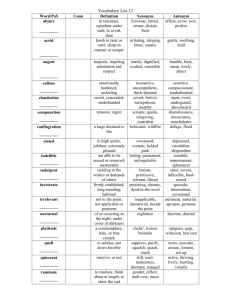

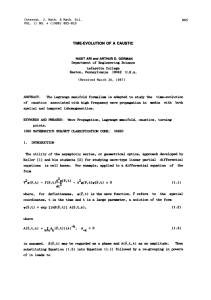

r, s Villa a l o c i N lay an and m a lch, C u e F H d a l a i av Ch ter ns Wa Felix D ru and e e P m , e i F n, S tes l YP e Olse ing no Repso t v e a t r e S p d eo ans an dation i provid , x o A Maug r S i ta s, U stic we ologie u n a h c c t e n T pe Peru. inery s f n e i r y a t i on facil T he Repsol YPF refinery in La Pampilla is the largest in Peru. The hydrocarbon streams contain sulfides and organic acids which are undesirable contaminants. These contaminants are removed by caustic treatment. Several different caustic treatment steps are performed through the refinery, making numerous spent caustic waste streams. Approximately 3000 m3/yr of combined spent caustic is generated. The spent caustic streams are malodorous and toxic, and are difficult to treat by conventional biological means. Beginning in 2005, Zimpro® wet air oxidation (WAO) is used to treat these streams prior to disposal. WAO allows on-site treatment without producing odorous offgas. Technology Wet oxidation is an aqueous phase process that operates at elevated temperature and pressure. Dissolved or entrained contaminants are oxidised in the liquid phase water. The process relies on the liquid water molecules to catalyse the oxidation. Oxygen is used as the oxidant and is supplied by mixing air with the spent caustic. When air is used as the source of oxygen, the process is referred to as wet air oxidation. For refinery spent caustic, the design operating temperature was 260 ˚C, which is well above the normal boiling point. System pressure is 88 kg/cm2 (1250 psi). The pressure keeps most of the water in the liquid phase, which also minimises the energy consumption. The typical reactions occurring during WAO of refinery spent caustic include the following: Sulfide oxidation: NaHS + 2O2 + NaOH → Na2SO4 + H2O Approximately 85% (by volume) of the spent caustic is produced continuously in the treatment of kerosene. The remaining 15% of the flow is produced in batches of varying quantities and compositions. Two storage tanks are used as equalisation tanks. One large batch of sulfidic spent caustic is segregated into one storage tank. The remaining spent caustics (sulfidic, naphthenic and cresylic) are combined and held in the other storage tank (called the main spent caustic). The partial segregation is done so that the sulfide concentration fed to the WAO unit can be better regulated. This is done to control oxygen uptake and corrosion that can result from uncontrolled sulfide concentration spikes. Metering pumps are used to control the flow rate of spent caustic from the two storage tanks and the fresh caustic. Dilution water is added to control the heat release from the oxidation. The water is added using a centrifugal pump. Caustic is consumed by the oxidation products. If there is insufficient caustic, the pH of the oxidised effluent will become acidic, which can damage the nickel alloys used in the high temperature portion of the WAO system. Fresh caustic is added to the feed to maintain the discharge pH above eight. Mercaptan oxidation: NaSR + O2 + NaOH → NaSO3R’ + NaHCO3 + Na2SO4 (unbalanced) Naphthenics and cresylics oxidation: NaOOR + O2 + NaOH → NaOOR’ + NaHCO3 + H2O (unbalanced) Where R’ is an organic chain, it is typically acetate or oxalate in the oxidised compounds. Description of the oxidation system Description of wastewater The spent caustic comes from multiple streams and includes sulfidic, naphthenic, and cresylic spent caustics. Sulfidic spent caustics come from the caustic scrubbing of liquefied petroleum gas (LPG) and pentane from fluid catalytic cracker (FCC) and continuous distillation unit (CDU). Naphthenic spent caustics come from the Merox® type treatment of kerosene. Cresylic spent caustics come from the Merox® type treatment of visbreaker gasoline. The compositions are shown in Table 1. A block flow diagram of the wet oxidation system is shown in Figure 1 and photographs of the system are shown in Figures 2 and 3. The operating conditions for the system are shown in Table 2. The four feed streams are combined and pass through the high pressure feed pump. Compressed air is added to the feed and the mixture is heated in the feed/effluent