable development criteria set by host country DNA

(http://pasarkarbon.dnpi.go.id/web/index.php/komnasmpb/cat/5/kriteria-p.)

• Turbine specification and lifetime from Turbomach

• Letter of Designed operational life of HRSG by Mackenzie Industries Sdn Bhd

• Procedure for employee recruitment by PT Wirajaya Packindo

• Minutes of Meeting for CDM Stakeholder Consultation dated 05/10/2011

• Approval letter from Environmental Agency for Environmental Management and

Monitoring Plan dated 08/11/2011

• Contract for new paper machine duplex by supplier in China

• Contract for Coal Boiler by Shanghai Distribution co. Ltd, dated 05/06/2008 and

10/08/2008

• Business license for PT Wirajaya Packindo

• Prior consideration form submitted to UNFCCC dated 18/07/2011

• Commitment fee Invoice by Caterpillar dated 01/11/2010

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 16 of 92

Revision 0.9, 07 November 2012

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Invoice for boiler maintenance of pipe from PT. Zug Industry Indonesia dated

15/09/2011

Purchase order for boiler maintenance to Shanghai Chenguan Import and Export

co. Ltd dated 27/10/2011

Invoice for gas consumption from PT Gas Negara (PGN) dated 05/10/2009 and

04/10/2011

Agreement of grace period by Catterpilar finance

Offer to lease and acceptance between PT Wirajaya Packindo and PT Caterpillar

Finance Indonesia dated 08/09/2011

Offer for insurance for HRSG operation by ACA Asuransi dated 19/09/2011

Spreadsheet for coal price of July 2009 to August 2011

News translation on gas price increase in 2011 by Indonesia Finance Today

(14/09/2011), Liputan 6 SCTV (13/04/2011) and Kabarbisnis (07/10/2011)

PGN business presentation slides

News on gas export price increase from Jakarta Globe dated 15/09/2011

News on Indonesia: searching for gas supplies from Jakarta Post dated

05/09/2011

News on gas price renegotiation from Jakarta Post dated 07/09/2011

News on industrial gas price increase from Indo Finance dated 14/09/2011

News on BP Migas seeks to hike PGN gas price by 200% from Jakarta Globe

dated 2 August 2011

News on Kadin protest for industrial gas price increase from Kadin Sumatera Utara

website dated 29/09/2011

News on gas price increase by PGN to be reported to government from

Kabarbisnis dated 07/10/2011

Purchase order for Coal Boiler to Shanghai Distribution co. Ltd, dated 07/06/2008

Spreadsheet of plant historical data

2006 IPCC Guidelines for National Greenhouse Gas Inventories

Supporting data for CDM project by PT Wirajaya Packindo dated 23/07/2011

Spreadsheet data for Coal GCV

Gas composition before and after project activity

Gas turbine specification by Turbomach

Boiler specification report, dated 22/02/2011

Spreadsheet for CER calculation dated 14/11/2011

Diagram for heat mass balance by PT Wirajaya Packindo

Spreadsheet for GCV gas specification

DEG Technical Audit for energy optimization services by Siemens, dated

10/07/2011 to 15/07/2011

Electric power requirement information of baseline and HRSG

Gas specification of PT PGN dated 29/03/2011

Gas specification by Pertamina dated 27/03/2011

12 MW Operational capacity information

Letter from PGN on gas price increase dated: 08/05/2012, Ref:

069900.S/PP.01.01/SBU1/2012

Gas turbine mechanical and electrical drawings

Gas turbine manual

Gas turbine O&M Manual

Turbomach witness test of gas turbine dated: 05/09/2008

Gas Turbine Exhaust Silencer General Arrangement dated 15 April 2009

Email clarification from the German DNA on its requirements for approval dated:

06/11/2012

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 17 of 92

Revision 0.9, 07 November 2012

Category B documents (other documents referenced)

• Clean development mechanism validation and verification standard Version 03.0

• Guidelines for completing the simplified project design document (CDM-SSC-PDD)

and the form for proposed new small scale methodologies (CDM-SSC-NM),

Version 05 (14 September 2007)

• Project Design Document Form (CDM-SSC-PDD) Version 03

• Indicative simplified baseline and monitoring methodologies for selected small

scale CDM project activity categories AMS-III.Q “Waste energy recovery

(gas/heat/pressure) projects” version 04

• Tool to calculate project or leakage CO2 emissions from fossil fuel combustion

Version 2

• Tool to determine the remaining lifetime of equipment Version 1

• General guidelines to SSC CDM Methodologies Version 19.0

• Guidelines on the assessment of investment analysis Version 5

• Non-binding best practice examples to demonstrate additionality for SSC project

