Digitalized Product Service Systems in Manufacturing Firms A Case Study Analysis

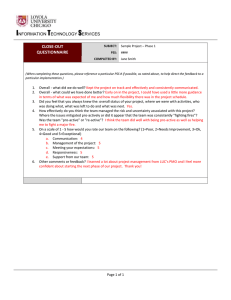

advertisement

Research-Technology Management ISSN: 0895-6308 (Print) 1930-0166 (Online) Journal homepage: http://www.tandfonline.com/loi/urtm20 Digitalized Product-Service Systems in Manufacturing Firms: A Case Study Analysis Christian Lerch & Matthias Gotsch To cite this article: Christian Lerch & Matthias Gotsch (2015) Digitalized Product-Service Systems in Manufacturing Firms: A Case Study Analysis, Research-Technology Management, 58:5, 45-52, DOI: 10.5437/08956308X5805357 To link to this article: https://doi.org/10.5437/08956308X5805357 Published online: 23 Dec 2015. Submit your article to this journal Article views: 697 View Crossmark data Citing articles: 4 View citing articles Full Terms & Conditions of access and use can be found at http://www.tandfonline.com/action/journalInformation?journalCode=urtm20 FEATURE ARTICLE Digitalized Product-Service Systems in Manufacturing Firms A Case Study Analysis Linking digital systems with physical products to create novel product-service bundles that provide services independently and proactively can enable advanced services and promote growth. Christian Lerch and Matthias Gotsch OVERVIEW: The merging trends of digitalization and servitization harbor extensive and largely unexplored potential for manufacturing firms. Digital systems can be linked with product-service bundles to build novel digitalized product-service systems (PSS), which use digital architectures to provide services independently and proactively. This paper gives an overview of service digitalization in industrial firms and describes three types of digitalized PSS, differentiated by purpose and by technical and organizational architecture. Each of the three types addresses a different stage of the product life cycle and improves performance or efficiency; in the long run, digitalized PSS can help improve a firm’s overall innovation activity. KEYWORDS: Servitization, Digitalization, Product-service systems The term servitization has been used in recent years to describe a growing service orientation among product manufacturers, who are increasingly moving from simply selling products to offering supportive services tailored to the product (Baines et al. 2009; Wise and Baumgartner 1999; Vandermerwe and Rada 1988). These services range from traditional product-related services such as maintenance, repair, and training to advanced customer-oriented services (Lay 2014; Oliva and Kallenberg 2003; Mathieu 2001). Advanced services typically take the form of product-service systems (PSS), or physical products bundled with intangible Christian Lerch is a senior researcher at the Competence Center for Sustainability and Infrastructure Systems at the Fraunhofer Institute for Systems and Innovation Research ISI, Karlsruhe, Germany. He studied economics engineering at the Karlsruhe Institute of Technology and wrote a PhD thesis on managing interactions of product and service innovations in industrial companies at FU Berlin. He has directed several research projects in the field of industrial services, analyzing the causes and effects of servitization in manufacturing and its contribution to industrial change. The results of his studies have been published in national and international articles. christian.lerch@isi.fraunhofer.de Matthias Gotsch is a senior researcher at the Competence Center for Sustainability and Infrastructure Systems at the Fraunhofer Institute for Systems and Innovation Research ISI, Karlsruhe, Germany. He holds a PhD from Brandenburg Technical University and a diploma in industrial engineering with a focus on industrial business, technology and innovation management from the University of Erlangen-Nürnberg, Germany. He has expertise in service innovations, industrial services, and innovative service-based business models and has contributed several papers and articles to the field of service science. matthias.gotsch@isi.fraunhofer.de DOI: 10.5437/08956308X5805357 services in a customized manner to fulfill highly individual customer needs (Tukker and Tischner 2006; Goedkoop et al. 1999). These innovative, individualized product-service bundles increase the value delivered to the customer and hence increase the competitiveness of the provider (Boyt and Harvey 1997). The move toward servitization has coincided with a rising trend toward digitalization, with manufacturers equipping products with intelligent digital systems that allow the products to operate independently of human intervention and communicate with other machines. As a logical consequence of the confluence of servitization with this trend toward intelligent machines, an increasing number of manufacturers are using digital systems to support their services (Münster and Meiren 2011), creating totally new industrial productservice offerings, such as comprehensive remote services that bring digital and physical systems together to pave the way for, for instance, availability guarantees. These new kinds of offerings may in turn lead to far-reaching reconfigurations of the mechanisms