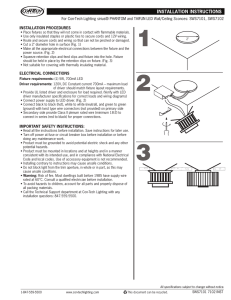

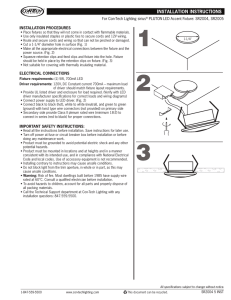

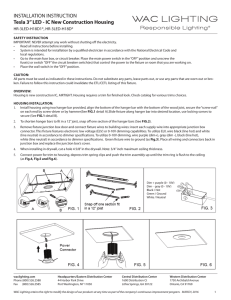

Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 Contents lists available at ScienceDirect Robotics and Computer-Integrated Manufacturing journal homepage: www.elsevier.com/locate/rcim Review A review and analysis of current computer-aided fixture design approaches Iain Boyle a,n, Yiming Rong a, David C. Brown b a b CAM Lab, Department of Mechanical Engineering, Worcester Polytechnic Institute, 100 Institute Road, Worcester, MA 01609, USA Computer Science Department, Worcester Polytechnic Institute, 100 Institute Road, Worcester, MA 01609, USA a r t i c l e in fo abstract Article history: Received 17 September 2009 Received in revised form 12 May 2010 Accepted 27 May 2010 A key characteristic of the modern market place is the consumer demand for variety. To respond effectively to this demand, manufacturers need to ensure that their manufacturing practices are sufficiently flexible to allow them to achieve rapid product development. Fixturing, which involves using fixtures to secure workpieces during machining so that they can be transformed into parts that meet required design specifications, is a significant contributing factor towards achieving manufacturing flexibility. To enable flexible fixturing, considerable levels of research effort have been devoted to supporting the process of fixture design through the development of computer-aided fixture design (CAFD) tools and approaches. This paper contains a review of these research efforts. Over seventy-five CAFD tools and approaches are reviewed in terms of the fixture design phases they support and the underlying technology upon which they are based. The primary conclusion of the review is that while significant advances have been made in supporting fixture design, there are primarily two research issues that require further effort. The first of these is that current CAFD research is segmented in nature and there remains a need to provide more cohesive fixture design support. Secondly, a greater focus is required on supporting the detailed design of a fixture’s physical structure. & 2010 Elsevier Ltd. All rights reserved. Keywords: Computer-aided fixture design Fixture design Fixture planning Fixture verification Setup planning Unit design Contents 1. 2. 3. 4. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Fixture design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Current CAFD approaches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.1. Setup planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.1.1. Approaches to setup planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.2. Fixture planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.2.1. Approaches to defining the fixturing requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3.2.2. Approaches to non-optimized layout planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3.2.3. Approaches to layout planning optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3.3. Unit design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3.3.1. Approaches to conceptual unit design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3.3.2. Approaches to detailed unit design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3.4. Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.4.1. Approaches to constraining requirements verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.4.2. Approaches to tolerance requirements verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.4.3. Approaches to collision detection requirements verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.4.4. Approaches to usability and affordability requirements verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3.5. Representation of fixturing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 An analysis of CAFD research . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.1. The segmented nature of CAFD research . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2. Effectively supporting unit design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.3. Comprehensively formulating the fixturing requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 n Corresponding author. Current address: Department of Design, Manufacture and Engineering Management, University of Strathclyde, James Weir Building, 75 Montrose Street, Glasgow G1 1XJ, UK. Tel.: + 44 141 548 2374; fax: + 44 141 552 0557. E-mail address: iain.m.boyle@strath.ac.uk (I. Boyle). 0736-5845/$ - see front matter & 2010 Elsevier Ltd. All rights reserved. doi:10.1016/j.rcim.2010.05.008 2 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 5. 4.4. Validating CAFD research outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 1. Introduction A key concern for manufacturing companies is developing the ability to design and produce a variety of high quality products within short timeframes. Quick release of a new product into the market place, ahead of any competitors, is a crucial factor in being able to secure a higher percentage of the market place and increased profit margin. As a result of the consumer desire for variety, batch production of products is now more the norm than mass production, which has resulted in the need for manufacturers to develop flexible manufacturing practices to achieve a rapid turnaround in product development. A number of factors contribute to an organization’s ability to achieve flexible manufacturing, one of which is the use of fixtures during production in which workpieces go through a number of machining operations to produce individual parts which are subsequently assembled into products. Fixtures are used to rapidly, accurately, and securely position workpieces during machining such that all machined parts fall within the design specifications for that part. This accuracy facilitates the inter-changeability of parts that is prevalent in much of modern manufacturing where many different products feature common parts. The costs associated with fixturing can account for 10–20% of the total cost of a manufacturing system [1]. These costs relate not only to fixture manufacture, assembly, and operation, but also to their design. Hence there are significant benefits to be reaped by reducing the design costs associated with fixturing and two approaches have been adopted in pursuit of this aim. One has concentrated on developing flexible fixturing systems, such as the use of phase-changing materials to hold workpieces in place [2] and the development of commercial modular fixture systems. However, the significant limitation of the flexible fixturing mantra is that it does not address the difficulty of designing fixtures. To combat this problem, a second research approach has been to develop computer-aided fixture design (CAFD) systems that support and simplify the fixture design process and it is this research that is reviewed within this paper. Section 2 describes the principal phases of and the wide variety of requirements driving the fixture design process. locating unit Subsequently in Section 3 an overview of research efforts that have focused upon the development of techniques and tools for supporting these individual phases of the design process is provided. Section 4 critiques these efforts to identify current gaps in CAFD research, and finally the paper concludes by offering some potential directions for future CAFD research. Before proceeding, it is worth noting that there have been previous reviews of fixturing research, most recently Bi and Zhang [1] and Pehlivan and Summers [3]. Bi and Zhang, while providing some details on CAFD research, tend to focus upon the development of flexible fixturing systems, and Pehlivan and Summers focus upon information integration within fixture design. The value of this paper is that it provides an in-depth review and critique of current CAFD techniques and tools and how they provide support across the entire fixture design process. 