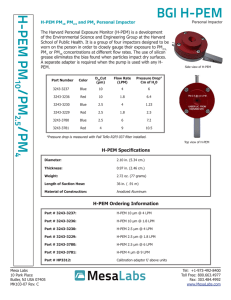

UNIVERSITI TEKNOLOGI MARA FAKULTI KEJURUTERAAN KIMIA HEAT & MASS TRANSFER LABORATORY (CHE504) NAME STUDENT NO GROUP EXPERIMENT DATE PERFORMED SEMESTER PROGRAMME / CODE SUBMIT TO No. 1 2 3 4 5 6 7 8 9 10 11 12 13 : NURLINA SYAHIIRAH BINTI MD TAHIR : 2017632214 : EH2204I : GAS ABSORPTION (L8) (INDIVIDUAL REPORT) : 5th APRIL 2018 :4 : CHEMICAL ENGINEERING / EH220 : MADAM SYAFIZA BINTI ABD HASHIB Title Abstract/Summary Introduction Aims Theory Apparatus Methodology/Procedure Results Calculations Discussion Conclusion Recommendations Reference Appendix TOTAL MARKS Allocated Marks (%) Marks 5 5 5 5 5 10 10 10 20 10 5 5 5 100 Remarks: Checked by: Rechecked by: --------------------------- --------------------------- Date: Date: TABLE OF CONTENT 1.0 ABSTRACT ................................................................................................................... 2 2.0 INTRODUCTION......................................................................................................... 3 3.0 OBJECTIVES ............................................................................................................... 4 4.0 THEORY ....................................................................................................................... 5 5.0 MATERIALS & APPARATUS ................................................................................... 7 6.0 METHODOLOGY ....................................................................................................... 8 7.0 RESULTS .................................................................................................................... 10 8.0 CALCULATIONS ...................................................................................................... 14 9.0 DISCUSSION .............................................................................................................. 17 10.0 CONCLUSION ........................................................................................................... 19 11.0 RECOMMENDATIONS............................................................................................ 20 12.0 REFERENCES ............................................................................................................ 21 13.0 APPENDIX .................................................................................................................. 22 LAB REPORT ON GAS ABSORPTION (L8) 1 1.0 ABSTRACT Gas absorption is mass transfer operation where one or more species is removed from a gaseous stream by dissolution in a liquid. Packed tower with Rashchig Rings packings is used in the experiment. The main objective of the experiment is to examine the air pressure drop across the column as a function of air flow rate for different water flow rates through the column. The pressure drop is observed every 2 minutes at air flowrate of 20 LPM, 40 LPM, 60 LPM, 80 LPM, 100 LPM, 120 LPM, 140 LPM, 160 LPM and 180 LPM for water flowrate of 1 LPM, 2 LPM and 3 LPM, respectively. The experiment is ongoing for the respective water flowrate until flooding occurs. Then, the water flowrate is changed. The pressure drop increases as the air flowrate is increases. Comparing with their respective theoretical data, the pressure drop at 1 LPM and 2 LPM shows higher value but lower value at 3 LPM. The percentage error is determined at 12.50%, 33.33% and 20.00% for water flow rate of 1 LPM, 2 LPM and 3 LPM, respectively. Packing tower work efficiently at lower liquid flow rate. Low liquid flow rate enabling the absorption rate to be maximize. The objectives are successfully obtained, thus the experiment is successfully done. LAB REPORT ON GAS ABSORPTION (L8) 2 2.0 INTRODUCTION Gas absorption is mass transfer operation where one or more species is removed from a gaseous stream by dissolution in a liquid. The component that is extracted from the gaseous stream is known as solute and the component that extracting the solute is known as solvent. Packed column is one of the commonly used gas absorption equipment. Packed column can be operated in co-current as well as