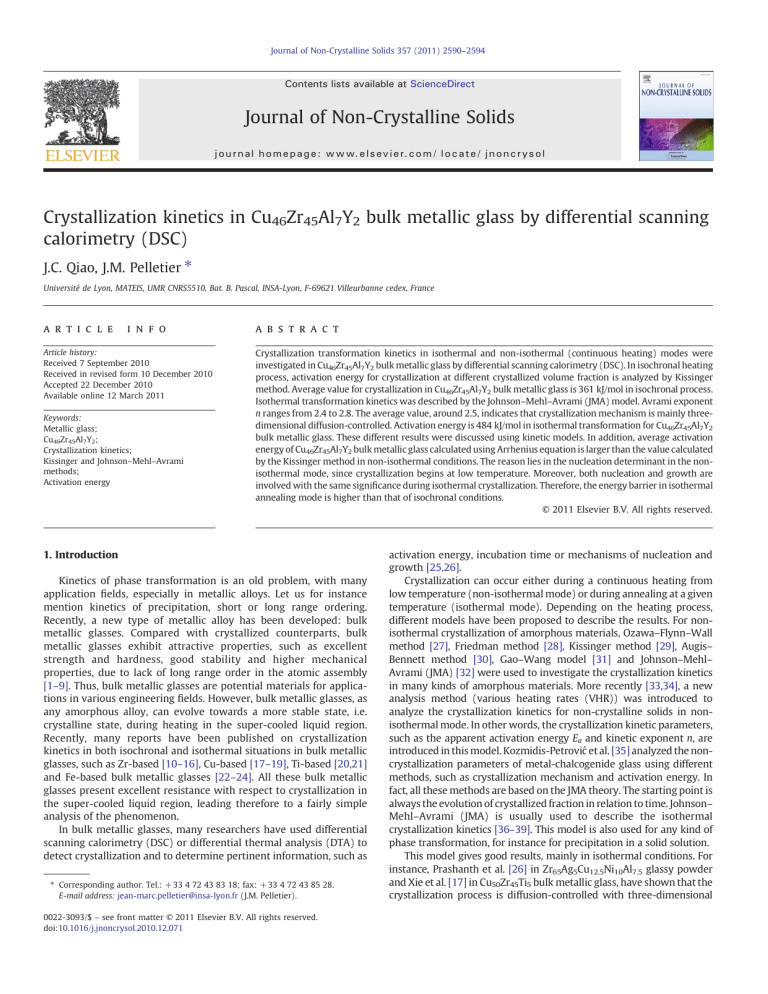

Journal of Non-Crystalline Solids 357 (2011) 2590–2594 Contents lists available at ScienceDirect Journal of Non-Crystalline Solids j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / j n o n c r y s o l Crystallization kinetics in Cu46Zr45Al7Y2 bulk metallic glass by differential scanning calorimetry (DSC) J.C. Qiao, J.M. Pelletier ⁎ Université de Lyon, MATEIS, UMR CNRS5510, Bat. B. Pascal, INSA-Lyon, F-69621 Villeurbanne cedex, France a r t i c l e i n f o Article history: Received 7 September 2010 Received in revised form 10 December 2010 Accepted 22 December 2010 Available online 12 March 2011 Keywords: Metallic glass; Cu46Zr45Al7Y2; Crystallization kinetics; Kissinger and Johnson–Mehl–Avrami methods; Activation energy a b s t r a c t Crystallization transformation kinetics in isothermal and non-isothermal (continuous heating) modes were investigated in Cu46Zr45Al7Y2 bulk metallic glass by differential scanning calorimetry (DSC). In isochronal heating process, activation energy for crystallization at different crystallized volume fraction is analyzed by Kissinger method. Average value for crystallization in Cu46Zr45Al7Y2 bulk metallic glass is 361 kJ/mol in isochronal process. Isothermal transformation kinetics was described by the Johnson–Mehl–Avrami (JMA) model. Avrami exponent n ranges from 2.4 to 2.8. The average value, around 2.5, indicates that crystallization mechanism is mainly threedimensional diffusion-controlled. Activation energy is 484 kJ/mol in isothermal transformation for Cu46Zr45Al7Y2 bulk metallic glass. These different results were discussed using kinetic models. In addition, average activation energy of Cu46Zr45Al7Y2 bulk metallic glass calculated using Arrhenius equation is larger than the value calculated by the Kissinger method in non-isothermal conditions. The reason lies in the nucleation determinant in the nonisothermal mode, since crystallization begins at low temperature. Moreover, both nucleation and growth are involved with the same significance during isothermal crystallization. Therefore, the energy barrier in isothermal annealing mode is higher than that of isochronal conditions. © 2011 Elsevier B.V. All rights reserved. 1. Introduction Kinetics of phase transformation is an old problem, with many application fields, especially in metallic alloys. Let us for instance mention kinetics of precipitation, short or long range ordering. Recently, a new type of metallic alloy has been developed: bulk metallic glasses. Compared with crystallized counterparts, bulk metallic glasses exhibit attractive properties, such as excellent strength and hardness, good stability and higher mechanical properties, due to lack of long range order in the atomic assembly [1–9]. Thus, bulk metallic glasses are potential materials for applications in various engineering fields. However, bulk metallic glasses, as any amorphous alloy, can evolve towards a more stable state, i.e. crystalline state, during heating in the super-cooled liquid region. Recently, many reports have been published on crystallization kinetics in both isochronal and isothermal situations in bulk metallic glasses, such as Zr-based [10–16], Cu-based [17–19], Ti-based [20,21] and Fe-based bulk metallic glasses [22–24]. All these bulk metallic glasses present excellent resistance with respect to crystallization in the super-cooled liquid region, leading therefore to a fairly simple analysis of the phenomenon. In bulk metallic glasses, many researchers have used differential scanning calorimetry (DSC) or differential thermal analysis (DTA) to detect crystallization and to determine pertinent information, such as ⁎ Corresponding author. Tel.: + 33 4 72 43 83 18; fax: + 33 4 72 43 85 28. E-mail address: jean-marc.pelletier@insa-lyon.fr (J.M. Pelletier). 