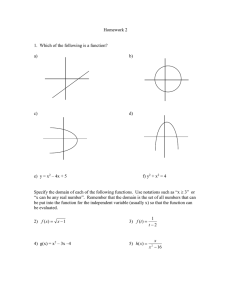

The Purification of Aldolase KyoungMin Kevin Park Partner: Yuqi Wang Due: March 26, 2019 Submitted: March 26, 2019 Objective: The goal for this experiment is to purify, isolate, and figure out the specific activity of rabbit muscle aldolase through various methods such as extraction, ammonium sulfate fractionation, dialysis, affinity chromatography, and activity assays. Materials and Methods: All steps of the experiment were proceeded under the condition at 4 °C and aliquots were stored at -20 °C. Extraction: Ground rabbit muscle was extracted through suspending 80.1g of rabbit muscle in 150 ml of 0.03M KOH, 0.001 M EDTA solution while continuously mixing for 20 minutes. Then, the solution was centrifuged for 10 minutes at 10,000 x g. The supernatant was filtered by glass wool. The pH of the solution was set up to 7.5 with 0.1 N KOH and then 1 ml aliquot was replaced separately for the future procedure (Fraction I). Salt Fractionation: The supernatant, fraction I, was set up to a 50% saturation of (NH4)2SO4 through adding an equal volume of (NH4)2SO4 that 100% saturated. The resulting solution was slowly stirred on ice for 1 hour, then centrifuged for 30 minutes at 10,000 x g. The supernatant was filtered by glass wool, then a 1ml aliquot was replaced separately (Fraction II). This solution was set up to a 60% saturation of (NH4)2SO4 through adding 65g of solid (NH4)2SO4 per liter of solution that present. The pH of the solution was set up to 7.5 by 1 N NH4OH. For the continuous experiment, this solution was saved in a cold room for a week. Dialysis: By centrifugation for 30 minutes at 10,000 x g, the precipitate from the above solution was isolated. Then the pH of the supernatant was recorded and the volume was measured. A 1 ml aliquot was replaced separately from the supernatant (Fraction III). The remained pellet from the centrifugation was suspended in 2.5 ml of equilibration buffer (10mM Tris HCL, pH 7.5; 5mM EDTA). This solution was centrifuged for 15 minutes at 10,000 x g and a 0.1 ml aliquot was replaced separately from the supernatant, then diluted to 1ml with equilibration buffer (Fraction IV). A dialysis tubing (MWCO 14,000 Da) was utilized for dialysis of the supernatant against equilibration buffer at 4°C. Affinity Column: About 20 ml of phosphocellulose, the 50/50 slurry in equilibration buffer, was utilized to isolate aldolase in batch mode. The dialyzed fraction was centrifuged for 15 minutes at 10,000 x g, and a 0.1 ml aliquot was replaced separately and diluted to 1 ml with equilibration buffer (Fraction V). Phosphocellulose resin was centrifuged for 5 minutes at 3,000 x g. The outcome supernatant was replaced separately and then fraction V was added to the resin. This was prepared to equilibrate for 5 minutes and then was centrifuged for 5 minutes at 3,000 x g. The supernatant was replaced and the absorbance at 280 nm (A280) was measured by utilizing the Genesys-5 Spectrophotometer. These steps were continued until the absorbance at 280 nm was set up to below 0.51. A 1 ml aliquot was replaced from the supernatant and micro-fuged at maximum velocity for 1 minute (Wash Fraction). The volume of wash fraction was measured as 66ml, and 1 ml of the sample was saved for the future procedure. Aldolase was eluted from the resin by adding 100 ml of elution buffer (2.5 mM FBP; 50mM Tris, pH 7.5). The resin was suspended, then prepared to equilibrate for 5 minutes. The outcome was then centrifuged at 3,000 x g for 5 minutes and then the supernatant was gathered. Bound proteins were eluted with the 1ml/min flow rate, and 40 fractions (1ml for each) were gathered. A 1 ml aliquot was replaced separately (Fraction VIA) and micro-fuged for 1 minute at maximum velocity. A 0.1 ml portion from the outcome was then diluted to 1 ml (Highest peak of VIA). This step was repeated while adding another elution buffer, and centrifuging that producing Fraction VIB (15ml). Then, the 0.1 aliquots from each Fraction VI were diluted to 1 ml with the equilibration buffer and left for future analysis. Protein Determination: A protein standard curve was formed while 1-25 μg of six solutions of bovine serum albumin and a color reagent (0.0032%(w/v) of Coomassie Brilliant Blue G250, 4.7% of ethanol, and 8.5% of phosphoric acid were contained) were utilized. Each fraction was properly diluted and combined with 0.15M NaCl and the color reagent to create the final volume as 1 ml. The absorbance of the colored solution was set up to 595 nm. This result was used to compare to the protein standard curve to figure out the concentration of the protein