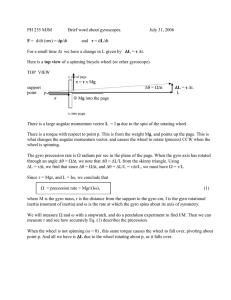

Experiment Instructions TM 630 Gyroscope Gyroscope All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 TM 630 TM 630 Gyroskop Gyroscope 104 20.4 -1 in Drehzahl / Speed m -1 ed in Drehzahl / Spe m On Off Drehzahl Speed scope Gyroskop/Gyro On Off Drehzahl Speed cession Präzession/Pre Experiment Instructions Please read and follow the instructions before the first installation! Publication-No.: 914.000 00 A 630 12 03/04 TM 630 Gyroscope 03/97 Table of Contents 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 2 Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 3 Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.1 Precession of a gyro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3.2 Determining the moments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 4 Experiments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4.1 Performing the experiment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4.2 Experimental verification of the gyroscopic laws . . . . . . . . . . . . . . . . 8 5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 5.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 5.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 5.3 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 1 TM 630 1 Gyroscope Introduction The TM 630 gyroscope is used to demonstrate the properties of guided gyros. All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 The unit can be used to investigate the moments of the gyro effect. In practice, these moments generate often significant bearing forces, which need to be taken into account in the design of machinery (edge milling, pivot of wheel sets and ship propeller shafts etc.). Conversely, guided gyros are used as stabilising elements for ships, single-rail track vehicles etc. Fig. 1.1: Guided gyro Due to its simple, compact and clearly laid out design, the unit is suitable both for demonstration of the effect and for student experimentation. The digital display of rotational speeds and the simple measurement of moments by means of a balance bar with a rider permit the experiment to be evaluated easily and precisely. 1 Introduction 1 TM 630 Gyroscope 2 Unit description 2.1 Function 2 7 All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 3 1 4 5 A 6 The core of the unit is a driven centrifugal mass (2), supported in a rocker (1). This centrifugal mass together with the drive motor (3) form the guided gyro. The balance bar (4) with the slider weight (5) and the precision weights (6) are attached to the extension of the gyro axis. A The rocker is pivot-borne around the axis A, and can rock back and forth between the stop limits (7). The sliding of the weight (5) creates a moment around the axis A on the gyro. Fig. 2.1: Gyro setup B The complete system is in turn also pivot-borne around the vertical axis B. By means of a second motor (8) and the belt drive (9) the setup can be driven around the vertical axis . B 10 11 9 8 The power supply to the gyro motor is provided by way of two carbon brushes (10) and slip rings (11). Fig. 2.2: Sectional drawing Each of the two motor speeds can be adjusted steplessly with a 10-speed potentiometer (12). The speeds are displayed in rpm on the digital tachometer (13). 14 24.0 Drehzahl / Speed min-1 On Off TM630 104 Gyroskop Gyroscope Drehzahl / Speed min-1 Drehzahl On Speed Gyroskop/Gyroscope Off Drehzahl Speed The apparatus can only be started up when the protective hood (14) is located in its retaining ring. Important! Präzession/Precession 13 12 13 12 When the forced cut-off has been triggered by raising the protective hood, the motor must be restarted. Fig. 2.3: Total view 2 Unit description 2 TM 630 2.2 Gyroscope Safety 03/97 DANGER! Danger of injury from rotating parts! All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany Always operate the unit with the protective hood! IMPORTANT! 