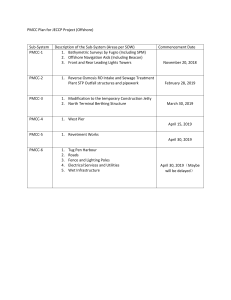

Tool and Die Design (MEng 5261) Pre-requisites: MEng 3504, Production Engineering Debre Tabor University Lectur-1 WEEK-1 12/6/2019 Prepared by: Berhe Syum 1 Course Outline 1. INTRODUCTION TO TOOL AND DIE DESIGN 2.WORK PIECE HOLDING PRINCIPLES 3. CLAMPING PROCESS 4. JIG AND FIXTURE DESIGN 5. TOOL MATERIAL SELECTION 6. SINGLE POINT CUTTING TOOL DESIGN 7. DESIGN OF FORM TOOLS 8. DESIGN OF FORMING DIE (. function, and type of forming die , Design of punching dies, bending die, Progressive drawing dies design, Design forging dies and Design of blow and injection molding dies 12/6/2019 Prepared by: Berhe Syum 2 Chapter-One Introduction TOOL DESIGN ❖Tool design is the process of designing and developing the tools, methods, and techniques necessary to improve manufacturing efficiency and productivity. ❖It does this at a level of quality and economy that will ensure that the cost of the product is competitive. ❖ No single tool or process can serve all forms of manufacturing, tool design is an ever-changing, growing process of creative problem solving. 12/6/2019 Prepared by: Berhe Syum 3 TOOL AND DIE DESIGN AND MANUFACTURING Tool and die design and manufacturing -is a specialized area of manufacturing engineering which comprises the analysis, planning, design, construction and application of tools, methods and procedures necessary to increase manufacturing productivity. ❖Work holding tools – Jigs and Fixtures ❖Cutting tools ❖Forming Die ( Sheet metal ,Forging , Rolling, Extrusion dies) ❖ Welding and inspection fixtures ❖ Injection molds ❖Tooling for Casting 12/6/2019 Prepared by: Berhe Syum 4 TOOL AND DIE DESIGN OBJECTIVES The main objective of tool design is to lower manufacturing costs while maintaining quality and increased production. To accomplish this, the tool designer must satisfy the following objectives: ✓Provide simple, easy-to-operate tools for maximum efficiency. ✓Reduce manufacturing expenses by producing parts at the lowest possible cost. ✓Design tools that consistently produce parts of high quality. ✓Increase the rate of production with existing machine tools. ✓Design the tool to make it foolproof and to prevent improper use. ✓Select materials that will give adequate tool life. ✓Provide protection in the design of the tools for maximum safety of the operator. 12/6/2019 Prepared by: Berhe Syum 5 During designing of tool and die the designer must consider ✓Overall size and shape of the part ✓Type and condition of the material used for the part ✓Type of machining operation to be performed ✓Degree of accuracy ✓Number of pieces to be made ✓Locating and clamping surface ✓Sequence of operation ✓ Safety and Ergonomics ✓Tool Materials 12/6/2019 Prepared by: Berhe Syum 6 The Tool Design Process • Statement and analysis of the problem • Analysis of the requirements • Development of initial ideas • Development of design alternatives • Finalization of design ideas 12/6/2019 Prepared by: Berhe Syum 7 Statement of the problem • Problem without tooling • What the tool is supposed to do? • drill four holes • Bottleneck in assembly • Low productivity with out tooling • • • • • • • Analysis of the requirements Must perform certain functions Must meet certain minimum precision requirements Must keep the cost to a minimum Must be available when the production schedule requires it Must be operated safely Must meet other requirements such as Adaptability to the machine tool. 12/6/2019 Prepared by: Berhe Syum 8 JIGS AND FIXTURES TYPE AND FUNCTIONS OF JIGS AND FIXTURES • Jigs and fixtures are special purpose tools which are used to facilitate production (machining, assembling and inspection operations) when work pieces are to be produced on a mass scale. • Jigs and fixtures provide a means of manufacturing interchangeable parts since they establish a relation, with predetermined tolerances, between the work and the cutting tool. • They eliminate the necessity of a special set up for each individual part. • Once a jig or fixture is properly set up, any number of duplicate parts may be readily produced without additional set up. 12/6/2019 Prepared by: Berhe Syum 9 jigs and fixtures are used: 1. To reduce the cost of production, as their use eliminates the laying out of work and setting up of tools. 2. To increase the production. 3. To assure high accuracy of the parts. 4. To provide for interchangeability. 5. To enable heavy and complex-shaped parts to be machined by being held rigidly to a machine 6. Reduced quality control expenses. 7. Increased versatility of machine tool. 8. Less skilled labor. 9. Saving labor. 10. Their use partially automates the machine tool. 11. Their use improves the safety at work, thereby lowering the rate of accidents. Prepared by: Berhe Syum 12/6/2019 10 JIGS ❖It is a work holding device that holds, supports and locates the work piece and guides the cutting tool for a specific operation. ❖A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products. ❖A device that does both functions (holding the work and guiding a tool) is called a jig. 12/6/2019 Prepared by: Berhe Syum 11 FIXTURES • It is a work holding device that holds supports and locates the work piece for a specific operation but does not guide the cutting tool. Examples: Vises, chucks 12/6/2019 Prepared by: Berhe Syum 12 How do jigs and fixtures differ? JIGS JigS Fixture 1. It is a work holding device that holds, supports and locates the work piece and guides the cutting tool for a specific operation 1 It is a work holding device that holds, supports and locates the work piece for a specific operation but does not guide the cutting tool 2. Jigs are not clamped to the drill press table unless large diameters to be drilled and there is a necessity to move the jig to bring one each bush directly under the drill. 3. The jigs are special tools particularly in drilling, reaming, tapping and boring operation. 