of value creation in manufacturing. Thus, manufacturers cannot afford to ignore these emerging forces, which have the power to completely reshape the industrial landscape. Companies that do not keep up with these developments may find themselves threatened with extinction in the near future, as competitors with more customized, responsive offerings gain advantage. Three practical case studies from our joint research projects on servitization show how companies can combine digital systems with PSS to harvest value and build competitive advantage. Research-Technology Management • September—October 2015 | 45 Digitalization significantly increases the complexity, abstraction, and problemsolving skills needed by employees. Services Innovation and Digitalization Previous studies of servitization have assumed that manufacturers move from product manufacturer to solution provider along a defined transformation path (Gebauer, Fleisch, and Friedli 2005; Gebauer 2004). This transition path is typically described as taking place in stages, with each stage offering different potentials for differentiation (see, for example, Matthyssens and Vandenbempt 2010; Gebauer, BravoSanchez, and Fleisch 2008; Matthyssens and Vandenbempt 2008; Penttinen and Palmer 2007; Oliva and Kallenberg 2003; More 2001). At the end of the path, manufacturers offer innovative PSS, such as availability guarantees or build–operate–transfer (BOT) models, which increase customer value on the one hand and create competitive advantage for the provider on the other (Brady, Davies, and Gann 2005; Boyt and Harvey 1997). While PSS have been widely discussed—see Velamuri, Neyer, and Möslein (2011) for a review of the literature—the effect of the digital revolution on this servitization pathway has been less well explored. Most articles have dealt with the new challenges and impacts of digitalized services, focusing on how they differ from more traditional product-related services. What is missing in the literature is a comprehensive framework bringing together the emerging trends of servitization and digitalization in one conceptual structure. The integration of digitalization with services innovation has important implications for services. For instance, because digital services can be provided independent of manufacturer and customer location, traditional service characteristics like perishability and inseparability do not apply to digital service creation (Holtbrügge, Holzmüller, and von Wangenheim 2007). Additionally, the increasing digitalization of services demands new capabilities, opening up opportunities to simplify, accelerate, or optimize processes and create new forms of customer integration (Schuh and Fabry 2014). Researchers have identified a number of factors that may either hinder or stimulate the digitalization of industrial services. For example, the complexity of services offered seems to influence the degree of digitalization: the more advanced and ambitious the services, the more support is needed from smart ICT solutions (Lerch and Gotsch 2014; Gebauer, Gustafsson, and Vittel 2011). The complexity of the core product and production batch sizes also influence digitalization. Generally speaking, companies producing more complex products or smaller batch sizes tend to have closer contacts with customers and offer products with a higher degree of individualization (Dachs et al. 2013). These complex and individualized machines and diverse systems 46 | Research-Technology Management require a huge range of accompanying services (Seegy 2009; Rainfurth 2003; Borgmeier 2002), some of which can be offered digitally. The degree of digitalization of the core product influences the degree of digitalization of accompanying services. Digitalization makes it technically feasible to connect products to the Internet and assign them an IP address so that they can communicate and interact, with other components and with remote controllers, thus enabling more advanced services. However, in order to integrate services effectively into the communication network, the services must be digitalized in close coordination with the physical components (Hoffmann 2014; Bauer et al. 2014). Finally, some company attributes affect the degree of service digitalization, including company size and the share of sales from exports. Large enterprises are more likely to have the resources and competencies needed to create and support digital components and digital services. SMEs often do not have IT service divisions and thus are not able to provide individualized digital solutions (Reichwald, Krcmar, and Nippa 2009; Rainfurth 2003). The share of a company’s sales that come from exports seems to be another driver of service digitalization. Companies with a high proportion of export sales benefit from new digital opportunities because digital and remote-controlled services allow downstream activities to be offered independent of location. Maintenance and repair services can be provided remotely, without requiring local personnel. Conversely, high-quality products that are equipped with the technology to support such geographically independent services