counter currently. Counter-current flow is preferable since the contact time between the liquid and gas is greater. This equipment usually consists of a cylindrical column containing a gas inlet and distributing space at the bottom, a liquid inlet and a packing or filing in the tower. The packed column used in the experiment is SOLTEQ-QVF Absorption Column BP751-B which used Raschig Rings as the packings medium. Air and water as the gas and liquid, respectively. At low gas velocity, the pressure drop is proportional to the flow rate. At loading point, the gas starts to hinder the liquid flow and accumulation occurs in the packings. At the upper limit of the gas flow rate which is called flooding velocity, flooding occurs. The operating packed column, in actual operating or industries should be well below flooding since the equipment cannot operate above the flooding velocity. The pressure drop within the system increases as the flow rate of the gas or liquid is increases. LAB REPORT ON GAS ABSORPTION (L8) 3 3.0 OBJECTIVES The following are the objectives for the experiment: 1) To examine the air pressure drop across the column as a function of air flow rate for different water flow rates through the column. 2) To plot the graph of column pressure drop against the air flow rate in a log – log graph. 3) To obtain the pressure drop from the generalized correlation chart as in Appendix. 4) To compare the experimental value and the correlated value. LAB REPORT ON GAS ABSORPTION (L8) 4 4.0 THEORY Gas absorption is mass transfer operation where one or more species is removed from a gaseous stream by dissolution in a liquid. The component that is extracted from the gaseous stream is known as solute and the component that extracting the solute is known as solvent. Carrier gas is the insoluble component present in the gas that is not absorbed by the solvent. The transfer is based on the preferential solubility of solutes in the solvent (Gas Absorption And Desorption, n.d.). Packed towers are used for continuous countercurrent contacting of gas and liquid in absorption (Geankoplis, 1993).The mechanism in packed tower is the gas and liquid phases flows counter – currently where they interact on the packings interface. The liquid flows in downward direction, over the surface of the packing, whereas the gas flows through the space or voids of the packings in upward direction. The gas flow is driven by pressure while the liquid flow is driven by the gravity force. The gas undergoes pressure drop due to the liquid occupied some part of the open space and voids of the packing. Thus, reducing the area available for the gas to flow. If the packing is dry with no liquid feed, then maximum flow gas is available. The pressure drop increases as the liquid flowrate into the tower increases. High flux will resulting in flooding. This occurrence happen at the upper limit of the gas flow rate called flooding velocity since the liquid is blown out with the gas at the flooding point. The gas start to hinder the liquid flow at loading point where accumulation of liquid start appearing in the packing. Low flux will resulting in channelling or weeping. There are two types of packings types which is random and structured. Figure 1 - Typical Packed Tower Packings: (a) Raschig ring, (b) Lessing ring, (c) Berl Saddle, (d) Pall Ring (Geankoplis C. J., 1993) LAB REPORT ON GAS ABSORPTION (L8) 5 One of the oldest specially manufactured types of random packings are Raschig rings and still in general use. (Separation Columns (Distillation, Absorption and Extraction)) They provide a large surface area within the volume of the column for the interaction between liquid and gas. They also enhance the contact time between liquid and gas. (iitb.vlab.co.in, 2011) The generalized correlation for pressure drops in packed column (Eckert, 1970) Figure 2 - Generalized Correlation for Pressure Drop in Packed Columns (Eckert, Chem. Eng. Prog., 66(3), 39 (1970) y − axis = x − axis = Where, Gy Gy 2 FP vx 0.1 g C (ρx − ρy )ρy ρy Gx √ Gy ρx − ρy (Equation 1) (Equation 2) = Gas Mass Velocity, kg/m2.s Gx = Liquid Mass Velocity, kg/m2.s ρy = Density of Gas, kg/m3 ρx = Density of Liquid, kg/m3 FP = Packing Factor, m-1 vx = Kinematic Viscosity of Liquid, m2/s gC = gravitational constant, LAB REPORT ON GAS ABSORPTION (L8) 6 5.0 MATERIALS & APPARATUS 5.1 Materials 1) Water. 