0022-3093/$ – see front matter © 2011 Elsevier B.V. All rights reserved. doi:10.1016/j.jnoncrysol.2010.12.071 activation energy, incubation time or mechanisms of nucleation and growth [25,26]. Crystallization can occur either during a continuous heating from low temperature (non-isothermal mode) or during annealing at a given temperature (isothermal mode). Depending on the heating process, different models have been proposed to describe the results. For nonisothermal crystallization of amorphous materials, Ozawa–Flynn–Wall method [27], Friedman method [28], Kissinger method [29], Augis– Bennett method [30], Gao–Wang model [31] and Johnson–Mehl– Avrami (JMA) [32] were used to investigate the crystallization kinetics in many kinds of amorphous materials. More recently [33,34], a new analysis method (various heating rates (VHR)) was introduced to analyze the crystallization kinetics for non-crystalline solids in nonisothermal mode. In other words, the crystallization kinetic parameters, such as the apparent activation energy Ea and kinetic exponent n, are introduced in this model. Kozmidis-Petrović et al. [35] analyzed the noncrystallization parameters of metal-chalcogenide glass using different methods, such as crystallization mechanism and activation energy. In fact, all these methods are based on the JMA theory. The starting point is always the evolution of crystallized fraction in relation to time. Johnson– Mehl–Avrami (JMA) is usually used to describe the isothermal crystallization kinetics [36–39]. This model is also used for any kind of phase transformation, for instance for precipitation in a solid solution. This model gives good results, mainly in isothermal conditions. For instance, Prashanth et al. [26] in Zr65Ag5Cu12.5Ni10Al7.5 glassy powder and Xie et al. [17] in Cu50Zr45Ti5 bulk metallic glass, have shown that the crystallization process is diffusion-controlled with three-dimensional J.C. Qiao, J.M. Pelletier / Journal of Non-Crystalline Solids 357 (2011) 2590–2594 2591 growth. In contrast, Wang et al. [40] have used an integral fitting method to describe the isochronal transformation kinetics in Ti50Cu42Ni8 amorphous alloy and they found that this model is more suitable to describe the crystallization kinetics. Cu-based bulk metallic glasses show excellent glass forming ability, wide super-cooled liquid region and high mechanical properties [41–43]. However, only few investigations have been conducted in Cu46Zr45Al7Y2 bulk metallic glass [44], especially concerning the crystallization phenomenon. Therefore, DSC experiments in this bulk metallic glass are presented and discussed in the present work to give further information on this phenomenon. 2. Experimental 2.1. Sample preparation Master ingots of alloys with composition Cu46Zr45Al7Y2 were kindly provided by Prof. Y. Yokoyama, Institute of Materials Research, Tohoku University, Sendai, Japan. Cylindrical samples were mechanically cut to prepare DSC samples. In order to remove surface oxidation prior to experiments, these samples were carefully polished using diamond paste and finally washed in ethanol in an ultrasonic cleaning machine. 