Activities (Annex 34, EB 35)

• Submission status of Prior Consideration of CDM to CDM Secretariat

http://cdm.unfccc.int/Projects/PriorCDM/notifications/index_html

• Indonesian DNA website: http://pasarkarbon.dnpi.go.id/web/index.php/home.html

• EB Clarification SSC 579

(http://cdm.unfccc.int/methodologies/SSCmethodologies/clarifications/40482)

• Bank of Indonesia website

• Google website for confirmation of geo-coordinates

• Project Mechanisms Act available on the website of German DNA

7.3

Appendix C: List of persons interviewed

Wirajaya Packindo

Budi Hartoyo H

Harimas Hutama

Ari Liberto

Eko Prasetyo

Muji Sarjono

Wira Rahardjo

KfW

Cynthia Hendrayani

Biosphere Capital

Thet Lin Thu

Angus McEwin

Local stakeholders

Mimin Priatna

Wawan

PT. PGN

Arys Djuanda

Rudiatmoko

Environmental Agency of Tangerang region (BPLH)

Agus Prasetyo

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 18 of 92

Revision 0.9, 07 November 2012

Arjono

Risdiana Setiawan

7.4

Appendix D: How due account has been taken to the public input

made to the validation requirements

The PDD was made publicly available in accordance with the requirements of the

Procedures for processing and reporting on validation of a CDM project activity for the

period of 29/10/2011 to 27/11/2011 as per

http://cdm.unfccc.int/Projects/Validation/DB/SY7X21Y5CMMDJDGCAL596JSNKSDP9

N/view.html

No comment was received during this period.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 19 of 92

Revision 0.9, 07 November 2012

7.5

Appendix E: Certificate of Appointment

Validation of “Installation of Waste Heat Recovery Steam Boiler

at Wirajaya Packindo”

We hereby certify that the following personnel have engaged in the validation process

that has fully satisfied the competence requirements of the validation of the CDM

project activity.

Name of Person

Assigned Roles

Ankush Jain

Cholid Bafagih

Hikmat Wijaya

M. Nursyam

Ketan Deshmukh

Brahim Abdullah

Chiba Michiaki

Team Leader

Team Member

Team Member

Sector Expert

Technical Reviewer

Sector Expert

Decision Maker

Signed by

Decision Maker

Michiaki Chiba

Climate Change Manager – Asia & Pacific

04/12/2012

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 20 of 92

Revision 0.9, 07 November 2012

7.6

Appendix F: Validation Protocol and findings log

LLOYDS REGISTER QUALITY ASSURANCE

Clean Development Mechanism

Validation Protocol and Findings

This document has been produced by the LRQA Validation Team after the completion of the desk review and the site visit.

It outlines the validated situation in relation to a number of criteria, including those defined in the Validation and Verification Standard (VVS) produced by the CDM

Executive Board.

The questions within this document must be completed in full and in your own words. The purpose of this protocol is to record LRQA’s opinion and LRQA’s findings.

If LRQA has identified issues requiring corrective action or clarification, make a reference in the ‘Conclusion’ column, and state details in the section marked ‘Findings’.

Conclusion

Validated situation

SECTION 1. Approval

Host Country Approval

1. Has the Host country DNA provided a written

approval?

2. Confirm that the letter has been issued by the

Party’s DNA and is valid for the proposed CDM

project activity under validation

3. Mention the means of validation employed to

assess the authenticity of the Letter of Approval.

Indicate the source of the LoA (for example, PP or

directly from the DNA)

1

Yes

No

NA

CAR 01 was issued as LoA was not submitted for validation. In response to the

finding, the PP has submitted the LoA. The resolution is as detailed in the findings

section of this protocol.

Yes

No

NA

The LoA is issued on 06/03/2012 by the National committee on CDM, which is the

DNA of the host Party as per http://cdm.unfccc.int/DNA/index.html. The LoA is

issued for the proposed project activity.

CAR 01

OK

The LoA was made available by the PP.

Validation team compared the LoA from the original submitted by the DNA.

Comparison with other approved projects by the DNA was also conducted to check

the authenticity of the letter (included project ref 5468 and 5240).

