Uploaded by

Eduardo Bittencourt

Linear Hybrid Reluctance Motor: High Density Force Article

advertisement

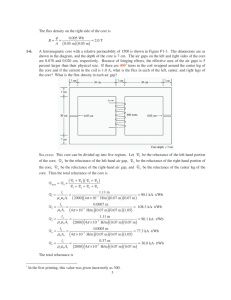

energies Article Linear Hybrid Reluctance Motor with High Density Force Jordi Garcia-Amorós Departament d’Enginyeria Electrònica, Elèctrica i Automàtica, Universitat Rovira i Virgili, 43007 Tarragona, Spain; jordi.garcia-amoros@urv.cat; Tel.: +34-977-559-695 Received: 20 September 2018; Accepted: 16 October 2018; Published: 18 October 2018 Abstract: Linear switched reluctance motors are a focus of study for many applications because of their simple and sturdy electromagnetic structure, despite their lower thrust force density when compared with linear permanent magnet synchronous motors. This study presents a novel linear switched reluctance structure enhanced by the use of permanent magnets. The proposed structure preserves the main advantages of the reluctance machines, that is, mechanical and thermal robustness, fault tolerant, and easy assembly in spite of the permanent magnets. The linear hybrid reluctance motor is analyzed by finite element analysis and the results are validated by experimental results. The main findings show a significant increase in the thrust force when compared with the former reluctance structure, with a low detent force. Keywords: linear switched reluctance machine; finite element analysis; PM-assisted; thrust-force performance 1. Introduction Currently, there are many applications that use hydraulic or pneumatic drives that are being substituted by linear electric actuators in manufacturing industries and robotic systems because of their more stable, precise, and controllable force, along with a higher energy efficiency [1]. In this context, reluctance machines present good environmental behavior due to their high efficiency and inherent ease of assembly and dismantling [2]. For these reasons, among others, there are several studies that have focused on new magnetic structures [3–5], in order to enhance their force performance [6] and increase force density by adding permanent magnets [7–14]. As an example, linear switched reluctance motors (LSRM) and linear permanent magnet synchronous motors (LPMSMs) have been proposed for propelling a ropeless elevator [15,16], for an automotive suspension system [17], and for a linear generator in direct drive wave-power converter [18]. Up to now, LPMSMs have a higher power density and efficiency when compared with LSRMs, despite their inherent detent or cogging force, which can be reduced or eliminated by applying several techniques [19,20]. Many current research papers deal with developing and optimizing linear motors in order to increase power density and efficiency [21–23]. With this aim, this work presents and analyzes a four-phase LSRM, whose novelty is in the mover. A series of vertically magnetized permanent magnets (PMs) are inserted into the slots of the mover of the LSRM. The resulting actuator is analyzed by finite element analysis (FEA) and a prototype was built and tested. The FEA results and the experimental results are in good agreement and reveal an approximately 100% increase in the peak thrust force; a moderate ripple factor operating in single pulse; and a relative low detent force, about 10% of peak thrust force. The results obtained anticipate an interesting actuator for high force density applications, such as those cited above. Energies 2018, 11, 2805; doi:10.3390/en11102805 www.mdpi.com/journal/energies Energies 2018, 11, x FOR PEER REVIEW 2 of 14 2. Linear Hybrid Reluctance Motor Structure and Operation Principle Energies 2018, 11, 2805 2 of 14 LSRMs are classified according to the relation between the planes that contain the flux lines and the axis of movement. Longitudinal flux LSRM is when these planes are parallel, and transverse flux Linear Hybrid Motor Longitudinal Structure and Operation Principle LSRM is 2.when they are Reluctance perpendicular. flux LSRM may be tubular or flat, with single or double side LSRMs for theareflat case. according The LSRM has two between main parts: thethat active part, the classified to the relation the planes contain the which flux linescontains and the axis of movement. Longitudinal flux LSRM is when these planes are parallel, and transverse flux concentrated windings, also called primary part; and the passive or secondary part, made of an empty LSRM is when they are perpendicular. Longitudinal flux LSRM may be tubular or flat, with single slotted iron structure. This work focuses on the double-sided longitudinal flux LSRM, referred to or double side for the flat case. The LSRM has two main parts: the active part, which contains the from now on as LSRM. concentrated windings, also called primary part; and the passive or secondary part, made of an empty Theslotted proposed structure iswork shown in Figure 1. The ironlongitudinal lamination is theto same iron structure. This focuses on the double-sided fluxstructure LSRM, referred from as that of a conventional four-phase double-sided longitudinal flux LSRM (see Figure 1 in grey), the now on as LSRM. The proposed structure shown in Figure 1. The iron in lamination structure is theFrom same as thatreluctance of modelling, simulation, and testisof which are reported