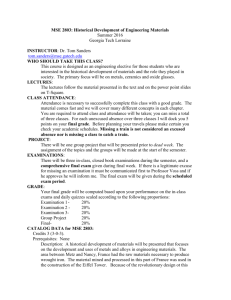

Revised: 28/11/2017 INTI INTERNATIONAL UNIVERSITY COURSE STRUCTURE PROGRAMME: BACHELOR OF ENGINEERING (HONS) IN MECHANICAL ENGINEERING (BMEGI) 1. NAME OF COURSE/MODULE: ENGINEERING MATERIALS 2. COURSE CODE: EGR2208 3. RATIONALE FOR THE INCLUSION OF THE COURSE/MODULE IN THE PROGRAMME: According to EAC Manual 2017, this is the core subject of mechanical engineering discipline and is under the area of materials. Total Student Independent Total Face to Face Learning Time Student Learning Time (SLT) L T P O A B/O IL 4. L = Lecture T = Tutorial P = Practical(Lab) O= Others A= Assessment B/O=Blended /Online learning IL= Independent learning 42 14 12 4 88 5. 6. CREDIT VALUE: 4 credits PREREQUISITE (IF ANY): None 7. LEARNING OUTCOMES: On completion of the course, students will be able to: 1. Describe the atomic and crystal structures of materials, and the results of diffusion in solids. 2. Relate the mechanical properties of metals and alloys to various failure modes and strengthening mechanisms. 3. Analyze various types of phase diagrams in pure substances and alloys. 4. Classify and compare the properties of polymers, ceramics and composite materials, and the electrical and electronic characteristics in materials. 8. SYNOPSIS: The course involves the application of appropriate knowledge and skills learned, to study and to develop a solution to an engineering project/problem. It is a double-module course. 9. MODE OF DELIVERY: Lectures, tutorial and laboratory. Lectures and tutorial will be conducted both face to face and online. 10. ASSESSMENT METHODS AND TYPES: Method Types Weightage (%) Assignments 10 Continuous Assessment Test 1 10 Test 2 10 Lab/Project 10 Summative Assessment Final Examination 60 11. CONTENT OUTLINE OF THE COURSE/MODULE AND THE SLT PER TOPIC: Sessions Topics LO L T P B/O O A IL Revised: 28/11/2017 1-4 5–7 8–9 10 – 11 Materials Science & Engineering Types of Materials: Metals, Ceramics and Glasses, Polymers, Composites, Semiconductors. Bonds in These Materials. Comparison of Physical and Mechanical Properties of These Materials, Materials selection. The Nature and Structure of Atom Electronic Structure of Element/Atom, Periodic Table, Interatomic and Molecular Forces, Bonds between Atoms. Crystal Structures Space Lattice and Unit Cells, Metallic Crystal Structures, Polymorphism or Allotropy, Amorphous Structures. Defects and Imperfections in Solids Solidification of Metals, Metal Solid Solutions, Types of Crystalline Imperfection, Porosity, Inclusion, Segregation. 1 3 1 1 3 1 1 5 1 1 1 3 1 1 3 2 2 3 1 2 3 2 2 3 1 3 4 2 2 4 8 1 2 Diffusion, Thermally Activated Processes Rate Processes in Solids, Diffusions in Solids, Temperature Effect 12 – 13 Mechanical Behavior Elastic and Plastic Deformation of Solids. Stress/Strain relationships, Yield Stress, 88 Tensile Strength, Ductility 14 – 15 Strengthening mechanism Solid Solution Strengthening, Annealing, Precipitation Hardening and 8 Strain 1 Hardening, Recovery and Recrystallization 16 – 17 Ductile and Brittle Fracture Variation of properties with temperature. Fatigue, Creep 18 – 20 Metals, Alloys and Phase Diagram Gibbs Phase Rule, Binary System, IronCarbon phase diagram. Heat Treatment of Plain Carbon Steel, Stainless Steels 21 –25 Polymer, Ceramics and Composite Materials Structures and properties of polymers, ceramics and composites 1 Revised: 28/11/2017 26 – 28 Electrical and Electronic Materials Ohm’s Law and Conductivity, EnergyBand Structure, Electrical and Electronic Characteristics of Semiconductors and Conductors, 4 4 1 42 14 1 Insulators. Semiconductivity, Dielectric Effect of Temperature on Electrical Conductivity. TOTAL 12 4 88 Lecture (L), Tutorial (T), Practical (P), O (Other), Assessment (A), B/O ((Blended/Online learning); Independent Learning (IL); Learning Outcome (LO) 12. MAIN REFERENCE(S) SUPPORTING COURSE: 1. Smith, W and Hashemi, J, Foundations of Materials Science and Engineering. 5 th ed., McGraw-Hill Science/Engineering/Math, 2011. ADDITIONAL REFERENCES (AT LEAST 2): 1. Shackelford JF, Introduction to Materials Science for Engineers. 8th ed., Prentice Hall, 2014. 2. Callister, WD and Rethwisch DG, Materials Science and Engineering - An Introduction. 