1 2 3 4 Ensure the grub screw (1) of the slider weight (2) on the balance bar (3) is correctly tightened. Counter-lock the precision weights (4)! Weights may otherwise work loose and fly off. 2 Unit description 3 TM 630 Gyroscope 3 Theory 3.1 Precession of a gyro 03/97 When a guided gyro is set in rotation, its centre axis retains its planar position, since no torques are acting on the gyro. All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany D A F B Fig. 3.1: Guided gyro _D L The gyro is forced to rotate around the vertical axis _ k B. It is observed that the axis of the gyro pivots L around the horizontal axis A in addition to the _L forced rotation. The rotating gyro has a certain angular momentum vector L _ k, for which the direction is given by the direction of rotation of the gyro body. With the assumed direction of rotation, the momentum vec_ k points to the right in the direction of the gyro tor L axis. As a result of the forced torque D, of which the vector is vertical, the gyro acquires an additional angular momentum L _ D, which joins with the _ k in the way shown to angular momentum vector L form the resulting angular momentum vector L _. The gyro axis then moves in the direction of this resulting angular momentum: the gyro drops. This movement of the gyro under the influence of an external force is termed the precession of the gyro. 3 Theory 4 TM 630 3.2 Gyroscope Determining the moments For the gyro shown, guided with ωF, the angular momentum theorem states 03/97 y we wF B x All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany A ïe _x 0 0 ï dL _s ï ï =ω __F x L _ s = ïe _ y ωF ωF Jyï = e _ x ωF ωe Jz = M __S = M __x dt ïe ï _ 0 ωe Jz ï z ï z wF Fig. 3.2: Determination the moments 3 Theory or for the bearing forces in A and B FBy = − FAy = Mx l 5 TM 630 4 Gyroscope Experiments 03/97 In the following experiments the correlation established in Chapter 3.2 is proven by experimentation. 4.1 Performing the experiment All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany Removing the transport protection 2 1 Fig. 4.1: Removing the transport protection - Loosen both M6 hexagon socket screws (1). - Remove the red safety block (2). Precision adjustment of the balance bar - Release the slider weight by loosening the grub screw. - Push the slider weight onto the rocker. - Tighten the slider weight. - Unscrew the precision weights and adjust them until the balance bar is aligned horizontally. - Counter-lock the precision weights. Fig. 4.2: Precision adjustment of balance bar 4 Experiments 6 TM 630 Gyroscope Adjusting the slider weight - Release the slider weight by loosening the grub screw. - Set the desired radius r (max. 95 mm). - Tighten the grub screw. All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 r Fig. 4.3: Adjusting the slider weight Performing the measurement - Place the protective hood (1) in the retaining ring. - Turn the two speed potentiometers (2+3) to zero. - Switch on the motor for the gyro (precession) (switch 4). - With the speed potentiometer (3) run up to the desired rotational speed. - Switch on the motor for the frame (gyroscope) (switch 5). - With the speed potentiometer (2) increase the rotational speed until the balance bar (6) is horizontally aligned. - Make a note of both rotational speeds. 1 24.0 TM 630 104 Drehzahl / Speed min-1 Drehzahl On Gyroskop Gyroscope Drehzahl / Speed min-1 Drehzahl On Speed Speed Off Off Gyroskop/Gyroscope 5 Präzession/Precession 2 4 Fig. 4.4: Measurement 4 Experiments 3 6 7 TM 630 4.2 Gyroscope Experimental verification of the gyroscopic laws In the experiments the slider weight is set to various radii (r = 25 mm, 50 mm, 75 mm, 95 mm). 03/97 The mass of the slider weight (m = 65.6 g), the acceleration due to gravity g, and the radius r of the slider weight produce the moment MW dictated by the balance bar: m All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany MW = m ⋅ g ⋅ r = 0.0656kg ⋅ 9.81 ⁄s2 ⋅ r = 0.6435N ⋅ r This moment MW is counteracted by the gyroscopic moment, causing the balance bar to be lifted to the horizontal position. The theoretical gyroscopic moment Mk is calculated from the rotational speed of the frame nF, the rotational speed of the gyro ne and the mass moment of inertia of the gyro Jz (Jz = 375 cm2g) as follows: MK = ωF ωe Jz = 2π 2π n ⋅ n ⋅ 0.0000375 kg m2 60 F 60 e The measurement and calculation results are compared in the following table. 