2.2. Structure characterization Structure of the specimens in the bulk metallic glasses was examined by X-ray diffraction at room temperature using the Cu Kα radiation produced by a commercial device (D8, Bruker AXS Gmbh, Germany). 2.3. DSC experiments Thermal properties and phase transformations were investigated using a standard commercial instrument (Pekin Elmer, DSC-7) under high purity dry nitrogen at a flow rate of 20 ml min−1. Alumina pans were used as sample holders. In order to ensure the reliability of the data in the experiments, temperature and enthalpy calibration were calibrated with an indium standard specimen (T m = 429.7 K, ΔH c = 28.48 J/g) and zinc standard specimen with 3.283 mg (Tm = 692.6 K, ΔHc = 108.37 J/g), giving an accuracy of ±0.2 K and ±0.02 mW, respectively. The baselines of DSC in the present work were described in Ref. [45]. First isochronal DSC experiments were carried out using different constant heating rates. Then, isothermal crystallization of the samples was tested in the super-cooled liquid region (SLR), i.e. above the glass transition temperature (Tg) and below the temperature corresponding to the onset of crystallization (Tx). The samples were heated up to the annealing temperature at a heating rate of 20 K min−1 and then hold at this temperature to follow the crystallization until completion. Finally, samples were cooled down to room temperature. Fig. 1. DSC curves in Cu46Zr45Al7Y2 bulk metallic glass, with various heating rates. position of which shifts to higher temperatures when the heating rate is increased. Therefore, crystallization process is simple, in contrast for instance to what is observed in the classical VIT1 bulk metallic glass (Zr–Ti–Cu–Ni–Be bulk metallic glass) where a complex double peak is obtained. This double peak was attributed to the existence of a decomposition phenomenon which precedes the crystallization phenomenon itself [46]. This was confirmed by transmission electron microscopy (TEM) observations [46]. In this alloy, analysis of the crystallization kinetics is difficult to perform, since the two contributions have to be separated. In the present alloy, a direct analysis is possible. From the DSC curves, the crystallized volume fraction for nonisothermal crystallization, α, can be deduced as a function of the temperature using the following equation [47–49]: T α= ∫T ðdHc =dT ÞdT 0 T∞ ∫T ðdHc =dT ÞdT 0 = A0 A∞ ð1Þ where T0 and T∞ are the temperatures at which crystallization begins and ends in amorphous materials, dHc/dT is the heat capacity at constant pressure. In addition, A0 and A∞ are the areas under the DSC curves, respectively. The crystallization volume fraction is plotted as a function of temperature in Fig. 2. All the curves present a sigmoidal dependence with temperature. The same evolution has been observed in all the amorphous materials (bulk metallic glasses and polymers) during the non-isothermal crystallization processes. 3. Results and discussion 3.1. XRD analysis of the as-cast bulk metallic glasses XRD pattern of the as-prepared Cu46Zr45Al7Y2 bulk metallic glass presents a typical broad diffuse maximum, without diffraction peak corresponding to a crystalline phase. Therefore, this alloy exhibits the typical characteristics of an amorphous structure. 