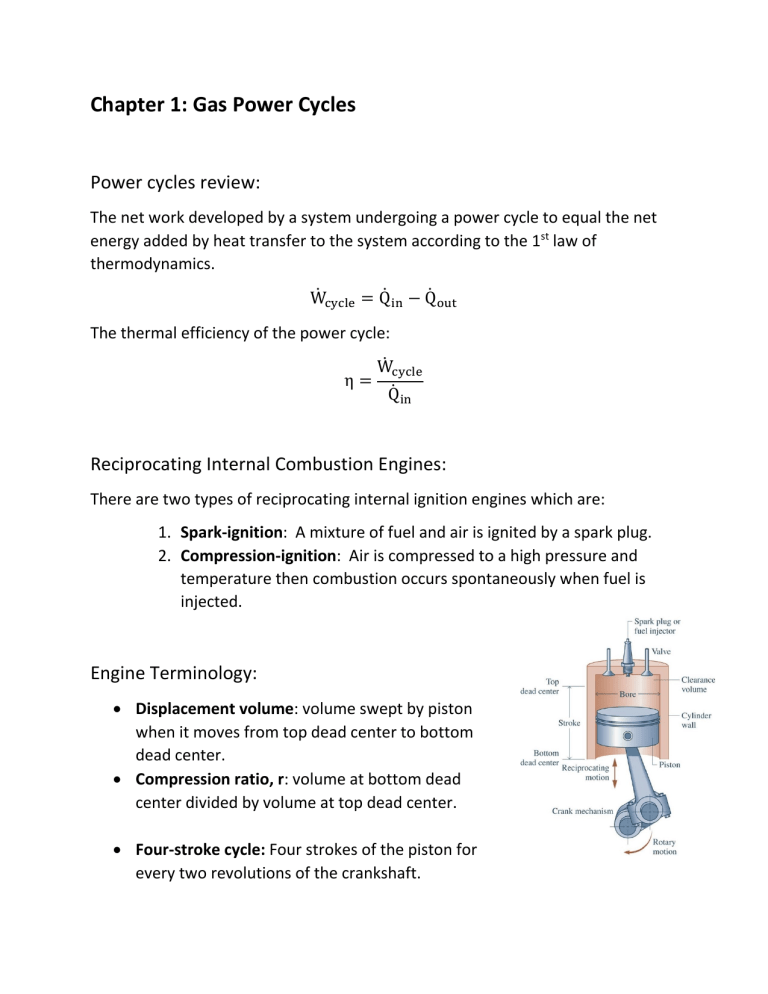

Chapter 1: Gas Power Cycles Power cycles review: The net work developed by a system undergoing a power cycle to equal the net energy added by heat transfer to the system according to the 1st law of thermodynamics. Ẇ cycle = Q̇ in − Q̇ out The thermal efficiency of the power cycle: Ẇ cycle η= Q̇ in Reciprocating Internal Combustion Engines: There are two types of reciprocating internal ignition engines which are: 1. Spark-ignition: A mixture of fuel and air is ignited by a spark plug. 2. Compression-ignition: Air is compressed to a high pressure and temperature then combustion occurs spontaneously when fuel is injected. Engine Terminology: • Displacement volume: volume swept by piston when it moves from top dead center to bottom dead center. • Compression ratio, r: volume at bottom dead center divided by volume at top dead center. • Four-stroke cycle: Four strokes of the piston for every two revolutions of the crankshaft. Intake stroke: With the intake valve open, piston stroke draws a fresh charge into the cylinder. o For spark-ignition engines, the charge includes fuel and air. o For compression-ignition engines, the charge is air alone. Compression stroke: With both valves closed, piston compresses charge, raising the pressure and temperature, and requiring work input from the piston to the cylinder contents. o For spark-ignition engines, combustion is initiated by the spark plug. o For compression-ignition engines, combustion is initiated by injecting fuel into the hot compressed air. Power stroke: The gas mixture expands and work is done on the piston as it returns to bottom dead center. Exhaust stroke: The burned gases are purged from the cylinder through the open exhaust valve. • Smaller engines operate on two-stroke cycles with intake, compression, expansion, and exhaust accomplished in one revolution of the crankshaft. • Mean effective pressure: It is a theoretical constant pressure that if it acted on the piston during the power stroke would produce the same net work as actually developed in one cycle. mep = Wnet Vdisplacement An air-standard analysis has the following elements: • A fixed amount of air modeled as an ideal gas is the working fluid. • The combustion process is replaced by heat transfer from an external source. • There are no intake and exhaust processes. The cycle is completed by a constant-volume heat transfer process while the piston is at bottom dead center. • All processes are internally reversible. • In a cold air-standard analysis, the specific heats are assumed constant at their ambient temperature values. For reciprocating internal combustion engines, three cycles that adhere to air-standard cycle idealizations: • Otto cycle: Heat addition at constant volume. • Diesel cycle: Heat addition at constant pressure. • Dual cycle: Heat addition at constant volume followed by heat addition at