Uploaded by

Jigar Patel

Manufacturing KPIs: Raw Material, Delivery, Utilization Metrics

advertisement

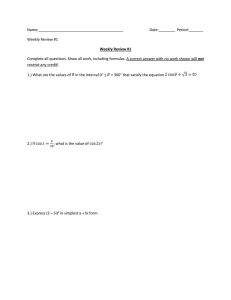

Data Type (Continuou Measure Title s or Discrete) Raw Material Continuou Lead Time s Raw Material Continuou Quality s % of Late Deliveries & Expected Quantitiy Continuou s Stratification Factors (By who/what/ where/when) Who and Sampling How Notes (Person (Time Frame, responsible etc.) and method Check By Time of Day Receiving Deparment Sampling all orders weekly Receiving Department Expected day of delivery Sampling all Type of Material orders weekly Receiving Department Quality Standard e.g. 60 The amount of late Type of supplier; delivers by suppliers and Expected vs Sampling all expected quanity vs Delivered orders weekly delivered quantity Quantity Receiving Department 0% late and expected quantity delivered Receiving Department 0% unsorted boxes Operational Definition The amount of days it takes from the moment the we submit raw materials order to the moment the order is delivered. The quality of raw materials ordered from suppliers (Denim, Khaki, Cotton, Silk) % of Continuou unsorted raw s materials The number of unsorted raw materials each week Types of unsorted raw materials Machine Utilization Continuou s The amount of machine sitting idle Type of machine Employee Utilization Continuou Employee work utilization s Space Utilization Continuou s Space Utilization Quarterly Process Time Continuou s Time at each machine Type of Production % of on-time delivery Continuou s % of on-time delivery to the clients Daily Weekly Weekly All machine all Production orders Department Green Two machines sitting idle Two workers in 1 worker not All each utilized to full Departments department potential All Analyze each All departments' department's Departments space setup utilized Analyze All machine process time Production utilized at each Department appropriate machine daily Sample on90-100% ontime deliverys, Shipping time delivery weekly Department