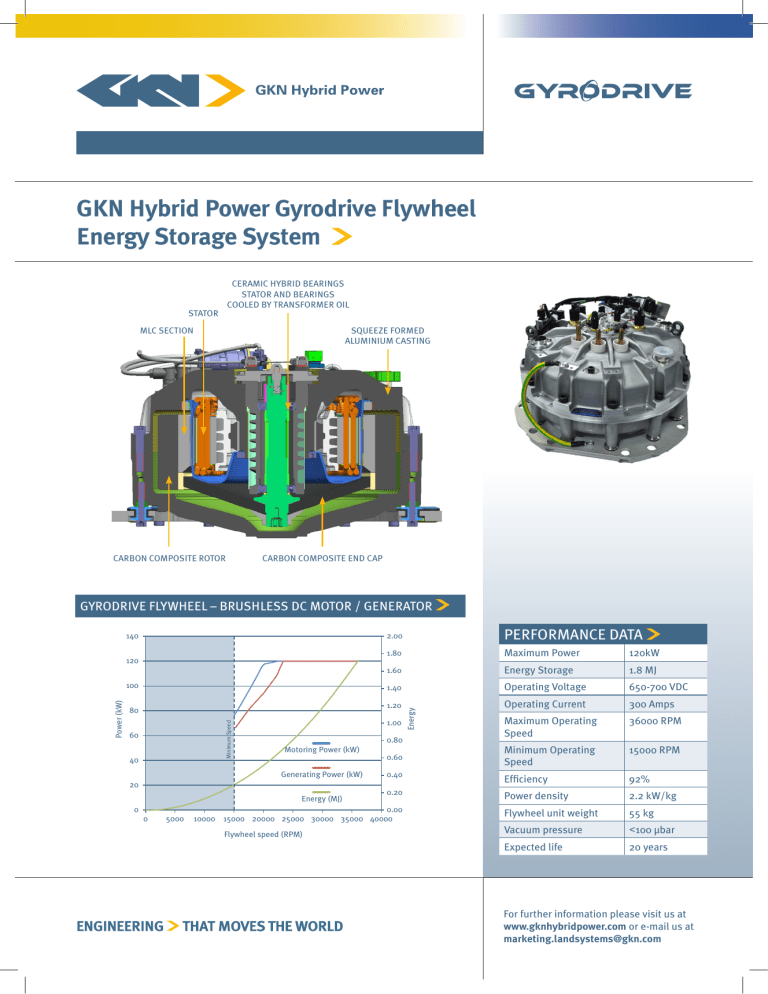

GKN Hybrid Power Gyrodrive Flywheel Energy Storage System CERAMIC HYBRID BEARINGS STATOR AND BEARINGS COOLED BY TRANSFORMER OIL STATOR MLC SECTION SQUEEZE FORMED ALUMINIUM CASTING CARBON COMPOSITE ROTOR CARBON COMPOSITE END CAP GYRODRIVE FLYWHEEL – BRUSHLESS DC MOTOR / GENERATOR 120 80 Minimum Speed Power (kW) 100 60 40 Energy (MJ) 5000 Maximum Power 120kW 1.60 Energy Storage 1.8 MJ 1.40 Operating Voltage 650-700 VDC 1.20 Operating Current 300 Amps Maximum Operating Speed 36000 RPM Minimum Operating Speed 15000 RPM 0.40 Efficiency 92% 0.20 Power density 2.2 kW/kg Flywheel unit weight 55 kg Vacuum pressure <100 µbar Expected life 20 years 0.80 Motoring Power (kW) Generating Power (kW) 0 PERFORMANCE DATA 1.80 1.00 20 0 2.00 0.60 0.00 10000 15000 20000 25000 30000 35000 40000 Flywheel speed (RPM) Energy 140 For further information please visit us at www.gknhybridpower.com or e-mail us at marketing.landsystems@gkn.com GKN Hybrid Power Gyrodrive Flywheel Energy Storage System HOW DOES IT WORK? Flywheel & Radiator In a conventional mechanical driveline When the driver brakes, a traction motor on one of the axles retards the vehicle, generating electricity at the same time. This electricity is used to charge the flywheel, spinning it at up to ~36,000 rpm. When the driver accelerates, the system works in reverse and the energy is drawn from the flywheel and converted back into electricity to power the traction motor helping to accelerate the vehicle. BRAKING Power Electronics In an electrical or electro hydraulic driveline ACCELERATING The flywheel controller can be connected directly into the power electronics of the base system. Instead of returning energy from lowering a boom, slewing, stopping etc being burnt off in a resistor bank or hydraulic retarder, the power is used directly to charge the flywheel. POTENTIAL CONFIGURATION PARALLEL HYBRID Kinetic energy re-used Diesel engine sized for peak performance SERIES HYBRID Engine sized for average power use Peak power demands met from flywheel Kinetic energy re-used Greater fuel saving Savings in engine, transmission and driveline costs offset system costs For further information please visit us at www.gknhybridpower.com or e-mail us at marketing.landsystems@gkn.com