in individual samples. Assay II for Aldolase Activity. A 30 ml Master Mix consisting of 86.7mM pH 7.2Histidine HCl buffer, 0.13mM NADH in His HCl buffer pH 7.2, 6.7mM fructose 1,6-bisphosphate (FBP), 4-5IU/ml αglycerophosphate (α-GP) dehydrogenase was prepared for ten reactions to test aldolase activity; then, the master mix was shared into 9 cuvettes. Furthermore, 10μl of each fraction were added into nine cuvettes, and reaction rates of each protein fraction were read at 340nm. Assay II for Triose Phosphate Isomerase Activity. A 30ml Master Mix (86.7mM pH7.2 His HCl buffer, 0.13Mm NADH in His HCl buffer pH7.2, 0.167Mm glyceraldehyde 3-phosphate, and 4-5UI/ml α-GP dehydrogenase) was made to test the triose phosphate isomerase activity in each protein fraction; the master mix was split into 9 cuvettes, and the reaction rate of each fraction was measured at 340nm after reacting 10μl protein fraction with the master mix in cuvette. Results: Extraction: To extract muscle aldolase from the rabbit muscle, the osmotic lysis was proceeded. The supernatant (Fraction I) had pinkish color, and the pH was set up from 7.23 to 7.5 by using 0.1N KOH. The protein concentration of the Fraction I was recorded as 15mg/ml. Salt Fractionation: Ammonium sulfate ((NH4)2SO4) was added into Fraction I to get 50% saturation to remove the untargeted proteins. The Fraction II’s color was paler than color of Fraction I, and its pH was set up from 7.3 to 7.5. The recorded concentration of the Fraction II was 5.94mg/ml. Approximately 20.475g of ammonium sulfate was added to Fraction II to set up 60% saturation and then was centrifuged. The protein concentration of supernatant (Fraction III) that have impurities from Fraction II was 3.2932 mg/ml. Then, after dissolving gathered precipitate from Fraction II and centrifugation, Fraction IV was seemed have no color and its protein concentration was 130 mg/ml. Dialysis: After the Dialysis procedure, the Fraction V was gathered by centrifugation and its protein concentration was 150 mg/ml. Affinity Column: Phosphocellulose resin was utilized by cation exchange chromatography. The wash sample was gathered first and its protein concentration was recorded as 2.0526mg/ml. In continue, the aldolase was eluted and gathered in 40 fractions that have 1ml per each fraction. The fractions displayed diverse absorbance at 280 nm (Figure 1). Absorbance of Eluted solution at 280nm 3,5 3 Absorbance 2,5 2 1,5 1 0,5 0 0 5 10 15 20 25 30 35 40 Fraction Number Figure 1) The absorbance of eluted protein at 280nm. The elution was gathered by phosphocellulose resin at 1ml/min rate flow. For the 40 fractions, the slope was slowly increased until fraction 10, and it rapidly increased from 10 to 13 fraction. According to the chart, fraction 13 is the peak of the absorbance which had 4.85225mg/ml for protein concentration (Figure 1). Moreover, the fraction VIA had the elution from 11 to 21, which has 2.7875mg/ml for protein concentration. In addition, the absorbance values of the other fractions tended to decrease. The Fraction VIB that represent the tail of the peak had 0.5181mg/ml for the protein concentration. Protein Determination The Bradford Method was utilized to figure out the protein concentration in each Fraction. The standard curve was created by bovine serum albumin (BSA) with Brad reagent before recording the absorbance and concentration of each Fraction (Figure 2). After adding BSA, the color of the Bradford reagent changed to blue. Figure 2) Bovine Serum Albumin (BSA) Standard Curve. Diverse amount of BSA (25ug/ml) that ranged 1-25ug, was combined with adequate amounts of color reagent (combination of 0.032%(w/v) Coomassie Brilliant Blue G250, 4.7% ethanol, and 8.5% phosphoric acid) and 0.15M NaCl. The absorbance of the final solution was set up to 595nm and measured by Genesys-5 Spectrophotometer. The Figure 2 above displays an increase in concentration of BSA outcomes that proportional to the increase in absorbance. The Table 1 contains more detail information below. Table 1. Protein determination using the Bradford Method Name of Fraction Final Dilution Bradford Absorbance Protein Concentration (μg/ml) I 1/4000 0.160 3.7521 II 1/2000 0.134 2.9735 III 1/400 0.298 8.2330 IV 1/5000 0.666 26 V 1/2000 0.278 7.5416 Wash 1/200 0.354 10.263 The Peak 1/500 0.339 9.7045 VIA 1/500 0.218 5.5575 Assay II for Aldolase Activity: In order to figure out the aldolase activity and specific activity of each fraction, Assay II for aldolase activity was proceeded. Each fraction contained different reaction rate as displayed in Table 2. This implies that the reaction of the aldolase