encourage foreign customers to purchase (Holtbrügge, Holzmüller, and von Wangenheim 2007). However, delivering these services requires ubiquitous, real-time communication networks with high data transfer rates and the ability to move large amounts of data. Without such a stable and reliable technical infrastructure, digital services cannot be offered economically. Only broadband networks provide the capability and stability required to allow providers and customers to access all the advantages of digital solutions (Bauer et al. 2014; Westkämper et al. 2013). Thus, digitized services may face significant challenges where such in infrastructure is not available. Another major barrier to the digitalization of services is a lack of qualified employees to develop and provide such services (Kagermann 2014). Digitalization significantly increases the complexity, abstraction, and problem-solving skills needed by all employees. Further, those employees directly providing the services need a technical qualification profile that includes knowledge of engineering, mechatronics, and IT. Special training and further professional development courses must be offered to overcome this barrier and prepare staff to offer digital services. Very few authors have attempted to offer a theoretical model for the evolution from a product focus to the offering of advanced digitalized services. Lerch and Gotsch (2014) build on existing servitization transformation models, analyzing the role of digitalization in the transition process. Digitalized Product-Service Systems in Manufacturing Firms Based on an analysis of three case studies, they argue that a more developed service orientation with more complex service offerings leads to a greater need for digital solutions. At the same time, they argue, the integration of ICT systems into products opens up new avenues for providing innovative services. The interactive effect of servitization and digitalization means that manufacturers progress along a transition path that is influenced by both digitalization and servitization, and shaped by the individual characteristics and activities of the manufacturer (Lerch and Gotsch 2014). At each stage, companies reach an equilibrium point, which remains stable as long as the company does not change its service offerings. At equilibrium, the firm can minimize investment in innovation processes and easily accommodate sales of existing PSS. However, increasing competition, external forces, or internal developments can trigger innovation, destabilizing the system and moving the manufacturer along the transformation path until a new equilibrium is reached. Ultimately, Lerch and Gotsch (2014) develop a transformation model that includes four generic stages (Figure 1): 1. Manufacturer: Manufacturers at the first stage provide obligatory product-related services, such as installation or maintenance and repair, and use standard ICT solutions to support services, including digital text files, e-mail, and videoconferencing. ICT solutions are used for daily work but have almost no impact on how service offerings are differentiated in the market. 2. IT-based services: Companies at this stage use ICT solutions to improve existing service offerings. A well-known and widely spread example is the concept of teleservices, the monitoring and controlling of machines over distance. As a result, companies are able to provide services faster, with less resource input and higher quality. 3. Pure digital services: At this stage, companies offer novel services enabled by ICT systems, including softwarebased simulations, virtual or augmented reality applications, and digital technical analyses. These services both extend the company’s service offerings and significantly enhance the performance of the product or service that is the core offering. 4. Digitalized PSS: Manufacturers at this stage not only provide complex PSS to their customers, but also incorporate ICT solutions as a novel component in the productservice bundle, creating intelligent, independent operating systems that deliver the highest level of availability possible and optimize operations while reducing resource inputs. Digitalized PSS are frequently offered via outcomes-based business models in which revenues are tied to the efficiencies delivered by the product-service bundle (Lerch and Gotsch 2014). Thus, digitalized PSS may be defined as an integrated bundle of physical products, intangible services, and digital architectures designed to fulfill individual customer needs via automated, independent operation, with the goal to significantly improve customer outcomes. We argue that as the final step of the transition to a services focus, digitalized PSS move firms beyond traditional service offerings in their high degree of automation and in their FIGURE 1. Servitization-digitalization transformation framework (translated from Lerch and Gotsch 2014) Digitalized Product-Service Systems in Manufacturing Firms September—October 2015 | 47 Small and medium-sized companies can share resources and expertise to produce PSS that benefit all parties, extending the portfolios of all