OK

OK

1

For each section and question where a YES / NO / NA answer is required, explain your choice.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date: 04/12/2012

Page 21 of 92

Revision 0.9, 07 November 2012

Validated situation

Conclusion

OK

4. Does the written Letter of Approval confirm the

following:

(a) The Party is a Party to the Kyoto Protocol

(including ratification)?

(b) Participation is voluntary?

(c) The proposed CDM project activity

contributes to the sustainable

development of the country?

(d) It refers to the precise proposed CDM

project activity title in the PDD being

submitted for registration?

Yes

No

NA

The LoA confirms:

(a) The host country Party ratified the KP on 28/07/2004.

(b) The participation is voluntary.

(c) The proposed project activity will assist the host country in achieving sustainable

development.

(d) LoA indicates the precise title of the proposed project activity as indicated in the

PDD

5. Is the letter of approval unconditional with respect

of (a) to (d) above?

Yes

No

NA

The LoA does not add any specific condition to the points stated therein

OK

6. Does the LoA from the host party acknowledge

the bundle activity (if applicable)?

Yes

OK

No

NA

Annex I Party Approval

7. Has the Annex I country DNA provided a written

approval?

8. Confirm that the letter has been issued by the

Party’s DNA and is valid for the proposed CDM

project activity under validation.

9. Mention the means of validation employed to

assess the authenticity of the Letter of Approval.

Indicate the source of the LoA (for example, PP or directly

from the DNA).

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Yes

No

NA

CAR 01 was issued as LoA from the Annex I Party has not been submitted for

validation. In response to finding the PP has submitted the LoA. The resolution is as

detailed in the findings section of this protocol.

Yes

No

NA

CAR 01 OK

LoA was confirmed from the list of projects available at the DNA website. Ref:

https://www.jicdm.dehst.de/promechg/pages/project1.aspx

OK

Page 22 of 92

Revision 0.9, 07 November 2012

OK

Validated situation

Conclusion

10. Does the written Letter of Approval confirm the

following:

(a) The Party is a Party to the Kyoto Protocol

(including ratification)?

(b) Participation is voluntary?

(c) It refers to the precise proposed CDM

project activity title in the PDD being

submitted for registration?

Yes

No

NA

The LoA confirms:

(a) The Annex-I country Party ratified the KP.

(b) The participation is voluntary.

(c) LoA indicates the precise title of the proposed project activity as indicated in the

PDD

OK

11. Is the letter of approval unconditional with respect

of (a) to (c) above?

Yes

No

NA

The LoA does not add any specific condition to the points stated therein

OK

Yes

CAR01

OK

Host Country and Annex I Party Approval

12. Do any of the Letters of Approval contain

additional specification of the project activity? Like:

- PDD Version number?

- Validation report version number?

Make sure that the request for registration is made on the

basis of the documents specified in any of the letters.

No

NA

LoAs from the host party DNA and Annex I Party do not include any specification of

the project activity, like specific version numbers of the PDD and validation report.

The LoA from the Annex I Party’s DNA refers to the project data base wherein

versions of the PDD and validation report earlier submitted are made available. The

project data base of German DNA is referring to PDD Version 4.0.0 and Validation

report Version 01.

The current versions are PDD Version 5.5 and the validation report Version 2.14 that

has accounted for issues raised during the internal review process at LRQA.

Validation team reviewed the Project Mechanisms Act and the email clarification sent

by the German DNA to the PP dated 06/11/2012 and confirmed that the German

DNA accepts a draft validation report for the approval even though the LoA refers to

the final validation report.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 23 of 92

Revision 0.9, 07 November 2012

Validated situation

Conclusion

SECTION 2. Participation

1

Confirm that the PPs are listed in a tabular form in

section A.3 of PDD and that this information is

consistent with the contact details provided in

Appendix 1 of the PDD and with the contact details in

the MoC.

2

Confirm that each of the PPs has been approved by

at least one Party involved.

3

Confirm that no entities other than those approved as

PPs are included in section A.3 of PDD.

4

Ensure that the approval of participation has been

issued from the relevant DNA. If in doubt verify this

with the corresponding DNA.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Host Party PP name in PDD/ A.4

PT Wirajaya Packindo

Host Party PP name in PDD/ Appendix 1

PT Wirajaya Packindo

Host Party PP name in MoC

PT Wirajaya Packindo

Annex 1 Party PP name in PDD/ A.4

KfW

CL 01 was raised as name of the PP

was inconsistent between section A.3

and Annex 1. In response to the finding,

the PP has corrected the name of the

PP, therefore, finding was closed. The

resolution is as detailed in the findings

section of this protocol.