2. Fixture design This section outlines the main features of fixtures and more pertinently of the fixture design process against which research efforts will be reviewed and critiqued in Sections 3 and 4, respectively. Physically a fixture consists of devices that support and clamp a workpiece [4,5]. Fig. 1 represents a typical example of a fixture in which the workpiece rests on locators that accurately locate it. Clamps hold the workpiece against the locators during machining thus securing the workpiece’s location. The locating units themselves consist of the locator supporting unit and the locator that contacts the workpiece. The clamping units consist of a clamp supporting unit and a clamp that contacts the workpiece and exerts a clamping force to restrain it. Typically the design process by which such fixtures are created has four phases: setup planning, fixture planning, unit design, and verification, as illustrated in Fig. 2, which is adapted from Kang et al. [6]. During setup planning workpiece and machining information is analyzed to determine the number of setups required to perform all necessary machining operations and the appropriate locating datums for each setup. A setup represents the combination of processes that can be performed on a clamp baseplate clamp supporting unit workpiece Fig. 1. A typical fixture (a) without and (b) with a workpiece. I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 workpiece CAD model, machining information, design considerations Setup planning: Identify setups Determine locating datums Fixture planning: Define fixturing requirements Determine fixture layout plan Unit design: Conceptual unit design Detailed unit design Verification: Verify fixture against fixturing requirements (Table 1) finished setup plan, fixture design, materials listing Fig. 2. The fixture design process (adapted from Kang et al. [6]). 3 can be grouped into six classes (Table 1). The ‘‘physical’’ requirements class is the most basic and relates to ensuring the fixture can physically support the workpiece. The ‘‘tolerance’’ requirements relate to ensuring that the locating tolerances are sufficient to locate the workpiece accurately and similarly the ‘‘constraining’’ requirements focus on maintaining this accuracy as the workpiece and fixture are subjected to machining forces. The ‘‘affordability’’ requirements relate to ensuring the fixture represents value, for example in terms of material, operating, and assembly/disassembly costs. The ‘‘collision detection’’ requirements focus upon ensuring that the fixture does not collide with the machining path, the workpiece, or indeed itself. The ‘‘usability’’ requirements relate to fixture ergonomics and include for example needs related to ensuring that a fixture features error-proofing to prevent incorrect insertion of a workpiece, and chip shedding, where the fixture assists in the removal of machined chips from the workpiece. As with many design situations, the conflicting nature of these requirements is problematic. For example a heavy fixture can be advantageous in terms of stability but can adversely affect cost (due to increased material costs) and usability (because the increased weight may hinder manual handling). Such conflicts add to the complexity of fixture design and contribute to the need for the CAFD research reviewed in Section 3. Table 1 Fixturing requirements. Generic requirement Abstract sub-requirement examples Physical The fixture must be physically capable of accommodating the workpiece geometry and weight. The fixture must allow access to the workpiece features to be machined. Tolerance The fixture locating tolerances should be sufficient to satisfy part design tolerances. Constraining The fixture shall ensure workpiece stability (i.e., ensure that workpiece force and moment equilibrium are maintained). The fixture shall ensure that the fixture/workpiece stiffness is sufficient to prevent deformation from occurring that could result in design tolerances not being achieved. Fig. 3. The six degrees of freedom. workpiece without having to alter the position or orientation of the workpiece manually. To generate a fixture for each setup the fixture planning, unit design, and verification phases are executed. During fixture planning, the fixturing requirements for a setup are generated and the layout plan, which represents the first step towards a solution to these requirements is generated. This layout plan details the workpiece surfaces with which the fixture’s locating and clamping units will establish contact, together with the surface positions of the locating and clamping points. The number and position of locating points must be such that a workpiece’s six degrees of freedom (Fig. 3) are adequately constrained during machining [7] and there are a variety of conceptual locating point layouts that can facilitate this, such as the 3-2-1 locating principle [4]. In the third phase, suitable unit designs (i.e., the locating and clamping units) are generated and the fixture is subsequently tested during the verification phase to ensure that it satisfies the fixturing requirements driving the design process. It is worth noting that verification of setups and fixture plans can take place as they are generated and prior to unit design. Fixturing requirements, which although not shown in Kang et al. [6] are typically generated during the fixture planning phase, Affordability The fixture cost shall not exceed desired levels. The fixture assembly/disassembly times shall not exceed desired levels. The fixture operation time shall not exceed desired levels. Collision prevention The fixture shall not cause toolpath–fixture collisions to occur. The fixture shall cause workpiece–fixture collisions to occur Usability (other than at the designated locating and clamping positions). The fixture shall not cause fixture–fixture collisions to occur (other than at the designated fixture component connection points). The fixture weight shall not exceed desired levels. The fixture shall not cause surface damage at the workpiece/fixture interface. The fixture shall provide tool guidance to designated workpiece features. The fixture shall ensure error-proofing (i.e., the fixture should prevent incorrect insertion of the workpiece into the fixture). The fixture shall facilitate chip shedding (i.e., the fixture should provide a means for allowing machined chips to flow away from the workpiece and fixture). 4 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 3. Current CAFD approaches This section describes current CAFD research efforts, focusing on the manner in which they support the four phases of fixture design. Table 2 provides a summary of research efforts based upon the design phases they support, the fixture requirements they seek to address (bold text highlights that the requirement is addressed to a significant degree of depth, whilst normal text that the degree of depth is lesser in nature), and the underlying technology upon which they are primarily based. Sections 3.1–3.4 describes different approaches for supporting setup planning, fixture planning, unit design, and verification, respectively. In addition, Section 3.5 discusses CAFD research efforts with regard to representing fixturing information. 3.1. Setup planning Setup planning involves the identification of machining setups, where an individual setup defines the features that can be machined on a workpiece without having to alter the position or orientation of the workpiece manually. Thereafter, the remaining phases of the design process focus on developing individual fixtures for each setup that secure the workpiece. From a fixturing viewpoint, the key outputs from the setup planning stage are the identification of each required setup and the locating datums (i.e., the primary surfaces that will be used to locate the workpiece in the fixture). The key task within setup planning is the grouping or clustering of features that can be machined within a single setup. Machining features can be defined as the volume swept by a cutting tool, and typical examples include holes, slots, surfaces, and pockets [8]. Clustering of these features into individual setups is dependent upon a number of factors (including the tolerance dependencies between features, the capability of the machine tools that will be used to create the features, the direction of the cutting tool approach, and the feature machining precedence order), and a number of techniques have been developed to support setup planning. Graph theory and heuristic reasoning are the most common techniques used to support setup planning, although matrix based techniques and neural networks have also been employed. 