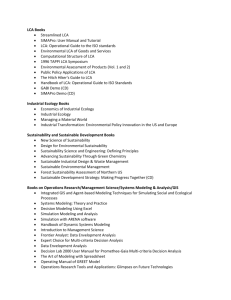

ABSTRACT Nowadays, the industry's rapid development has created environmental pollution problems due to the production of consumer products from waste products. Design for Environment has been implemented to address this issue. DfE is used to eliminate or reduce the environmental problems that happened during the manufacture of goods. DfE's functions include manufacturing the product without less hazardous waste, ensuring that manufacturers use sustainable products, ensuring that chemical pollution and energy consumption are lower, using non-hazardous recycling material, designing a product that can easily disassemble and reassemble, and ensuring that the product produced can be reused when broken or disposed. This study discusses the issue of the environmental problems and their counter-back with the Design for Environment process. CHAPTER 1 INTRODUCTION Background According to Sharma. K, development of technology has improved the lifestyle of humans and high quality of life archiving. As more advanced technology products are produced to improve and facilitate human life, this also results in increased human impact on the environment. In this context, the word "environmental impact" applies to energy use and the production of waste products from consumer products such as household devices, electronic applications and automobiles. (Van et al., 2014) Sustainable technology has resulted in efforts to reduce or mitigate the negative environmental impacts of consumer products. Based on the study conducted by Lockton, Harrison, & Stanton, 2008, the main objective of sustainable technology is to improve the performance of consumer products while reducing the waste generated by the products. In other words, the main concerns of manufacturing industries are producing products that are environmentally friendly. Despite making a longlasting product, the use of renewable materials and recyclable materials should be taken into account. Hence, the green design is introduced in Design for Environment (DfE) to help manufacturers create greener products during the early design phases. Therefore, it supports the Design of Environmental concept, which is the systematic analysis of design quality in terms of environmental, health and safety priorities over the entire product and process life cycle. DFE aims to address the product life-cycle issues early in the development phase. It is therefore similar to production design (DFM), assembly design (DFA), and production design (DFP). DFE combines several design-related topics including disassembly, recovery, recycling, disposal, regulatory compliance, impact on human health and safety, and minimization of hazardous materials (P. Fitzgerald, William Herrmann & Thornton H., 2007). Scope Shoes rack is selected as the case study in this study. DfE tools like life cycle analysis (LCA), eco web design and eco indicator were used in this study. LCA is used to identify the environmental impacts of a product, ranging from product design, extraction of raw materials, production, use and final disposal. Eco web design is used to compare shoe rack components from factors like material choice, material usage, delivery, product use, lifespan and end-of-life, while the eco indicator is used to measure the product's environmental impact. CHAPTER 2 LITERATURE REVIEW In this chapter, related information of the assignment summarized. The literature review includes the introduction to sustainability, life cycle assessment (LCA), type of shock rack and recycle material. Sustainable Development The term sustainability can be defined as “the process of changes in which exploitation of resources, investment directions, technical progress directions and institutional changes are in harmony with and provide, currently and in the future, the opportunities to satisfy human needs and aspirations” (Kadłubek, 2015). Besides that, sustainability well-known define from Our Common Future, also known as Brundtland Report which defines as "Sustainable development is a development that meets the needs of the present without compromising the ability of future generations to meet their own needs." Sustainability become one of the most pressing challenge of our century, and has been a main keyword in the global research and political agenda for decades (D’Amato et al., 2017). There are 17 sustainable development goals (Wu & Zhi, 2016) and all the goals are to end poverty, protect the planet and ensure prosperity for all as part of a new sustainable development agenda. Each goal has specific targets to be achieved over 15 years (Wu & Zhi, 2016). As figure 2.1 shows the goals are: 1. End poverty in all its forms everywhere. 2. End hunger, achieve food security and improved nutrition and promote sustainable agriculture. 3. Ensure healthy lives and promote well-being for all at all ages. 4. Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all. 5. Achieve gender equality and empower all women and girls. 6. Ensure availability and sustainable management of water and sanitation for all. 7. Ensure access to affordable, reliable, sustainable and modern energy for all. 8. Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all. 9. Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation. 