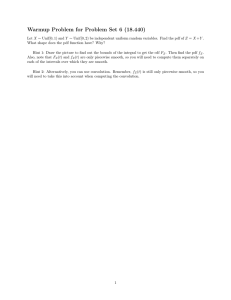

Ideal Work Method Introduction The ideal work or uniform energy method is the simplest method for force prediction in metal working processes. The method performs an energy balance between the external work and the energy consumed for deforming a workpiece. Simplifications: • Material is homogeneous and isotropic • Material has a rigid-plastic behaviour and all the effects that may result from elastic deformation are ignored • Plastic deformation is homogeneous, that is, all the sections or slices that are initially parallel will remain parallel after deformation • The influence of friction and redundant work is generally ignored but can be accounted by means of empirical corrective factors applied in the overall energy consumed in deforming the workpiece • States of stress are reduced to equivalent cases of pure tension or compression 1 Ideal Work Method Introduction From what was mentioned before it may be concluded that ideal work (or uniform energy) method cannot be utilized to determine: •Velocity fields •Strain distribution •Stress distribution The method is mainly applied for force prediction based on a work or energy balance and may be used in process design (e.g. selection of the materials for the dies and machine tools, among other things) 2 Ideal Work Method Rod under simple tension A circular rod under simple tension is taken as an example. The external work is equated to the energy consumed in deforming the workpiece. l 0 l0 F n =K unif wi n l ln l0 K n unif n 1 wi ln ( l ) l0 0 =K l l W V axial d axial F dl W V ij d ij F dl F ln ( l ) l0 Manufacturing process Efficiency Ideal work (per unit volume) w i axial d axial 0 K n 1 n d d K d unif 1 n 0 0 0 Total work (per unit volume) w wi w f wr Uniaxial tension and compression ~1.0 Forjing 0.2-0.95 Rolling 0.75-0.9 Extrusion 0.5-0.65 Wire drawing 0.55-0.7 Stamping 3 0.7-0.8 wi w Ideal Work Method Forward rod extrusion Again, the external work is equated to the energy consumed in deforming the workpiece. W 1 V ij d ij F dl F l 1 W V axial d axial F dl 0 l0 l A ln ln 0 A l0 unif K n n 1 0.5 ~ 0.65 1 A0 dl 0 unif pA0 dl 0 Extrusion pressure p 1 unif Extrusion force F 1 unif A0 4 Ideal Work Method Summary (steady-state vs. non steady-state plastic flow) Steady-state (e.g. extrusion): l A f ln f ln 0 Af l0 K fn unif n 1 saída K fn Extrusion pressure p 1 unif f unif Qpsteady Extrusion force F 1 unif f A0 Non steady-state (ex. forging): A h f ln 0 ln f K fn hf A0 Forging pressure p 1 Qptransient Forging force F 1 Af 5 Ideal Work Method Self-study Solve the proposed exercises. F T 6