3.1.1. Approaches to setup planning The use of graph theory to determine and represent setups has been a particularly popular approach [9–11]. Graphs consist of two sets of elements: vertices, which represent workpiece features, and edges, which represent the relationships that exist between features and drive setup identification. Their nature can vary, for example in Sarma and Wright [9] consideration of feature machining precedence relationships is prominent, whereas Huang and Zhang [10] focus upon the tolerance relationships that exist between features. Given that these edges can be weighted in accordance with the tolerance magnitudes, this graph approach can also facilitate the identification of setups that can minimize tolerance stack up errors between setups through the grouping of tight tolerances. However, this can prove problematic given the difficulty of comparing the magnitude of different tolerance types to each other thus Huang [12] includes the use of tolerance factors [13] as a means of facilitating such comparisons, which are refined and extended by Huang and Liu [14] to cater for a greater variety of tolerance types and the case of multiple tolerance requirements being associated with the same set of features. While some methods use undirected graphs to assist setup identification [11], Yao et al. [15], Zhang and Lin [16], and Zhang et al. [17] use directed graphs that facilitate the determination and explicit representation of which features should be used as locating datums (Fig. 4) in addition to setup identification and sequencing. Also, Yao et al. refine the identified setups through consideration of available machine tool capability in a two stage setup planning process. Experiential knowledge, in the form of heuristic reasoning, has also been used to assist setup planning. Its popularity stems from the fact that fixture design effectiveness has been considered to be dependent upon the experience of the fixture designer [18]. To support setup planning, such knowledge has typically been held in the form of empirically derived heuristic rules, although object oriented approaches have on occasion been adopted [19]. For example Gologlu [20] uses heuristic rules together with geometric reasoning to support feature clustering, feature machining precedence, and locating datum selection. Within such heuristic approaches, the focus tends to fall upon rules concerning the physical nature of features and machining processes used to create them [21,22]. Although some techniques do include feature tolerance considerations [23], their depth of analysis can be less than that found within the graph based techniques [24]. Similarly, kinematic approaches [25] have been used to facilitate a deeper analysis of the impact of tool approach directions upon feature clustering than is typically achieved using rule-based approaches. However, it is worth noting that graph based approaches are often augmented with experiential rule-bases to increase their overall effectiveness [16]. Matrix based approaches have also been used to support setup planning, in which a matrix defining feature clusters is generated and subsequently refined. Ong et al. [26] determine a feature precedence matrix outlining the order in which features can be machined, which is then optimized against a number of cost indicators (such as machine tool cost, change over time, etc.) in a hybrid genetic algorithm-simulated annealing approach through consideration of dynamically changing machine tool capabilities. Hebbal and Mehta [27] generate an initial feature grouping matrix based upon the machine tool approach direction for each feature which is subsequently refined through the application of algorithms that consider locating faces and feature tolerances. Alternatively, the use of neural networks to support setup planning has also been investigated. Neural networks are interconnected networks of simple elements, where the interconnections are ‘‘learned’’ from a set of example data. Once educated, these networks can generate solutions for new problems fed into the network. Ming and Mak [28] use a neural network approach in which feature precedence, tool approach direction, and tolerance relationships are fed into a Kohonen selforganizing neural network to group operations for individual features into setups. 3.2. Fixture planning Fixture planning involves the comprehensive definition of a fixturing requirement in terms of the physical, tolerance, constraining, affordability, collision prevention, and usability requirements listed in Table 1, and the creation of a fixture layout plan. The layout plan represents the first part of the fixture solution to these requirements, and specifies the position of the locating and clamping points on the workpiece. Many layout planning approaches feature verification, particularly with regard to the constraining requirements. Typically this verification forms part of a feedback loop that seeks to optimize the layout plan with respect to these requirements. Techniques used to support fixture planning are now discussed with respect to fixture requirement definition, layout planning, and layout optimization. I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 5 Table 2 Current CAFD approaches. Research effort Amaral et al. [74] An et al. [63] Bansal et al. [23] Boyle et al. [31] Brost and Goldberg [40] Cai et al. [25] Camelio et al. [79] Cecil [66] Deng and Melkote [30] Gologlu [20] Hebbal and Mehta [27] Hu and Rong [84] Huang [12] Huang and Liu [14] Huang and Zhang [10] Hunter et al. [32] Hunter et al. [33] Hurtado and Melkote [68] Hurtado and Melkote [67] Joneja and Chang [34] Kang et al. [6] Kashyap and DeVries [44] Kaya [47] Kim et al. [24] Kong and Ceglarek [53] Krishnakumar and Melkote [45] Krishnakumar et al. [46] Kumar and Nee [18] Kumar et al. [60] Kumar et al. [59] Kumar et al. [82] Lee et al. [54] Li et al. [36] Li and Melkote [51] Liao and Hu [29] Lin and Huang [38] Liu and Strong [70] Mervyn et al. [88] Mervyn et al. [65] De Meter [50] Ming and Mak [28] Nee and Kumar [35] Nnaji and Alladin [55] Ong et al. [26] Pelinescu and Wang [42] Peng et al. [64] Perremans [57] Rai and Xirouchakis [76] Rameshbabu and Shunmugam [21] Ratchev et al. [75] Roy and Liao [83] Roy and Liao [39] Roy and Liao [72] Ryll et al. [81] Sarma and Wright [9] Satyanarayana and Melkote [78] Siebenaler and Melkote [77] Song and Rong [71] Trappey and Liu [69] Vallapuzha et al. [48] Waiyagan and Bohez [22] Wang [80] Wang and Rong [37] Wang et al. [41] Wu et al. [58] Wu et al. [61] Wu and Chan [43] Wu and Zhang [19] Wu et al. [73] Yao et al. [15] Zhang et al. [17] Zhang and Lin [16] Zhou et al. [11] SP FP UD | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | V Requirements considered Underlying technology | | | | | | | | | | | | | | | | | | | | | | | PR, CR PR PR, TR, CR PR, TR, AR, CR, CDR, UR PR, CR PR, TR PR, TR PR, CR PR, CR PR, TR PR, TR, AR CDR PR, TR PR, TR PR, TR PR, TR PR, TR, CR PR, CR PR, CR PR, CR PR, TR, CR PR, CR PR, CR PR, TR PR PR, CR PR, CR PR, TR, CR, UR PR, AR PR PR, CDR PR PR PR, CR PR, CR PR PR, CR PR PR, CR PR, CR PR, TR PR, TR, CR, AR, CDR PR, CR PR, AR PR, CR PR, CDR PR PR, CR PR PR, CR PR, CR, CDR PR, CR PR, CR PR, TR, CDR PR, AR PR, CR PR, CR PR, CR PR, CR PR, CR PR PR, TR PR, TR PR, CR PR PR, TR, CR PR, CR PR, TR PR, CR, UR PR, TR, AR PR, TR PR, TR PR, TR Displacement optimization Parametric modeling Rule-based approach, tolerance sensitivity analysis Case-based reasoning with displacement analysis Geometry and graphical force analysis Kinematic algorithm Kinematic variation analysis Stress fracture analysis Force analysis using Particle Swarm Optimization [90] Heuristic rule-base approach with geometric reasoning Matrix analysis Augmented two dimensional geometric overlay Graph theory using tolerance factors Graph theory using tolerance normalization Graph theory using tolerance analysis Rule-based approach Rule-based approach Stiffness-displacement analysis Optimized stiffness-displacement analysis Heuristic preferences with screw-set theory Geometric and kinetic model analysis Displacement optimization using penalty-function methods Genetic Algorithm (GA) based optimized stiffness-displacement analysis Qualitative rule-based analysis Procrustes-based pairwise optimization Displacement optimization using GA Displacement optimization using GA Case-based reasoning GA/neural network Rule induction and re-use Swept volume analysis Genetic algorithm optimization Case-based reasoning Nonlinear optimization algorithm Finite element and nonlinear rigid body dynamics analysis Group technology/neural network Force and moment analysis Heuristic rule-base Non-optimized evolutionary algorithm Pseudo-gradient based optimization Neural network Rule-based approach augmented with FEA Rule-based approach, stability analysis Precedence matrix with genetic algorithm Multi-objective optimization using an interchange algorithm Geometric constraint based reasoning Rule-based approach Finite element analysis Rule-based approach featuring graph analysis Finite element analysis Blackboard framework Rule-based with displacement analysis Force and moment equilibrium analysis Geometric reasoning Graph approach Finite element analysis Finite element analysis Geometric constraint reasoning Force and moment equilibrium analysis Genetic algorithm optimization using finite element analysis Rule-based approach Tolerance analysis Case-based reasoning Multi-criteria optimization Geometry and rule-based approach Geometry-based reasoning GA based optimization using screw theory Object oriented reasoning with fuzzy set optimization Mechanical linkage analysis Directed graph theory using tolerance analysis Directed graph theory using tolerance analysis Directed graph theory using tolerance analysis Graph theory using tolerance analysis | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | Key: SP—setup planning; PR—physical requirements; FP—fixture planning; TR—tolerance requirements; UD—unit design; AR—affordability requirements; V—verification; CR—constraining requirements; CDR—collision detection requirements; UR—usability requirements. 