10. Reduce inequality within and among countries. 11. Make cities and human settlements inclusive, safe, resilient and sustainable. 12. Ensure sustainable consumption and production patterns 13. Take urgent action to combat climate change and its impacts. Conserve and sustainably use the oceans, seas and marine resources for sustainable development. 13. Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss. 14. Promote peaceful and inclusive societies for sustainable development, provide access to justice for all and build effective, accountable and inclusive institutions at all levels. 15. Strengthen the means of implementation and revitalize the Global Partnership. Figure 2.1: Sustainable development goals (Assembly, G. 2015) Based on Figure 2.2, circle of sustainable development cover all of three important components which are economy, environment and social community. Each component involves the specific area and issues that need more attention in order to meet the sustainable development. Thus, we can say that the sustainability should integrate social, economic and environmental aspects. Figure 2.2: Circles of sustainable development Economy Sustainable Development For urban economy, Wu & Zhi, (2016) pointed out that the urban sustainability should have the development of economics towards the direction of effectiveness and innovation with limited resources. In industry especially in the manufacturing industry, the manufacturing activities will create waste and contribute to the environmental pollution. Thus, in order to prevent and minimize this problem, the manufacturing industry should practise Lean manufacturing principles. These principles provide a strategic way forward for manufacturing industries while providing critical elements in a sustainable operation (“Sustainable Manufacturing Manufacturing For Sustainability,” n.d.). Beside lean principles, cleaner production, as shown in Table 2.1 can provide a sustainable environment in the manufacturing industry. Cleaner production can be defined as a precautionary company-specific environmental protection which to minimise waste and emissions and maximise product output by analysing the flow of materials and energy in production (“Sustainable Manufacturing Manufacturing for Sustainability,” n.d.). Environment Sustainable Development The environment can be sustainable when three of these things are fulfilled (Thwink.org, 2014): 1. For renewable resources, the rate of harvest should not exceed the rate of regeneration (sustainable yield); 2. For pollution, the rates of waste generation from projects should not exceed the assimilative capacity of the environment (sustainable waste disposal); and 3. For non-renewable resources, the depletion of the non-renewable resources should require the comparable development of renewable substitutes for that resource The renewable resources is a resource can be used repeatedly and replace naturally such as oxygen, tree, soil, fresh water, solar energy and biomass. Generally, renewable resources harvesting do not contribute to the environmental pollution and global warming. The renewable resources offer various of benefits such as reduce defence on fossil fuel that contributes to the emission of sulphur dioxide, providing possible backup if fossil fuel supply is failing and providing the capacity of natural energy from natural resources. The management of the wastes in industries can reduce the environment pollution. The use of renewable energy avoids the consumption of depletable resources such as fossil fuels (Haanstra et al.,2017). The industries should not generate waste more than the assimilative capacity of the environment in order to manage the waste disposal. There are many type of waste generated in the industry. Solid waste (SW) is the material that no longer has any value to a person or an industry but if the waste are not manage successfully, they will contribute the impact to humans and environment (Biraja, 2010).Thus, proper education of public especially in industries area should be taking into serious issues to minimize the community problem regarding the waste management. Social Community Sustainable Development In order to meet the goals of sustainable development the urban social sustainability is expected to develop the cable communication and information dissemination that are accessibility (Wu & Zhi, 2016). Besides that, Wu & Zhi (2016) stated that the sustainable city should also be a living city, getting different environments accustomed to the needs of diverse lifestyles besides provide employment as well as training chances, averting social. In Malaysia, especially in the agricultural area, the government had put an effort for good practices in agriculture by establishing a Malaysia (Shobri et al., 2016). The community is expose to the better practise in order to achieve the sustainable development of the social among them. Shobri (2016) stated that, by improving the Malaysia standards in Good Agriculture Practices can give guidance to the farmer in sustainable agriculture practices, meanwhile at the same time help to assist farmers in understanding a boarder definition of sustainability farming practices. Besides, to achieve the sustainable