participants. ability to act independently and forecast product service requirements and failure modes. Digitalized PSS in Manufacturing Firms—A Case Study Analysis To deepen our understanding of digitalized PSS, we conducted a series of joint research studies in German manufacturing firms in which the authors worked with companies to help them develop new digitalized PSS to solve customer problems and build market presence. Although the participating firms vary widely in size and specific industry, all three have advanced service offerings that are connected with digital systems, creating innovative product-service bundles (Table 1). These three cases are obviously specific to the particular needs of the firm involved; however, they represent different types of digitalized PSS and have a generic character that allows for broadly relevant conclusions. The primary source of data for the case studies is transcripts of workshops held with each firm to conceptualize ideas for new digitalized PSS. The workshops, which we organized and conducted, were held virtually or face to face and lasted between 45 minutes and three hours. Due to their novelty, the PSS developed in these cases are not necessarily market-ready; therefore, these cases should be understood as describing the development of prototypes for digitalized PSS. Nevertheless, we believe the PSS developed in these cases are likely to attain broad market diffusion. Smart Service Delivery Smart service delivery provides support for maintenance and repair, optimizing service processes and maintenance schedules via intelligent systems that communicate their service needs, allowing companies to act proactively to avoid breakdowns. For a small plant constructor engaged in developing, designing, and assembling stages that are then installed in theaters around the world, smart service delivery could help streamline maintenance and optimize resources, for both the firm and its customers. The company’s current service offerings are well developed compared to the state of the art in this market. They include maintenance and repairs, tests and verifications, the supply of spare parts, and a 24-hour service hotline. One particular challenge for this business is the extremely long life cycle of the stages and the appearance of service needs that are not always foreseen. Currently, maintenance services and checks are performed manually, which requires a lot of time and resources and is error prone. The large distances between the manufacturer and its clients adds further complexity, making it impossible for the company to react quickly to breakdowns and other customer needs. Moreover, most theaters have very few on-site resources for servicing the stages, making the firm’s service offerings critical to the theaters’ continued operation. Integrating digital service architectures into the technical structure of the stages offers a way to address these challenges, by creating an intelligent infrastructure that will allow the stages to observe their status, predict when components are likely to fail, and communicate this data to the firm so that maintenance can be scheduled proactively. The system will also offer recommendations for action to the stage operator and define the financial implications of each potential action. The autonomous nature of these systems will allow the manufacturer to save time now spent on error diagnostics and optimize its modest resources for maintenance. Some portion of the cost savings may be passed on to customers, which can create a competitive advantage. In pursuit of this solution, the company is cooperating with a manufacturer of electronic systems to develop digital components that can be integrated into the stages. The electronics manufacturer, which is of a similar size to the primary firm, is located close to the firm. Its portfolio focuses on radio data transmission and its offerings range from highly synchronized hardware components to customized wireless solutions. The development of digital services systems is a new business area for the company. In addition to demonstrating how a smart service delivery PSS may work, this case also demonstrates how small or medium-sized companies can leverage collaboration to create powerful digitalized PSS. While large enterprises considering developing digitalized PSS typically face the classical makeor-buy decision, small and medium-sized companies can share resources and expertise to produce PSS that benefit all parties, extending the portfolios of all participants. TABLE 1. Overview of case studies Case Company Firm Size* 1 Theatrical stage manufacturer 80/n.a. 2 Enameling line manufacturer 350/€80m 3 Machine tool manufacturer 1,700/€320m Service Offerings Customers Maintenance and repair, testing, spare parts, 24-hour service hotline Theaters Remote services, maintenance and repair, engineering services, project planning and implementation, training, service hotline Automotive manufacturers, Consumer goods manufacturers Technical support, spare parts, maintenance and repair, training, inspections, upgrade and retrofit of used machines, online help desk Automotive manufacturers * Firm size given in terms of number of employees/annual sales. 