Annex 1 Party PP name in PDD/

Appendix 1

KfW

Annex 1 Party PP name in MoC

KfW

CL-01

OK

Yes

No

NA

The PP, PT. Wirajaya Packindo is approved by the host Party, i.e. Indonesia, DNA.

The PP, KfW is approved by the Annex-I Party, i.e. Germany, DNA.

Yes

No

NA

CAR01

OK

The approval by the host country DNA and Annex I Party DNA has been issued by

the correct organizations. Validation team had also confirmed the LoAs from the

similar cases. LoA was also confirmed from the German DNA’s website at

https://www.jicdm.dehst.de/promechg/pages/project1.aspx

CAR01

OK

Page 24 of 92

Revision 0.9, 07 November 2012

CAR01

OK

Validated situation

Conclusion

SECTION 3. Modalities of communications

1

Validate the corporate identity of all the PPs and the focal

point included in the MoC letter:

- Validate the signatures

- Validate the employment status.

To validate this use any of the following options:

a. Directly checking with evidence from PPs and the

corresponding companies, for example, contracts,

personal identity card or passport, HR records.

b. Notarised documentation, e.g power of attorney for

signing on behalf of the company and the other PPs.

c. Written confirmation from the PP that all the personal

details are valid and accurate.

2

If a written confirmation (option c) is chosen from the

options above, the following issues shall be validated:

- The PP sending the written confirmation and signing

it shall be the one signing the contract with LRQA.

- The person signing the written confirmation and the

person signing the MoC (if they are different persons)

are duly authorised to do so on behalf of all the PPs,

that is, they have a signed authorisation from the

other PPs and the identity and role of the person who

has signed this authorisation has been checked.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Validation team confirmed the corporate identity of the PPs from the signed

validation contract, HRSG contract and ERPA term sheet.

Further, written confirmation has been submitted by the PT. Wirajaya Packindo

on the corporate identity, name & employment status and specimen signatures

of the signatory of MoC.

OK

Corporate identity, name, employment status and specimen signature were

confirmed from the note by Board of Directors of KfW, ERPA and website of

KfW.

The written confirmation by the PP was submitted. The signature in the written

confirmation was checked with other contracts of the PP made available for

validation.

Page 25 of 92

Revision 0.9, 07 November 2012

OK

3

Has the MoC been completed as per the latest

“Procedures for MoC between the project participants

and the Executive Board”?

- No modifications to the template / form should be made

and each document should be clearly dated

- Title of the project and names of project participants and

focal points should be fully consistent with those

indicated in all other project documentation

- Focal point scopes should be clearly and correctly

indicated

- Contact details and specimen signatures of focal point

entities including those of project participants in Annex 1

should be correctly entered. Only one telephone, fax,

email contact should be entered per authorized

signatory. In cases where additional contact details are

included, only the first indicated information will be taken

into account and only the official business address of the

proposed entity should be provided on the F-CDMMOC form.

- The Statement of Agreement in Section 3 should be

signed by one authorized signatory for each project

participant; signatures made available in Section 3

should correspond to those indicated in the related

Annex 1 document; focal point entities who are not

designated as project participants should not sign

Section 3.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Yes

No

NA

OK

MoC is consistent with the PDD.

Validation team confirms that:

1. No modification in the template has been made.

2. Dates have been clearly mentioned in the MoC.

3. Title of the project and names of project participants and focal points are

fully consistent with the PDD. The PPs, PT. Wirajaya Packindo and KfW,

consistent between PDD, and the MoC.

4. Focal point scopes are clearly and correctly indicated

5. Statement of Agreement in Section 3 is signed by one authorized

signatory of project participant.

Page 26 of 92

Revision 0.9, 07 November 2012

Validated Situation

Conclusion

SECTION 4. Project design document

1. Is the project activity Small Scale or Normal Scale?

2. Has the PDD used the latest template and guidance

from the CDM Executive Board available on the

UNFCCC CDM Website?

Check outputs from the completeness check.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Normal Scale

Small Scale

(cross as appropriate)

Yes

Bundled Small Scale

No

OK

OK

F-CDM-SSC-PDD template Version 04.1 and Guidelines for Completing the

Project Design Document form for small-scale CDM project activities, version

01.0, which are the current versions for CDM VVS track available in UNFCCC

CDM website, are used.