in Fraction IV was the highest one among nine fractions, and there was no aldolase activity detected in Wash Fraction. Table 2. Absorbance values of each fraction in Assay II for aldolase activity Name of Fraction Rate of Aldolase (Abs/min) Velocity of Aldolase (μmol/min) I 0.797 0.383 II 0.293 0.141 III 0.053 0.025 IV 1.194 0.573 V 0.213 0.102 Wash 0 0 The Peak 0.135 0.0648 VIA 0.055 0.026 VIB 0.009 0.00432 After combining the data from Table 1 and 2, the protein concentration of each fraction was figured out as displayed in Table 3. Furthermore, the specific activity of aldolase in nine fractions were measured based on the total aldolase activities and the protein amount. Table 3. Data of Enzyme Purification for aldolase Fraction Volume Activity Total Protein Total Specific Yield Fold Name (ml) (Units/ml) Units (mg/ml) Protein(mg) Activity (%) Purification (units/mg) I 168 38.3 6434.4 15 2520 2.553 100 1 II 315 14.1 4441.5 5.94 1872 2.3725 69.03 0.93 III 325 2.5 812.5 3.2932 1070.4 0.759 12.63 0.297 IV 6.4 573 3667.2 130 832 4.4077 0.57 1.726 V 15.9 102 1621.8 15.0832 239.822 6.7625 25.2 2.649 Wash 66 0 0 2.0526 135.4716 0 0 0 The Peak 1 64.8 64.8 4.85225 4.85225 13.355 1.007 5.231 VIA 14 26 364 2.7875 39.025 9.327 5.66 3.653 VIB 15 4.32 64.8 0.5181 7.7715 8.338 1.007 3.266 The yield percentage represents the percentage of total units of any Fraction compared to percentage of Fraction I. Also, the Fold Purification represents the percentage of the specific activity of any fraction compared to the percentage of Fraction I. From the Table 3, the yield percentage from fraction I to fraction III, IV, and V were noticeably decreased, and the activity of aldolase decreased with subsequent procedures except Fraction III and Wash. During the purification step, total activity had similar trend as the activity of aldolase. Moreover, total amount of protein tended to decrease as the extraction and purification procedure goes on. In addition, during the extraction and purification step, the specific activity of aldolase tended to increase except for the Fraction III and Wash that contained impurities. Assay II for Triose Phosphate Isomerase Activity Assay II utilizing the TPI as the catalyst in main reaction was proceeded to figure out the contamination of each fraction through Triose Phosphate Isomerase (TPI). The rate of TPI and the reaction rate of each fraction were recorded in the Table 4 below. Based on the information of Table 1 and 4, TPI activity, specific activity, and protein concentration were recorded and explained in the Table 5 below. Table 4. Absorbance values of each fraction in Assay II for triose phosphate isomerase activity. Name of Fraction Rate of Aldolase (Abs/min) Velocity of Aldolase (μmol/min) I 0.144 0.06912 II 0.072 0.03456 III 0.1 0.048 IV 0.051 0.02448 V 0.013 0.00624 Wash 0.027 0.01296 The Peak 0.004 0.00192 VIA 0 0 VIB 0.001 0.00048 Table 5. Data of Enzyme Purification for triose phosphate isomerase Fraction Volume Activity Total Protein Total Specific Yield Fold Name (ml) (Units/ml) Units (mg/ml) Protein(mg) Activity (%) Purification (units/mg) I 168 6.912 1161.216 15 2520 0.4608 100 1 II 315 3.456 1088.64 5.94 1872 0.5815 93.75 1.26 III 325 4.8 1560 3.2932 1070.4 1.4573 134.3 3.16 IV 6.4 24.48 156.672 130 832 0.1883 13.5 0.409 V 15.9 6.24 99.216 15.0832 239.822 0.4137 8.54 0.898 Wash 66 1.296 85.536 2.0526 135.4716 0.6314 7.37 1.37 The Peak 1 1.92 1.92 4.85225 4.85225 0.396 0.165 0.859 VIA 14 0 0 2.7875 39.025 0 0 0 Fraction 15 0.48 7.2 0.5181 7.7715 0.926 0.62 2.01 VIB The yield percentage represents the percentage of total units of any Fraction compared to percentage of Fraction I. Also, the Fold Purification represents the percentage of the specific activity of any fraction compared to the percentage of Fraction I. Based on the information of the Table 5 above, the total activity of TPI decreased with subsequent procedures of extraction and the purification procedure except the Fraction VIB. The specific activity of TPI increased until the dialysis procedure that indicated that the TPI in both Fraction IV and V displayed the lower specific activity than others. During the purification procedure, the Fraction Wash had the higher specific activity than Fraction V. Since there was no TPI in the Fraction VIA, the Fraction VIB had larger specific activity than Fraction VIA in the purification procedure. The Figure 3 below summarized the information of specific activities of aldolase and triose phosphate isomerase from Table 3 and 5. Specific Activites vs. TPI 16 Aldolase Triose Phosphate Isomerase Specific Activity 14 12 10 8 6 4 2 0 I II III