4.Lighter in construction 2. Fixtures should be securely clamped to the table of the machine upon which the work is done. 12/6/2019 3. Fixtures are specific tools used particularly in milling machine, shapers and slotting machine. 4. Heavier in construction. 13 Prepared by: Berhe Syum Fig. 1.2. A Simple Jig and a Fixture 12/6/2019 Prepared by: Berhe Syum 14 Advantages of Jigs and Fixtures Productivity: • Jigs and fixtures increase the productivity by eliminating the individual marking, positioning and frequent checking. The operation time is also reduced due to increase in speed, feed and depth of cut because of high clamping rigidity. • Interchangeability and quality: • Jigs and fixtures facilitate the production of articles in large quantities with high degree of accuracy, uniform quality and interchangeability at a competitive cost. • Skill reduction: • There is no need for skillful setting of work on tool. Jigs and fixtures makes possible to employ unskilled or semi skilled machine operator to make savings in labor cost. • Cost reduction: • Higher production, reduction in scrap, easy assembly and savings in labour cost results in ultimate reduction in unit cost. 12/6/2019 Prepared by: Berhe Syum 15 Classification of jigs Jigs may be divided into two general classes • boring jigs and • drill jigs. Boring jigs are used to bore holes that either are too large to drill or must be made an odd size (Figure 22) 12/6/2019 16 Prepared by: Berhe Syum • Drill jigs are used to drill, ream, tap, chamfer, counter bore, countersink, reverse Spot face, or reverse countersink (Figure 2–3). The basic jig is almost the same for either machining operation. The only difference is in the size of the bushings used. 12/6/2019 Prepared by: Berhe Syum 17 TYPES OF Drilling JIGS Drill jigs may be divided into two general types, • open and closed Jigs . • Open jigs are for simple operations where work is done on only one side of the part. • Closed, or box, jigs are used for parts that must be machined on more than one side. • The names used to identify these jigs refer to how the tool is built 12/6/2019 Prepared by: Berhe Syum 18 Type of open jigs • Template, plate, table, sandwich, and angle plate jigs are all open jigs Template jigs are normally used for accuracy rather than speed. ❑This type of jig fits over, on, or into the work and is not usually clamped (Figure 2–4). ❑Templates are the least expensive and simplest type of jig to use. ❑They may or may not have bushings. When bushings are not used, the whole jig plate is normally hardened. 12/6/2019 Prepared by: Berhe Syum 19 12/6/2019 Figure 2–4 Template jigs Prepared by: Berhe Syum 20 • Plate jigs are similar to templates (Figure 2–5). The only difference is that plate jigs have built-in clamps to hold the work. • These jigs can also be made with or without bushings, depending on the number of parts to be made. 12/6/2019 Figure 2–5 Plate jig 21 Box or Closed jig Box jigs, or tumble jigs, usually totally surround the part (Figure 2–10). This style of jig allows the part to be completely machined on every surface without the need to reposition the work in the jig. 12/6/2019 Figure 2–10 Box or tumble jig. 22 Box or Closed jig Channel jigs are the simplest form of box jig (Figure 2– 11). • The work is held between two sides and machined from the third side. In some cases, where jig feet are used, the work can be machined on three sides. 12/6/2019 Figure 2–11 Channel jig. 23 Box or Closed jig Leaf jigs are small box jigs with a hinged leaf to allow for easier loading and unloading (Figure 2–12). 12/6/2019 Figure 2–12 Leaf jig. 24 Classification of fixtures Fixtures are normally classified by the type of machine on which they are used. • For example, if a fixture is designed to be used on a milling machine, it is called a milling fixture. • if it is used in lathe it is called lathe fixture TYPES OF FIXTURES • The names used to describe the various types of fixtures are determined mainly by how the tool is built. 12/6/2019 Prepared by: Berhe Syum 25 By construction fixtures are found in the following form 1.Plate fixtures are the simplest form of fixture (Figure 2–17). The basic fixture is made from a flat plate that has a variety of clamps and locators to hold and locate the part. The simplicity of this fixture makes it useful for most machining operations. Its adaptability makes it popular. Figure 2–17 Plate fixture 12/6/2019 26 ✓The angle-plate fixture is a variation of the plate fixture (Figure 2–18). ✓With this tool, the part is normally machined at a right angle to its locator. ✓While most angle-plate fixtures are made at 90 degrees, there are times when other angles are needed. 12/6/2019 Figure 2–18 Angle-plate fixtures. 27 • Vise-jaw fixtures are used for machining small parts (Figure 2–20). • Vise-jaw fixtures are the least expensive type of fixture to make parts. • Their use is limited only by the sizes of the vises available. 12/6/2019 Figure 2–20 Vise-jaw fixture 28 • Indexing fixtures are very similar to indexing jigs (Figure 2– 21). • These fixtures are used for machining parts that must have machined details evenly spaced components. • The parts shown in Figure 2–22 are examples of the uses of an indexing fixture. Figure 2–21 Indexing fixtures. 12/6/2019 29 Figure 2–22 Parts machined with an indexing fixture 12/6/2019 Prepared by: Berhe Syum 30 ❖Profiling fixtures are used to guide tools for machining contours that the machine cannot normally follow. ❖These contours can be either internal or external. Since the fixture continuously contacts the tool, an incorrectly cut shape is almost impossible. ❖The operation in Figure 2–24 shows how the cam is accurately cut by maintaining contact between the fixture and the bearing on the milling cutter. Figure 2–24 Profiling fixture. 