48 | Research-Technology Management Digitalized Product-Service Systems in Manufacturing Firms Smart Product Optimization Smart product optimization deploys digital technologies such as digital remote monitoring and supervision services to optimize the operation and function of the core product. These kinds of services provide competitive advantage by delivering increased value to the customer. A manufacturer of enameling lines sought to develop smart optimization PSS as a way to support availability guarantees for customers, thus creating competitive advantage. The manufacturer is a specialist in surface technology applications, manufacturing products such as spray systems and wallpaper strippers; it is also involved in the design and construction of enameling lines at customer plants and assembles solutions for powder and liquid coatings for industrial customers, primarily in the automotive industry. The firm operates globally and has customers throughout Europe and Asia; about 50 percent of its products are exported. This high export share presents significant challenges for the firm’s service business, which must provide services over long distances. In recent years, the manufacturer has steadily expanded its service offerings, increasingly relying on remote services to supplement traditional services performed on-site. For instance, the manufacturer has introduced a service hotline and developed various offerings around engineering services, project planning, and training. The digital offerings add to the value the manufacturer delivers to all of its customers, but they also help address the challenges presented by the geographic dispersion of customers. Ultimately, the objective of developing and implementing digital service concepts for this manufacturer is to offer availability guarantees for its machines and plants, which would allow customers to avoid expensive production outages and line shutdowns. This would require tying plants at customers’ facilities to the company’s digital architecture. Therefore, the company’s communication network must be adapted and upgraded to meet the robust requirements of such services and to be compatible with customers’ sites. The company believes that the right digital architecture and accompanying service structures to support preemptive maintenance could increase system availability by several percentage points, even given the non-optimal conditions under which many of its foreign customers operate the enameling lines. Ultimately, the manufacturer could offer comprehensive availability guarantees for its machines and plants under a new business model. Digital Brain In the most sophisticated form of digitalized PSS, the digital and physical systems come together to deliver comprehensive remote services. These sophisticated systems pave the way for lifecycle cost guarantees and similar business models. At the same time, and even more promising, such systems can deliver to the service provider important information that can be fed into the innovation process and used to improve the next generations of products and service offerings. This is the digital brain stage of services innovation. Digitalized Product-Service Systems in Manufacturing Firms For a large machine tool manufacturer, a digital brain approach can help achieve long-term advantages in the form of lifecycle cost guarantees and precise availability data. The globally active company mainly supplies automotive manufacturers and offers a comprehensive range of services via global service centers. Examples of such services include technical support, maintenance and repair operations, a spare parts supply service, training, inspections, an online help desk, and upgrading and retrofitting of used machines. The manufacturer is increasing digitalization of its products with two goals in mind: First, by integrating conditionmonitoring systems into its machines, it wants to identify precise availability rates for different components and component groups. Based on these rates, the manufacturer can then determine the availability and lifecycle costs for the various components of the machine and thus make the full lifecycle cost of the system transparent and controllable. This would provide the basis for a contractually defined availability and cost guarantee, providing a far-reaching competitive advantage. Second, the manufacturer wants to feed the plant data collected as a result of the first effort back to its product development teams, to support systematic improvement in new products. Taking advantage of the operational data, the manufacturer believes, could shorten product development cycles dramatically. Ultimately, the firm’s vision is to create an availabilityand cost-oriented PSS using a condition-monitoring system integrated into the machine as a digital supporting component. The data delivered by the system will allow current information regarding failure behavior, failure cause, and spare parts requirements to be evaluated and concrete values to be identified for mean time between failures, mean time to repair, and