IV V Fraction Name Wash Peak VIA VIB Figure 3) Specific Activities of Aldolase and TPI. The activity of each individual enzyme was determined for each fraction from the aldolase and TPI assays. The protein content was also determined by utilizing the Bradford Method. Figure 3 indicates that the specific aldolase activities were relatively higher than that in the TPI except the fraction III. Sample Calculation: 1. Concentration of protein (mg/ml) = (mg/ml of protein in tube) x (Dilution Factor) Total protein (mg) = concentration of protein (mg/ml) x (volume of total fraction) 2. Absorbance (340nm) /min = ε x c x l /t Therefore, Absorbance (340nm) /min x volume / ε x l = U (μmol/min) ε = molar extinction coefficient (6.2 ml/ (μmol x cm) for NADH at 340nm), l is the path length (usually 1cm), and c is the solution’s concentration. Tube Reaction Velocity (μmol/min) = Absorbance (340nm) / min x 0.48 μmol U/ (volume of sample) x dilution factor = Units/ml Units/ml x volume of total fraction = Total Units of Activity 3. Specific Activity (Units/mg) = Total Units of Activity/ Total Protein 4. Yield Percentage = Total Units for certain Fraction / Total Units of Fraction I 5. Fold Purification = Specific Activity for certain Fraction / Specific Activity for Fraction I Discussion: Throughout the experiment, total four procedures were proceeded to extract and purify the muscle aldolase from the rabbit muscle, which were extraction/solubilization, stabilization, concentration/isolation, and the specific assays. For the extraction procedure, 0.03M KOH and 0.001M EDTA were utilized to form a hypotonic condition in osmotic lysis for rabbit muscle. After the extraction of proteins from muscle cells, the proteins that extracted were stabilized on ice at 0-4℃ and set up with EDTA. For the enzymes, the low temperature from ice facilitated to keep enzymes’ activity, and EDTA inhibited proteases that lysed with selected proteins. Since most of the protease requires metal ions, EDTA were utilized since it tends to inhibit metalloproteins by chelating metal ions. After the extraction procedure, the 50-60% saturated (NH4)2SO4 solution was utilized to precipitate the aldolase. Since the salt tend to compete water with proteins in the solution, proteins have to be precipitated if there are dissolved salts in water. In addition, the dialysis procedure was performed since the pores in dialysis membrane only allowed substances to penetrate. The size of the substances had to be smaller than 14,000 Da (Dalton). Through this procedure, the aldolase and substances that larger than 14,000 Da were filtered by the dialysis bag. In continue, the chromatography was utilized to concentrate aldolase after the dialysis procedure. The phosphate groups in phosphocellulose resin bound to arg-148 of aldolase and equilibration buffer was utilized to washed away the untargeted proteins. Then, the equilibration buffer that consist of FBP, the natural substrate of aldolase, was utilized to elute the aforementioned bounded proteins. After the concentration procedure, Specific assay (Assay II) were utilized to measure the aldolase and triose phosphate isomerase (TPI) activity for each enzyme. The rate of disappearance of NADH in coupled reaction was utilized to measure the reaction rates of two enzymes that tested in experiment at 340 nm. In this procedure, dihydroxyacetone reaction with NADH was performed to from α-glycerophosphate (α-GP) with NAD+ by catalyzing the α-GP dehydrogenase. The main reaction for two assays were different since the aldolase convert fructose to glycerate 3-phospate (Ga3P) and dihydroxyacetone phosphate (DHAP), and TPI converted Ga3P to DHAP reversibly that could inhibit the aldolase activity. The main reason for testing TPI activity is because there are the potentials for contamination through TPI. To determine the concentration of protein, the Bradford Method was utilized after the Coomassie dye reaction between SO3and NH4+ of proteins while the absorbance of proteins reached to 595nm. After the isolation step, the total proteins tended to decrease over time except the Fraction VIA as recorded on the Table 3 above. 