the work of [24]. this double-sided flux LSRM Figure 1 in grey), the modelling, structure,a conventional a series of four-phase permanent magnets longitudinal type NdFeB N32 (in(see black/white, see Figure 1) have been simulation, and test of which are reported in the work of [24]. From this reluctance structure, a series of placed in the secondary slotted lamination. The PMs are vertically magnetized following the permanent magnets type NdFeB N32 (in black/white, see Figure 1) have been placed in the secondary arrangement in Figure 1. Each phase magnetized has four coils per pole connectedshown in series, in such slottedshown lamination. The PMs are vertically following the arrangement in Figure 1. a way that onlyEach onephase fluxhas path produced. The main dimensions of the (active part) are the pole fouriscoils per pole connected in series, in such a way thatprimary only one flux path is produced. main width dimensions the primary (active𝑐part) are the pole length l p , pole widththe b p , and slot width length 𝑙𝑝The , pole 𝑏𝑝 ,ofand slot width defines primary pole pitch 𝑝 , the sum of which c p , the sum of which defines the primary pole pitch τp = b p + c p . For the secondary (passive) part, the 𝜏𝑝 = 𝑏𝑝 + 𝑐𝑝 . For the secondary (passive) part, the pole dimensions are the length 𝑙𝑠 , the width 𝑏𝑠 , pole dimensions are the length ls , the width bs , the slot width cs , and the mover pole pitch, defined as the slot width 𝑐 , and the mover pole pitch, defined as 𝜏 = 𝑏𝑠 + 𝑐 . The magnet dimensions are the τs = bs +𝑠cs . The magnet dimensions are the length lm and𝑠 width bm . 𝑠The stack lamination width is length 𝑙𝑚denoted and width as LW . 𝑏𝑚 . The stack lamination width is denoted as 𝐿𝑊 . Figure 1. Longitudinal flux linear hybrid reluctance motor (LHRM) arrangement. Figure 1. Longitudinal flux linear hybrid reluctance motor (LHRM) arrangement. Figure 2 shows the LHRM operating principle in which the four coils of phase A are colored in Figure 2 shows theblue LHRM operatingthe principle in which four ofside phase Acurrent are colored in red and blue, the side represents current entering the the paper andcoils the red is the flowing out of the paper. The red line of Figure 2a represents the main flux line (Φ ) of phase at current + red and blue, the blue side represents the current entering the paper and the Ared side isAthe pole-alignment position, when it is fed with a positive current (I A+ ). When phase A current is inverted flowing out of the paper. The red line of Figure 2a represents the main flux line (Φ𝐴+ ) of phase A at (I A− ), (see Figure 2b) the blue line represents the main flux line at the same aligned position. In both pole-alignment position, when it is fed with a positive current (Iforce ). When phase A current is inverted cases, a significant force appears at pole alignment positions. The 𝐴+ is to the right FX,A+ when the (I𝐴− ), (seecurrent Figure the blue line represents the main flux line at the same aligned position. In both is I2b) A+ , and to left FX,A− when the current is I A− . This phenomenon does not appear in an cases, a significant appears alignment positions. The force is to the right 𝐹𝑋,𝐴+ when the LSRM, whereforce the force is nullat at pole aligned and unaligned pole positions. current is I𝐴+ , and to left 𝐹𝑋,𝐴− when the current is I𝐴− . This phenomenon does not appear in an LSRM, where the force is null at aligned and unaligned pole positions. Energies 2018, 11, 2805 3 of 14 Energies 2018, 11, x FOR PEER REVIEW 3 of 14 Energies 2018, 11, x FOR PEER REVIEW 3 of 14 (a) (a) (b) Linear hybrid reluctance motor main fluxpaths. paths. (a) AA excited withwith I A+ , positive force force Figure 2. Figure Linear2.hybrid reluctance motor main flux (a)Phase Phase excited IA+ , positive FX,A+ . (b) Phase A excited with I A− , negative force FX,A− . FX,A+ . (b) Phase A excited with IA− , negative force FX,A− . The LSRM propulsion force versus position x and current i, (F ( x, i)) has the same direction (right/left) in the interval x ∈ [0, τS /2], and for whatever current sign. In the LHRM, the propulsion force is null at the unaligned pole positions, or when the stator poles are aligned with any of the PM poles (N/S) for any current, see Figure 3a,c. The LHRM propulsion force has a positive direction (left to right) in the interval x ∈ [0, τS ](b) , (see Figure 3b) and a negative direction (right to left) in the interval x ∈2. [Linear τS , 2·τhybrid Figure 3d). Thismain implies a current sign A dependency the LHRMforce over the Figure motor flux paths. (a) Phase excited withof IA+ , positive S ] (see reluctance propulsion force. FX,A+ . (b) Phase A excited with IA− , negative force FX,A− . (a) (b) (c) (d) Figure 3. Linear hybrid reluctance motor operating principle. (a) Unaligned mover position. x = 0 mm, 1 FX = 0. (b) Aligned position. x = 2·𝜏𝑠 mm, FX > 0. (c) Unaligned position. x = 𝜏𝑠 mm, FX = 0. (d) 3 Aligned position. x=2 · 𝜏𝑠 mm, FX < 0. (a) (b) (c) (d) The LSRM propulsion force versus position xprinciple. and current i, (𝐹(𝑥, 𝑖)) has the same direction Figure Figure 3. 