or mean costs for replacement parts, for individual components or entire component groups. These data will provide the initial basis for availability and lifecycle cost guarantees. The condition-monitoring system will also support those guarantees by allowing the manufacturer to monitor and control the machine and proactively identify maintenance and repair needs. Thus, the manufacturer can reduce the risk associated with offering a comprehensive PSS. The accumulated data can also be fed back to product development to drive product improvements and new solutions. Thus, the technological solution both enables competitive advantage in the current market, via the provision of lifecycle cost guarantees, and feeds the company’s innovation process, building competitive advantage for the future. Thus, the technological solution both enables competitive advantage in the current market and feeds the company’s innovation process, building competitive advantage for the future. September—October 2015 | 49 The Nature of Digitalized PSS As these cases illustrate, digitalized PSS differ from traditional service offerings in their high degree of automation and in their ability to forecast likely failures and maintenance needs. This ability arises from the fact that digitalized PSS integrate not only tangible products and intangible services but also digital architectures. This third component— the digital architecture—connects the physical product to the intangible service by providing a medium of communication and provides the capability for autonomy. Therefore, we argue that the essential attribute of digitalized PSS is their intelligence. The intelligent character of digitalized PSS gives them the potential to improve performance and efficiency significantly, which can lead to far-reaching competitive advantages. The three types of digitalized PSS explored in our case studies operate at different stages of the product life cycle (Table 2): • Smart service delivery: Smart service delivery improves the service process itself, to shorten the time and reduce the resources required and hence to decrease the costs associated with the service offering. Smart service delivery is generally associated with maintenance and repair services and mainly improves the intangible component of the PSS. • Smart product optimization: Smart product optimization works to improve the performance and efficiency of the core product. Smart optimization may save resources or increase the output or capacity of the product during operation; hence, it mainly improves the physical component of the PSS. • Digital brain: The digital brain product delivers important information to the provider, which is fed back into the development process to improve products and services in the next generation. This type of PSS affects manufacturers’ innovation activities and becomes effective during research and development. Customers benefit from these activities via upgrades that make the digitalized PSS more automated or independent— such as with a software upgrade—or more efficient or more powerful—such as with a new or extended physical or service module. The digital brain improves not just the physical but also the intangible part of the PSS. These distinct types of digitalized PSS hold the potential to revolutionize value creation in manufacturing generally. However, these business models create new dependencies and risks as well as revenue opportunities (Iansiti and Lakhani 2014). This trade-off results in a number of challenges for strategic management. Implications for Strategic Management The merging of the trends toward digitalization and servitization has extensive and as-yet-unexplored potentials for manufacturing firms. Concepts based on digitalized PSS may have far-reaching consequences for industrial firms and for the entire manufacturing industry. For instance, creating digitalized PSS will require close collaboration between manufacturing firms and electronic equipment providers, and delivering those services will build closer relationships between manufacturers and customers. This cross-linking offers the possibility of highly individualized, customer-oriented solutions that offer significant improvements and real value. This development may widely change market structures. However, these kinds of complex, individualized services won’t come without challenges. The processes of value creation will link the industrial economy and the digital economy, allowing them to grow together, but they will also greatly increase the number of actors participating in the value creation process, the complexity of the products, and the resources and competencies required to create and support them. To manage this shift successfully, industrial firms must begin by identifying their service digitalization potential firstly. This potential includes internal capabilities, of course, but it also includes the latent needs of customers and markets. Manufacturers contemplating a shift to services innovation must answer two questions: What kind of digitalized PSS can the firm handle and what capabilities must the firm develop to move in this