6 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 Setup 1 F Setup 2 A X C A Y B D Z B Z Datum feature E Machining feature Fig. 4. A workpiece (a) and its directed graphs showing the locating datums (b) (adapted from Zhang et al. [17]). 3.2.1. Approaches to defining the fixturing requirement Comprehensive fixture requirement definition has received limited attention, primarily focusing upon the definition of individual requirements within the physical, tolerance, and constraining requirements. For example, Zhang et al. [17] undertake tolerance requirement definition through an analysis of workpiece feature tolerances to determine the allowed tolerance at each locating point and the decomposition of that tolerance into its sources. The allowed locating point accuracy is composed of a number of factors, such as the locating unit tolerance, the machine tool tolerance, the workpiece deformation at the locating point, and so on. These decomposed tolerance requirements can subsequently drive fixture design: e.g., the tolerance of the locating unit developed in the unit design phase cannot exceed the specified locating unit tolerance. In a similar individualistic vein, definition of the clamping force requirements that clamping units must achieve has also received attention [29,30]. In a more holistic approach, Boyle et al. [31] facilitate a comprehensive requirement specification through the use of skeleton requirement sets that provide an initial decomposition of the requirements listed in Table 1, and which are subsequently refined through a series of analyses and interaction with the fixture designer. Hunter et al. [32,33] also focus on functional requirement driven fixture design, but restrict their focus primarily to the physical and constraining requirements. 3.2.2. Approaches to non-optimized layout planning Layout planning is concerned with the identification of the locating principle, which defines the number and general arrangement of locating and clamping points, the workpiece surfaces they contact, and the surface coordinate positions where contact occurs. For non-optimized layout planning, approaches based upon the re-use of experiential knowledge have been used. In addition to rule-based approaches [20,34,35] that are similar in nature to those discussed in Section 3.1, case-based reasoning has also been used. CBR is a general problem solving technique that uses specific knowledge of previous problems to solve new ones. In applying this approach to layout planning, a layout plan for a workpiece is obtained by retrieving the plan used for a similar workpiece from a case library containing knowledge of previous workpieces and their layout plans [18,36,37]. Workpiece similarity is typically characterized through indexing workpieces according to their part family classification, tolerances, features, and so on. Lin and Huang [38] adopt a similar workpiece classification approach, but retrieve layout plans using a neural network. Further work has sought to verify layout plans and repair them if necessary. For example Roy and Liao [39] perform a workpiece deformation analysis and if deformation is too great employ heuristic rules to relocate and retest locating and clamping positions. 3.2.3. Approaches to layout planning optimization Layout plan optimization is common within CAFD and occurs with respect to workpiece stability and deformation, which are both constraining requirements. Stability based optimization typically focuses upon ensuring a layout plan satisfies the kinematic form closure constraint (in which a set of contacts completely constrain infinitesimal part motion) and augmenting this with optimization against some form of stability-based requirement, such as minimizing forces at the locating and/or clamping points [40–42]. Wu and Chan [43] focused on optimizing stability (measuring stability is discussed in Section 3.4) using a Genetic Algorithm (GA), which is a technique frequently employed in deformation based optimization. GAs, which are an example of evolutionary algorithms, are often used to solve optimization problems and draw their I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 inspiration from biological evolution. Applying GAs in support of fixture planning, potential layout plan solutions are encoded as binary strings, tested, evaluated, and subjected to ‘‘biological’’ modification through reproduction, mutation, and crossover to generate improved solutions until an optimal state is reached. Typically deformation testing is employed using a finite element analysis in which a workpiece is discretized to create a series of nodes that represent potential locating and clamping contact points, as performed for example by Kashyap and DeVries [44]. Sets of contact points are encoded and tested, and the GA used to develop new contact point sets until an optimum is reached that minimizes workpiece deformation caused by machining and clamping forces [45,46]. Rather than use nodes, some CAFD approaches use geometric data (such as spatial coordinates) in the GA, which can offer improved accuracy as they account for the physical distance that exists between nodes [47,48]. Pseudo-gradient techniques [49] have also been employed to achieve optimization [50,51]. Vallapuzha et al. [52] compared the effectiveness of GA and pseudo-gradient optimization, concluding that GAs provided higher quality optimizations given their ability to search for global solutions, whereas pseudo-gradient techniques tended to converge on local optimums. Rather than concentrating on fixture designs for individual parts, Kong and Ceglarek [53] define a method that identifies the fixture workspace for a family of parts based on the individual configuration of the fixture-locating layout for each part. The method uses Procrustes analysis to identify a preliminary workspace layout that is subjected to pairwise optimization of fixture configurations for a given part family to determine the best superposition of locating points for a family of parts that can be assembled on a single reconfigurable assembly fixture. This builds upon earlier work by Lee et al. [54] through attempting to simplify the computational demands of the optimization algorithm. 3.3. Unit design Unit design involves both the conceptual and detailed definition of the locating and clamping units of a fixture, together with the baseplate to which they are attached (Fig. 5). These units consist of a locator or clamp that contacts the workpiece and is itself attached to a structural support, which in turn connects with the baseplate. These structural supports serve multiple functions, for example providing the locating and clamping units with sufficient rigidity such that the fixture can withstand applied machining and clamping forces and thus result in the part feature design tolerances being obtained, and allowing the clamp or clamp work action clamp fulcrum supporting units baseplate connectors Fig. 5. An example of a clamping unit. 7 locator to contact the workpiece at the appropriate position. Unit design has in general received less attention than both fixture planning and verification, but a number of techniques have been applied to support both conceptual and detailed unit design. 3.3.1. Approaches to conceptual unit design Conceptual unit design has focused upon the definition of the types and numbers of elements that an individual unit should comprise, as well as their general layout. There are a wide variety of locators, clamps, and structural support elements, each of which can be more suited to some fixturing problems than others. As with both setup planning and fixture layout planning, rulebased approaches have been adopted to support conceptual unit design, in which heuristic rules are used to select preferred elements from which the units should be constructed in response to considerations such as workpiece contact features (surface type, surface texture, etc.) and machining operations within the setup [35,55–58]. In addition to using heuristic rules as a means of generating conceptual designs, Kumar et al. [59] use an inductive reasoning technique to create decision trees from which such fixturing rules can be obtained through examination of each decision tree path. Neural network approaches have also been used to support conceptual unit design. Kumar et al. [60] use a combined GA/neural network approach in which a neural network is trained with a selection of previous design problems and their solutions. A GA generates possible solutions which are evaluated using the neural network, which subsequently guides the GA. Lin and Huang [38] also use a neural network in a simplified case-based reasoning (CBR) approach in which fixturing problems are coded in terms of their geometrical structure and a neural network used to find similar workpieces and their unit designs. In contrast, Wang and Rong [37] and Boyle et al. [31] use a conventional CBR approach to retrieve units in which the fixturing functional requirements form the basis of retrieval, which are then subject to refinement and/or modification during detailed unit design. 