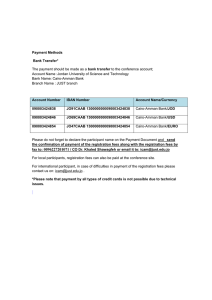

AIPS event name Date PIM #XXXXXXX (20XX Tier X #XX) PHOTO OF FACILITY OR EVENT Investigation Team A B C D E Peer Review A AIPS Event Summary PDO directorate/asset Directorate/Asset Event owner Name director or other event (incident) owner Location Name location Event date & time Date, time Event type AIPS Tier 1/Tier 2/LOPC/HiPo/HVL Actual risk rating RAM (only for applicable categories and only consequence, not likelihood) Potential risk rating RAM (rating for ALL 4 PEAR categories) Description of Event One liner of the event Injury/Damage/Loss List injury type List quantity of product lost List all direct associated cost and damage (including clean-up cost) List indirect cost (e.g. deferment) PIM ID XXXXXXX Immediate cause Description (to be taken from “Causation”sheet) Key latent mgmt failures • List no more than 4 failures (to be taken from “Causation” sheet) 2 Description of the Event Short to the point description of the event (incident) Include picture if/where relevant Overview photo/drawing of EVENT 3 Overview of Damage/Impact ADD PHOTOS/DRAWINGS or FLOWCHARTS (include any further photos in back-up) 4 Sequence of Events Date & Time Events INCLUDE summary sequence of events Detailed descriptions to be captured in BACK-UP 5 Loss of Barrier Assessment Which control/recovery barriers failed or were missing? Include barrier picture if/where relevant Include a bowtie representation if relevant 6 Key Findings ANY KEY findings relevant to the event (divide these over design/operational/technical, emergency response and supplemental findings) Design Integrity • ANY finding Technical Integrity • ANY finding Operating integrity • ANY finding Emergency response • ANY finding Supplemental Findings (any finding that is not directly related to the event, but was encountered during the event) • ANY finding 7 Causation Immediate Cause • Loss of containment ....... Underlying Causes • Max 4 to 5 underlying causes Latent Management Failures • Max 4 to 5 Latent MGT failures 8 AIPS Pattern Check (Populate below matrix with the key findings where applicable) Pattern DESIGN INTEGRITY TECHNICAL INTEGRITY OPERATIONAL INTEGRITY #1 Drive for production #2 Training and Development #3 Learning from Incidents #4 Creating Error conditions 9 Recommendations Recommendation Action Party Target Date Status 1 2 3 (Verify that: - Recommendations address root causes and a clear action to do - Recommendations are agreed by the action party as well as target date) 10 Recommendations (from MDIRC/IRC) Recommendation Action Party Target Date Status 1 2 3 (Verify that: - Recommendations address root causes and a clear action to do - Recommendations are agreed by the action party as well as target date) 11 PDO-LFI AIPS-20XX0X PROCESS SAFETY EVENT: Title of the event (Date of event) KEY WORDS: Add relevant key words, e.g. Design Integrity, Tier 1, Materials Corrosion & Inspection, Pipelines WHAT HAPPENED: Description of the event ACTUAL CONSEQUENCE(S): Description of the actual consequence and RAM rating [A3] POTENTIAL CONSEQUENCE(S): Description of potential consequence and RAM rating for all categories if applicable [A3C, P4B] KEY LEARNING(S): List and number all individual learnings and add integrity category (e.g. [DI]) and ensure learnings are endorsed by appropriate CFDH, e.g. 1. Formation water with low resistivity (<100 ohm.cm) can conduct CP (stray) currents. If in any doubt about the potential for water production assume it will occur at some time in the operational life and design for it [DI] 2. Cross-bond of existing Isolation Joints can only be a temporary measure, and needs to be followed by replacement or installation of SSD for earthing [TI] KEY DISCIPLINES: KEY STANDARDS: Add relevant key disciplines, e.g. Add relevant standards, e.g. Process Engineering (UEP1P), PR-1418 Incident Notification and Investigation Material Corrosion & Inspection (UEC) DEP 80.45.10.10 Design of Pressure Relief, Flare and Vent Add relevant photos/drawings of EVENT 20XX-Tier X #XX, PIM XXXXXXX 12 Back Up 13 20XX-Tier 1 #XX Process Safety Event MDIRC Initial Update Status on DD MM YYYY PROCESS SAFETY EVENT: Directorate – Title of event (DD MM YYYY) WHAT HAPPENED: Provide short description of the event IMMEDIATE CAUSE: Description of immediate cause PRELIMINARY UNDERLYING ROOT CAUSES: List and describe potential underlying causes of the event, e.g. Stopping the incoming feed by third party supplier happened too late PRELIMINARY LATENT MANAGEMENT FAILURES: List and describe potential management failures of the event, e.g. Inappropriate quality control systems for maintenance and inspection Add relevant photos/drawings of EVENT PRELIMINARY LEARNINGS (not CFDH approved yet): List all immediate learnings (note that these learnings are not necessarily complete nor will be approved at this stage), and add integrity category (DI, OI, TI), e.g. Enforce third party communication protocol in the event of an emergency [OI] Monitor the flare KOD level at all times and treat the HH level trip/alarm with the highest priority, even if the unit or plant is down and closed in [OI] INVESTIGATION TEAM: List all investigation team members NEXT MDIRC SCHEDULED UPDATE: DD MM YYYY (within 60 days date of event) (Provide a copy of the MDIRC Initial Update (Tier 1 only), required within 10 days after notification) 20XX-Tier 1 #XX, PIM XXXXXXX 14 Recommendations – Asset specific Recommendation 1 Action Party Target Date Status Add any immediate and/or further asset specific actions 2 3 15 Overview of Damage (More pictures and description if applicable) 16 Witness Statements (Refer to witness statements where applicable) 17 TRIPOD Ianadequate process implemenation for working plant, S/D, S/U Inadequate Management of Change implementation Inappropriate quality control system Inadequate implemenation of Standards Project initiated to replace pumps Pre-start up check list not available for Ops Work instrcutons not clearly communicated ??? Design/ construction flaw Operations check prior to pump start not done Not following communication procedure by Technician Preventive maintenance discontinued in 2013 Modular skid design without draining facility Ignition by heat of friction between pump-house and shaft Piping stress action on pump nozzle Fire at the Hot Oil pump B Pump skid draining facilities Piping stress elimination Pump bolts loosen and release Pump Vibration Condition monitoring Maintenance Loss of shaft center line damage the pump seal Hot Oil LOPC from damaged seal Both Hot Oil pump damaged due to fire Operations Pump seal B Hot Oil pumps Pump nozzle Pump bolts Bearing pump B (Provide Tripod diagram if Tripod has been used in the investigation) (If other method has been used, provide any representation that may come with it) 18 ICAM Causation description Findings: Immediate Causes Unsafe Actions IC Ref # ICAM Causation description Justification (Provide ICAM tables if ICAM has been used in the investigation) 19 ICAM Causation description Findings: Immediate Causes Unsafe Conditions IC Ref # ICAM Causation description Justification (Provide ICAM tables if ICAM has been used in the investigation) 20 ICAM Causation description Findings: Underlying Causes (Human and Workplace) IC Ref # UC Ref # ICAM Causation Description Justification (Provide ICAM tables if ICAM has been used in the investigation) 21 ICAM Causation description Findings: Management System failures (MSF) UC Ref # MSF Ref # ICAM MSF Description Justification for management system failure cited Life Saving Rules - Were LSR breached related to the event? Yes/No (Provide: description which rule was breached, did the breach caused the event, was it a violation or negligent error) 22