heat exchanger (F/E HX). The F/E HX is a concentric tube exchanger with the feed passing through the inner tubes and the hot reactor effluent through the Figure 1. WAO system annular space of the outer tube. block flow diagram. The feed is heated further in the trim heat exchanger. The system operating temperature is regulated by the steam flow to the trim heat exchanger. The oxidation reactions begin with the heat addition in the heat exchangers. The hot fluid enters the bottom of the reactor. The exothermic reaction heats the fluid to the final operating temperature in the reactor. Table 1. Spent caustics composition The reactor is a bubble column, with the gas bubbles Reported as Sulfidic spent Naphthenic spent Cresylic spent rising through the liquid phase. (g/L) caustics caustics caustics The reactor is sized to provide COD O2 7 – 110 50 – 100 165 – 230 the retention time necessary TOC C 0.02 – 4 11 – 25 23 – 60 to achieve the desired degree DIC C 0.15 – 5 0 – 0.16 0.33 – 0.35 of treatment. The fluid exits the top of the reactor and Sulfide S 2 – 53 <0.001 0 – 64 passes through the shell of the Sulfite S 0.002 – 0.48 0.004 – 0.009 0.8 – 1.6 F/E HX for heat recovery. After Mercaptans CH3SH 0 – 28 <0.03 0 – 5.4 partial cooling in the F/E HX, Thiosulfate S2O3 0 – 3.7 0.07 – 0.13 10 – 12 the oxidised effluent passes through the process cooler and 0.005 - 0.025 0.025 - 0.03 Iron Fe then to the process separator. Total phenols C 6H 6O 0.003 – 0.02 2 – 10 14 – 20 The offgas is separated from Note: Values reported as <# represent non detection, with # being the analytical detection limit. the oxidised liquor by gravity R E AC TOR O F F G A S T O B U R NE R C O O L ING WA T E R R E TUR N MA IN S U L F IDIC DIL U T IO N FR E S H S P E NT S P E NT WA T E R C A U S T IC C A U S T IC C A U S T IC H IG H P R E S S U R E F E E D P U MP FE E D E F F L U E NT HE AT E XC H A NG E R S TE AM P R OC E S S S E P AR ATOR T R IM HE AT E XC H A NG E R PR E S S UR E C ONTR OL VALVE P R OC E S S C OOLE R C O O L ING WA T E R S UPPLY E FFLUE NT TO S E A P R OC E S S A IR C O MP R E S S O R Reprinted from HydrocarbonEngineering November2008 www.hydrocarbonengineering.com Table 2. Operating conditions for the wet oxidation system Sulfidic caustic feed rate 0.04 m3/hr (0.2 gpm) Main spent caustic feed rate 0.31 m3/hr (1.4 gpm) Fresh caustic feed rate (20 ˚Be) 0.21 m3/hr (0.9 gpm) Dilution water feed rate 0.08 m3/hr (0.4 gpm) Reactor temperature Reactor pressure 250 ˚C 88 kg/cm2 (1250 psi) in the separator. The liquid effluent is discharged to the sea. The offgas is scrubbed and is sent to a burner used to fire a distillation column. Figure 2. Overview of WAO system. Performance The performance of the system is shown in Table 3. The combined spent caustic and fresh caustic composition is reported in the feed column of Table 3. Dilution water is added to the feed after the feed sample point. Additionally, scrubber water is added to the oxidised effluent in the process separator. These water streams dilute the oxidised effluent to approximately 60% strength, which is reflected in the effluent column in Table 3. After correcting for the dilution effect, the WAO system destroyed 85% of the COD, 73% of the TOC, and >99.97% of the sulfide. Figure 4 is a photograph showing the sulfidic spent caustic, the main spent caustic (mostly naphthenic with some cresylic components), and the oxidised effluent. Safety The oxygen supply is limited by the capacity of the compressor. This prevents excessive temperature increase in the event of a COD excursion in the feed. The liquid water and air in the reactor is an energy sink to further dampen temperature excursions. The pressure in the reactor is regulated, so an excessive energy release in the reactor creates more steam at the process temperature, rather than excessively increasing the temperature or pressure. The offgas may contain 5 - 21% O2 and some volatile organic compounds. To prevent a fire hazard in a flare system (due to the oxygen) a dedicated offgas line is used to take this gas to the firebox of a burner. The system processes spent caustic at elevated temperature and pressure. Typical spray and spill protections are used to protect personnel and the environment. There have been no safety