4 Experiments 8 TM 630 Gyroscope All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 Experimental verification of the gyroscopic laws Radius r in m Moment MW in Nm Rotational speed of gyro ne in rpm Rotational speed of frame nF in rpm Moment MK in Nm Deviation in % 0.025 0.0161 2600 15.8 0.0169 5.0 0.025 0.0161 2950 14.1 0.0171 6.2 0.025 0.0161 4220 9.3 0.0161 0.0 0.025 0.0161 6650 5.5 0.0150 -7.3 0.050 0.0322 2500 32.0 0.0329 2.2 0.050 0.0322 3180 24.1 0.0315 -2.2 0.050 0.0322 4210 17.7 0.0306 -5.2 0.050 0.0322 6690 11.1 0.0305 -5.6 0.075 0.0483 4130 29.0 0.0492 1.0 0.075 0.0483 5080 22.6 0.0473 -2.1 0.075 0.0483 5800 20.8 0.0496 2.7 0.075 0.0483 6746 17.4 0.0483 0.0 0.095 0.0611 2350 62.6 0.0605 -1.0 0.095 0.0611 3720 40.5 0.0619 1.3 0.095 0.0611 4540 32.0 0.0597 -2.3 0.095 0.0611 6679 22.7 0.0623 2.0 The graph on the following page once again represents the theoretical and measured gyroscopic moment curves. The measurement results very clearly demonstrate the theoretical moment curve. 4 Experiments 9 TM 630 Gyroscope 100 90 Measured values for M=0.0483Nm 70 Measured values for M=0.0322Nm 60 Measured values for M=0.0161Nm 50 40 30 20 M=0.0611Nm M=0.0483Nm M=0.0322Nm M=0.0161Nm 10 7000 6500 6000 5500 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 0 All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 Measured values for M=0.0611Nm 80 ne [rpm] Fig. 4.5: Gyro moment curve 4 Experiments 10 TM 630 Gyroscope 5 Appendix 5.1 Technical data All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 Physical parameters Slider weight mass: 65.8 Slider weight radius: 0 - 95 Adjustable moment: 0 - 61.1 Gyro moment of inertia: 375 Gyro rotational speed: 1000 - 6000 Frame rotational speed: 5 - 63 g mm Nmm cm2g rpm rpm Gyro rotational speed measurement (precession) Display: 8 digit LCD Resolution: 0000 Frame rotational speed measurement (gyroscope) Display: 8 digit LCD Resolution: 00.0 Dimensions: WxL xH Weight: Power supply: Alternatives optional, see tpye plate 5 Appendix 420x435x280 22 230 V ~ / 50 mm kg Hz 11 TM 630 5.2 Gyroscope Symbols All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany 03/97 D: Torque Nm _ x,e e _ y, e _ z: Unity vectors of the Cartesian coordinates system F: Motive force N Fy: Scalar component of the force N g: Acceleration due to gravity m/s2 Jz: Mass moment of inertia referred to z-axis m2kg l: Bearing gap m _: L Angular momentum, resulting _ D: L Angular momentum, forced Nm _Lk: _ S: L ne: nF: m: Mk: __s: M 5 Appendix Angular momentum, calculated Angular momentum vector Nm Nm rpm rpm kg Nm Mw: __x: M Rotational speed of gyro Rotational speed of frame Mass Moment, gyro Torque vector around centre of gravity Moment, balance bar x-component of the torque vector P: r: t: Motive force Radius Time N m s ωe: Self-rotation rev/s ωF: Angular velocity, guidance system rev/s Nm Nm Nm 12 TM 630 5.3 Gyroscope Index A Angular momentum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Angular momentum theorem . . . . . . . . . . . . . . . . . . . . . . 5 03/97 B Balance bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 6 Bearing force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 C Carbon brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 All rights reserved G.U.N.T. Gerätebau GmbH, Barsbüttel, Germany D Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 G Gyro, guided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Gyroscopic moment, theoretical . . . . . . . . . . . . . . . . . . . . 8 M Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Measurement result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Moments, determining. . . . . . . . . . . . . . . . . . . . . . . . . . . . Momentum vector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 9 5 4 P Performing the experiment . . . . . . . . . . . . . . . . . . . . . . . . 6 Precession . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Precision weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 6 S Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Slider weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 6 Slip ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 T Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Transport protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 U Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5 Appendix 13