12/6/2019 Prepared by: Berhe Syum 31 SUMMARY The following important concepts were presented in this unit: • Jigs and fixtures are production work holding devices designed to hold, support, and locate a Work piece. • A jig guides the cutting tool with a drill bushing. • A fixture references the cutting tool with a set block and feeler, or thickness gauges. • Jigs are divided into two general classes: drill jigs and boring jigs. • The type of jig is determined by how it is built. • The two types of jigs are open and closed. • Template, plate, table, sandwich, and angle plate jigs are all open jigs. • Box, channel, and leaf jigs are all closed jigs. 12/6/2019 Prepared by: Berhe Syum 32 SUMMARY Count… Other variations, such as indexing, rotary, turnon, pump, and multi station jigs, are made as either open or closed jigs. ❖Fixture types are determined by the way they are built. ❖The most common types are plate, angle plate, vise-jaw, indexing, and multi station fixtures. ❖Fixture classes are determined by the machine tools on which they are used and sometimes by the operations performed. ❖A fixture used for a straddle-milling ❖operation is classed as a mill fixture, but it may also be classed as a straddle-milling fixture. 12/6/2019 Prepared by: Berhe Syum 33 CHAPTER TWO CLAMPING AND WORK HOLDING PRINCIPLES Debre Tabor University Lectur-2 12/6/2019 Prepared by: Berhe Syum 34 CHAPTER TWO WORK HOLDING and PRINCIPLES General Considerations for Work holding • Physical characteristics of the work piece • • • • 12/6/2019 Degree of precision Strength and stiffness of work piece Production requirements Safety requirements Prepared by: Berhe Syum 35 WORK HOLDING PRINCIPLES Standard work holders • Placing the work in a specific position in work holding devices or on a machine table is called a setup which includes two processes locating and clamping. • Within a setup, one or more manufacturing operations may be carried out to process work piece surfaces with dimensional, form, positional and oriental specifications. • A work piece consists of surface; there exist dimensional and orientation relationships among these surfaces based on the design specifications. 12/6/2019 Prepared by: Berhe Syum 36 WORK HOLDING PRINCIPLES The datum is the points, lines and surfaces which can be used to determine the positions and orientation of other point’s lines, surfaces on work piece. There are two categories of datum (i.e., design datum and manufacturing datum). ❑Design datum is used in specifying the work geometry (dimension, positions, and orientations, especially with tolerances) in terms of design and functional requirements. ❑Manufacturing datum is used in specifying the work geometric relationships in manufacturing processes of the work piece including operational datum, locating datum and measuring datum. 12/6/2019 Prepared by: Berhe Syum 37 Purpose & Function of Work Holder The main purpose and function of work holder is the following ❖Locating ❖ Clamping ❖ Support ❖Cutting forces ❖ Safety 12/6/2019 Prepared by: Berhe Syum 38 PRINCIPLE OF LOCATING REFERENCING ✓To ensure precision in any machining operation, the work must be properly positioned with respect to the cutter or other tool. ✓ This is called referencing. ✓ To ensure the desired accuracy, the tool designer must make sure the part is precisely located and rigidly supported. ✓Locators, in addition to properly positioning the part, make sure that the tool is easily loaded and unloaded. ✓They must also make the tool foolproof. ✓The tool designer must also provide rigid support for the part. 12/6/2019 Prepared by: Berhe Syum 39 The choice of a location system Primary datum: This establishes the orientation of the part (stablies the part ) to the datum reference frame. ❖The part contacts the datum plane with at least three points of contact. The primary datum restricts Five degree of freedom ( four rotary and one linear) Secondary datum: This locates the part (restricts part movement) within the datum reference frame. ❖Requires a minimum of two points of contact with the secondary datum. The Secondary datum restricts THREE additional degree of freedom (Two rotary and One linear ). Tertiary datum: This locates the part (restricts part movement) within the datum reference frame. ❖Requires a minimum of one points of contact with the secondary datum. The tertiary datum restricts the one degree of freedom ( Linear ) 12/6/2019 Prepared by: Berhe Syum 40 BASIC RULES FOR LOCATING ❑To restrict the movement of a part and have the part positioned properly requires skill and planning. ❑A tool designer must keep the following points in mind while designing the tool: ✓Positioning the locators ✓Part tolerance ✓Fool proofing ✓Duplicate location 12/6/2019 Prepared by: Berhe Syum 41 BASIC RULES FOR LOCATING Positioning the Locators • Locators should contact the work on a machined surface. This permits accurate placement of the part in the tool and ensures the repeatability of the jig or fixture. • Repeatability is the feature of the tool that allows different parts to be machined consistently within their required tolerances. • Accurate location is an important element in the repeatability of any tool. • Locators should be spaced as far apart as possible. This permits the use of fewer locators and ensures complete contact over the locating surface. • the locators should be relieved (Figure 3–1). 12/6/2019 Prepared by: Berhe Syum 42 BASIC RULES FOR LOCATING Figure 3–1 Methods of relieving locators. 12/6/2019 Prepared by: Berhe Syum 43 BASIC RULES FOR LOCATING Tolerance • When designing a tool, the designer must keep the part tolerance in mind. As a general rule, the tool tolerance should be between 20 and 50 percent of the part tolerance. Figure 3–2 Tolerance relationship. 12/6/2019 Figure 3–3 Part and tool size relationship. 