2) Air. 5.2 Apparatus 1) SOLTEQ-QVF Absorption Column BP751-B Figure 3 - The Packed Column Used in The Experiment with Raschig Rings as The Packings LAB REPORT ON GAS ABSORPTION (L8) 7 6.0 METHODOLOGY 6.1 Start-Up Procedures 1) All the valves are ensured to be closed except for the ventilation valve, V13. 2) All the gas connections are checked to be properly fitted. 3) All the valve on the compressed air supply line is opened. The supply pressure is set to between 2 to 3 bars by turning the regulator knob clockwise. 4) The shut-off valve on the CO2 gas cylinder is opened and the pressure is checked. 5) The power for the control panel is turned on. 6.2 Experimental Procedures: Hydrodynamics of a Packed Column (Wet Column Pressure Drop) 1) The receiving vessel B2 is filled through the charge port with 50L of water by opening valve V3 and V5. Then, valve V3 is closed. 2) Valves V9 and V10 is opened slightly. The flow of the water from vessel B1 through pump P1 is observed. Pump P1 is switched on. 3) Valve V11 is slowly opened and adjusted to give a water flowrate of around 1L/min. 4) The water is allowed to enter the top of the column K1, flow down the column and accumulated at the bottom until it overflows back to vessel B1. 5) The valve V11 is opened and adjusted to give a water flow rate of 1 L/min into column K1. 6) The valve V1 is opened and adjusted to give and air flow rate of 20L/min into column K1. 7) The liquid and gas flow in the column K1 is observed. The pressure drop across the column at dPT-201 is recorded. 8) Steps 3 to 5 is repeated with different values of air flow rate, each time increasing by 20 L/min each time after two minutes while maintaining the same water flow rate. 9) Steps 3 to 6 is repeated with different values of water flow rate, each time increasing by 1 L/min by adjusting valve V11. LAB REPORT ON GAS ABSORPTION (L8) 8 6.3 Shut-Down Procedures 1) Pump, P1 is switched off. 2) Valves, V1, V2 and V12 is closed. 3) The valve on the compressed air supply line is closed and the supply pressure is exhausted by turning the regulator knob counter clockwise all the way. 4) The shut-off valve on the CO2 gas cylinder is closed. 5) All the liquid in the column K1 is drained by opening valve V4 and V5. 6) All the liquid from the receiving vessels, B1 and B2 is drained by opening valves, V7 and V8. 7) All the liquid from the pump P1 is drained by opening valve V10. 8) The power for the control panel is turned off. LAB REPORT ON GAS ABSORPTION (L8) 9 7.0 RESULTS Table 7.1: Pressure Drop At Different Water Flow Rate and Air Flow Rate. Flow rate Pressure Drop (L/min) (mBar) Air 20 40 60 80 100 120 140 160 180 1.0 0 0 2 4 5 11 14 25 32 (F) 2.0 0 2 3 6 10 14 25 41(F) F 3.0 1 2 5 10 18 36(F) F F F 160 180 Water *F = Flooding Table 7.2: Pressure Drop At Different Water Flow Rate and Air Flow Rate. Flow rate Pressure Drop (L/min) (mm H2O/m) Air 20 40 60 80 100 1.0 0.00 0.00 25.49 50.99 63.73 2.0 0.00 25.49 38.24 76.48 127.46 178.45 318.66 3.0 12.75 25.49 63.73 127.46 229.44 Water 120 140 140.21 178.45 318.66 458.87 (F) F 522.60 (F) F 407.89 (F) F F *F = Flooding Table 7.3: Theoretical Pressure Drop At Different Water Flow Rate and Air Flow Rate. Flow rate Theoretical Pressure Drop (L/min) (in H2O/ft) Air 20 Water 40 60 80 100 120 140 160 180 1.0 0.0000 0.0906 0.2000 0.2917 0.4205 0.7500 1.1667 F F 2.0 0.0750 0.2500 0.3958 0.5000 1.0000 F F F F 3.0 0.1600 0.4318 0.7500 1.5000 F F F F F *F = Flooding LAB REPORT ON GAS ABSORPTION (L8) 10 Table 7.4: Theoretical Pressure Drop At Different Water Flow Rate and Air Flow Rate. Flow Theoretical Pressure Drop rate (mm H2O/m) (L/min) Air 20 Water 40 60 1.0 0.0000 2.0 6.2483 20.8275 32.9741 3.0 7.5479 16.6620 80 100 120 140 160 180 24.3015 35.0319 62.4825 97.1978 F F 41.6550 83.3100 13.3296 35.9733 62.4825 124.9650 F F F F F F F F F *F = Flooding Table 7.5: Log Pressure Drop and Log