3.2. Non-isothermal crystallization behaviour DSC curves in Cu46Zr45Al7Y2 bulk metallic glass recorded during continuous heating with different heating rates are shown in Fig. 1. Crystallization phenomenon induces a simple exothermic peak, the Fig. 2. Plots of crystallization volume fraction α as a function of temperature, using different heating rates. 2592 J.C. Qiao, J.M. Pelletier / Journal of Non-Crystalline Solids 357 (2011) 2590–2594 Fig. 3. Kissinger plots for different crystallization volume fractions α in Cu46Zr45Al7Y2 bulk metallic glass (ranging from 0.1 to 0.9). The activation energy Ea can be determined by the Kissinger's relationship [16,50,51] ln Rh Tθ2 ! =− Ea +C RTθ ð2Þ where, Rh is the heating rate during the experiment, Tθ is the characteristic temperatures such as Tg, Tx, and Tp (crystallization peak temperature) and C is a constant. Plots of ln(Rh/T2θ )versus 1/T2 for different crystalline volume fractions α (range from 0.1 to 0.9) are shown in Fig. 3 and Fig. 4. Results are in good agreement with the Kissinger's equation, since straight lines are clearly observed. The activation energy in Cu46Zr45Al7Y2 bulk metallic glass is nearly independent on crystalline volume fraction. An average value (361 kJ/mol) can be calculated in non-isothermal heating mode. 3.3. Isothermal behaviours In isothermal crystallization conditions, evolution of the crystalline volume fraction α, as a function of time is given by [47]: A α= = 0 A ∞ ∫t ðdHc = dt Þdt 0 t∞ exothermic peak after a given incubation time (τ). This incubation time decreases when the annealing temperature is increased, due to a higher mobility at higher annealing temperature, which facilitates concentration fluctuations necessary for large-scale crystallization [52]. These results are in good agreement with previously reported data in Pd-based bulk metallic glasses [53], Zr-based bulk metallic glasses [15,40,54] and Cu-based bulk metallic glasses [19]. From these curves, the evolution of the crystalline volume fraction is shown in Fig. 6, versus the annealing time during isothermal annealing. All the curves exhibit a typical sigmoidal trend. 3.3.1. Kinetic parameters Transformation kinetics can be described using the Johnson– Mehl–Avrami (JMA) equation [11,40,55,56]: n αðt Þ = 1−exp −K ðt−τÞ ð3Þ 0 where dHc/dt is the heat flow. The DSC curves obtained at different annealing temperatures are shown in Fig. 5. They look like those recorded in non-isothermal conditions. DSC curves exhibit a single Fig. 4. Activation energy Ea in Cu46Zr45Al7Y2 bulk metallic glass as a function of crystallization volume fraction α (α ranging from 0.1 to 0.9) in non-isothermal heating process. ð4Þ where τ is the incubation time, which in fact is a fitting parameter. Taking the double logarithm of Eq. (4), the following expression is deduced [40,55]: ln½−lnð1−αðt ÞÞ = nln K + nlnðt−τÞ t ∫t ðdHc = dt Þdt Fig. 5. Isothermal DSC curves at different annealing temperatures in Cu46Zr45Al7Y2 bulk metallic glass. ð5Þ By plotting of ln[− ln(1 − α)] versus ln(t − τ) at various annealing temperatures with 0.2 ≤ α ≤ 0.8 (Fig. 7), the kinetic exponent n and the reaction rate constant K can be calculated. Values are given in Table 1. Kinetic exponent n varies with annealing temperatures from 2.4 to 2.8. Similar variations have been reported in other bulk metallic Fig. 6. Crystallization volume fraction α as a function of annealing time for various annealing temperatures in Cu46Zr45Al7Y2 bulk