Page 27 of 92

Revision 0.9, 07 November 2012

Validated situation

Conclusion

SECTION 5. Project description

1. Describe the process undertaken to validate that the

description of the proposed CDM project activity as

contained in the PDD sufficiently covers all relevant

elements, is accurate, and that it provides the reader

with a clear understanding of the nature of the

proposed CDM project activity.

The project activity is recovery of waste heat from the existing 12MW gas

turbine to generate steam. The steam generated from the project activity will be

used in the existing and new paper production lines. The project activity involves

installation of waste heat recovery boiler of capacity 50TPH. The waste heat

recovery boiler uses waste heat from the gas turbine. Additional energy for

generation of steam will be supplied through natural gas. Prior to the project

activity the equivalent steam would have been generated through the existing

coal based boilers. In the absence of the project activity, the equivalent steam

would have been generated from the existing coal based boilers. The project

activity reduces the GHG emissions from the utilisation of waste heat and use of

cleaner fossil fuel.

CL-02

OK

During the process of validation, LRQA confirmed the capacity, unique

identification of project activity, estimated steam generation, technical

specification and necessary clearances required/taken for the project activity.

The list of documents reviewed during the course of validation is presented

under Appendix B.

CL 02 was raised on inconsistency in the capacity of gas turbine. In response to

the finding, the PP has clarified that designed capacity was based on

International Standards Organisation (ISO) test conditions whereas actual

capacity was based on site conditions. Relevant section of the PDD was

corrected. The resolution is detailed in the findings section of this protocol.

2. Confirm that the exact project location is provided in

the PDD with Geographical coordinates, check the

accuracy of them and the format of the notation

(Grades, minutes, seconds or decimal indicating

latitude N or S and Longitude E or W)

Please include here the Geographical coordinates:

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

The PDD provides the exact project location with geographical coordinates.

The project activity is located at Koang Jaya village, about 1 hour drive north

west of Jakarta, the capital city of Indonesia. The geographical coordinates of

the project activity are:

6°12’14.03’’ S and 106° 37’18.80’’ E

The geographical coordinates of the project site were confirmed through

document review, i.e. Google website, and during the site visit.

Page 28 of 92

Revision 0.9, 07 November 2012

OK

Conclusion

Validated situation

3. Confirm that the physical site inspection reflects the

description in the PDD of the proposed CDM project

activity.

The physical site inspection was conducted during the site visit. During the site

visit, construction of the project was under progress. The process steam

required for the paper mill is being generated by the existing coal fired boilers.

Existing gas turbine was used to meet the electricity requirement of the paper

mill. Waste heat from the gas turbine was released in the atmosphere.

Therefore, team confirms the description given in the PDD to be accurate.

OK

4. If the team did not undertake a physical site

inspection, describe the justification as approved by

the CDM Quality Manager. (VVM 01.2: 60-61)

The team has visited the site from 13/12/2011 to 14/12/2011. During this period,

the team visited the manufacturing facility including paper mill, gas turbine

generator unit, and waste heat recovery boiler, gas supplier, official

departments.

OK

Describe briefly the physical site inspection: Travel

details and installations, facilities and buildings visited.

5. If the proposed CDM project activity involves the

alteration of an existing installation or process, ensure

that the project description clearly states the

differences resulting from the project activity compared

to the pre-project situation.

6. Potential public funding for the project from Parties in

Annex I shall not be a diversion of official development

assistance (ODA).

Pre-project

No waste heat recovery system was

installed at gas turbine

Steam sourced from the existing coal

fired boilers.

Project activity

OK

Recovery and utilisation of waste heat

from the existing gas turbine to

generate steam. Natural gas will be

used as supplementary fuel of the new

waste heat recovery boiler.

PDD section A.4.4 confirms that there is no public funding or Official

Development Assistance from Annex I countries.

OK

The validation team interviewed the PP and the stakeholders and confirmed that

the project activity is funded by equity of the private investors and loan from the

private banks. However, the debt/equity ratio of the project activity is not yet

determined.

7. If the project activity is a small scale one, confirm that

it is not a debundled component of a large scale

project, in line with appendix C of the simplified M&P

for SSC CDM project activities and the Guidelines for

assessment of de-bundling for SSC project activities.

PDD Section A.4.5 confirming that it is not a debundled component of a large

scale project, in line with appendix C of the simplified M&P for SSC CDM project

activities and the Guidelines for assessment of de-bundling for SSC project

activities.

Through site visit, the validation team confirmed that there was no similar project

whose project boundary is within 1 Km of the project boundary of the project

activity.