15ml of Fraction VIA should contain more proteins than Fraction Peak since there was only 1ml aliquot for Fraction Peak. In continue, the total aldolase activity mostly decreased except for Fraction III, Wash, and VIA (Table 3). The Fraction III contained less aldolase than that in Fraction IV since it was the supernatant that gathered after the salt precipitation. Also, the Fraction Wash had zero for the aldolase activity since it consisted of unbounded proteins. The Fraction VIA had relatively higher than Fraction Peak total aldolase activity since it contained eleven fractions in the dialysis process that represented the peak part. For the specific aldolase activity, Fraction III and Wash had relatively higher value and Fraction VIA and VIB had a little bit lower amount of it compare to Fraction Peak (Table 3). The amount of aldolase activity in Fraction III is very low due to low specific activity. On the other hand, the Fraction Peak had higher specific activity than Fraction VIA and VIB since the less total protein and higher total activity were displayed in the Fraction Peak. Since two assays used the same fraction in the experiment for the enzyme activity test, the total protein change had the similar trend with that for aldolase which implies that the protein concentration of each fraction must stay as constant. Except the Fraction VIB, the TPI activities were tending to decrease with subsequent procedures. Throughout the isolation and purification procedures, less TPI must display in the later fraction. The total TPI activity in Peak seemed to be lower slightly due to less volume of Fraction Peak compare to Fraction VIB. Also, during the salt precipitation, the specific activity of TPI tended to increase since there was more amount of precipitation of aldolase in 60% saturated (NH4)2SO4 solution. This indicated that TPI was remaining more in the supernatant for Fraction III. Also, its specific activity tended to decrease due to more precipitation based on the abundant amount of aldolase were in the Fraction IV. After the dialysis procedure, the dialysis bag was utilized to filter the proteins that larger than 14,000 Da. As the result of this procedure, the specific activity for TPI was slightly increased. Throughout the Chromatography procedure, the unbounded proteins were droved out into the Fraction Wash that lead TPI to be monitored better in Wash. Sine the Fraction Peak, VIA, and VIB were mainly gathered aldolase throughout the chromatography procedure, the specific activity of TPI tended to decrease in those fractions. The most effective procedure in purification to increase the specific aldolase activity was the chromatography procedure (Figure 3). Based on using the resin to choose aldolase from the mixture, the large difference in specific activity between Fraction V and Peak was monitored. Also, the specific TPI activity tended to higher in Fraction Wash than Fraction V. For these reasons, TPI must be the hydrophilic protein that tend to remain soluble for high concentration. The wash procedure facilitated TPI to elute since it can’t bind to the phosphate group. To compare with the experiment from Penhoet and Rutter, they achieved about 71% yield of aldolase after ammonium sulfate fractionation, and 69% yield of aldolase after phosphocellulose affinity chromatography.2 On the other hand, our experiment achieved 69% yield percentage of aldolase after ammonium sulfate fractionation, but only 25.2% of aldolase after phosphocellulose affinity chromatography was yielded. Though the yield % of aldolase after ammonium sulfate fractionation were similar between two experiments, there was a huge gap in between two experiments for phosphocellulose affinity chromatography. The most predictable reason for this gap is due to the usage of batch mode in this experiment, since the washes were gone through mixing resin and centrifugation procedures. This might lead to loss of aldolase throughout the process that result the lower yield percentage in our experiment. In addition, only two elution went through the resin that indicates some aldolase to stay bounded to the resin due to the batch mode. Though this alternative method couldn’t bring the close result to the experiment from Penhoet and Rutter, it still proved that the batch method is able to achieve the aldolase yield %. In this experiment, the improvement could be proceeded for reducing the gap among the fractions for the aldolase activity. The salt might be poured too quickly that lead to premature precipitation of aldolase in fractions. To sum up, the experiment performed successfully. The individual subsequent purification procedure resulted the higher purity of aldolase as shown on the Table 2 and 3 above. The only problem that encountered during the experiment was the relatively lower aldolase yield percentage compare to the result from Penhoet and Rutter, but it is still not a bad reason consider for utilizing other method. References 1. Bradford, M.M., Analytical Biochemistry, 72: 248-254 (1976). 2. Penhoet, E.E. and Rutter, W.J., Methods in Enzymology, 42: 240-249 (1975)