constant pressure. Air-Standard Otto Cycle: The Otto cycle consists of four internally reversible processes in series: • Process 1-2: isentropic compression. • Process 2-3: constant-volume heat addition to the air from an external source. • Process 3-4: isentropic expansion. • Process 4-1: constant-volume heat transfer from the air. The Otto cycle compression ratio is: r= V1 V4 𝑉𝑉𝑚𝑚𝑚𝑚𝑚𝑚 = = V2 V3 𝑉𝑉𝑚𝑚𝑚𝑚𝑚𝑚 Ignoring kinetic and potential energy effects, closed system energy balances for the four processes of the Otto cycle reduce to give: W12 = u2 − u1 m W34 = u3 − u4 m Q 23 = u3 − u2 = cv (T3 − T2 ) m Q 41 = u4 − u1 = cv (T4 − T1 ) m The thermal efficiency is the ratio of the net work to the heat added: η𝑡𝑡ℎ,𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂 = ,𝑤𝑤ℎ𝑒𝑒𝑒𝑒𝑒𝑒 𝑘𝑘 = (u3 − u2 ) − (u4 − u1 ) u4 − u1 𝑇𝑇4 − 𝑇𝑇1 1 =1− =1− = 1 − 𝑘𝑘−1 𝑟𝑟 u3 − u2 𝑇𝑇3 − 𝑇𝑇2 u3 − u2 𝑐𝑐𝑝𝑝 𝑐𝑐𝑣𝑣 The T-s diagram: On the T-s diagram, heat transfer per unit of mass is ∫Tds. Thus, • Area 2-3-a-b-2 represents heat added per unit of mass. • Area 1-4-a-b-1 is the heat rejected per unit of mass. • The enclosed area is the net heat added, which equals the net work output. The p-v diagram: On the p-v diagram, work per unit of mass is ∫pdv. Thus, • Area 1-2-a-b-1 represents work input per unit of mass during the compression process. • Area 3-4-b-a-3 is the work done per unit of mass in the expansion process. • The enclosed area is the net work output, which equals the net heat added. The compression ratio: • An increase in the compression ratio changes the cycle from 1-2-3-4-1 to 1-2′-3′-4-1. • Since the average temperature of heat addition is greater in cycle 1-2′-3′-4-1, and both cycles have the same heat rejection process, cycle 1-2′-3′-4-1 has the greater thermal efficiency. Accordingly, the Otto cycle thermal efficiency increases as the compression ratio increases. Air-Standard Diesel Cycle: The Diesel cycle consists of four internally reversible processes in series: • Process 1-2: isentropic compression. • Process 2-3: constant-pressure heat addition to the air from an external source. • Process 3-4: isentropic expansion. • Process 4-1: constant-volume heat transfer from the air. The Diesel cycle has a two-step power stroke: process 2-3 followed by process 34. The Diesel cycle compression ratio is: The Diesel cycle cut-off ratio is: r= V1 V2 rc = V3 V2 Process 2-3 is heat addition at constant pressure. Accordingly, the process involves both heat and work. The work is given by: 3 W23 = � p dv = p2 (v3 − v2 ) m 2 From the closed system energy balance for process 2-3 and solving for Q23/m gives Q 23 = (u3 − u2 ) + p(v3 − v2 ) = (u3 − pv3 ) − (u2 − pv2 ) = h3 − h2 m = 𝑐𝑐𝑝𝑝 (𝑇𝑇3 − 𝑇𝑇2 ) 𝑄𝑄41 = 𝑢𝑢4 − 𝑢𝑢1 = 𝑐𝑐𝑣𝑣 (𝑇𝑇4 − 𝑇𝑇1 ) 𝑚𝑚 The thermal efficiency is the ratio of the net work to the heat added: η𝑡𝑡ℎ,𝐷𝐷𝐷𝐷𝐷𝐷𝐷𝐷𝐷𝐷 Wcycle Q 41 u4 − u1 𝑇𝑇4 − 𝑇𝑇1 = m =1− m =1− =1− Q 23 Q 23 h3 − h2 𝑘𝑘(𝑇𝑇3 − 𝑇𝑇2 ) m m 1 𝑟𝑟𝑐𝑐𝑘𝑘 − 1 = 1 − 𝑘𝑘−1 � � 𝑟𝑟 𝑘𝑘(𝑟𝑟𝑐𝑐 − 1) Like the Otto cycle, thermal efficiency increases with increasing compression ratio. The T-s diagram: On the T-s diagram, heat transfer per unit of mass is ∫Tds. Thus, • Area 2-3-a-b-2 represents heat added per unit of mass. • Area 1-4-a-b-1 is the heat rejected per unit of mass. • The enclosed area is the net heat added, which equals the net work output. The p-v diagram: On the p-v diagram, work per unit of mass is ∫pdv. Thus, • Area 1-2-a-b-1 represents work input per unit of mass during the compression process. • Area 2-3-4-b-a-2 is the work done per unit of mass in the twostep power stroke: process 2-3 followed by process 3-4. • The enclosed area is the net work output, which equals the net heat added. Air-Standard Dual Cycle: By considering heat transfer to the air undergoing the power cycle as occurring in two steps: constant volume followed by constant pressure, the air-standard Dual cycle aims to mimic the pressure-volume variation of actual internal combustion engines more closely than achievable with the Otto and Diesel cycles. The air-standard Dual cycle consists of five internally reversible processes in series: • Process 1-2: isentropic compression. • Process 2-3: constant-volume heat addition to the air from and external source. • Process 3-4: constant-pressure heat addition to the air from an external source. • Process 4-5: isentropic expansion. • Process 5-1: constant-volume heat transfer from the air. As for the Diesel cycle, the Dual cycle has a two-step power stroke: process 3-4 followed by process 4-5. Thermal efficiency for the air-standard Dual Cycle can be developed: η𝑡𝑡ℎ,𝐷𝐷𝐷𝐷𝐷𝐷𝐷𝐷 = Wcycle /m Q 51 /m =1− (Q 23 /m + Q 34 /m) (Q 23 /m + Q 34 /m) (u5 − u1 ) =1− (u3 − u2 ) + (h4 − h3 ) Like the Otto and Diesel cycles, thermal efficiency increases with increasing compression ratio. Areas on the T-s and p-v diagrams of the Dual cycle can be interpreted as heat and work, respectively, as in the cases of the Otto and Diesel cycles. Actual Reciprocating Internal Combustion Engines: • As implied by the discussion of the Otto, Diesel, and Dual cycles, it is advantageous for actual reciprocating internal combustion engines to have high compression ratios. • However, since the temperature of the fuel-air mixture being compressed in spark-ignition engines also increases with compression ratio, the possibility of auto ignition or “knock” limits the compression ratio of such engines to the range 9.5-11.5, when fueled with unleaded gasoline. • Since only air is compressed in the cylinder, compression-ignition engines do not experience engine knock due to premature auto ignition of fuel. Accordingly, such engines can: Operate at higher compression ratios than spark-ignition engines. Use less refined fuels having higher ignition temperatures than the volatile fuels required by spark-ignition engines.