3.3.2. Approaches to detailed unit design Many, but not all systems that perform conceptual design also perform detailed design, where the dominant techniques are rule, geometry, and behavior based. Detailed design involves the definition of the units in terms of their dimensions, material types, and so on. Geometry, in particular the acting height of locating and clamping units, plays a key role in the design of individual units in which the objective is to select and assemble defined unit elements to provide a unit of suitable acting height [61,62]. An et al. [63] developed a geometry based system in which the dimensions of individual elements were generated in relation to the primary dimension of that element (typically its required height) through parametric dimension relationships. This was augmented with a relationship knowledge base of how different elements could be configured to form a single unit. Similarly, Peng et al. [64] use geometric constraint reasoning to assist in the assembly of user selected elements to form individual units in a more interactive approach. Alternatively, rule-based approaches have also been used to define detailed units, in which workpiece and fixture layout information (i.e., the locating and clamping positions) is reasoned over using design rules to select and assemble appropriately sized elements [32,55,56]. In contrast, Mervyn et al. [65] adopt an evolutionary algorithm approach to the development of units, in which layout planning and unit design take place concurrently until a satisfactory solution is reached. Typically, rule and geometry based approaches do not explicitly consider the required strength of units during their 8 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 design. However for a fixture to achieve its function, it must be able to withstand the machining and clamping forces imposed upon it such that part design tolerances can be met. To address this, a number of behaviorally driven approaches to unit design have been developed that focus upon ensuring units have sufficient strength. Cecil [66] performed some preliminary work on dimensioning strap clamps to prevent failure by stress fracture, but does not consider tolerances or the supporting structural unit. Hurtado and Melkote [67] developed a model for the synthesis of fixturing configurations in simple pin-array type flexible machining fixtures, in which the minimum number of pins, their position, and dimensions are determined that can achieve stability and stiffness goals for a workpiece through consideration of the fixture/workpiece stiffness matrix, and extended this for modular fixtures [68]. Boyle et al. [31] also consider the required stiffness of more complex unit designs within their case-based reasoning method. Having retrieved a conceptual design that offers the correct type of function, this design’s physical structure is then adapted using dynamically selected adaptation strategies until it offers the correct level of stiffness. 3.4. Verification Verification focuses upon ensuring that developed fixture designs (in terms of their setup plans, layout plans, and physical units) satisfy the fixturing requirements. It should be noted from Table 2 that the majority of CAFD approaches perform some type of verification, but within this section of the review the focus will be upon those research efforts in which verification is a major feature of the work. Verification takes place against the tolerance, constraining, collision detection, usability, and affordability requirements (Table 1). Explicit verification against the physical requirements is not normally considered to be a significant verification task given its tight coupling with the process of designing fixtures. Constraining requirements verification has received the most research attention, closely followed by tolerance and collision detection requirements verification. In contrast, work on affordability and usability requirements verification has attracted little focus. 3.4.1. Approaches to constraining requirements verification Constraining requirements verification focuses upon verification of a fixture design against stability and deformation requirements. Stability verification seeks to ensure that part motion is restrained during machining (other than that caused by fixture and workpiece deformation). While some stability verification approaches are analytical and focus upon ensuring that force and moment equilibrium exists on a workpiece when subjected to machining and clamping forces [6,61,69,70], others adopt a less rigorous approach in which locating directions are assessed to determine if a workpiece’s six degrees of freedom are restrained [31,71]. As discussed in Section 3.2, verification is often performed during optimization [41] and in such a vein Liao and Hu [29] consider the effects dynamically varying machining forces have on the minimum clamping forces required to maintain stability, and Deng and Melkote [30] also consider how dynamic material removal affects the required clamping loads. Whilst the majority of approaches provide a boolean definition of stability, Roy and Liao [72] attempt to qualitatively define the stability of a fixture design through initially determining the critical stability situation for a layout plan. Subsequently the locating and clamping positions are altered and the virtual work required to maintain equilibrium calculated to provide a qualitative evaluation of relative stability between different layout plans. Kang et al. [6] adopt the concept of a normalized contact stability index (CSI) to explicitly measure stability at a specific contact fixture/workpiece contact point. In a less analytical approach, Wu et al. [73] use a rule-based approach to qualitatively evaluate stability of a layout plan. Deformation analysis has focused primarily upon analyzing workpiece deformation using finite element analysis [39,44,74,75]. This involves discretizing the workpiece into elements that form a mesh, selecting the type of analytical elements to represent the mesh during analysis, and defining the boundary conditions that exist on the workpiece (e.g., at the fixture/workpiece interface). Rai and Xirouchakis [76] extend the finite element analysis to consider the effects of workpiece geometry changes due to material removal during machining. Variations in such approaches include the different boundary condition definitions and mesh elements selected, and Siebenaler and Melkote [77] investigate the effects of various mesh parameters on predicted workpiece deformation. Similarly, Satyanarayana and Melkote [78] discuss the modeling of boundary conditions at the workpiece/fixture contact interface and develop and experimentally validate a set of guidelines for modeling the contact interface. In comparison to the significant quantity of research that has been conducted on workpiece deformation, work on analyzing fixture deformation is very limited and where values are required to support workpiece deformation analysis when specifying the workpiece/fixture boundary conditions, they are assumed. Boyle et al. [31] do however explicitly measure the deformation of individual units and amend the fixture structure if the deformation exceeds that required, and Hurtado and Melkote adopt a similar approach for pin-array [67] and modular fixtures [68]. 3.4.2. Approaches to tolerance requirements verification The focus within research on tolerance requirements verification has varied. For example, Camelio et al. [79] developed a methodology based upon linking part errors to the fixture faults causing them via a kinematics-based machining process variation model. In contrast to this, Wang [80] developed a tolerance analysis technique that computed the new positions of part features in response to different locator and workpiece datum geometric errors, and Bansal et al. [23] facilitate sensitivity analysis using different locating positions to determine which minimize the locating error. However it should be noted that such techniques do not confirm tolerance satisfaction by relating the results of such an analysis to the required design tolerances (many fixture planning optimization techniques suffer from a similar issue). Kang et al. [6] do directly relate part feature deviations to locating tolerance errors, and amend locating tolerances until the part design tolerances are satisfied, and Boyle et al. [31] extend such an approach to consider locator unit deformation during machining and the effect that has upon satisfying part tolerances. 