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 29 of 92

Revision 0.9, 07 November 2012

OK

Validated situation

Conclusion

SECTION 6. Baseline and monitoring methodology

1. Have the baseline and monitoring methodologies selected by

the project participants been previously approved by the CDM

Executive Board, that is, does it appear on the methodologies

page of the UNFCCC website?

2. If the project activity is a Small Scale one; does it qualify within

the threshold of the three possible types of small scale

projects? Confirm information provided in the PDD.

3. If the project activity is a Small Scale one; which approved

small scale methodology does the project apply? Confirm that

the SSC methodology is applied with the general guidelines to

SSC CDM methodologies.

4. Determine whether the methodology selected is applicable to

the project activity including that the used version is valid.

Describe steps taken to assess the relevant information contained in the

PDD in the table below.

Yes

No

NA

The project activity applies the small-scale methodology, AMS-III.Q

version 4.0 “Waste Energy Recovery (gas/heat/pressure) Projects”.

CL-04 was raised on application of combination of methodologies

AMS.III.Q and AMS.II.D. PP has removed the methodology AMS.II.D.

The resolution is detailed in the findings section of this protocol.

CL-04

OK

The project activity recovers and utilises waste heat from the existing

gas turbine. Therefore, the project activity is characterised as ‘Type III’

activity. Validation team confirms from the review of the PDD and its

supporting evidence; and its sectoral expertise that the estimated

annual emission reduction from the project activity is 56,427

tCO2e/annum, less than 60,000 tCO2e/year, every year throughout the

crediting period.

The project applies the methodology of “Waste Energy Recovery

(gas/heat/pressure) Projects” AMS-III.Q, in conjunction with the general

guidelines of SSC-CDM methodologies.

OK

The project activity applies the version 4.0 of the small-scale

methodology AMS.III.Q. This version of the methodology is the most

recent during the completion of this report.

CL 03 was raised as applicable version of the guidelines was not

referred in the PDD. PP has revised the PDD to mention the applicable

version of guidelines. The resolution is detailed in the findings section

of this protocol.

CL-03

OK

OK

No.

Applicability conditions in the AMS-III.Q

version 4.0

Information in the PDD

Steps taken to assess PDD

information

Conclusion

1

The category is for project activities that utilize

The project will utilise waste heat generated

The proposed project utilises waste heat

OK

LRQA Reference: ENQ/2607/11/IRE

MSBSF43847

Date 04/12/2012

Page 30 of 92

Revision 0.9, 07 November 2012

waste gas and/or waste heat at existing

facilities as an energy source for:

(a) Cogeneration; or

(b) Generation of electricity; or

(c) Direct use as process heat; or

(d) Generation of heat in elemental process

(e.g. steam, hot water, hot oil, hot air); or

(e) Generation of mechanical energy.

at the existing facility as an energy source for

generation of heat in elemental process (i.e.

steam)

for generation of steam. Validation team

confirmed the description from the review

of PDD, EPC contract for waste heat

recovery boiler and site visit.

2

The category is also applicable to project

activities that use waste pressure to generate

electricity at existing facilities

The Project does not involve the use of waste

pressure

OK

3

The recovery of waste gas/heat/pressure

should be a new initiative (no waste

gas/heat/pressure was recovered from the

project activity source prior to the

implementation of the project activity)

Measures are limited to those that result in

emission reductions of less than or equal to

60 kt CO2 equivalent annually

Prior to the implementation of the project, no

waste gas/heat/pressure was recovered from

the project activity source

Not relevant.

Validation team confirmed from the

review of PDD, EPC contract for waste

heat recovery boiler, and site visit that

the project activity does not involve use

of waste pressure.

Validation team confirmed the description

from the review of EIA report,

manufacturer’s specification of gas

turbine, and site visit.

The project activity is expected to result in

emission reductions of less than 60kt of CO2

equivalent annually

Validation team confirmed from the

review of PDD and emission reduction

spreadsheet that the emission reduction

for the project has been correctly

calculated as 56,427tCO2e/annum,

every year during the crediting period.

OK

The steam produced using the waste heat is

measurable

Validation team confirmed from the

review of PDD, site visit and its sectoral

expertise that energy output from the

steam produced is measurable.

OK

Energy generated in the project activity is

entirely used within the industrial facility

Validation team confirmed from the

review of PDD, interview of the PP, site

visit and its sectoral expertise that energy

OK

4

5

(a)

(b)

OK

The category is applicable under the following

conditions:

The energy produced with the recovered waste