44 BASIC RULES FOR LOCATING Fool proofing • Fool proofing is a means by which the tool designer ensures that the part will fit into the tool only in its correct position. • The part in Figure 3–4A must be machined on the tapered end, so the tool designer includes a pin to prevent the part from being loaded incorrectly. This pin fool proofs the tool. • The part in Figure 3–4B shows a hole that must be drilled with reference to the holes in the flange. • A simple pin placed in one of these holes makes it impossible to load the tool incorrectly. 12/6/2019 Prepared by: Berhe Syum 45 BASIC RULES FOR LOCATING 12/6/2019 Figure 3–4 Fool proofing Prepared by: Berhe Syum 46 BASIC RULES FOR LOCATING Duplicate Locators • The use of duplicate locators should always be avoided. • Figure 3–5 shows examples of duplicate locators. • Locator duplication not only costs more but also could cause inaccuracies. • For example, the flange in Figure 3–5A is located on both the underside of the flange and the bottom of the hub. Since these are parallel surfaces, only one is needed and the other should be eliminated. • If the reference surface is the flange, as in Figure 3–5B, the hub locator is not necessary. If the hub is the reference surface, as in Figure 3–5C, the flange locator is unnecessary. Prepared by: Berhe Syum 12/6/2019 47 BASIC RULES FOR LOCATING • To correct this, the tool designer must first determine which surface is to be referenced. Only then should the locators for that surface be specified. Figure 3–5 Duplicate locators. 12/6/2019 Prepared by: Berhe Syum 48 BASIC RULES FOR LOCATING • To avoid this problem(dupolicate locators), the tool designer must specify whether the part is to be located from its holes or its edges, never both. Figure 3–6 Position and locational differences 12/6/2019 Prepared by: Berhe Syum 49 PLANES OF MOVEMENT • An unrestricted object is free to move in any of twelve possible directions. • Figure 3–7 shows an object with three axes, or planes, along which movement may occur. • An object is free to revolve around or move parallel to any axis in either direction. • To illustrate this, the planes have been marked X-X, Y-Y, and Z-Z. • The directions of movement are numbered from one to twelve. Figure 3–7 Planes of movement. 12/6/2019 Prepared by: Berhe Syum 50 Restricting Movement • To accurately locate a part in a jig or fixture, movements must be restricted. • This is done with locators and clamps. • Restriction the movement of tool should increase accuracy and productivity of the part. 12/6/2019 Prepared by: Berhe Syum 51 LOCATING THE WORK • Work piece surfaces • Flat surfaces • Cylindrical surfaces • Irregular surfaces Types of location • Plane • Concentric • Radial • Combined 12/6/2019 Prepared by: Berhe Syum 52 LOCATING THE WORK Locating from a Flat Surface • There are three primary methods of locating work from a flat surface:(solid supports, adjustable supports, and equalizing supports. • These locators set the vertical position of the part, support the part, and prevent distortion during the machining operation. • Solid supports are the easiest to use. They can be either machined into the tool base or installed (Figure 3–13). This type of support is normally used when a machined surface acts as a locating point. 12/6/2019 Figure 3–13 Solid supports 53 LOCATING THE WORK Adjustable supports are used when the surface is rough or uneven, such as in cast parts. ✓ Adjustable locators are normally used with one or more solid locators to allow any adjustment needed to level the work. ✓ A few of the more common are the threaded (Figure 3–14A), ✓ The threaded style is the easiest and most economical, and it has a larger adjustment range than the others 12/6/2019 . 54 LOCATING THE WORK spring (Figure 3–14B), and push types (Figure 3–14C ). Figure 3–14B Adjustable supports, spring type Figure 3–14C Adjustable support, push type. 12/6/2019 Prepared by: Berhe Syum 55 LOCATING THE WORK Equalizing supports are also a form of adjustable support (Figure 3–15). ❖They provide equal support through two connected contact points. ❖As one point is depressed, the other raises and maintains contact with the part. ❖ This feature is especially necessary on uneven cast surfaces. 12/6/2019 Figure 3–15 Equalizing supports 56 Locating from an Internal Diameter ✓Locating a part from a hole or pattern is the most effective way to accurately position work. ✓Nine of the twelve directions of movement are restricted by using a single pin, and ✓Eleven directions of movement are restricted with two pins. 12/6/2019 Figure 3–16 Internal locators 57 Locating from an Internal Diameter Pin-type locators are used for smaller holes and for aligning members of the tool (Figure 3–17 Figure 3–17 Pin locators and bushing ❑Pins used for part location are made with either tapered ends or rounded ends, allowing the parts to be installed and removed easily (Figure 3–18). 12/6/2019 Figure 3–18 Round and tapered locators. Locating from an Internal Diameter ❖In the round pin locates the part and the diamond pin prevents the movement around the pin (Figure 3– 19). Figure 3–19 Locating with one relieved locator. 12/6/2019 Prepared by: Berhe Syum 59 Locating from an Internal Diameter ❖Relieved locators reduce the area of contact between the work piece and the locator. ✓Decreasing the contact area has little or no effect on the overall locational accuracy; ✓However, reducing the contact area helps make the jig or fixture easier to load and unload and lessens the problems caused by dirt, chips, and burrs. 12/6/2019 Figure 3–21 Relieved locators 60 Locating from an External Profile ❖Profile locators position the work in relation to an outside edge or the outside of a detail, such as a hub or a boss. ❖common ways a part can be located from its profile are ❖Nesting locators position a part by enclosing it in a depression, or recess, of the same shape as the part. ❖ Nesting is the most accurate locating device for profile location. ❖Nests are very expensive to design for complicated shapes. ❖The most common type is the ring nest, which is normally used for cylindrical profiles (Figure 3–26). 