metallic glass. J.C. Qiao, J.M. Pelletier / Journal of Non-Crystalline Solids 357 (2011) 2590–2594 2593 Fig. 8. Plots for activation energy determination in Cu46Zr45Al7Y2 bulk metallic glass. Fig. 7. Avrami plots at various annealing temperature in Cu46Zr45Al7Y2 bulk metallic glass with 0.2 ≤ α ≤ 0.8. glasses: Zr65Ag5Cu12.5Ni10Al7.5[40], Zr55.9Cu18.6Ta8Al7.5Ni10[57] and Zr63.33Ti8.89Cu15.45Ni12.33 [58]. These variations are fairly limited. According to the diffusion-controlled growth theory [52], n = 1.5 means that growth of particles occurs with a nucleation rate close to zero; 1.5 b n b 2.5 indicates a growth of particles with decreasing nucleation rate, n = 2.5 reflects growth of particles with constant nucleation rate, and n N 2.5 corresponds to the growth of small particles with an increasing nucleation rate [58,59]. The average kinetic exponent n in Cu46Zr45Al7Y2 bulk metallic glass is close to 2.5. Similar values of n have been reported in other based bulk metallic glasses: Ca50Mg22.5Cu27.5 [38] and Cu52.5Ti30Zr11.5Ni6 [19]. So in these various bulk metallic glasses, growth of crystalline particles occurs with a constant nucleation rate. 3.3.2. Activation energy The activation energy for the crystallization process in isothermal model can be determined using the Arrhenius equation [19]: E t ðaÞ = t0 exp a RT ð6Þ where t0 is a constant. Plots of ln t(a) versus 1/T during isothermal annealing are shown in Fig. 8. All the fitting curves are almost straight lines. Activation energy is nearly constant, with an average value of 484 kJ/mol. Fig. 9 presents activation energy Ea as a function of crystallization volume fraction α in Cu46Zr45Al7Y2 bulk metallic glass (α range from 0.1 to 0.9) in isothermal mode. This average activation energy corresponding to isothermal conditions calculated using Arrhenius equation is larger than the value calculated by the Kissinger method in non-isothermal conditions (during a continuous heating). This phenomenon has also been observed in other bulk metallic glasses: Cu52.5Ti30Zr11.5Ni6 bulk metallic glass [19] and Zr65Cu27Al8 bulk metallic glass [60]. Yang et al. [19] suggested that isochronal heating induces higher temperature compared with isothermal heating condition and then crystallization transformation from metastable state to crystalline phases is easier at higher heating temperature. Thus, the energy barrier in isothermal annealing mode is higher than that of non-isothermal conditions. Two phenomena occur during the crystallization process: nucleation and growth. Generally, it is assumed that nucleation is determinant in the non-isothermal mode, since crystallization begins at low temperature. On the other hand, during isothermal crystallization, both nucleation and growth are involved with the same significance. Therefore, the crystallization mechanism in non-isothermal and isothermal modes is different. Cu46Zr45Al7Y2 bulk metallic glass has a higher apparent activation energy than Mg-based [61], Cu-based [62] and Zr-based [12], but lower than Al33Ni16Zr51 bulk metallic glass [63]. 