Air Flowrate Value (Experimental) Flow rate Log Pressure Drop (L/min) (mm H2O/m) Air Water 1.3010 1.6021 1.7782 1.9031 2.0000 2.0792 2.1461 2.2041 2.2553 1.0 - 2.0 - 3.0 - 1.4064 1.7074 1.8044 2.1468 2.2515 2.5033 1.4064 1.5825 1.8835 2.1054 2.2515 2.5033 1.1054 1.4064 1.8044 2.1054 2.3607 2.6617 (F) F 2.7182 (F) F 2.6105 (F) F F *F = Flooding Table 7.6: Log Pressure Drop and Log Air Flowrate Value (Theoretical) Flow rate Log Theoretical Pressure Drop (L/min) (mm H2O/m) Air Water 1.3010 1.6021 1.7782 1.9031 2.0000 2.0792 2.1461 2.2041 2.2553 1.0 - 0.8778 1.2217 1.3856 1.5445 1.7958 1.9877 F F 2.0 0.7958 1.3186 1.5182 1.6197 1.9207 F F F F 3.0 1.1248 1.5560 1.7958 2.0968 F F F F F *F = Flooding LAB REPORT ON GAS ABSORPTION (L8) 11 Table 7.7: Data from Calculation to Determine Theoretical Pressure Drop Air Gas Mass Capacity Liquid Mass Velocity Flow Parameter Flowrate Velocity Parameter (𝑮𝒙 ) 𝐤𝐠/𝐦𝟐 𝐬 (x-axis) (𝐕𝐲 ) (𝑮𝐲 ) (y-axis) LPM 𝐤𝐠/𝐦𝟐 𝐬 20 0.0779 0.0011 3.3025 6.6049 9.9074 1.4566 2.9132 4.3698 40 0.1558 0.0046 3.3025 6.6049 9.9074 0.7283 1.4566 2.1849 60 0.2338 0.0103 3.3025 6.6049 9.9074 0.4855 0.9711 1.4566 80 0.3117 0.0184 3.3025 6.6049 9.9074 0.3641 0.7283 1.0924 100 0.3896 0.0287 3.3025 6.6049 9.9074 0.2913 0.5826 0.8740 120 0.4675 0.0414 3.3025 6.6049 9.9074 0.2428 0.4855 0.7283 140 0.5454 0.0563 3.3025 6.6049 9.9074 0.2081 0.4162 0.6243 160 0.6234 0.0735 3.3025 6.6049 9.9074 0.1821 0.3641 0.5462 180 0.7013 0.0931 3.3025 6.6049 9.9074 0.1618 0.3237 0.4855 1 2 3 1 2 3 LPM LPM LPM LPM LPM LPM Table 7.8: Percentage Error of The Experiment Water Flow Theoretical Flooding Experimental Flooding Percentage Error Rate Air Flow Rate Air Flow Rate (%) (L/min) (L/min) (L/min) 1 160 180 12.50 2 120 160 33.33 3 100 120 20.00 LAB REPORT ON GAS ABSORPTION (L8) 12 Log Pressure Drop vs Log Air Flowrate 3.0000 2.5000 Log Pressure Drop 2.0000 Exp (1 LPM) Exp (2 LPM) 1.5000 Exp (3 LPM) Theory (1 LPM) Theory (2 LPM) 1.0000 Theory (3 LPM) 0.5000 0.0000 0.0000 0.5000 1.0000 1.5000 2.0000 Log Air Flowrate (LPM) 2.5000 Figure 4 - Log Pressure Drop vs Loq Air Flowrate The graph shows the log pressure drop increases as the log air flowrate increases. Also indicates as air flowrate increases, the pressure drop increases. At 1 LPM and 2 LPM water flowrate, the experimental data shows a higher pressure drop compared to theory but at 3 LPM water flowrate, the experimental data shows a smaller pressure drop compared to theory. LAB REPORT ON GAS ABSORPTION (L8) 13 8.0 CALCULATIONS Density of Air, ρy = 1.175kg/m3 Density of Water, ρx = 996kg/m3 (R. H. Perry, 1973) Packing Factor, FP = 900m3 Column Diameter, D = 80mm Water viscosity, μx = 0.0008 kg/ms (Bingham, 1922) *All properties are at T= 30°C *All calculation is done via excel so the value may vary from calculator Sample Calculation for Kinematic Viscosity of Water, vx Kinematic Viscosity of Water, vx = vx = Dynamic Viscosity, μx Density of Water, ρx 0.0008 kg/ms 996kg/m3 vx = 0.8032 × 10−6 m2 /s Sample Calculation for Cross Sectional Area of Packed Column πD2 Cross Sectional Area, AC = 4 π(0.08m)2 AC = 4 AC = 0.0050 m2 Sample Calculation for Gas Mass Velocity, 𝐆𝐲 Gas Mass Velocity, Gy = Volume Flowrate, Vy (Density of Gas, ρy ) Cross − Sectional Area, AC 20L 1m3 1min 1.175kg ( ) ( min 1000L 60s ) ( m3 ) Gy = 0.0050m2 Gy = 0.0779 kg/m2 s LAB REPORT ON GAS ABSORPTION (L8) 14 Sample Calculation for Liquid Mass Velocity, 𝐆𝐱 Liquid Mass Velocity, Gx = Volume Flowrate, Vx (Density of Liquid, ρx ) Cross − Sectional Area, AC 1L 1m3 1min 996kg min (1000L) ( 60s ) ( m3 ) Gx = 0.0050m2 Gx = 3.3025 kg/m2 s Sample Calculation for Capacity Parameter, y-axis y − axis = Gy 2 FP vx 0.1 g C (ρx − ρy )ρy 0.1 0.0783 kg 2 10−6 m2 ( ) (900m−1 ) (0.8032 × 2 s ) m s y − axis = 996kg 1.175kg 1.175kg (1) ( − )( ) m3 m3 m3 y − axis = 0.0011 Sample Calculation for Flow Parameter, x-axis x − axis = ρy Gx √ Gy ρx − ρy 3.3025 kg 1.175kg ( ) m2 s m3 √ x − axis = 0.0779 kg 996kg 1.175kg ( ) − m2 s m3 m3 x − axis = 1.4566 Sample Calculation for Theoretical Pressure Drop Units, in H2O/ft to mm H2O/m Theoretical Pressure Drop, ∆PTheory = 0.0750in H2 O 83.31 ∗ mm H2 O/m ( ) ft 1 in H2 O/ft ∆PTheory = 6.2483 mmH2 O/m *Eckert, Chem. Eng. Prog., 66(3), 39 (1970) LAB REPORT ON GAS ABSORPTION (L8) 15 Sample Calculation for Pressure Drop Units, mBar to mm H2O/m Pressure Drop, ∆PExp 2mBar 10.197162129779 mmH2 O = ( ) Height of Column, H 0.8𝑚 1 mBar ∆PExp /H = 25.49 mmH2 O/m *1 mBar = 10.197162129779 mm H2O (ConvertUnits.com, n.d.) *Height column = 0.8 m Sample Calculation for Percentage Error Experimental value − Theoretical Value Percentage Error (%) = | | × 100% Theoretical Value 180 − 160 Percentage Error (%) = | | × 100% 160 Percentage Error (%) = 12.5% Sample Calculation for Pressure Drop Figure 5 - The Theoretical Pressure Drop Is Located at The Intersection Between Flow Parameter and Capacity Parameter for The Respective Flow Rate LAB REPORT ON GAS ABSORPTION (L8) 16 9.0 DISCUSSION The main objective for the experiment is to examine the air pressure drop across the column as a function of air flow rate for different water flow rates through the column which being visualize in the log – log graph (Figure 4). The air flow rate is adjusted from 20 L/min until 180 L/min with 20 L/min increment within 2 min as the allocated time for each flow rate to collect the pressure drop for the particular gas flow rate at 1 L/min of water flow rate. The data is collected until flooding occurs before proceeding to the next water flow rate up to 3 L/min with increment of 1 L/min. Based on Figure 4, the log pressure drop increases as the log air flow rate increases. This also indicates that as the air flow rate increases, the pressure drop also increases. From the graph, we could also observe that, the higher the water flow rate, the lower the log air flow rate. This is due to the water flow downwards hinder the air flow upwards, resulting in high pressure drop. Thus, at high water flow rate, flooding happens rather faster than at the lower one since the resistance that the water flow give to the air flow is greater. The same case happens for the theoretical data. Proving that the experimental data shows the same pattern as theoretical one. Although for both theory and experimental data, the relationship between pressure drop and air flow rate is proportional to each other, the experimental pressure drop is larger compared to the theoretical pressure drop at water flow rate of 1 L/min and 2 L/min. Vary at 3 L/min, the experimental pressure drop is smaller compared to the theoretical pressure drop. This could be due to error in controlling the water flowrate from hindering the gas flowrate downwards at the bottom of the gas absorption column. The flooding occurrence at water flow rate of 1 L/min according to the theory should have been at 160 L/min air flow rate, however during the experiment the flooding occurs at 180 L/min. As for water flow rate of 2 L/min and 3 L/min, theoretical flooding occurs at 120 L/min and 100 L/min however the experimental flooding happens at 160 L/min and 120 L/min, respectively. This resulting in error for the experiment which is 12.50%, 33.33% and 20.00% for water flow rate of 1 L/min, 2 L/min and 3 L/min, respectively. The reason of the error could be due to human error. During the experiment, the students need to control the water from exceeding the entrance of the gas flow rate at the bottom of the column. However, at any time the water level at the bottom could be too high which hinder the gas flow thus resulting in the late flooding flow rate. LAB REPORT ON GAS ABSORPTION (L8) 17 The error could also happen due to parallax error during the adjustment of the next flow rate in case of the student did not read the marking scale at eye level where the eyes should be perpendicular to the marking scale. For instance, from 1 L/min to 2 L/min, maybe the student mistakenly adjusted at 1.9 L/min. Thus, also affecting the flooding flow rate. The equipment itself might not properly maintain which resulting in different value at the marking scale of the flow rate and the real flow rate happening within the system of the packed tower. Besides, the theoretical data and the experimental data vary could also due to the differences in