direction? And what are the needs of current customers and what is the potential for moving into new markets with innovative PSS bundles? Simply asking these questions can move firms along the transformation path. Once the firm has identified its own capabilities to create and the market’s capacity to take up new offerings, TABLE 2. Types of digitalized PSS PSS Type Lifecycle Stage Focus Impact I. Smart Service Delivery Maintenance and repair Intangible part of PSS (directly, single product) • Reduction of reaction, delivery time • Reduction in resource inputs • Higher service quality for customer • Optimization of performance (greater availability, higher output) • Optimization of efficiency (fewer required resources, less facility usage) • Shortening innovation cycles • Triggering of incremental innovation in the short run (via upgrades) • Long-run improvement II. Smart Product Optimization III. Digital Brain Production R&D and design 50 | Research-Technology Management Physical part of PSS (directly, single product) Physical and/or intangible parts of PSS (directly by upgrades, indirectly in the next generation) Digitalized Product-Service Systems in Manufacturing Firms appropriate digital PSS offerings must be designed. Often, these new offerings will require totally new competencies, resources, and collaborations. This development process will, consequently, have a great impact on the firm’s innovation management systems, creating a need for new instruments and processes as well as new capabilities. To be successful, firms will have to expand their understanding of innovation management, moving R&D away from its traditional focus on physical products and toward an approach that integrates additional features, such as services and IT systems, to create meaningful bundles. This shift is a necessary step for mastering the transformation to servitization. Finally, as digitalized PSS are introduced to markets, new management systems will be needed, powered by new methods and management concepts. The diffusion of digitalized PSS in the market will create new challenges for their providers. In addition to building a powerful customer service function with the capacity and authority to handle the requirements of automated services, firms must learn to work with highly complex algorithms and an external digital infrastructure as it evolves. These challenges will lead to a totally new framework for the management of product-service bundles that will affect the full range of strategic management. Conclusion As digitalization and servitization come together to speed manufacturers’ evolution toward a focus on services, firms that are able to master this transformation will integrate tangible products, intangible services, and digital architectures to deliver novel digitalized PSS that provide highly customer-oriented and highly customized solutions. These developments will have far-reaching consequences for customers and for the value creation process. They will also force firms to broaden and extend their understanding of innovation management. Manufacturers must open up their perspective on innovation and rethink how to manage innovation processes. This trend will have consequences for the entire economy, creating new markets and new ways of creating and delivering value, which may be shared by different players. Future research should focus on a number of different aspects of this trend, to collect data around companies’ experience in delivering new digitalized PSS to market, identify the technical and economic impact of the digitalized PSS, and understand their contribution to industrial change. Only a deeper understanding of the opportunities and challenges presented by digitalized PSS, built on both theoretical and empirical research, will deliver the deeper insights needed to guide companies through this transition. References Baines, T., Lightfoot, H., Benedettini, O., and Kay, J. 2009. The servitization of manufacturing: A review of literature and reflection on future challenges. Journal of Manufacturing Technology Management 20(5): 547–567. Bauer, W., Schlund, S., Marrenbach, D., and Ganschar, O. 2014. Industrie 4.0—Volkswirtschaftliches Potenzial für Deutsch- Digitalized Product-Service Systems in Manufacturing Firms As digitalized PSS are introduced to markets, new management systems will be needed, powered by new methods and management concepts. land. [Industry 4.0—Economic potential for Germany.] Berlin: BITKOM. https://www.bitkom.org/files/documents/Studie_ Industrie_4.0.pdf Borgmeier, A. 2002. Teleservice im Maschinen- und Anlagenbau: Anwendungen und Gestaltungsempfehlungen. [Remote Services in Mechanical Engineering: Applications and Design Recommendations.] Wiesbaden: Deutscher Universitätsverlag. Boyt, T., and Harvey, M. 1997. Classification of industrial services—A model with strategic implications. Industrial Marketing Management 26(4): 291–300. Brady, T., Davies, A., and Gann, D. 2005. Creating value by delivering integrated solutions. International Journal of Project Management 23(5): 360–365. Dachs, B., Biege, S., Borowiecki, M., Lay, G., Jäger, A., and Schartinger, D. 