4. Conclusion Kinetics of crystallization in Cu46Zr45Al7Y2 bulk metallic glass was studied by DSC in both non-isothermal and isothermal modes. The main results are as follows: • Classical models developed in the literature (Kissinger model or JMA model) are really appropriate to describe the crystallization process. • During a non-isothermal annealing, the average value of activation energy, determined using the Kissinger method, is 361 kJ/mol. • In isothermal annealing conditions, the Johnson–Mehl–Avrami model applies. Avrami exponent n ranges from 2.4 to 2.8. These values, close to 2.5, indicate that the crystallization mechanism is mainly diffusion-controlled. Crystal growth occurs by a threedimensional long range ordering. The average value of activation energy is 484 kJ/mol. • Two phenomena occur during the crystallization process: nucleation and growth. Generally, it is assumed that nucleation is Table 1 Kinetic exponent n, reaction rate constant K and incubation time τ at different annealing temperatures with 0.2 ≤ α ≤ 0.8 in Cu46Zr45Al7Y2 (Cu-based) BMG. Annealing temperature (K) n τ (min) K 753 748 743 738 2.5 2.7 2.4 2.4 0.25 0.47 1.23 1.65 0.64 0.38 0.25 0.14 Fig. 9. Activation energy Ea as a function of crystallization volume fraction α for Cu46Zr45Al7Y2 bulk metallic glass (α range from 0.1 to 0.9) in isothermal mode. 2594 J.C. Qiao, J.M. Pelletier / Journal of Non-Crystalline Solids 357 (2011) 2590–2594 determinant in the non-isothermal mode, since crystallization begins at low temperature. On the other hand, during isothermal crystallization, both nucleation and growth are involved with the same significance. Therefore, the energy barrier in isothermal annealing mode is higher than that in non-isothermal conditions. Acknowledgements One of the authors, J.C. Qiao, wants to express his thanks to Dr. J.M. Chenal and Dr. S. Cardinal, for valuable discussion and assistance in XRD and DSC experiments during the course of the work. Prof. Y. Yokoyama is acknowledged for providing the bulk metallic glasses. Qiao thanks China Scholarship Council (CSC) for providing the scholarship. References [1] Q.P. Cao, J.F. Li, P.N. Zhang, A. Horsewell, J.Z. Jiang, Y.H. Zhou, J. Phys. Condens. Matter 19 (2007) 246206. [2] A.L. Greer, Science 267 (1995) 1947. [3] C.J. Byrne, M. Eldrup, Science 321 (2008) 502. [4] A. Inoue, Acta Mater. 48 (2000) 279. [5] W.H. Wang, C. Dong, C.H. Shek, Mater. Sci. Eng. R 44 (2004) 45. [6] A. Inoue, W. Zhang, T. Zhang, K. Kurodaka, Acta Mater. 49 (2001) 2645. [7] W.H. Wang, Adv. Mater. 21 (2009) 4524. [8] W.H. Wang, Prog. Mater. Sci. 52 (2007) 540. [9] Q. Luo, W.H. Wang, J. Non-Cryst. Solids 355 (2009) 759. [10] J.F. Li, Z.H. Huang, Y.H. Zhou, Intermetallics 15 (2007) 1013. [11] J.Z. Jiang, Y.X. Zhuang, H. Rasmussen, J. Saida, A. Inoue, Phys. Rev. B 64 (2001) 094208. [12] A.H. Cai, W.K. An, Y. Luo, T.L. Li, X.S. Li, X. Xiong, Y. Liu, J. Alloys Comp. 490 (2010) 642. [13] Y.L. Gao, J. Shen, J.F. Sun, G. Wang, D.W. Xing, H.Z. Xian, B.D. Zhou, Mater. Lett. 57 (2003) 1894. [14] P.F. Xing, Y.X. Zhuang, W.H. Wang, L. Gerward, J.Z. Jiang, J. Appl. Phys. 91 (2002) 4956. [15] J.S.C. Jang, L.J. Chang, G.L. Chen, J.C. Huang, Intermetallics 13 (2005) 907. [16] K.N. Lad, R.T. Savalia, A. Pratap, G.K. Dey, S. Banerjee, Thermochim. Acta 473 (2008) 74. [17] G.Q. Xie, D.V. Louzguine-Luzgin, Q.S. Zhang, W. Zhang, A. Inoue, J. Alloys Comp. 483 (2009) 24. [18] X. Ou, G.Q. Zhang, X. Xu, L.N. Wang, J.F. Liu, J.Z. Jiang, J. Alloys Comp. 441 (2007) 181. [19] Y.J. Yang, D.W. Xing, J. Shen, J.F. Sun, S.D. Wei, H.J. He, D.G. McCartney, J. Alloys Comp. 415 (2006) 106. [20] H.C. Kou, J. Wang, H. Chang, B. Tang, J.S. Li, R. Hu, L. Zhou, J. Non-Cryst. Solids 355 (2009) 420. [21] J. Wang, H.C. Kou, J.S. Li, X.F. Gu, L.Q. Xing, L. Zhou, J. Alloys Comp. 