development of the social, the community need the non-formal educational to gives them a better understanding and keep sustainable development continues growing (Nasibulina, 2015). Life cycle assessment (LCA) In order to fully understand the environmental impact, it is often necessary to consider the entire life cycle of a product or process. LCA is a tool for enhancing process and system environmental performance and is often applied in sustainability work. The benefit of LCA is decreasing environmental destruction, in part by increasing resources conservation and efficiency. Besides that, LCA can prevent pollution and use in green design effort. According to Rosen (2006), there are 4 steps of a life cycle assessment which are scope and goal definition, life-cycle inventory analysis, impact assessment and interpretation. LCA has access to design/selection strategies for products, materials, processes, reuse, recycling and final disposal. EcoDesign A research conducted by Karlsson & Luttropp, 2006, EcoDesign is a concept that integrates multifaceted aspects of design and environmental considerations to reducing adverse environmental impacts throughout a product’s life cycle” (Navajas, 2017). The aim of EcoDesign is to find sustainable solutions that fulfil human requirements and they want. The word of “Eco” concern living environment and to housekeeping (Natural). While EcoDesign likes as economy and ecology (Reine Karlsson and Conrad Luttropp, 2006). Figure 2. 3: Linguistic map of ‘‘EcoDesign’’.( Reine Karlsson a, Conrad Luttropp) Design for Environment (DFE) Design for Environment (DFE) is a concept and a set of tools that help industry improve the environmental performance of a product across its entire life cycle. Design strategies that improve environmental performance include the selection of low impact materials ensuring the use of ‘clean’ production technologies, optimizing distribution systems, enhancing use phase attributes, and ensuring the product has minimal impact on the environmental once it has reached the end of its use (Luzadis et al. 2009). Some organization are now also exploring Design for Sustainability which incorporates not only environmental considerations but also a range of other sustainability pactices associated with a product system, from the sustainability of the materials, to labour practice, to total costs. One key to successful DFE initiatives, whether initiated by industry or government, is to align DFE with internal and external business, market and regulatory drivers (Luzadis et al. 2009). Figure 3.0 shows the strategy wheel of DFE. Principles and Approaches of Design for Environment DFE principles and approaches have been developed to guide designers in creating product concepts and layouts when lack of time and detailed information prohibit a full life cycle assessment (LCA) (Telenko et.al, 2008). DFE principles often reflect lessons learned from LCA that pinpoint flaws or potential improvements in candidate designs for improved environmental impact. The principles and approaches of DFE also promote consistency and systematization between design process, facilitate communication of new discoveries, and provide an important set of environmental solutions to complement or replace unavailable LCA data (Telenko et al., 2008). LCA, Design for Environment (DfE), Product Service Systems (PSS) & Integrated Product Policy (IPP) are all responses to the identified need for a paradigm shift in our approach to achieving sustainable development each builds on the concept of life cycle thinking. he principles of DFE consist of: i) Ensure sustainability of resources This principle aims to address resource depletion by encouraging reuse of resources within the techno sphere, such as materials and components, and renewability of consuming resources, such as energy. ii) Ensure healthy inputs and outputs Healthy inputs and outputs are those that do no cause environmental degradation or adversely affect human health. This principle requires elimination of hazardous substances and pollutants as well as the conversion of waste to useful materials for products and ecosystem. iii) Ensure minimal use of resources in production and transportation phases This principle encourages the designer to think about how product attributes affect the efficiencies of seemingly unrelated processes. iv) Ensure minimal use of resources during use This principle motivates the product’s design to be efficient in its consumption of energy and material and its interactions with the user during the usage stage of its life cycle. v) Ensure appropriate durability of the product and components Expanding the product life by avoiding extra transportation and processing steps, as well as postponing waste, recycling, and remanufacturing steps. This aspect can be addressed in two important strategies: durability for long life, coupled with the ability to update the product to current best practices. vi) Enable disassembly, separation, and purification Recycling, remanufacturing, reuse, repair, and upgrading can be facilitated by incorporating these features for disassembly, separation, and purification. CHAPTER 3 METHODOLOGY 3.1 Process Tree Process tree is a schematics diagram that represent the overview of product’s life cycle. Process tree help to think ahead in which situation, activities and process that the new product will turn up. This tool includes some sub processes like fabrication, assembly, packaging, disposal, etc that essential for later stage of product development. The outcome of the Process Tree is a structured overview of the main process and important sub process that product faced. 