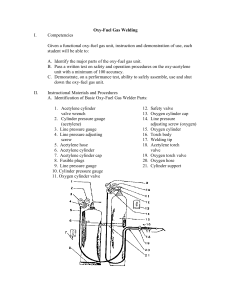

Construction Tech OA Welding Review Safety: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. Never use oil on oxygen connections Never force connections Fasten cylinders to wall or cart before cracking valve Red hose = left hand threads = fuel gas Check connections before using Use shade 3-5 lenses Use friction lighters, not matches Check pressures carefully, acetylene cannot be set above 15 Keep cylinders away from fire Never use leaky cylinders Open acetylene only ½ to 1 turn Drain valves and remove pressure from regulators when done Do not drag flame across hoses or cylinders Replace cracked hoses Never attempt to transfer gas from one cylinder to another Be aware of combustibles in area Never do any welding or cutting on containers that have held a flammable substance Galvanized metal is highly toxic. Do not weld or cut without excellent ventilation Ventilate area in which you are welding Do not relight flame in pocket or small confined space Wear appropriate clothes for welding or cutting Store extra cylinders away from work area Store cylinders upright, always Be ready to put out a fire! Shut off acetylene first, then oxygen (to blow out flame) Be comfortable, but safe Keep flashbacks or backfires at a minimum by proper maintenance of equipment. Backfires are caused by: a. dirty tips b. improper gas pressures (low) c. leaks or loose connections d. overheating the metal and tip e. luminous cone in pool Flashbacks (burning behind mixing chamber) are caused by: a. loose tip or nozzle b. dirty or damaged seat c. cracked or distorted torch head 1) Turn on unit a) Check torch valves are off b) Adjusting screw is loose c) Gages are zeroed d) Adjusting screw is pointed away from people e) Turn on oxygen all the way. f) Turn on acetylene ½ turn g) Adjust oxygen screw to 25 psi on working pressure gage h) Adjust acetylene to 5 psi on working pressure gage i) Turn on oxygen torch valve all the way Parts: Acetylene (C2H2) is produced from calcium carbide and water. At 70 degrees F: Acetylene is stored in cylinders of approximately 100 or 60 cu ft. The cylinder is packed with a porous material. Usually asbestos and balsa wood is saturated with acetone, because acetylene can never be stored in a free state. A cylinder will be packed to 250 psi. The acetone is heavier, thus settles to bottom. None is lost through the valve, unless cylinder has been laid on its side. Oxygen is stored in cylinders of approximately 244 or 122 cu ft. (2200 psi at 244), as temperatures decrease, pressures do also. As temperatures rise, so do pressures. Cylinder safety devices: Acetylene: fusible plugs Oxygen: bursting disks Regulators: Gages: Working and cylinder Torch body and parts: Three Flames: Oxidizing Neutral Carburizing Set up and operate equipment: 2) Secure cylinders 3) Crack cylinder valves 4) Attach regulators 5) Connect hoses to regulators 6) Blow out hoses 7) Connect hoses to blowpipe 8) Attach tip 9) Turn on unit a) Check torch valves are off b) Adjusting screw is loose c) Gages are zeroed d) Adjusting screw is pointed away from people e) Turn on oxygen all the way. f) Turn on acetylene ½ turn g) Adjust oxygen screw to 25 psi on working pressure gage h) Adjust acetylene to 5 psi on working pressure gage i) Turn on oxygen torch valve all the way 10) Test for leaks using soapy water (it will bubble) 11) Light the torch How do you run puddle? How do you run a bead? How do you cut metal?