3.Linear Linearhybrid hybridreluctance reluctance motor motor operating operating principle. (a) (a) Unaligned Unaligned mover mover position. position. xx ==00mm, mm, 1 [ ] 1, and (right/left) inFFthe interval 𝑥 ∈ 0, 𝜏 /2 for whatever current sign. In the LHRM, the = 0. (b) Aligned position. x = · 𝜏 mm, F > 0. (c) Unaligned position. x = 𝜏 mm, F = 0. (d) propulsion 𝑆 position. x = 2 2mm, XX = 0. (b) 𝑠 FX > 0. X (c) Unaligned position. x = τs mm, F𝑠X = 0. (d) X Aligned 3 3 position. x = 2 ·τs x= mm,·pole <positions, 0. FX < 0. force is null at the unaligned or when the stator poles are aligned with any of the PM Aligned position. 𝜏F𝑠X mm, 2 poles (N/S) for any current, see Figure 3a and 3c. The LHRM propulsion force has a positive direction LSRM propulsion andand current i, (𝐹(𝑥, 𝑖)) has the same direction [0, 𝜏𝑆versus ], (see position (left to right)The in the interval 𝑥 ∈ force Figure x3b) a negative direction (right to left) in the (right/left) in the interval 𝑥 ∈ [0, 𝜏𝑆 /2], and for whatever current sign. In the LHRM, the propulsion interval 𝑥 ∈ [𝜏𝑆 , 2 · 𝜏𝑆 ] (see Figure 3d). This implies a current sign dependency of the LHRM over the force is null at the unaligned pole positions, or when the stator poles are aligned with any of the PM propulsion force. poles (N/S) for any current, see Figure 3a and 3c. The LHRM propulsion force has a positive direction Energies 2018, 11, 2805 4 of 14 In summary, the LHRM is, similar to the LSRM, a position dependent machine, so an encoder is necessary to operate this actuator, along with an H-bridge inverter, which has to be used instead of the asymmetric bridge converter because of its current sign dependence. 3. Mathematical Model Equations The presence of the PM allows one to split the total phase flux linkage (ψ) as the sum of the flux due to the phase-current (ψi ) and the PMs flux-linkage (ψPM ), as follows: ψ( x, i ) = ψi ( x, i ) + ψPM ( x, i ) (1) The electrical phase circuit equation is as follows: dψ = V − R· I dt (2) where I, V, and R are the phase current, voltage, and resistance, respectively. Expressing the phase-current flux linkage as the product of the phase inductance and the current, that is: ψi (i, x) = L(i, x)· I, and combining Equations (1) and (2), it yields the electrical circuit equation of the LHRM given by the following: dI dL dψPM −1 −1 = −L R + v· ·I + L · V − (3) dt dx dt In which the mover velocity is denoted as v. The motion equation neglecting friction is given as follows: dv Fx + Fd = M· + Fl (4) dt where Fx is the electromagnetic force, Fd is the detent force, Fl is the load, and M is the mover mass. The instantaneous electromagnetic force (Fx ) is computed from the differential change of co-energy respect to position for a given phase current, as follows: m Fx = ∑ k =1 ∂ ∂x I Z 0 ψ( x, ik )·dik (5) where m is the number of phases. This set of Equations (1)–(5) performs the dynamic and static behavior of the LHRM, which can be implemented in MATLAB-Simulink software for their solution as in LSRM. The apparent power per phase, SVA or volt-ampere requirement per phase, is defined as the product of peak voltage (Vp ) and peak current (Ip ) multiplied by the number of switching devices per phase (n). From the area of the energy conversion loop (W), the average output power is given as follows: 2 ·W Pout = ·u (6) τs ·k d b where k d is the magnetic duty cycle factor defined as k d = 2· xo f f /τs . The ratio between the power output and the apparent power or W/VA ratio is given by the following: Pout 2 ·W ·u = SVA n·τs ·k d ·Vp · I p b (7) 4. Finite Element Analysis Results The electromagnetic propulsion force is obtained from a 2D-FEM solver [25]. It uses the weighted Maxwell stress tensor technique [26], which is one of the most reliable approaches for force and torque computations [27]. It consists of computing the Maxwell stress tensor over a set of concentric surfaces of thickness δ and contour Γ(δ) wrapping the mover (see Equation (8)), with ny being a Energies 2018, 11, 2805 5 of 14 normal unit vector in the y-direction; and Bx and By are the magnetic field density in the x and y directions, respectively. Z Z LW 1 δ Fx = ·ny · Bx · By ·dΓ·dδ (8) δ 0 Γ ( δ ) µ0 Energies 2018, 11, x FOR PEER REVIEW 5 of 14 The main dimensions of the FEM model of LHRM shown in Figure 4 are reported in Table A1, see Appendix A. Figure 4 shows the flux lines obtained from the FEA for the zero current excitation phase. phase. This position (see Figure 4) is set as the initial position x = 0 mm, with this position being This position (see Figure 4) is set as the initial position x = 0 mm, with this position being equivalent equivalent toposition the position in3c, Figure is,left thephase upper left phase poleanis aligned to the shownshown in Figure that is,3c, thethat upper A primary poleAisprimary aligned with with anS–N S–Nmagnet. magnet. Figure 4. Two-dimensional-finite element fluxplot plot 𝐼𝐴 I= 𝐼𝐵 I= 𝐼𝐶 I= Figure 4. Two-dimensional-finite elementanalysis analysis (FEM) (FEM) flux forfor IA = B = D 𝐼= C = 𝐷 0=at0, at x = 0 x = 0 mm. mm. The electromagnetic force is evaluated for a sequence of even positions in the interval x ∈ [0, 2·τs ] Theand electromagnetic force is density evaluated for even2 . positions in the thesame interval 𝑥 ∈ for a set of constant current values J ∈a[±sequence 5, ±10, ±15of The LSRM has ] A/mm 2 [0, 2 · 𝜏𝑠 iron ] and for a setand of constant currentmagnets. density values J ∈ [± 5, ± 10, ± 15] A/mm . The LSRM laminations coils, but without Asiron can be observed, there twobut forcewithout profiles for the LHRM (see Figure 5); one for positive has the same laminations andare coils, magnets. current feeding (continuous line, see Figure 5) and one for (discontinuous As can be observed, there are two force profiles forthe thenegative LHRMcurrent (see Figure 5); oneline). for positive The LHRM force profiles are substantially higher than in the LSRM. The main FEM comparison results current feeding (continuous line, see Figure 5) and one for the negative current (discontinuous line). obtained from phase A are summarized in Table 1. The LHRM force profiles are substantially higher than in the LSRM. The main FEM comparison results obtained from phase A are summarized in Table 1. LHRM phase A+ LHRM phase ALSRM phase A 60 60 40 40 20 20 0 0 -20 -20 -40 -40 -60 -60 -80 -80 0 5 10 15 20 25 30 0 x (mm) 5 10 15 20 25 30 x (mm) (a) 80 PM-LSRM phase B+ PM-LSRM phase BLSRM base phase B 80 F X (N) F X (N) 80 (b) LHRM phase C+ 80 LHRM phase D+ [0, 2 · 𝜏𝑠 ] and for a set of constant current density values J ∈ [± 5, ± 10, ± 15] A/mm . The LSRM has the same iron laminations and coils, but without magnets. As can be observed, there are two force profiles for the LHRM (see Figure 5); one for positive current feeding (continuous line, see Figure 5) and one for the negative current (discontinuous line). The LHRM force profiles are substantially higher than in the LSRM. The main FEM comparison Energies 2018, 11, 2805 6 of 14 results obtained from phase A are summarized in Table 1. LHRM phase A+ LHRM phase ALSRM phase A 60 60 40 40 20 20 0 PM-LSRM phase B+ PM-LSRM phase BLSRM base phase B 80 F X (N) F X (N) 80 0 -20 -20 -40 -40 -60 -60 -80 -80 0 5 10 15 20 25 30 0 5 10 x (mm) (a) 20 25 30 (b) 80 LHRM phase C+ LHRM phase CLSRM phase C 80 60 LHRM phase D+ LHRM phase DLSRM phase D 60 40 40 20 F X (N) 20 F X (N) 15 x (mm) 0 0 -20 -20 -40 -40 -60 -60 -80 -80 0 5 10 15 20 25 30 0 5 10 x (mm) 15 20 25 30 x (mm) (c) (d) Figure 5. FEM propulsion force comparison results for linear switched reluctance motor (LSRM) and LHRM at J = ±15 A/mm2 . (a) Phase A. (b) Phase B. (c) Phase C. (d) Phase D. Table 1. Two-dimensional-finite element analysis (FEM) comparison results for the linear hybrid reluctance motor (LHRM) and linear switched reluctance motor (LSRM). Phase-A, (IA =2.95 A) 1 Average force (N) for FX,A > 0 Average force (N) for FX,A < 0 1 Positive peak force (N) Negative peak force (N) 1 LHRM LSRM ∆FX,A (%) 42 −43.2 99.1 −90 23.1 −23.1 35.2 −35 82 87 181 157 The average force is computed for positive and negative semi-periods. The phase-force profiles are shifted τs mm when feeding with positive or negative phase current, that is, FX ( x + τS , − I ) = FX ( x, I ), as can be seen in Figure 5. Table 2 shows the comparison results between phases, when feeding with a positive current density of J = +15 A/mm2 (I = +2.95 A), along with the cogging force values whose force profile is depicted in Figure 6. As is usual in the linear machines, the border phases (i.e., phases A and D) are expected to have slightly different values because of the loss of magnetic symmetry in the borders. Table 2. Phase comparison LHRM main results. J =15 A/mm2 , (I=2.95 A) FX,A+ FX,B+ FX,C+ FX,D+ FCogging Average force (N) for FX > 0 Average force (N) for FX < 0 Positive peak force (N) Negative peak force (N) 42 −43.2 99.1 −90 45.7 −42.7 96.4 -94.6 42.9 −45.5 94.8 −96.2 42 −42 90.1 −99 2.93 −2.91 8.8 −8.8 0 Average force (N) for 𝐹𝑋 < 0 Positive peak force (N) Energies 2018, 11, 2805 Negative peak force (N) 42 45.7 42.9 42 2.93 −43.2 −42.7 −45.5 −42 −2.91 99.1 −90 96.4 -94.6 94.8 −96.2 90.1 −99 8.8 −8.8 7 of 14 Figure 6. Coggingforce force FEM Figure 6. Cogging FEMresult. result. The force profiles shown in Figure 5 are depicted together in Figure 7a. From this figure, an The activation force profiles shown in are depicted in Figure(to 7a.left, From an phase-sequence forFigure positive5(to right, x > 0) ortogether negative movement x < 0)this can figure, be activationdeduced. phase-sequence for positive (to starting right, xfrom > 0)x or movement (to left, xmust < 0) can be For obtaining a positive thrust = 0 negative mm, the phase-activation sequence [B+, C−, D+, A+, B−, C+, Dthrust −, A−,starting B+...], and for a xnegative thrust, it must be [D−, A−,sequence B+, C−, must deduced.beFor obtaining a positive from = 0 mm, the phase-activation D+, A+, B − , C+, D − ...]. The curve resulting from wrapping the force peaks (see Figure 7a, red thick be [B+, C-, D+, A+, B-, C+, D-, A-, B+...], and for a negative thrust, it must be [D-, A-, B+, C-, D+, A+, Bline) is the total propulsion force when the motor phases are excited following the above-mentioned , C+, D-...]. The curve resulting from wrapping the force peaks (see Figure 7a, red thick line) is the positive sequence for a flat current waveform and without overlapping phase currents. The optimal total propulsion when the motor phases areinexcited following thethe above-mentioned Energies 2018,force 11,interval x FOR PEER 7 of 14 positive conduction forREVIEW phase A is also depicted Figure 7a, in which for LHRM dimensions sequencegiven for ina Table flat A1 current without overlapping phase are [8.75,waveform 12.75 mm] forand A+, and [24.75, 28.75 mm] for −A. Figurecurrents. 