3.2 Life Cycle Analysis Life Cycle Analysis (LCA) is a method used to assess the environmental impact of a product associated with all the stage from extraction and processing of material. Manufacture, distribution, use and disposal. According to Sajid et al. (2016), LCA is a commonly accepted method for quantifying environmental impacts of a product, from the procurement of materials through the return of materials to the environment or processing plant. The Figure 3.1 shows the illustration of the LCA. Figure 3. 1: Illustration of the LCA According to Gierej (2017) LCA provides a very wide perspective that includes various life cycle phases, like: Acquisition of resources (metal ores, crude oil, coal extraction processes, etc.), Raw materials production, from which the final product is being made (production processes of metals, alloys, plastic, ceramic, etc.), Raw materials, materials and semi-products transport (influence of transport means on the environment), Final product manufacturing processes (direct environmental impact of the product manufacturer), Packaging production, Product distribution (supplying the product to wholesaler's, chain stores and customers environmental impact of transport), Phase of product usage (materials needed, energy consumption), Waste disposal – getting rid of the product, packaging and materials after being used (environment impact of disposal methods such as re-use, recycling, landfill processes, waste incineration, etc.) 3.3 Eco Design Web Eco Design Web is one of the qualitative methods of analysing products against some important aspect such as material usage, product use, optimal life, etc. The purpose of eco design web is to rate an existing product or design and identify problem areas for your design ideas. The activity is aimed to indicate areas of the product that can be redesigned to improve its environmental sustainability. The Eco-design web is useful when assessing an existing product for redesign, assessing design ideas and helping to improve ideas and products. Figure 3.2 shows the eco web colour handout. Figure 3. 1: Eco web colour handout 3.4 Standard Eco Indicator Standard Eco Indicator is a quantitative method that used numbers to express the total environmental load of a product or process. With the standard eco indicator any designer or product manager can analyse the environmental loads of products over the life cycle. Generally, the standard eco-indicator available for the following items: 1. Production of materials In determining the indicator for the production of materials all the processes are included from the extraction of the raw materials up to and including the last production stage, resulting in bulk material. Transport processes along this route are also included up to the final process in the production chain. Which process that is, can be derived from the explanation in the Ecoindicator list. For plastic, for example, all the processes are included from extraction of the oil up to and including the production of the granules: for sheet steel all the processes are included from extraction of the ore and coke up to and including the rolling process. The production of capital goods (machines, buildings and such like) is not included. 2. Production processes The Eco-indicators for treatment processes relate to the emissions from the process itself and emissions from the energy generation processes that are necessary. Here too, capital goods, like machines and dies, are not included. 3. Transport Transport processes include the impact of emissions caused by the extraction and production of fuel and the generation of energy from fuel during transport. The unit is the transport of one tonne (1000 kg) goods over km (1tkm). A different unit is used for bulk road transport. 4. Energy The energy indicators refer to the extraction and production of fuels and to energy conversion and electricity generation. 5. Waste processing and recycling Not all products are disposed of in the same manner Therefore, when using indicators careful consideration must be given to which waste processing method is the most appropriate. REFERENCE Van Kernebeek, H. R. J., Oosting, S. J., Feskens, E. J. M., Gerber, P. J., & De Boer, I. J. M. (2014). The effect of nutritional quality on comparing environmental impacts of human diets. Journal of cleaner production, 73, 88-99. Sharma, K. Global Warming, Anthropogenic and Other Factors and Environmental Concerns: A Synthesis Based on Climate Stability Trends through Time. www. excelpublish. com, 15. Assembly, G. (2015). sustainable Development goals. SDGs), Transforming our world: the, 2030. Robert, K. W., Parris, T. M., & Leiserowitz, A. A. (2005). What is sustainable development? Goals, indicators, values, and practice. Environment: science and policy for sustainable development, 47(3), 8-21. 17