incidents with the WAO system. Figure 3. Spent caustic storage tanks (foreground). WAO system is behind the tanks. Reliability Since unit startup in 2005, the WAO system has proven to be reliable. The only item of note is fouling in the heat transfer equipment. After approximately 12 months of operation the tubes of the heater exchangers became fouled. This caused an increase in pressure drop and a loss of heat transfer efficiency. According to the process provider (Siemens Water Technologies), this is unusual for a spent caustic application. The scale was found to be mostly iron and is formed from unusually high concentrations of iron in the feed. There was also an organic fraction to the scale. Due to the small size of the tubes, it was not practical to hydroblast the exchanger tubes. The tubes were partially cleaned using steam. This did not remove very much of the scale. A better solution was needed for scale removal and the process provider conducted a series of laboratory tests to identify a solvent and cleaning procedure that would be effective at removing the scale, but not damaging to the www.hydrocarbonengineering.com Figure 4. Sulfidic spent caustic (left), main spent caustic (centre) and oxidised effluent (right). metallurgy. The best compromise found for this scale was a pickling solution of the following composition: l 535 mL 20˚ Baume HCl l 33 g CuCl2 l 1000 mL H2O This solution dissolves the scale at room temperature. On corrosion coupons, it was found this solution has a general corrosion rate of 38 MPY at 25 ˚C. Elevating the temperature to 80 ˚C increased the effectiveness of the solvent at scale removal, but also greatly increased the general corrosion rate Reprinted from November2008 HydrocarbonEngineering to 600 MPY. Based on the laboratory tests, it was concluded that this solvent can be used for up to a maximum of seven total days per year at 25 ˚C in order to achieve suitable scale removal while maintaining acceptable corrosion from the solvent to the piping. This solution was cycled through the heat exchangers and was found to be effective at scale removal without damaging the equipment. The heat exchanger has been cleaned once using this method, with an exposure time of 8 hours. It is anticipated that the exchanger will need to be cleaned every 6 months. In addition, flanged unions may be installed on some of the loops of the exchanger. This will allow access for mechanical cleaning of the equipment as well. Conclusion The WAO system is an effective approach for treating the spent caustic. Sulfides and mercaptans are destroyed to below analytical detection limits. TOC and COD are greatly diminished and the oxidation products neutralise the pH to between 8 and 10. The gaseous and liquid effluents are not malodorous. The oxidised spent caustic is discharged to a holding tank, and then directly to the sea. The offgas is of sufficient quality that it is directed to a burner to destroy the volatile compounds. System operation has proven reliable. After a year of operation an iron/organic scale had accumulated in the heat transfer equipment due to unusually high iron concentrations in the spent caustic feed. This scale accumulation was successfully removed using a pickling solution solvent. Reprinted from HydrocarbonEngineering Table 3. WAO system performance at 250 ˚C Reported as (mg/L) Feed Effluent (as measured, after dilution) COD O2 73 000 6300 TOC C 15 000 2400 DIC C 1200 5600 Sodium Na 41 000 24 000 pH - 13.2 8.9 Sulfide S 8500 <1 Sulfite S 100 <2 Mercaptans CH3SH 1500 <30 Thiosulfate <30 S2O3 1500 Total phenols C 6H 6O 6500 36 Flow rate m3/hr 0.67 1.14 Note: Values reported as <# represent non detection, with # being the analytical detection limit. References 1. 2. 3. Carlos, T., Maugans, C. ‘Manage refinery spent caustic efficiently’ Hydrocarbon Processing, pp 89 - 92, February 2002. Grover, R. and Gomaa, H., ‘Proven technologies manage olefin plant’s spent caustic’, Hydrocabon Processing, pp 61 - 69, September 1993. Maugans, C. and Ellis, C., ‘Wet Air Oxidation: A Review of Commercial Sub-Critical Hydrothermal Treatment’, 21st Annual International Conference on Incineration and Thermal Treatment Technologies, New Orleans, May 13 - 17, 2002. November2008 www.hydrocarbonengineering.com