2013. Servitization in European manufacturing industries: Empirical evidence from a large-scale database. The Service Industries Journal 33(1): 1–21. Gebauer, H. 2004. Die Transformation vom Produzenten zum produzierenden Dienstleister. [The Transformation from Producer to Producing Service Provider.] St. Gallen: Difo-Druck. Gebauer, H., Bravo-Sanchez, C., and Fleisch, E. 2008. Service strategies in product manufacturing companies. Business Strategy Series 9(1): 12–20. Gebauer, H., Fleisch, E., and Friedli, T. 2005. Overcoming the service paradox in manufacturing companies. European Management Journal 23(1): 14–26. Gebauer, H., Gustafsson, A., and Vittel, L. 2011. Competitive advantage through service differentiation by manufacturing companies. Journal of Business Research 64(12): 1270–1280. Goedkoop, M., van Halen, C., Riele, H., and Rommens, P. 1999. Product Service Systems: Ecological and Economic Basics. The Hague: Vrom. Hoffmann, J. 2014. Der Entwicklungspfad zur Industrie 4.0. Die intelligente Fabrik der Zukunft. [The development path for industry 4.0: The intelligent factory of the future.]. In Tagungsband Wiener Produktionstechnik Kongress, ed. F. Bleicher and K. Lammer, 183–193. Wien: Klein Publishing. Holtbrügge, D., Holzmüller, H., and von Wangenheim, F. 2007. Remote Services. Wiesbaden: Gabler. Iansiti, M., and Lakhani, K. 2014. Digital ubiquity: How connections, sensors, and data are revolutionizing business. Harvard Business Review 92(11): 90–99. Kagermann, H. 2014. Industrie 4.0 und die Smart Service Welt—Dienstleistungen für die digitalisierte Gesellschaft. [Industry 4.0 and the smart service world—Services for the digital society.]. In Dienstleistungen in der digitalen Gesellschaft, ed. A. Boes, 67–71. Frankfurt am Main: Campus. Lay, G. 2014. Servitization of industry: Origins and definitions. In Servitization in Industry, ed. G. Lay, 1–20. New York, London: Springer. September—October 2015 | 51 Lerch, C., and Gotsch, M. 2014. Die Rolle der Digitalisierung bei der Transformation vom Produzenten zum produzierenden Dienstleister. [The role of digitization in the transformation process from producer to producing service provider.] Die Unternehmung 68(4): 249–266. Mathieu, V. 2001. Product services: From a service supporting the product to a service supporting the client. Journal of Business & Industrial Marketing 16(1): 39–58. Matthyssens, P., and Vandenbempt, K. 2008. Moving from basic offerings to value-added solutions: Strategies, barriers and alignment. Industrial Marketing Management 37(3): 316–328. Matthyssens, P., and Vandenbempt, K. 2010. Service addition as business market strategy: Identification of transition trajectories. Journal of Service Management 21(5): 693–714. More, R. 2001. Creating profits from integrated product-service strategies. Ivey Business Journal 65(5): 75–81. Münster, M., and Meiren, T. 2011. Internet-basierte Services im Maschinen- und Anlagenbau. [Internet-Based Services in Mechanical and Plant Engineering.] Stuttgart: Fraunhofer-Verlag. Oliva, R., and Kallenberg, R. 2003. Managing the transition from products to services. International Journal of Service Industry Management 14(2): 160–172. Penttinen, E., and Palmer, J. 2007. Improving firm positioning through enhanced offerings and buyer-seller relationships. Industrial Marketing Management 36(5): 552–564. Rainfurth, C. 2003. Dienstleistungsarbeit im produzierenden Maschinenbau. [Service Work in Mechanical Engineering.] Stuttgart: Fraunhofer IRB Verlag. 52 | Research-Technology Management Reichwald, R., Krcmar, H., and Nippa, M. 2009. Hybride Wertschöpfung. Konzepte, Methoden und Kompetenzen für die Preis- und Vertragsgestaltung. [Hybrid Value Creation: Concepts, Methods and Skills for Price and Contract Drafting.] Lohmar: Josef Eul Verlag. Schuh, G., and Fabry, C. 2014. Digitalisierung von Dienstleistungen—Potenziale und Herausforderungen. [Digitizing services—Potential and challenges]. In Dienstleistungen in der digitalen Gesellschaft, ed. A. Boes, 50–59. Frankfurt am Main: Campus. Seegy, U. 2009. Dienstleistungskompetenz im Maschinen- und Anlagenbau. Eine Untersuchung wesentlicher Handlungspotenziale und ihre Auswirkungen. [Service Expertise in Mechanical and Plant Engineering: An Investigation of Substantial Opportunities for Action and Their Implications.] Wiesbaden: Gabler. Tukker, A., and Tischner, U. 2006. Product-services as a research field: Past, present and future. Reflections from a decade of research. Journal of Cleaner Production 14(17): 1552–1556. Vandermerwe, S., and Rada, J. 1988. Servitization of business: Adding value by adding services. European Management Journal 6(4): 314–324. Velamuri, V., Neyer, A-K., and Möslein, K. 2011. Hybrid value creation: A systematic review of an evolving research area. Journal für Betriebswirtschaft 61(1): 3–31. Westkämper, E., Spath, D., Constantinescu, C., and Lentes, J. 2013. Digitale Produktion. [Digital Production.] Heidelberg: Springer. Wise, R., and Baumgartner, P. 1999. Go downstream—The new profit imperative in manufacturing. Harvard Business Review 77(5): 133–141. Digitalized Product-Service Systems in Manufacturing Firms