3.4.3. Approaches to collision detection requirements verification Verification checks that fixtures do not interfere with machine tool cutting paths, that fixture elements do not collide with each other, and that the fixture does not collide with the workpiece. The latter case is relatively simple to verify given the static interference checks that many modern CAD systems can perform and fixture–fixture collision detection can be checked using geometric constraint reasoning to ensure that fixture elements do not collide other than at their designed contact points [64]. Ryll et al. [81] perform collision detection for reconfiguration of flexible fixturing systems in which a list of reconfiguration steps I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 for altering contact positions are determined and virtually executed to identify if any units will collide. However, fixture–toolpath collision detection presents a more complex challenge. Kumar et al. [82] use a cutter swept volume approach in which the cross sectional area of a cutting tool is extruded along the toolpath to create a swept volume. A static interference check is then performed to ascertain if this swept volume coincides with any part of the fixture: i.e., if there is a collision. Roy and Liao [83] not only identify collisions but also use heuristic rules to adjust support and clamping positions such that collisions will not occur. Hu and Rong [84] developed a less computationally demanding two dimensional approach in which fixture elements and cutting tools are modeled in two dimensions with a height value. An interference algorithm then checks for overlaps between the 2D fixture and toolpath elements, and subsequently uses the height information to identify if a collision has occurred. 3.4.4. Approaches to usability and affordability requirements verification Verification of usability and affordability requirements has received comparatively little attention. Rule-based approaches to fixture design [35] can provide some capability for generating designs that satisfy these requirements, but more analytical approaches have been developed to perform verification. Boyle et al. [31] use heuristically developed algorithms to calculate fixture performance with regard to affordability requirements (e.g., cost, assembly time, operation time, etc.), and Ong et al. [26] enable optimization using a combined genetic algorithm-simulated annealing approach. 3.5. Representation of fixturing information In recent years, there has been an embryonic shift towards consideration of how fixture design information can be represented. CAFD research is segmented in nature, with research efforts focusing upon specific requirements or design phases of fixturing problems rather than providing holistic fixture design support. However, some initial work has been conducted with a view to obtaining a greater understanding of information representation in support of CAFD integration [85]. At an abstract level, Pehlivan and Summers [3] analyze fifteen CAFD tools in terms of which design phases they assist, and their information inputs and outputs. In addition to information flows, Cecil interviewed experienced fixture designers to develop an Information Intensive Function Model (IIFM) that relates information flows with fixture design activities [86]. Both Pehlivan and Summers and Cecil focus upon the information flows that exist within fixture design, but provide no details of how that information might be represented. At this deeper level of detail, a number of representations for fixturing information have been developed. Boyle et al. [31] propose the use of Axiomatic Design decomposition [87] as a means of representing and linking fixturing requirements and the fixture design parameters that satisfy them (see Section 3.2.1). Hunter et al. [32,33] use a Unified Modeling Language (UML) approach for representing fixture functional information to support knowledge re-use and link it to their Integration DEFinition Functional Model (IDEF0) of the fixture design process. At an implementation level, Extensible Markup Language (XML) schemas have been developed to represent fixture design information [37,64,88,89], which can support information integration through the ease with which they allow information to be represented and transferred. For example Wang and Rong [37] detail a fixturing dictionary that defines objects within fixture 9 design, their properties, and how the different entities are related, which is implemented using an XML schema. It is worth noting however that although research efforts are moving towards information representation within CAFD, there remains as yet no agreed standard to support effective integration. 4. An analysis of CAFD research As Section 3 has highlighted, there has been a considerable amount of research conducted with regard to the development of CAFD approaches and subsequent software implementations of those tools. In particular, CAFD research has focused upon setup planning, fixture planning, and verification, in which fixture planning and verification have been closely integrated with respect to minimizing workpiece deformation by controlling the locating and clamping positions. However there remain a number of research issues that if addressed would significantly increase the effectiveness with which fixture design can be supported. The remainder of Section 4 discusses the following four research issues, respectively: Much CAFD research is segmented in nature and a need remains to provide more holistic support for fixture design that integrates the four phases of the design process (Section 4.1). There remains a lack of attention on effectively supporting unit design (Section 4.2). There remains a lack of attention on developing CAFD approaches that can derive and subsequently incorporate a comprehensive understanding of the functional requirements for fixturing problems (Section 4.3). Many of the CAFD approaches have been tested for simple workpieces that are unrepresentative of those encountered in industry, thus the effectiveness of developed techniques cannot be stated with confidence (Section 4.4). 4.1. The segmented nature of CAFD research With regard to the segmented nature of CAFD research, Table 1 clearly illustrates that the need to integrate existing CAFD approaches to provide effective support across the four phases of the fixture design process remains. Although a number of research efforts have attempted to support all four phases [31,34,35], the depth of support that is provided varies across each phase and is typically not as great as that of those research efforts which concentrate on supporting specific phases. For example Joneja and Chang’s [34] ability to perform setup planning is less than that of Yao et al. [15], who focus exclusively on that task and for example pay more attention to consideration of tolerance stack-ups within their graph-based approach. There remains therefore a need to consider how all of the disparate CAFD approaches can be integrated to provide cohesive design support. This goes beyond the information integration considered by Pehlivan and Summers [3] and which has been partially addressed through the attempts to structure fixturing information (Section 3.5). The key issue of control also has to be resolved. This relates to controlling the design process and deciding where responsibility for decision making should fall if a conflict occurs between any of the individual approaches. This becomes an issue particularly when verification of the design is attempted. For example, given the situation where workpiece deformation is found to be excessive at the workpiece/locator contact points, there are three abstract courses of remedial action. One is to adjust the locating points, as performed in Vallapuzha et al. [48], a 10 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 second is to strengthen the locating units to provide greater rigidity, as performed in Boyle et al. [31], and the third is a combination of both. Integrating the above approaches from an information point of view will not resolve the problem of which remedial course of action should be taken. Rather, methods need to be developed to manage their integration so that the true cause of the fixture design failure can be identified, and an appropriate remedy generated and identified. Overall therefore, to achieve cohesive integration of current CAFD approaches at both an implementation and conceptual level, the need exists to define how their integration is controlled to ensure effective support is provided during fixture design. 