7b shows theThe totaloptimal 2 given in Table A1 are [8.75, 12.75 mm] for A+, and [24.75, 28.75 mm] for −A. Figure 7b shows the total propulsion force positive fordepicted the currentin densities J ∈ in ±10, ±for 15] A/mm . [±5, conduction interval forfor phase A thrust is also Figureof7a, which the LHRM dimensions propulsion force for positive thrust for the current densities of J∈ [±5, ±10, ±15] A/mm2. 110 80 100 60 90 80 40 70 F X (N) F X (N) 20 0 -20 60 50 40 -40 30 -60 A+ B+ C+ D+ A- B- C- D- -80 20 10 0 5 10 15 x (mm) (a) 20 25 30 0 J=5A/mm 0 5 10 2 J=10A/mm 15 2 J=15A/mm 20 2 25 30 x (mm) (b) Figure ±15 A/mm22,, all Figure7.7.FEM FEMresults. results.(a) (a)J J== ± 15 A/mm all phases phases propulsion propulsionforce, force,total totalpropulsion propulsionforce force(red (red thick ∈ [±5,5,±± ±]. 15]. thickline) line)and andconduction conductioninterval intervalfor forphase phaseA. A.(b) (b)Total Totalpropulsion propulsion force force at at JJ ∈ 10,10, ±15 Inorder orderto toassess assessthe thedemagnetization demagnetizationofofthe thepermanent permanentmagnets, magnets,the theairgap airgapflux fluxdensity densityhas has In been drawn in the y-direction, which is the PM-magnetization direction, and then comparing these been drawn in the y-direction, which is the PM-magnetization direction, and then comparing these fielddistributions distributionswith withzero zerocurrent currentand andwhen whenexciting excitingphase phase A. A. field ThePM PM operating operating point point where the the permeance of the circuitcircuit meets The pointisisdefined definedasasthethe point where permeance ofmagnetic the magnetic the magnet BH characteristic. The irreversible demagnetization occurs when the PM’s flux density meets the magnet BH characteristic. The irreversible demagnetization occurs when the PM’s flux decreases under magnet BH-characteristic knee value. N32 For grade, residual is 1.2 T at density decreases under magnet BH-characteristic kneeFor value. N32the grade, the induction residual induction ◦ ◦ ◦ ◦ ◦ the℃ knee are values 0.3 T atare 60 0.3 C, 0.4 at 80 T at C, and is201.2CTand at 20 andvalues the knee T atT60 ℃, C, 0.40.5 T at 80100 ℃, 0.5 T at0.6 100T at ℃,120 and C. 0.6 T at 120 ℃. The critical points for phase A are found when the propulsion force reach its peak values, which occurs at mover positions of 6 mm and 28 mm for JA = −15A/mm2, and at mover positions of 10 mm and 22 mm for JA = + 15A/mm2 (see Figure 7a). The points analyzed are at mover positions of 22 mm and JA = 15A/mm2, and mover at 28 mm and JA = −15A/mm2 (see Figure 8). The PM critical areas are field distributions with zero current and when exciting phase A. The PM operating point is defined as the point where the permeance of the magnetic circuit meets the magnet BH characteristic. The irreversible demagnetization occurs when the PM’s flux density decreases under magnet BH-characteristic knee value. For N32 grade, the residual induction Energies 11, 2805 is 1.2 T2018, at 20 ℃ and the knee values are 0.3 T at 60 ℃, 0.4 T at 80 ℃, 0.5 T at 100 ℃, and 0.68 of T 14 at 120 ℃. The critical points for phase A are found when the propulsion force reach its peak values, which The critical points for phase A are found when the propulsion force reach its peak values, which occurs at mover positions of 6 mm and 28 mm for JA = −15A/mm2, and at mover positions of 10 mm occurs at mover positions of 6 2mm and 28 mm for JA = −15A/mm2 , and at mover positions of 10 mm and 22 mm for JA = + 15A/mm (see Figure 7a). The points analyzed are at mover positions of 22 mm and 22 mm for JA 2= +15A/mm2 (see Figure 7a). The points analyzed are at mover positions of 22 mm and JA = 15A/mm , and mover at 28 mm and JA = −15A/mm2 (see Figure 8). The PM critical areas are and JA = 15A/mm2 , and mover at 28 mm and JA = −15A/mm2 (see Figure 8). The PM critical areas are highlighted (see Figure 8a,b). The By(x,J) distribution field is computed along the airgap red line highlighted (see Figure 8a,b). The By (x,J) distribution field is computed along the airgap red line shown shown in Figures 8a,b, with the variable x being the position over this line, and J being the current in Figure 8a,b, with the variable x being the position over this line, and J being the current density, density, whose values are zero in all phases J = 0, and 𝐽 = 𝐽𝐴 = ±2 15 A/mm2 (see Figures 8c and 8d whose values are zero in all phases J = 0, and J = J A = ±15 A/mm (see Figure 8c,d in black/red lines, in black/red lines, respectively). The results reveal that PM would be demagnetized when operating respectively). The results reveal that PM would be demagnetized when operating at JA = 15 A/mm2 at at JA = 15 A/mm2 at mover position of 22 mm (see Figure 8c), and for magnet temperature exceeding mover position of 22 mm (see Figure 8c), and for magnet temperature exceeding 80 ◦ C. 80 °C. Energies 2018, 11, x FOR PEER REVIEW (a) (c) (b) 8 of 14 (d) Figure8.8.FEM FEMresults resultsforfor the of the density. By field for mover 22 and mm Figure the ByBcomponent of the fluxflux density. (a) B(a) y field for mover at 22 at mm y component 2 . (b) B field for mover at 28 mm and feeding phase A at 2. (b) By and feeding = +15 A/mm feeding phasephase A at JA A =at + J15 A/mm field for mover at 28 mm and feeding phase A at J A = −15 y A 2 . (c) B distribution field along the airgap, see red line in Figure 8a, for J = 0 and JA = −2.15 A/mm (c)A/mm By distribution y field along the airgap, see red line in Figure 8a, for J = 0 and JA = 15 A/mm2. JA B =y 15 A/mm2 . field (d) Balong field theinairgap, inJAFigure 8b at J2. = 0 and (d) distribution the airgap, seealong red line Figure see 8b atred J = line 0 and = −15 A/mm y distribution 2 JA = −15 A/mm . 