12/6/2019 Prepared by: Berhe Syum 61 Locating from an External Profile Figure 3–26 Ring nest 12/6/2019 Prepared by: Berhe Syum 62 Locating from an External Profile ❑The full nest completely encloses shapes other than cylindrical (Figure 3–27). Figure 3–27 Full nests. ❑The partial nest is a variation of the full nest and encloses only a part of the work piece (Figure 3–28). 12/6/2019 Figure 3–28 Partial nest 63 Locating from an External Profile Vee locators are used mainly for round work. ❖They can locate flat work with rounded or angular ends and flat discs (Figure 3–29). Figure 3–30 Vee-block locators. ❖ One advantage vee locators have over other locators is their centralizing feature. 12/6/2019 Prepared by: Berhe Syum 64 Locating from an External Profile Fixed-stop locators are used for parts that cannot be placed in either a nest or a vee locator. They are either machined into the tool body (Figure 3–32), or installed (Figure 3–33). Figure 3–32 Machined fixed-stop locators. 12/6/2019 Figure 3–33 Installed fixed-stop locators Prepared by: Berhe Syum 65 Ejectors ✓Ejectors are used to remove work from close-fitting locators, such as full nests or ring nests. ✓These devices speed up the unloading of the part from the tool, which reduces the in-tool time and increases the production rate. ✓Figure 3–40 shows two styles of ejectors common to both jigs and fixtures. 12/6/2019 Figure 3–40 Ejectors Prepared by: Berhe Syum 66 SUMMARY OF LOCATORS ❖To achieve proper location, the locators must properly reference the part and ensure the repeatability of location throughout the production cycle. ❖Referencing is the process of properly positioning the part with respect to the cutter or other tool. ❖Repeatability is the feature of location that permits the parts to be made within their stated tolerances, part after part, throughout the production run. ❖The major concerns in locating a part that the designer must keep in mind are the position of the locators, locational tolerances, fool proofing the location, and avoiding duplicate location. 12/6/2019 Prepared by: Berhe Syum 67 SUMMARY OF LOCATORS ❑There are twelve planes of movement in any Work piece. When locating a part, the designer must select the locational method that will restrict a maximum number of these planes of movement. ❑The three-two-one, or six-point, location method will restrict a total of 9 planes of movement. ❑Locating a part by a single center hole will restrict nine planes of movement with a single locator. By positioning a second locator in another hole in the part, a total of eleven planes of movement can be restricted with two locators. ❑In either case, the remaining unrestricted planes of movement are restricted with the clamping device. ❑Locators positioned under a part are referred to as supports. Locators that position a part by its edges are called locators or stops. 12/6/2019 Prepared by: Berhe Syum 68 SUMMARY OF locators ✓The three primary supports are solid, adjustable, and equalizing. ✓The major types of locator used to locate parts on an internal diameter are shank-mounted locators and pin locators. Pin locators may also be used to locate a part from its external edges. ✓Other devices used to locate parts include nesting locators, vee locators, fixed-stop locators, adjustable-stop locators, and sight locators. ✓Ejectors are devices that are used to help remove a part from close-fitting locators. ✓Ejectors are made in many variations. ✓In mechanical-level ejector and spring-type ejector are two examples of these devices. 12/6/2019 Prepared by: Berhe Syum 69 CHAPTER THREE CLAMPING PROCESS Debre Tabor University Lectur-3 WEEK-3 12/6/2019 Prepared by: Berhe Syum 70 CLAMPING PROCESS WORKHOLDERS ❖the term work holder identifies the parts of a jig or fixture that clamp, chuck, hold, or grip the part. • The main purpose of a work holder, or clamping device, is to securely hold the position of the part against the locators throughout the machining cycle. The clamp used must meet the following conditions: ❖ strong enough to hold the part and to resist movement. ❖The clamp must not damage or deform the part. ❖Be fast-acting and allow rapid loading and unloading of parts. 12/6/2019 Prepared by: Berhe Syum 71 CONT…. Clamping • The proper and adequate clamping of a work piece is very important, the following design and operational factors should be take in to consideration : 1. The clamping pressures applied against the work piece must counteract the tool forces. 2. The clamping pressures should not be directed towards the cutting operation. Whenever possible, it should be directed parallel to it, Fig. 2.20. 12/6/2019 Prepared by: Berhe Syum 72 CONT…. Clamping Fig. 2.20. 12/6/2019 Prepared by: Berhe Syum 73 CONT…. Clamping 3. The clamping pressure must only hold the work piece and should never be great enough so as to damage, deform or change any dimensions of the work piece. 4. The clamping and cutting forces should be directed towards the locating pins, otherwise the work piece may get bent or forced away from the locating pins during machining. 5. Clamping should be simple, quick and foolproof. Complicated clamps lose their effectiveness as they wear. 6. The movement of a clamp should be strictly limited and if possible it should be positively guided. 7. Whenever possible, the lifting of the clamp by hand should be avoided if it can be done by means of a spring fitted to it. 12/6/2019 Prepared by: Berhe Syum 74 CONT…. Clamping 9. The clamps should always be arranged directly above the points supporting the work; otherwise the distortion of the work can occur, as illustrated in Fig. 2.21. 10. Fiber pads should be riveted to the clamp faces, otherwise soft and fragile work piece can get damaged. 11. A clamp should be designed to deliver the required clamping force when operated by the smallest force expected. 