4.2. Effectively supporting unit design The second issue relates to the continuing lack of focus upon supporting detailed unit design. As Table 2 indicates, there are several CAFD approaches that are capable of generating fixture unit structures, but with the exception of a handful of research efforts [31,68] unit design is typically confined to satisfying workpiece geometry. In essence this means identifying the necessary acting height of the unit and then determining all other dimensions based upon some form of parametric design or heuristic rule execution. While Boyle et al. [31] and Hurtado and Melkote [68] have made some initial progress on addressing the stiffness requirements of individual units within the design process, there remains considerable scope for further research, particularly with regard to the modeling and modification of more physically complex unit designs. It is also important to note that this lack of focus on unit design reduces the effectiveness of the fixture planning stages in which unit stiffness values are assumed because if subsequent unit designs are not designed to these assumed stiffness values then the fixture planning layout analysis is invalid. 4.3. Comprehensively formulating the fixturing requirement The third CAFD research issue relates to the above point, but in a more general form. Specifically, it concerns the lack of a comprehensive formulation of fixturing requirements. As the ‘‘requirements considered’’ column in Table 2 illustrates, the majority of CAFD approaches focus upon satisfying a restricted set from the physical, constraining, tolerance, or collision detection requirements, and indeed the affordability and usability requirements receive little attention at all in comparison. However, effective designs are reliant upon comprehensively understanding the problem for which they are intended to be the solution yet currently within the CAFD community research is typically focused on individual requirements. Research conducted on defining and representing fixturing requirements (Section 3.2.1) provides a solid basis for addressing this issue, but there remains a need to understand how these requirements influence the final design: e.g., how should the affordability and usability requirements be incorporated into setup planning, how do the constraining requirements affect setup planning, etc. 4.4. Validating CAFD research outputs The final issue concerning the current status of CAFD approaches is their validation. To illustrate that they represent value to industry, validation needs to take place within a context similar to that encountered within the manufacturing industry. Thus, CAFD approaches need to be tested and evaluated using complex workpieces that are representative of those encountered in industry. However, a significant number have been demonstrated and evaluated using simple workpieces that typically consist of planar and occasionally cylindrical surfaces [30,31,47], which do not represent challenging fixturing problems. This is not the case for all CAFD approaches though. For example Yao et al.’s [15] approach to setup planning has been applied to determining setups for brake calipers, Song and Rong [71] applied their fixture planning approach to a steering knuckle, and Wu et al. [73] applied their fixture planning approach to a pump-casing. It is to these types of workpieces that CAFD efforts need to be applied if they are to present a convincing argument that they represent value to industry and can reduce costs associated with fixturing. However, there is currently a lack of available literature on the effectiveness of CAFD systems within industry and some rigorous studies of their effectiveness, not only in terms of the quality of solution they generate but also on the impact they have at an organizational level (e.g., in terms of improved efficiency) would be of significant benefit in terms of justifying current CAFD research outputs and providing direction for future efforts. 5. Conclusion This paper has presented a review of current approaches for supporting fixture design. CAFD approaches have been reviewed in terms of the design phases they support and the underlying technology upon which they are based. Currently, the strengths of CAFD research lie within the verification approaches that focus upon checking workpiece stability and deformation during machining, and the layout planning approaches that seek to minimize workpiece deformation caused by machining forces. Similarly setup planning has received considerable attention although it is worth noting that little effort has been devoted to supporting setup optimization in the same vein as that for layout planning. However, the segmented nature of CAFD research and the continuing lack of focus upon unit design remain areas of concern within the fixture design domain. In terms of increasing the effectiveness of CAFD research outputs therefore, two primary avenues of development present themselves. Firstly, a greater focus is required on supporting unit design, particularly with regard to determining unit stiffness and relating unit stiffness requirements to unit structure. Secondly, there remains a need to cohesively integrate the segmented CAFD approaches together within a framework that incorporates a comprehensive understanding of fixturing requirements and that uses this understanding to drive the fixture design process. References [1] Bi ZM, Zhang WJ. Flexible fixture design and automation: review, issues, and future directions. Int J Prod Res 2001;39(13):2867–94. [2] Hazen FB, Wright PK. Workholding automation: innovations in analysis, design, and planning. Manuf Rev 1990;3(4):224–36. [3] Pehlivan S, Summers JD. A review of computer aided fixture design with respect to information support requirements. Int J Prod Res 2006;46(4): 929–47. [4] Rong Y, Zhu Y. Computer aided fixture design. New York: Marcel Decker; 1999. [5] Rong Y, Huang SH, Hou Z. Advanced computer-aided fixture design. San Diego: Elsevier Academic Press; 2005. [6] Kang Y, Rong Y, Yang J-C. Computer-aided fixture design verification. Int J Adv Manuf Technol 2003;21(10–11):827–49. [7] Boyes WE. Handbook of jig and fixture design, 2nd ed.. Michigan: Society of Manufacturing Engineers; 1999. [8] Chang TC. Expert process planning for manufacturing. New York: AddisonWesley; 1990. [9] Sarma SE, Wright PK. Algorithms for the minimization of setups and tool changes in ’simply fixturable’ components in milling. J Manuf Syst 1996;15(2):95–112. [10] Huang S, Zhang H-C. Tolerance analysis in setup planning for rotational parts. J Manuf Syst 1996;15(5):340–50. I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 [11] Zhou F, Kuo T-C, Huang SH, Zhang H-C. Form feature and tolerance transfer from a 3D model to a set-up planning system. Int J Adv Manuf Technol 2002;19:88–96. [12] Huang S. Automated setup planning for lathe machining. J Manuf Syst 1998;17(3):196–208. [13] Boerma JR, Kals HJJ. FIXES: a system for automatic selection of set-ups and design of fixtures. Ann CIRP 1988;37:443–6. [14] Huang S, Liu Q. Rigorous application of tolerance analysis in setup planning. Int J Adv Manuf Technol 2003;3:196–207. [15] Yao S, Han X, Yang Y, Rong Y, Huang SH, Yen DW, Zhang G. Computer-aided manufacturing planning for mass customisation: part 2, automated setup planning. Int J Adv Manuf Technol 2007;32:205–17. [16] Zhang H-C, Lin E. A hybrid-graph approach for automated setup planning in CAPP. Robot Comput Integr Manuf 1999;15:89–100. [17] Zhang Y, Hu W, Rong Y, Yen DW. Graph-based setup planning and tolerance decomposition for computer-aided fixture design. Int J Prod Res 2001;39(14): 3109–26. [18] A.S. Kumar, A.Y.C. Nee, A framework for a variant fixture design system using CBR technique. In: MED manufacturing science engineering proceedings, San Francisco, 1995, 2.1/3-1, 1995, pp. 763–775. [19] Wu R-R, Zhang H-M. Object-oriented and fuzzy set-based approach for set-up planning. Int J Adv Manuf Technol 1998;14:406–11. [20] Gologlu C. Machine capability and fixturing constraints-imposed automatic machining set-ups generation. J Mater Process Technol 2004;148:83–92. [21] Rameshbabu V, Shunmugam MS. Hybrid feature recognition method for setup planning from STEP AP-203. Robot Comput Integr Manuf 2009;25: 393–408. [22] K. Waiyagan, E.L.J. Bohez, Intelligent feature based process planning for five-axis mill-turn parts, Comput Ind, 2008, 10.1016/j.compind.2008.09.009. [23] Bansal S, Nagarajan S, Reddy NV. An integrated fixture planning system for minimum tolerances. Int J Adv Manuf Technol 2008;38:501–13. [24] Kim I-H, Oh J-S, Cho K-K. Computer aided setup planning for machining processes. Comput Ind Eng 1996;31(3/4):613–7. [25] Cai N, Wang L, Feng H-Y. Adaptive setup planning of prismatic parts for machine tolls with varying configurations. Int J Prod Res 2008;46: 571–94. [26] Ong SK, Ding J, Nee AYC. Hybrid GA and SA dynamic set-up planning optimization. Int J Prod Res 2002;40:4697–719. [27] Hebbal SS, Mehta NK. Setup planning for machining the features of prismatic parts. Int J Prod Res 2007;46(12):3241–57. [28] Ming XG, Mak KL. Intelligent setup planning in manufacturing by neural networks based approach. J Intell Manuf 2000;11:311–31. [29] Liao