5. Experimental Results 5. Experimental Results In order to validate the FEM results, an LHRM prototype (see Figures 9b and 9c) was built and In order to validate the FEM results, an LHRM prototype (see Figure 9b,c) was built and tested, tested, with the main dimensions shown in Table A1. The experimental setup (see Figure 9a) consists with the main dimensions shown in Table A1. The experimental setup (see Figure 9a) consists of a of a system for positioning the mover at a given position and a load cell for measuring the static thrust system for positioning the mover at a given position and a load cell for measuring the static thrust force. force. The force is measured in each millimeter, in the range 𝑥 ∈ [0, 2 · τ𝑆 ], which means 32 measures The force is measured in each millimeter, in the range x ∈ [0, 2·τS ], which means 32 measures for the for the 6 current densities J∈ [±5, ±10, ±15]. Considering the four phases, the total number of 6 current densities J ∈ [±5, ±10, ±15]. Considering the four phases, the total number of measures is measures is 4 x 6 x 32 = 768. These results are compared with the FEM results in Figures 10–13. The 4 × 6 × 32 = 768. These results are compared with the FEM results in Figures 10–13. The experimental experimental results are in agreement with the FEM results, which validates the FEM simulation results are in agreement with the FEM results, which validates the FEM simulation results. results. of a system for positioning the mover at a given position and a load cell for measuring the static thrust force. The force is measured in each millimeter, in the range 𝑥 ∈ [0, 2 · τ𝑆 ], which means 32 measures for the 6 current densities J∈ [±5, ±10, ±15]. Considering the four phases, the total number of measures is 4 x 6 x 32 = 768. These results are compared with the FEM results in Figures 10–13. The Energies 2018, 11, 2805 9 of 14 experimental results are in agreement with the FEM results, which validates the FEM simulation results. (a) (b) (c) Energies 11, x FORprototype. PEER REVIEW 9 of 14 Figure2018, LHRM (a) Experimental (b) LHRM frontal Moverassembly. magnets Figure 9.9.LHRM prototype. (a) Experimental setup.setup. (b) LHRM frontal view. (c)view. Mover(c) magnets assembly. Figure 10. Experimental vs. FEM simulation phase-force results for J = ± 5 A/mm . 2 Figure 10. Experimental vs. FEM simulation phase-force results for J = ±5 A/mm . 2 Energies 2018, 11, 2805 Figure 10. Experimental vs. FEM simulation phase-force results for J = ± 5 A/mm2. Energies 2018, 11, x FOR PEER REVIEW 10 of 14 10 of 14 Figure Experimentalvs. vs.FEM FEM simulation simulation phase-force results forfor J = J±= 10 A/mm . 2. Figure 11. 11. Experimental phase-force results ±10 A/mm 2 2. 2. Figure Experimentalvs. vs.FEM FEM simulation simulation phase-force results forfor J = J±= 15 A/mm Figure 12. 12. Experimental phase-force results ±15 A/mm Energies 2018, 11, 2805 11 of 14 Figure 12. Experimental vs. FEM simulation phase-force results for J = ± 15 A/mm2. Figure13. 13.Experimental Experimental vs. vs. FEM Figure FEM simulation simulationcogging coggingforce forceresults. results. 6. 6. Conclusions Conclusionsand andDiscussion Discussion From results,the theoperating operating principle profiles are validated and Fromthe theexperimental experimental results, principle andand forceforce profiles are validated and this enables thethe linear hybrid reluctance motor (LHRM) as a good candidate for applications with high this enables linear hybrid reluctance motor (LHRM) as a good candidate for applications with force density. Unlike LSRM, thisthis machine needs to to operate through a afour-phase full-bridge high force density. Unlike LSRM, machine needs operate through four-phase full-bridge converter, ordertotosupply supplythe thephase phase current current with the thethe mover converter, inin order the appropriate appropriatesign. sign.AsAsininLSRM, LSRM, mover position and currentsmust mustbe beacquired; acquired; therefore, therefore, aa linear areare required position and currents linearencoder encoderand andcurrent currentsensors sensors required implementing a force control. This force control can be designed for mitigating the force ripple forfor implementing a force (see Energies 2018, 11, x FOR PEERcontrol. REVIEW This force control can be designed for mitigating the force ripple 11 of 14 Figure 7b) by adjusting the currents waveform [28], and thus the force can remain almost flat to its (see Figure 7b) for by adjusting the currents maximum value each current density. waveform [28], and thus the force can remain almost flat to its From maximum value for each current density. the point of view of the cogging force (see Figure 13), this presents a series of peaks of about 2 , whichforce the force pointat ofJ view of the cogging (see Figurevalue. 