12/6/2019 Prepared by: Berhe Syum 75 CONT…. Clamping Fig 2.21. Position of Clamping . 12/6/2019 Prepared by: Berhe Syum 76 CONT…. Clamping 12. A clamp should be strong enough to withstand the reaction imposed upon it when the largest expected operating force is applied. 13. Clamping pressure should be directed towards the points of support, otherwise work will tend to rise from its support, Fig. 2.22. 12/6/2019 Fig. 2.22 Prepared by: Berhe Syum 77 Basic rules of clamping ❖The function of clamps to hold apart against the locators during the machining cycle. Positioning the Clamps ✓Clamps should always contact the work at its most point. This prevents the clamping force from bending or damaging the part. ✓The part must be supported if the work is clamped at a point where the force could bend the part. ✓ The flange in Figure 4–1 shows this point. ✓. If it is held by the outer edge, the part must be supported (Figure 4–2). 12/6/2019 Prepared by: Berhe Syum 78 Basic rules of clamping Figure 4–1 Flange ring. Figure 4–2 supporting the flange ring 12/6/2019 Prepared by: Berhe Syum 79 The Effect of Tool(cutting) Forces For clamping ✓To clamp a part correctly, the tool designer must know how tool forces, or cutting forces act in reference to the tool and the cutting force hold the work. ✓Figure 4–3 is an example of how the cutting force is used to hold the work ✓Most of the force is in a downward direction against the base of the tool. The forces that must be resisted cause the part to revolve around the drill axis, which in turn causes the part to climb the drill when the drill breaks through the opposite side of the part. Figure 4–3 using cutting force to hold a part 12/6/2019 Prepared by: Berhe Syum 80 Cont….Clamping Forces ❑Clamping force is the force required to hold a part against the locators. ❑Clamping prevents the part from shifting or being pulled from the jig or fixture during the machining operation ❑As a general rule, Clamping pressures hold only be enough to hold the part against the locators. ❑The locators should resist the bulk of the thrust. Figure 4–4 Clamping forces. 12/6/2019 Prepared by: Berhe Syum 81 TYPES OF CLAMPS ❖The type of clamp the tool designer chooses is determined by the shape and size of the part, the type of jig or fixture being used, and the work to be done. ❖The tool designer should choose the clamp that is the simplest, easiest to use, and most efficient. ✓The following are the common type of clamp we have to use in production process. 12/6/2019 Prepared by: Berhe Syum 82 Strap Clamps ✓Strap clamps are the simplest clamps used for jigs and fixtures (Figure 4–5). ✓Strap clamps can be grouped into three classes, each representing a form of lever (Figure 4–6). ✓Figure 4–6A shows the first clamp, which has the fulcrum between the work and the effort. ✓This is the principle of a first-class lever. ✓The second clamp, shown in Figure 4–6B, places the work between the fulcrum and the effort, as with a second-class lever. ✓The third clamp, shown in Figure 4–6C, uses the principle of a third-class lever by placing the effort between the work and the fulcrum. 12/6/2019 Prepared by: Berhe Syum 83 Strap Clamps . Figure 4–6 Lever classes of strap clamps 12/6/2019 Prepared by: Berhe Syum 84 Screw Clamps • Screw clamps are widely used and unlimited application potential, lower costs, and, in many cases, less complex designs. • The only disadvantage in using screw clamps is their relatively slow operating speeds. • The basic screw clamp uses the torque developed by a screw thread to hold a part in place either by direct pressure or by its action on another clamp (Figure 4–15). 12/6/2019 Figure 4–15 Indirect clamping with a screw clamp. 85 Swing Clamps ✓Swing clamps combine the screw clamp with a swinging arm that pivots on its mounting stud. ✓The holding power with this clamp is generated by the screw. ✓The rapid action needed is achieved by the swinging arm (Figure 4–16). 12/6/2019 Figure 4–16 Swing clamp 86 Hook Clamps • Hook clamps are similar to swing clamps but they are much smaller (Figure 4–17). • They are useful in tight places or where several small clamps rather than one large clamp must be used. • A variation of the hook clamp is shown in Figure 4–18. 12/6/2019 Prepared by: Berhe Syum 87 B) Hook Bolt Clamp Figure 4–17 Hook clamp Figure 4–18 Modified hook clamp 12/6/2019 Prepared by: Berhe Syum 88 Cam-Action Clamps ✓Cam-action clamps, when properly selected and used, provide a fast, efficient, and simple way to hold work (Figure 4–20). ✓Because of their construction and basic operating principles, the use of cam-action clamps is limited in some types of tools. ✓Cam clamps, which apply pressure directly to the work, are not used when a strong vibration is present. ✓This might cause the clamp to loosen, creating a dangerous condition. ✓Direct-pressure cam clamps must be positioned to resist the natural tendencies of the clamp to shift or move the work when the clamp is engaged. Figure 4–20 Direct-pressure cam clamp 12/6/2019 Prepared by: Berhe Syum 89 Figure 4–21 Indirect-pressure cam clamp. 12/6/2019 Prepared by: Berhe Syum 90 Toggle-Action Clamps ❖Toggle-action clamps, shown in Figure 4–29, are made with four basic clamping actions: hold down, squeeze, pull, and straight-line. ❖Toggle clamps are fast-acting. ❖Because of how they are made, they have the natural ability to move completely free of the work, thus allowing for faster part changes. ❖Another advantage is their high ratio of holding force to application force. 