packing tower such as the packings within the tower. Whether the packing itself is different or the condition of the Raschig rings is not the same with the one in the theory. The packings also degrade along with time, reduces the efficiency of the packings. Thus, also affecting the flooding flow rate. Although error occurs, the experiment is still considered success since the errors is not too big and the distance of the respective graph at the theory and experimental data is not far based on Figure 4. Based on the experiment, we could also observe the fact that the packed tower used in the experiment is working efficiently at lower liquid flow rate since flooding occurs at very high gas flow rate. This allow the contacting time between the gas and liquid to be lengthen and thus maximize the absorption rate. However, at high liquid flow rate, flooding is quick to happened even at low gas flow rate. This shorten the contact time between gas and liquid which then minimize the absorption rate. LAB REPORT ON GAS ABSORPTION (L8) 18 10.0 CONCLUSION The pressure drop increases as the air flowrate increases. The pressure drop also increases as the water flowrate increases. At 1 LPM and 2 LPM water flowrate, the pressure drop is higher than the theoretical value. At 3 LPM water flowrate, the pressure drop is lower than the theoretical value. The percentage error is determined at 12.50%, 33.33% and 20.00% for water flow rate of 1 LPM, 2 LPM and 3 LPM, respectively. Packing tower work efficiently at low liquid flow rate compared to high liquid flow rate. Low liquid flow rate enabling the absorption rate to be maximize. Since the objectives is successfully obtained, the experiment is successfully done. LAB REPORT ON GAS ABSORPTION (L8) 19 11.0 RECOMMENDATIONS There are several recommendations can be made to improve the experiment for a better result. The students should avoid errors that being caused from themselves such as parallax error. They need to make sure the reading at the marking scale is done correctly where their eyes are perfectly perpendicular to the meniscus of the liquid present in the scale. The packings used in the packed column should be change into a new one. Since, this will yield to more accurate data as the impact of channelling or weeping from previous experiment can be reduced. We could also use other type of packings that have a higher surface area and allows vapor – liquid contact area to be enhanced. The students also need to conduct the experiment with proper personal protective equipment (PPE) so that any risk regarding the experiment can be minimize. Lastly, the students should study the lab manual before conducting the experiment to ensure the experiment run smoothly. LAB REPORT ON GAS ABSORPTION (L8) 20 12.0 REFERENCES Bingham. (1922). Fluidity and Plasticity. New York: McGraw-Hill Book Company. ConvertUnits.com. (n.d.). Convert Milibar to mm H2O - Conversion of Measurement Units. Retrieved 23 April , 2018, from ConvertUnits.com: https://www.convertunits.com/from/millibar/to/mm+H2O Eckert. (1970). Chem. Eng. Prog. Gas Absorption And Desorption. (n.d.). Retrieved 20 April, 2018, from Separation Processes: http://www.separationprocesses.com/Absorption/GA_Chp03.htm Geankoplis, C. J. (1993). Transport Processes and Unit Operations (Edition 3 ed.). Minnesota, United States of America: Prentice-Hall International, Inc. Retrieved 20 April, 2018 Geankoplis, C. J. (1993). Transport Processes and Unit Operations (Third Edition ed.). Minnesota: Prentice Hall International. Retrieved 30 April, 2018 iitb.vlab.co.in. (2011). Gas Liquid Absorption. Retrieved 1 May, 2018, from Sakshat Virtual Labs: http://iitb.vlab.co.in/?sub=8&brch=116&sim=951&cnt=1 R.H. Perry, C. H. (1973). Chemical Engineers' Handbook (Fifth Edition ed.). New York: McGraw-Hill Book Company. Separation Columns (Distillation, Absorption and Extraction). (n.d.). Retrieved 24 April, 2018, from http://ceng.tu.edu.iq/ched/images/lectures/chemlec/st4/c1/EQUIPMENT_DESIGN_LECTURE_25%20mass%20transfer%20equipme nt%203.pdf LAB REPORT ON GAS ABSORPTION (L8) 21 13.0 APPENDIX LAB REPORT ON GAS ABSORPTION (L8) 22