13), this presents a series of peaks of 10% of From the peak = 15 A/mm is a reasonable Further research should be done 2, which is a reasonable value. Further research should be about 10% of the peak force at J = 15 A/mm to eliminate cogging force by phase-shifting, or by a sensitivity analysis in the pole’s proportions and done to eliminate cogging force by phase-shifting, or by a sensitivity analysis in the pole’s number of phases. proportions and number of phases. The LHRM actuator presented in this paper is conceived as a servomotor used in manufacturing The LHRM actuator presented in this paper is conceived as a servomotor used in manufacturing lines or precision positioning applications whose velocity is relatively low (ub < 2 m/s) and where the lines or precision positioning applications whose velocity is relatively low (ub < 2 m/s) and where the force control is required. For this reason, a typical hysteresis current control is adopted, which is robust force control is required. For this reason, a typical hysteresis current control is adopted, which is and fast [29], being the current controlled around a reference value (Iref ), and whose ripple depends on robust and fast [29], being the current controlled around a reference value (Iref), and whose ripple thedepends hysteresis range. The shape of the controlled current and voltage are shown in Figure 14, and it on the hysteresis range. The shape of the controlled current and voltage are shown in Figure is characterized by the turnby on/off positions (see Table 3) Table and by current,current, the value 14, and it is characterized the turn on/off positions (see 3) the andreference by the reference the of which directly to the desired force. force. valueisof which linked is directly linked to thepropulsion desired propulsion −1−1 Figure14. 14.Current Currentand andvoltage voltage waveforms waveforms simulation ×1010 ; voltage×10×1 ). Figure simulationresults results(current (current × ; voltage 1 10 ). Table 3. Turn on/off phase excitation. Excited Phase A+ Turn on Position, 𝒙𝒐𝒏 8.5 mm Turn off Position, 𝒙𝒐𝒇𝒇 12.5 mm Energies 2018, 11, 2805 12 of 14 Table 3. Turn on/off phase excitation. Excited Phase Turn on Position, xon Turn off Position, xoff A+ B+ C+ D+ A− B− C− D− 8.5 mm 28.75 mm 16.75 mm 4.5 mm 24.5 mm 12.75 mm 0.75 mm 20.5 mm 12.5 mm 0.5 mm 20.25 mm 8.75 mm 28.5 mm 16.5 mm 4.25 mm 24.25 mm The inherent fault tolerance of the reluctance machines and thus of LSRMs is preserved in the LHRM, because once the damaged phase is removed, the LHRM keeps operating at a new diminished force, as can be inferred from Figure 7a. The motor is easily assembled despite having to put permanent magnets in the mover slots (see Figure 9c), because flux lines attach the PM to the magnetic structure (see Figure 4) and there are no repulsion forces. The thermal aspect is also good because PMs are in the secondary (passive) part, which allows high current densities in the primary (active) part for intermittent operation. From all the findings reported above, this novel structure of linear hybrid reluctance motor can be an interesting option in applications, which requires a high thrust force for intermittent duty cycles, such as in manufacturing industries and robotic systems. Funding: This research was funded by the Spanish Ministerio de Economia, Industria y Competitividad, under the Grant DPI2016-80491-R (AEI/FEDER, UE). Conflicts of Interest: The author declare no conflict of interest. Appendix A. Table A1. LHRM prototype main dimensions and rated values. Parameter Symbol Primary pole width Primary slot width Primary pole length Secondary pole width Secondary slot width Secondary pole length Mover height Magnet width Magnet height Stack width Air gap length Phase wire diameter Number of wires per pole Rated voltage Rated current Rated power Rated force Rated speed Duty cycle Magnetic steel grade Insulation grade Duty type Permanent Magnet bp cp lp bs cs ls lst bm lm LW g d Nph Ub Ib Pb FX ub DC Value 6 mm 6 mm 30 mm 7 mm 9 mm 7 mm 30 mm 8 mm 6.5 mm 30 mm 0.5 mm 0.5 mm 180 120 V 3A 150 W 90 N 1.5 m/s 0.4 FeV 270/50 HA B-Class ∆T = 80 ◦ C S3 NdFeB32 Energies 2018, 11, 2805 13 of 14 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. Zhang, B.; Yuan, J.; Pan, J.; Wu, X.; Luo, J.; Qiu, L. Controllability and Leader-Based Feedback for Tracking the Synchronization of a Linear-Switched Reluctance Machine Network. Energies 2017, 10, 1728. [CrossRef] Andrada, P.; Blanque, B.; Martinez, E.; Perat, J.I.; Sanchez, J.A.; Torrent, M. Environmental and life cycle cost analysis of one switched reluctance motor drive and two inverter-fed induction motor drives. IET Electr. Power Appl. 2012, 6, 390–398. [CrossRef] Chen, H.; Nie, R.; Yan, W.A. Novel Structure Single-Phase Tubular Switched Reluctance Linear Motor. IEEE Trans. Magn. 2017, 53, 1–4. [CrossRef] Zhao, W.; Zheng, J.; Wang, J.; Liu, G.; Zhao, J.; Fang, Z. Design and Analysis of a Linear Permanent- Magnet Vernier Machine with Improved Force Density. IEEE Trans. Ind. Electr. 2016, 63, 2072–2082. [CrossRef] Enrici, P.; Dumas, F.; Ziegler, N.; Matt, D. Design of a High-Performance Multi-Air Gap Linear Actuator for Aeronautical Applications. IEEE Trans. Energy Convers. 