12/6/2019 Prepared by: Berhe Syum 91 Toggle-Action Clamps Figure 4–29 Toggle clamps 12/6/2019 Prepared by: Berhe Syum 92 Chucks and Vises ❖Commercially available chucks and vises offer the tool designer devices that, when modified, greatly reduce tooling costs. ❖Quite often, because of tight budgets, one chuck must be used for several tools. Non Mechanical Clamping ✓Non mechanical clamping is a term that is typically applied to the group of work holding devices used to hold parts by means other than direct mechanical contact. ✓This form of clamping is most often employed for work pieces that cannot be held with other devices due to the size, shape, or configuration of the fixture parts. ✓Other situations in which non mechanical clamps are frequently used are where the clamping forces must be applied evenly across the entire part to minimize any possible work piece distortion. ✓two principal forms of non mechanical clamping used for production manufacturing are magnetic clamping and vacuum clamping. 12/6/2019 Prepared by: Berhe Syum 93 SUMMARY ✓The term work holder is used to identify the complate jig or fixture as well as the devices used to actually hold the part. ✓The main purpose of a clamp is to hold the part ✓Against the locators throughout the production cycle Clamps must be strong enough to hold the part and resist movement. ✓Clamps must not damage or deform the part. ✓Clamps must be fast acting to permit rapid loading and unloading of parts. 12/6/2019 Prepared by: Berhe Syum 94 SUMMARY ❖The position of the clamps, the tool forces acting on the part, and controlling and directing the clamping forces. ❖The primary manual clamping devices are strap clamps, screw clamps, cam-action clamps, wedge clamps, and toggle-action clamps. ❖Other forms of clamping used for jigs and fixtures include power clamping, chucks and vises and magnetic and vacuum chucks used for non mechanical clamping. ❖Special arrangements may be used for clamping multiple parts or for holding odd-shaped parts. 12/6/2019 Prepared by: Berhe Syum 95 CHAPTER Four DESIGN OF JIG AND FIXTURE Debre Tabor University Lectur-4 WEEK-4 12/6/2019 Prepared by: Berhe Syum 96 CHAPTER Four DESIGN OF JIG AND FIXTURE ❖The design of a work holding device is governed by the geometry of the work piece and the dynamics of the manufacturing process in which it is expected to participate. ❖The jig and fixture must be able to hold the work piece in place (i.e., preventing motion and deflections) while it is subjected to external forces. 12/6/2019 Prepared by: Berhe Syum 97 CONT…DESIGN OF JIG AND FIXTURE Elements of Jig and Fixture ✓Jigs and fixtures are manually or partially power operated devices. ✓To full fill their basic purposes, jigs and fixtures are comprised of several elements (as indicated in Fig 3.1): ❑base and body or frame with clamping features ❑locating elements for proper positioning and orientation of the blank ❑supporting surfaces and base ❑clamping elements ❑tool guiding frame and bushes (for jig) ❑indexing plates or systems, if necessary ❑auxiliary elements ❑fastening parts 12/6/2019 Prepared by: Berhe Syum 98 Elements of Jig and Fixture Fig 3.1.Major elements of jig and fixtures. 12/6/2019 Prepared by: Berhe Syum 99 jigs and fixtures design Considerations the following factors are essentially considered during design, fabrication and assembly of jigs and fixtures: ❖Easy, quick and consistently accurate locating of the blank in the jig or fixture in reference to the cutting tool ❖Providing Quick, strong and rigid clamping of the blank in the jig or fixture without interrupting any other operations ❖Tool guidance for slender cutting tools like drills and reamers ❖Easy and quick loading and unloading the job to and from the jig or fixture ❖Use of minimum number of parts for making the jig or fixture • Use of standard parts as much as possible 12/6/2019 Prepared by: Berhe Syum 100 jigs and fixtures design Considerations Cont.. ❖Reasonable amount of flexibility or adjustability, if feasible, to accommodate slight variation in the job - dimensions. Prevention of jamming of chips, i.e. Wide chips-space and easy chip disposal ❖Easy, quick and accurate indexing system if required. ❖Easy and safe handling and moving the jig or fixture on the machine table, i.e., their shape, size, weight and sharp edges and corners ❖Easy and quick removal and replacement of small parts ❖Manufacturability i.e. Ease of manufacture ❖Durability and maintainability ❖Service life and overall expenses 12/6/2019 Prepared by: Berhe Syum 101 Jig and Fixture Design Procedure Three design stages is involved ✓Stage One deals with information gathering and analysis. ✓Stage Two involves the consideration of supporting, clamping and locating schemes. ✓Stage Three is the design of the structure of the jig and fixture body frame. A comprehensive Jig and fixture research plan should involve the analysis at different computational levels, viz., geometric, kinematic, force and deformation analyses. 12/6/2019 Prepared by: Berhe Syum 102 Jig and Fixture Design Procedure Cont… Geometric Analysis ✓Geometric analysis is closely associated with Jig and fixture planning and spatial reasoning. ✓It determines the selection of the type and number of fixturing elements, clamping, support and locating elements, the order of datum planes, etc. ✓ The analysis also includes the checking of interference between work piece and fixturing elements, as well as cutting tools. 12/6/2019 Prepared by: Berhe Syum 103 Jig and Fixture Design Procedure Cont Kinematic Analysis ❑It is used to determine whether a Jig and fixture configuration is able to correctly clamp, locate and provide complete constraint to a work piece. Force Analysis ✓In a machining fixture, different forces are experienced, viz., inertial, gravitational, machining and clamping forces. ✓While the first three categories of forces are usually more predictable, clamping force can be rather subjective in terms of magnitude, point of application as well as sequence of application. Deformation Analysis ✓Due to the complexity of force interaction, work piece deformation can be attributed to a combination of factors. ✓Firstly, a work piece would deform/ displace under high cutting and clamping forces. ✓Secondly, a work piece could also deform/displace if the support and locating elements are not rigid enough to resist the above mentioned forces. 