YJG, Hu SJ. Flexible multibody dynamics based fixture workpiece analysis model for fixturing stability. Int J Mach Tool Manuf 2000;40: 343–62. [30] Deng H, Melkote SN. Determination of minimum clamping force for dynamically stable fixturing. Int J Mach Tool Manuf 2006;46:847–57. [31] Boyle I, Rong Y, Brown DC. CAFixD: a case-based reasoning fixture design method: framework and indexing mechanisms. J Comput Inf Sci Eng 2006;6:40–8. [32] Hunter R, Vizan A, Perez J, Rios J. Knowledge model as an integral way to reuse the knowledge for fixture design process. J Mater Process Technol 2005;164–165:1510–8. [33] Hunter R, Rios J, Perez JM, Vizan A. A functional approach for the formalization of the fixture design process. Int J Mach Tool Manuf 2006;46: 683–97. [34] Joneja A, Chang T-C. Setup and fixture planning in automated process planning systems. IIE Trans 1999;31:653–65. [35] Nee AYC, Kumar AS. A framework for an object/rule-based automated fixture design system. Ann CIRP 1991;40(1):147–51. [36] Li W, Li P, Rong Y. Case-based agile fixture design. J Mater Process Technol 2002;128:7–18. [37] Wang H, Rong Y. Case based reasoning method for computer aided welding fixture design. Comput Aided Des 2008;40:1121–32. [38] Lin Z-C, Huang J-C. The application of neural networks in fixture planning by pattern classification. J Intell Manuf 1997;8:307–22. [39] Roy U, Liao J. Geometric reasoning for re-allocation of supporting and clamping positions in the automated fixture design system. IIE Trans 1999;31:313–22. [40] Brost RC, Goldberg KY. A complete algorithm for designing planar fixtures using modular components. IEEE Trans Robot Autom 1996;12(1):31–46. [41] Wang Y, Chen X, Liu Q, Gindy N. Optimisation of machining fixture layout under multi-constraints. Int J Mach Tool Manuf 2006;46:1291–300. [42] Pelinescu DM, Wang MY. Multi objective optimal fixture layout design. Robot Comput Integr Manuf 2002;18:365–72. [43] Wu NH, Chan KC. A genetic algorithm approach to optimal fixture configuration. Comput Ind Eng 1996;31(3/4):919–24. [44] Kashyap S, DeVries WR. Finite element analysis and optimization in fixture design. Struct Optim 1999;18:193–201. [45] Krishnakumar K, Melkote SN. Machining fixture layout optimization using the genetic algorithm. Int J Mach Tool Manuf 2000;40:579–98. [46] Krishnakumar K, Satyanarayana S, Melkote SN. Iterative fixture layout and clamping force optimization using the genetic algorithm. J Manuf Sci Eng 2002;124:119–25. [47] Kaya N. Machining fixture locating and clamping position optimization using genetic algorithms. Comput Ind 2006;57:112–20. 11 [48] Vallapuzha S, De Meter EC, Choudhuri S, Khetan RP. An investigation into the use of spatial coordinates for the genetic algorithm based solution of the fixture layout optimization problem. Int J Mach Tool Manuf 2002;42:265–75. [49] Bazaraa MS, Sherali HD, Shetty CM. Nonlinear programming theory and algorithms. New York: John Wiley; 1993. [50] De Meter EC. Fast support layout optimization. Int J Mach Tool Manuf 1998;38:1221–39. [51] Li B, Melkote SN. Improved workpiece location accuracy through fixture layout optimization. Int J Mach Tool Manuf 1999;39:871–83. [52] Vallapuzha S, De Meter EC, Choudhuri S, Khetan RP. An investigation of the effectiveness of fixture layout optimization methods. Int J Mach Tool Manuf 2002;42:251–63. [53] Kong Z, Ceglarek D. Fixture workspace synthesis for reconfigurable assembly using Procrustes-based pairwise configuration optimization. J Manuf Syst 2006;25(1):25–38. [54] Lee J, Hu SJ, Ward AC. Workspace synthesis for flexible fixturing of stampings. J Manuf Sci Eng 1999;121(3):478–84. [55] Nnaji BO, Alladin S. E-CAFFS: an expert computer-aided flexible fixturing system. Comput Ind Eng 1990;18(3):297–311. [56] Nnaji BO, Alladin S, Lyu P. A framework for a rule-based expert fixturing system for face milling planar surfaces on a CAD system using flexible fixtures. J Manuf Syst 1988;7(3):193–207. [57] Perremans P. Feature-based description of modular fixturing elements: the key to an expert system for the automatic design of the physical fixture. Adv Eng Software 1996;25:19–27. [58] Wu Y, Rong Y, Chu TC. Automated generation of dedicated fixture designs. Int J Comput Appl Technol 1997;10(3/4):213–35. [59] Kumar AS, Subramaniam V, Teck TB. Conceptual design of fixtures using machine learning techniques. Int J Adv Manuf Technol 2000;16:176–81. [60] Kumar AS, Subramaniam V, Seow KC. Conceptual design of fixtures using genetic algorithms. Int J Adv Manuf Technol 1999;15:79–84. [61] Wu Y, Rong Y, Ma W, LeClair SR. Automated modular fixture planning. Robot Comput Integr Manuf 1998;14:1–26. [62] Rong Y, Bai Y. Automated generation of fixture configuration design. ASME Trans Manuf Sci Eng 1997;119(2):208–19. [63] An Z, Huang S, Rong Y, Jayaram S. Development of automated dedicated fixture design systems with predefined fixture component types: basic design. Int J Flex Autom Integr Manuf 1999;7(3 and 4):321–41. [64] G. Peng, G. Wang, W. Liu, H. Yu, A desktop virtual reality-based interactive modular fixture configuration design system, Comput Aided Des, 2009, doi: 10.1016/j.cad.2009.02.003. [65] Mervyn F, Kumar AS, Nee AYC. Automated synthesis of modular fixture designs using an evolutionary search algorithm. Int J Prod Res 2005;43(23): 5047–70. [66] Cecil J. A clamping design approach for automated fixture design. Int J Adv Manuf Technol 2001;18:784–9. [67] Hurtado JF, Melkote SN. A model for the synthesis of the fixturing configuration in pin-array type flexible machining fixtures. Int J Mach Tool Manuf 2002;42:837–49. [68] Hurtado JF, Melkote SN. Improved algorithm for tolerance based stiffness optimization of machining fixtures. J Manuf Sci Eng 2001;123:720–30. [69] Trappey AC, Liu CK. An automatic workholding verification system. Robot Comput Integr Manuf 1992;9(4/5):321–6. [70] Liu JJ-X, Strong DR. Machining fixture verification for nonlinear fixture system. Int J Adv Manuf Technol 2003;21:426–37. [71] Song H, Rong Y. Locating completeness evaluation and revision in fixture plan. Robot Comput Integr Manuf 2005;21:368–78. [72] Roy U, Liao J. Fixturing analysis for stability consideration in an automated fixture design system. J. Manuf Sci Eng 2002;124:98–104. [73] Wu Y, Gao S, Chen Z. Automated modular fixture planning based on linkage mechanism theory. Robot Comput Integr Manuf 2008;24:38–49. [74] Amaral N, Rencis JR, Rong Y. Development of a finite element analysis tool for fixture design integrity verification and optimization. Int J Adv Manuf Technol 2005;25:409–19. [75] Ratchev S, Phuah K, Liu S. FEA-based methodology for the prediction of partfixture behavioir and its applications. J Mater Process Technol 2007;191: 260–4. [76] Rai JK, Xirouchakis P. Finite element method based machining simulation environment for analyzing part errors induced during milling of think-walled components. Int J Mach Tool Manuf 2008;48:629–43. [77] Siebenaler SP, Melkote SN. Prediction of workpiece deformation in a fixture system using the finite element method. Int J Mach Tool Manuf 2006;46: 51–8. [78] Satyanarayana S, Melkote SN. Finite element modelling of fixture-workpiece contacts: single contact modelling and experimental verification. Int J Mach Tool Manuf 2004;44:903–13. [79] Camelio J, Hu S, Zhing W. Diagnosis of multiple fixture faults in machining processes using designated component analysis. J Manuf Syst 2004;23(4): 309–15. [80] Wang M. Tolerance analysis for fixture layout design. Assem Autom 2002;22: 153–62. [81] Ryll M, Papastathis TN, Ratchev S. Towards an intelligent fixturing system with rapid reconfiguration and part positioning. J Mater Process Technol 2008;201:198–203. [82] Kumar AS, Subramaniam V, Teck TB. An automated design and assembly of interference-free modular setup. Comput Aided Des 2000;32:583–96. 12 I. Boyle et al. / Robotics and Computer-Integrated Manufacturing 27 (2011) 1–12 [83] Roy U, Liao J. Application of a blackboard framework to a cooperative fixture design system. Comput Ind 1998;37:67–81. [84] Hu W, Rong Y. A fast interference checking algorithm for automated fixture design verification. Int J Adv Manuf Technol 2000;16:571–81. [85] Bugtai N, Young RIM. Information models in an integrated fixture decision support tool. J Mater Process Technol 1998;76:29–35. [86] Cecil J. Computer-aided fixture design: using information intensive function models in the development of automated fixture design systems. J Manuf Syst 2002;21(1):58–71. [87] Suh NP. Axiomatic design advances and applications. New York: Oxford University Press; 2001. [88] Mervyn F, Kumar AS, Bok SH, Nee AYC. Development of an Internet enabled interactive fixture design system. Comput Aided Des 2003;35:945–57. [89] Fan L, Kumar AS. An XML based representation in a CBR system for fixture design. Comput Aided Des Appl 2005;2:339–48. [90] Kenny JK, Eberhart RC. Swarm intelligence. San Francisco: Morgan Kaufmann Publishers; 2001.