2016, 31, 896–905. [CrossRef] Pan, J.F.; Wang, W.; Zhang, B.; Cheng, E.; Yuan, J.; Qiu, L.; Wu, X. Complimentary Force Allocation Control for a Dual-Mover Linear Switched Reluctance Machine. Energies 2018, 11, 23. [CrossRef] Andrada, P.; Blanqué, B.; Martínez, E.; Torrent, M.; Garcia-Amorós, J.; Perat, J.I. New Linear Hybrid Reluctance Actuator. In Proceedings of the International Conference on Electrical Machines (ICEM), Berlin, Germany, 1–4 September 2014. Andrada, P.; Blanque, B.; Martinez, E.; Torrent, M. A Novel Type of Hybrid Reluctance Motor Drive. IEEE Trans. Ind. Electr. 2014, 61, 4337–4345. [CrossRef] Ullah, S.; McDonald, S.; Martin, R.; Atkinson, G.J. A permanent magnet assisted switched reluctance machine for more electric aircraft. In Proceedings of the International Conference on Electrical Machines (ICEM), Lausanne, Switerland, 4–7 September 2016. Hwang, H.; Hur, J.; Lee, C. Novel permanent-magnet-assisted switched reluctance motor (I): Concept, design, and analysis. In Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), Busan, Korea, 23–29 October 2013. Hua, W.; Cheng, M.; Zhu, Z.Q.; Howe, D. Analysis and Optimization of Back EMF Waveform of a Flux-Switching Permanent Magnet Motor. IEEE Trans. Energy Convers. 2008, 23, 727–733. [CrossRef] Hasegawa, Y.; Nakamura, K.; Ichinokura, O. Basic consideration of switched reluctance motor with auxiliary windings and permanent magnets. In Proceedings of the International Conference on Electrical Machines (ICEM), Marseille, France, 2–5 September 2012. Ding, W.; Yang, S.; Hu, Y.; Li, S.; Wang, T.; Yin, Z. Design Consideration and Evaluation of a 12/8 High-Torque Modular-Stator Hybrid Excitation Switched Reluctance Machine for EV Applications. IEEE Trans. Ind. Electr. 2017, 64, 9221–9232. [CrossRef] Afinowi, I.A.A.; Zhu, Z.Q.; Guan, Y.; Mipo, J.C.; Farah, P. Hybrid-Excited Doubly Salient Synchronous Machine with Permanent Magnets Between Adjacent Salient Stator Poles. IEEE Trans. Magn. 2015, 51, 1–9. [CrossRef] Lobo, N.S.; Lim, H.S.; Krishnan, R. Comparison of Linear Switched Reluctance Machines for Vertical Propulsion Application: Analysis, Design, and Experimental Correlation. IEEE Trans. Ind. Appl. 2008, 44, 1134–1142. [CrossRef] Lee, S.; Kim, S.; Saha, S.; Zhu, Y.; Cho, Y. Optimal Structure Design for Minimizing Detent Force of PMLSM for a Ropeless Elevator. IEEE Trans. Magn. 2014, 50, 1–4. [CrossRef] Lin, J.; Cheng, K.W.E.; Zhang, Z.; Cheung, N.C.; Xue, X. Adaptive sliding mode technique-based electromagnetic suspension system with linear switched reluctance actuator. IET Electr. Power Appl. 2015, 9, 50–59. [CrossRef] Chen, Y.; Cao, M.; Ma, C.; Feng, Z. Design and Research of Double-Sided Linear Switched Reluctance Generator for Wave Energy Conversion. Appl. Sci. 2018, 8, 1700. [CrossRef] Wang, M.; Li, L.; Pan, D. Detent Force Compensation for PMLSM Systems Based on Structural Design and Control Method Combination. IEEE Trans. Ind. Electr. 2015, 62, 6845–6854. [CrossRef] Hao, W.; Wang, Y. Comparison of the Stator Step Skewed Structures for Cogging Force Reduction of Linear Flux Switching Permanent Magnet Machines. Energies 2018, 11, 2172. [CrossRef] Hasanien, H.M. Particle Swarm Design Optimization of Transverse Flux Linear Motor for Weight Reduction and Improvement of Thrust Force. IEEE Trans. Ind. Electr. 2011, 58, 4048–4056. [CrossRef] Energies 2018, 11, 2805 22. 23. 24. 25. 26. 27. 28. 29. 14 of 14 Huang, X.; Tan, Q.; Wang, Q.; Li, J. Optimization for the Pole Structure of Slot-Less Tubular Permanent Magnet Synchronous Linear Motor and Segmented Detent Force Compensation. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [CrossRef] Amorós, J.G.; Andrada, P.; Blanque, B.; Marin-Genesca, M. Influence of Design Parameters in the Optimization of Linear Switched Reluctance Motor under Thermal Constraints. IEEE Trans. Ind. Electr. 2018, 65, 1875–1883. [CrossRef] Garcia-Amoros, J.; Molina, B.B.; Andrada, P. Modelling and simulation of a linear switched reluctance force actuator. IET Electr. Power Appl. 2013, 7, 350–359. [CrossRef] Meeker, D.C. Finite Element Method Magnetics, Version 4.2 (28 February 2018 Build). Available online: http://www.femm.info (accessed on 16 October 2018). Henrotte, F.; Deliège, G.; Hameyer, K. The eggshell method for the computation of electromagnetic forces on rigid bodies in 2D and 3D. In Proceedings of the Conference on Electromagnetic Field Computation CEFC, Perugia, Italy, 16–18 April 2002. Nogueira, A.F.L. Analysis of magnetic force production in slider actuators combining analytical and finite element methods. J. Microw. Optoelectron. Electromagn. Appl. 2011, 10, 243–250. [CrossRef] Schramm, D.S.; Williams, B.W.; Green, T.C. Torque ripple reduction of switched reluctance motors by phase current optimal profiling. In Proceedings of the Conference on IEEE Power Electronics Specialists Conference. PESC’92 Record, Toledo, Spain, 29 June–3 July 1992. Dorningos, J.L.; Andrade, D.A.; Freitas, M.A.A.; De Paula, H. A new drive strategy for a linear switched reluctance motor. In Proceedings of the Conference on IEEE International Electric Machines and Drives IEMDC’03, Madison, WI, USA, 1–4 June 2003. © 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).