12/6/2019 Prepared by: Berhe Syum 104 Fundamental principles of Jigs and Fixtures design ❖Locating points: Good facilities should be provided for locating the work. ❖Fool proof: The design of jigs and fixtures should be such that it would not permit the work piece or the tool to insert in any position other than the correct one. ❖Reduction of idle time: Design of Jigs and Fixtures should be such that the process, loading, clamping and unloading time of the Work piece takes minimum as far as possible. ❖Weight of jigs and fixtures: It should be easy to handle, smaller in size and low cost in regard to amount of material used without sacrificing rigidity and stiffness. ❖Materials for jigs and fixtures: Usually made of hardened materials to avoid frequent damage and to resist wear. ❖Clamping device: It should be as simple as possible without sacrificing effectiveness. The strength of clamp should be such that not only to hold the work piece firmly in place but also to take the strain of the cutting tool without springing when designing the jigs and fixtures. ❖Economical and safe 12/6/2019 Prepared by: Berhe Syum 105 Example1 Design of Drill Jigs ✓Drilling jigs are used to machine holes in mechanical products. ✓To obtain positional accuracy of the holes, hardened drill bushes o are used to locate and guide drills, reamers etc., in relation to the w ✓The portion of the jig into which the hardened bushes are fitted is plate. ✓It is clear that during the drilling operation, burrs will be produced. ✓The burr produced at the start of a hole is smaller than that prod end of the hole. ✓The first type is called 'minor burr ‘and the second type 'Major b the drill breaks through the material, Fig. 9.37). ✓When designing a drilling jig, these two types of burrs should be consideration since they may cause difficulty in unloading the work the jig after a hole has been drilled. 12/6/2019 Prepared by: Berhe Syum 106 Design of Drill Jigs Cont… Fig. 9.37. Major and Minor Burrs. 12/6/2019 Prepared by: Berhe Syum 107 Design Principles for Drill Jigs 1. A drilling jig should be of light construction consistent with adequate rigidity to facilitate its handling because it has to be handled frequently during the operation. 2. A drilling jig which is not normally clamped to the machine table should be provided with four feet so that it will rock if it is not resting square on the machine table and so warn the operator. 3. The stability of a drilling jig should be as good as possible since it is not usual to clamp it to the machine table and to ensure this, the feet or base of the jig should extend outside the holes to be drilled. 4. Drill bushings should be fitted in fixed portion of the jig and not in clamps except for a few special cases (for example, leaf type jig). 12/6/2019 Prepared by: Berhe Syum 108 DRILL BUSHINGS • Drill bushings are used to locate and guide drills, reamers, taps, counter bores, countersinks, spot facing tools, and any other rotating tools commonly used to make or modify a hole. • Drill bushings are usually hardened and ground to exact sizes to ensure the needed repeatability in the jig. 12/6/2019 Prepared by: Berhe Syum 109 Designing sizes for drill bushings DRILL JIG WING NUT CLAMP TOP PLATE LOCATING PLATE JIG BUSH BASE PLATE V - BLOCK SIDE CLAMP COMPONENT 74 Figure 5–4 Designing sizes for drill bushings. 12/6/2019 Prepared by: Berhe Syum 110 Types of Bushings ❖The most common drill bushings are renewable bushings, press-fit bushings, and liner bushings. • Renewable bushings are commonly divided into two groups, slip and fixed. They are used where bushings are changed many times during the jig life. • Slip-renewable bushings are used when more than one operation is performed in the same location, such as drilling and reaming • Fixed-renewable bushings are used where only one operation is performed in each hole but where several bushings must be used during the life of the tool 12/6/2019 Prepared by: Berhe Syum 111 WELDING Fixture Design Basic Design Considerations ❖In addition to locating and holding the part, the designer must also consider several other factors before a welding fixture can be designed. ❖Heat dissipation is an important consideration with any welding tool. ❖Several methods can be used to ensure that proper heat is maintained in the weld area. ❖The primary factor that determines the amount of heat required is the metal being joined. 12/6/2019 Prepared by: Berhe Syum 112 Basic Design Considerations Cont… ❖When metals such as steel and other poor heat conductors are joined, the excess heat should be carried off to prevent overheating the weld. To do this, backup bars of copper, titanium, or beryllium can be used. ❖For metals that are good conductors of heat,such as copper or aluminum, too rapid cooling becomes the problem. To prevent this, the fixture or jig must be made to contact the part in as small an area as possible (Figure 17–5). ❖Clamping supports must be provided to prevent distorting the work while it is in a heated condition. 12/6/2019 Prepared by: Berhe Syum 113 Basic Design Considerations for welding Fixture Cont… 12/6/2019 Prepared by: Berhe Syum 114 Common type of welding Fixture 12/6/2019 Prepared by: Berhe Syum 115 Common type of welding Fixture Cont.. 12/6/2019 Prepared by: Berhe Syum 116 SUMMARY ❖The three most common tool body forms are cast, welded, and built-up. ❖Using preformed materials can save time and money in building jigs and fixtures. ❖Several types of drill bushing are used for jigs. The most common types are renewable, press-fit, and liner bushings. ❖For the jig to perform as desired, the correct bushing must be selected. ❖To work properly, the bushing must be installed correctly. 12/6/2019 Prepared by: Berhe Syum 117