479 (2009) 835. [22] E. Illeková, Thermochim. Acta 280–281 (1996) 289. [23] N. Bayri, T. Izgi, H. Gencer, P. Sovak, M. Gunes, S. Atalay, J. Non-Cryst. Solids 355 (2009) 12. [24] K. Biswas, S. Venkataraman, W.Y. Zhang, S. Ram, J. Eckert, J. Appl. Phys. 100 (2006) 023501. [25] S.H. Al-Heniti, J. Alloy. Comp. 484 (2009) 177. [26] K.G. Prashanth, S. Scudino, K.B. Surreddi, M. Sakaliyska, B.S. Murty, J. Eckert, Mater. Sci. Eng. A 513–514 (2009) 279. [27] K.N. Lad, R.T. Savalia, A. Pratap, G.K. Dey, S. Banerjee, Thermochim. Acta 473 (2008) 74. [28] H.L. Friedman, J. Polym. Sci. C 6 (1964) 183. [29] H.E. Kissinger, Anal. Chem. 29 (1957) 1702. [30] M. Stoica, S. Kumar, S. Roth, S. Ram, J. Eckert, G. Vaughan, A.R. Yavari, J. Alloys Comp. 483 (2009) 632. [31] Y.Q. Gao, W. Wang, J. Non-Cryst. Solids 81 (1986) 129. [32] R.T. Savalia, K.N. Lad, A. Pratap, G.K. Dey, S. Banerjee, J. Therm. Anal. Cal. 78 (2004) 745. [33] M.M. Abd El-Raheen, H.M. Ali, J. Non-Cryst. Solids 356 (2010) 77. [34] M.S. Rasheedy, A.S. Soltan, A.A.I. Abd-Elmageed, J. Alloys Comp. 472 (2009) 581. [35] A.F. Kozmidis-Petrović, S.R. Lukić, G.R. Štrbac, J. Non-Cryst. Solids 356 (2010) 2151. [36] F. Xu, Y.L. Du, P. Gao, Z.D. Han, G. Chen, S.Q. Wang, J.Z. Jiang, J. Alloys Comp. 441 (2007) 76. [37] X.F. Wu, L.K. Meng, W. Zhao, Z.Y. Suo, Y. Si, K.Q. Qiu, J. Rare Earth 25 (2007) 189. [38] D. Okai, Y. Shimizu, N. Hirano, T. Fukami, T. Yamasaki, A. Inoue, J. Alloys Comp. 504 (2010) S247. [39] J.T. Zhang, W.M. Wang, H.J. Ma, G.H. Li, R. Li, Z.H. Zhang, Thermochim. Acta 505 (2010) 41. [40] J. Wang, H.C. Kou, J.S. Li, X.F. Gu, H. Zhong, H. Chang, L. Zhou, J. Phys. Chem. Solids 70 (2009) 1448. [41] J.C. Qiao, J.M. Pelletier, Intermetallics 19 (2011) 9. [42] Q.J. Chen, J. Shen, D.L. Zhang, H.B. Fan, J.F. Sun, D.G. McCartney, Mater. Sci. Eng. A 433 (2006) 155. [43] L.Z. Lin, H.Q. Wei, Y.H. Ding, P. Zhang, G.Q. Xie, A. Inoue, J. Alloys Comp. 475 (2009) 207. [44] D.H. Xu, G. Duan, W.L. Johnson, Phys. Rev. Lett. 92 (2004) 245504. [45] A.T.W. Kempen, F. Sommer, E.J. Mittemeijer, Acta Mater. 50 (2002) 1319. [46] J.M. Pelletier, B. Van de Moortèle, J. Non-Cryst. Solids 325 (2003) 133. [47] X.F. Lu, J.N. Hay, Polymer 42 (2001) 9423. [48] Y. Liu, G.S. Yang, Thermochim. Acta 500 (2010) 13. [49] S.H. Kim, A.H. Ahh, T. Hirai, Polymer 44 (2003) 5625. [50] N. Mehta, K. Singh, N.S. Saxena, Phys. B 403 (2008) 3928. [51] A.A. Soliman, S. Al-Heniti, A. Al-Hajry, M. Al-Assiri, G. Al-Barakati, Thermochim. Acta 413 (2004) 57. [52] S. Venkataraman, E. Rozhkova, J. Eckert, L. Schulta, D.J. Sordelet, Intermetallics 13 (2005) 833. [53] L. Liu, X.J. Zhao, C.L. Ma, T. Zhang, Intermetallics 17 (2009) 241. [54] D. Kasase, A.P. Tsai, A. Inoue, T. Masumoto, Appl. Phys. Lett. 62 (1993) 137. [55] Z.Z. Yuan, X.D. Chen, B.X. Wang, Y.J. Wang, J. Alloys Comp. 407 (2006) 163. [56] F. Xu, J.Z. Jiang, Q.P. Cao, Y.W. Du, J. Alloys Comp. 392 (2005) 173. [57] Q. Chen, L. Liu, K.C. Chan, J. Alloys. Comp. 419 (2006) 71. [58] S. Scudino, S. Venkatarama, J. Eckert, J. Alloys. Comp. 460 (2008) 263. [59] L.C. Zhang, J. Xu, J. Eckert, J. Appl. Phys. 100 (2006) 033514. [60] S.W. Wei, B.Z. Ding, T.Q. Li, Z.Q. Hu, Matter Lett. 37 (1998) 263. [61] Y.D. Sun, Z.Q. Li, J.S. Liu, J.N. Yang, M.Q. Cong, J. Alloys Comp. 506 (2010) 302. [62] R. Fernández, W. Carrasco, A. Zúñiga, J. Non-Cryst. Solids 356 (2010) 1665. [63] J.Ph. Braganti, O. Held, F.A. Kuhnast, E. Illekova, Thermochim. Acta 362 (2000) 71.