9th ed., Wiley, 2013. Revised: 28/11/2017 13. OTHER ADDITIONAL INFORMATION (IF ANY): A passing mark can only be achieved when the student attempts both the coursework and final exams. LABORATORY WORK: Experiment Title of Experiments 1 Impact Test 2 Fatigue Test 3 Study cracks of materials under different failure mode 4 Behaviors of plastic deformation in materials 5 Thermal conductivity of metals and non-metals 6 Materials processing and microstructure analysis FINAL EXAMINATION FORMAT: Duration: 2 hours The paper consists of FIVE questions; students are required to answer THREE compulsory questions plus another ONE selected question. GRADING SCALE: A+ (90-100), A (80–89), A- (75-79), B+ (70-74), B (65–69), B- (60–64), C+ (55–59) C (50–54), C- (45–49), D (40–44), F(0–39). Note: A student is deemed to have passed the module if the TOTAL of the coursework mark and the examination mark, weighted as above, is at least 50 marks, and the student is also required to obtain at least 40 % of the 100 marks in the final examination. Revised: 28/11/2017 14. COURSE OUTCOMES PROGRAMME OUTCOMES WITH INSTRUCTIONS AND ASSESSMENTS MATRIX Learning outcomes Describe the atomic and crystal structures of CO1 materials, and the results of diffusion in solids. CO2 CO3 CO4 PROGRAMME OUTCOMES THAT ARE ADDRESSED IN THIS SUBJECT PO1 PO2 INSTRUCTION Lecture. Relate the mechanical properties of metals and alloys to various failure modes and strengthening mechanisms. Analyze various types of phase diagrams in pure substances and alloys. Classify and compare the properties of polymers, ceramics and composite materials, and the electrical and electronic characteristics in materials. Lecture, Practical. Lecture, Practical. Lecture. ASSESSMENT Assignments, Test, Examination Assignments, Test, Examination, Lab Assignments, Test, Examination, Lab Assignments, Test, Examination The Mechanical Engineering Discipline has adopted a set of 12 programme outcomes, which, upon successful completion of the programme, graduates will be able to: 1. Engineering Knowledge - Apply knowledge of mathematics, natural science, engineering fundamentals and an engineering specialisation as specified in WK1 to WK4 respectively to the solution of complex engineering problems; 2. Problem Analysis - Identify, formulate, conduct research literature and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences and engineering sciences (WK1 to WK4); 3. Design/Development of Solutions - Design solutions for complex engineering problems and design systems, components or processes that meet specified needs with appropriate consideration for public health and safety, cultural, societal, and environmental considerations (WK5); 4. Investigation – Conduct investigation of complex engineering problems using research-based knowledge (WK8) and research methods including design of experiments, analysis and interpretation of data, and synthesis of information to provide valid conclusions; 5. Modern Tool Usage - Create, select and apply appropriate techniques, resources, and modern engineering and IT tools, including prediction and modelling, to complex engineering problems, with an understanding of the limitations (WK6); 6. The Engineer and Society - Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to professional engineering practice and solutions to complex engineering problems (WK7); 7. Environment and Sustainability - Understand and evaluate the sustainability and impact of professional engineering work in the solutions of complex engineering problems in societal and environmental contexts. (WK7); 8. Ethics - Apply ethical principles and commit to professional ethics and responsibilities and norms of engineering practice (WK7); 9. Individual and Team Work - Function effectively as an individual, and as a member or leader in diverse teams and in multi-disciplinary settings; 10. Communication - Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions; 11. Project Management and Finance - Demonstrate knowledge and understanding of engineering management principles and economic decision making and apply these to one’s own work, as a member and leader in a team, to manage projects in multidisciplinary environments; 12. Life Long Learning - Recognise the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. Revised: 28/11/2017