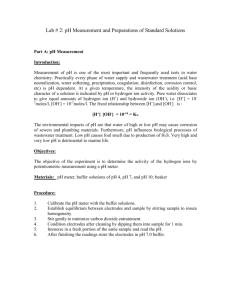

DARSHAN INSTITUTE OF ENGINEERING & TECHNOLOGY RAJKOT ENVIRONMENTAL ENGINEERING (2150603) LAB MANUAL DEGREE CIVIL ENGINEERING SEMESTER –V Name of Student: Roll No: Enrollment No: Class: A.Y. 2018-2019 LIST OF PRACTICALS Practical No. 01 : Introduction to Equipment in Environmental Engineering Laboratory Practical No. 02 : Introduction to Standards, Preservation of Samples Practical No. 03 : Presumptive Test for Coliform Bacteria Practical No. 04 : Determination wastewater of Practical No. 05 : Determination Settleable) of Practical No. 06 : Determination of Acidity, Alkalinity & Hardness Practical No. 07 : Determination of Fluoride & Nitrate Practical No. 08 : Determination of Chloride & Residual chlorine Practical No. 09 : Ambient air quality measurement using High Volume sampler Practical No. 10 : Exhaust gas analysis for air pollutants Practical No. 11 : Measurement of noise at different sources using sound meter Practical No. 12 : Characterization of municipal solid waste (physical and chemical) pH Sampling, & Conductivity Solids (Suspended, Collection for & water & Dissolved & INDEX Sr. No 1. 2. 3. Name of Experiment Introduction to Equipment in Environmental Engineering Laboratory Introduction to Standards, Sampling, Collection and Preservation of samples Presumptive test for Coliform Bacteria Page No. 4 5 12 4. Determination of pH 15 5. Determination of Conductivity 18 6. 7. 8. Determination of Suspended Solids Determination of Dissolved Solids Determination of Settleable Solids 20 23 26 9. Determination of Acidity 28 10. Determination Alkalinity 33 11. Determination Hardness 38 12. Determination of fluoride 42 13. Determination of Nitrate 45 14. Measurement of Chlorides 48 15. 16. 17. 18. 19. Measurement of Residual Chlorine Ambient air quality measurement using High Volume sampler Exhaust gas analysis for Air Pollutants Measurement of Noise at different sources using Sound Meter Characterization of Municipal Solid Waste (Physical and Chemical) 52 55 68 80 85 Date of Experiment Grade Signature [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Volumetric Analyses By common usage, accurately calibrated glassware for precise measurements of volume has become known as volumetric glassware. This group includes volumetric flasks, volumetric pipettes, and accurately calibrated burettes. Less accurate types of glassware including graduated cylinders and serological and measuring pipettes also have specific uses in the analytical laboratory when exact volume is unnecessary. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 1 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Safety Rules & Experiment Instruction 1. Do not add water to concentrated acid. A concentrated acid should be added carefully to water. 2. Do not handle chemicals with bare hands. 3. Do not blowout the last drop from the pipette when the liquid is drained out completely. Touch the tip of pipette to the inner surface of the vessel. 4. Read the level of the curve (Miniscus) in all volumetric glass coarse with the eye approximately the same level as the curve of the solution. 5. Clean all the apparatus used with distilled water before and after the experiment. Techniques in Preparation Solution: Normality (N): The number of gram equivalent weight of substance dissolved in 1 liter of water is called Normality. For Example: The gram equivalent weight of HCl is 36.5 grams. So, if 36.5 grams of HCl is added to 1 liter of water, it gives a solution of 1N. Similarly for oxalic acid = 90/2 = 45 grams in 1 liter of water, it gives a solution of 1N. Molarity (M): The number of gram molecular weight of the substance dissolved in 1 liter of water is called Molarity. For Example: The gram molecular weight of oxalic acid is 90 grams. If 90 grams of Oxalic acid is dissolved in 1 liter of water it is called 1 molar solution. (1M) Molality: The number of gram moles of substance dissolved in 1 Kg (1000 grams) of the solvent. For Example: If 40 grams of NaOH (Molecular weight = 40) of Sodium hydroxide is dissolved in 1 Kg of water, the molarity of the solution is 1. Percent by weight: To make up a solution based on percentage by weight, one would simply determine what percentage was desired. As an example, let's consider a 12% by weight sodium chloride solution. Such a solution would have 12 grams of sodium chloride for every 100 grams of solution. To make such a solution, you could weigh out 12 grams of sodium chloride, and then add 88 grams of water, so that the total mass for the solution is 100 grams. Since mass (unlike volume) is conserved, the masses of the components of the solution, the solute and the solvent, will add up to the total mass of the solution Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 2 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Percent by volume: Solutions based on percent by volume are calculated the same as for percent by weight, except that calculations are based on volume. Thus one would simply determine what percentage was desired For example, rubbing alcohol is generally 70% by volume isopropyl alcohol. That means that 100 mL of solution contains 70 mL of isopropyl alcohol. That also means that a liter (or 1000 ml) of this solution has 700 mL of isopropyl alcohol plus enough water to bring it up a total volume of 1 liter, or 1000 mL Percent by weight/volume: Another variation on percentage concentration is weight/volume percent or mass/volume percent. This variation measures the amount of solute in grams but measures the amount of solution in milliliters. ( ) ( ) An example would be a 5% (w/v) NaCl solution. It contains 5 gm of NaCl for every 100 mL of solution. Dilution: Dilution is the mixing of a small accurately measured sample with a large volume of sterile water or normal saline called (diluents or dilution blank). ( ) ( ) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 3 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 1 : Introduction to Equipment in Environmental Engineering Laboratory Laboratory Equipments and Facilities: A well-equipped laboratory is a prerequisite for efficient analytical control. The size and equipment of the laboratory depends more upon the nature of the processes to be controlled and to a lesser extent on the size of the plant. The laboratory could be divided into several units like physical and chemical laboratory, a bacteriological laboratory, a preparation room and a store. For a small plant, the various units could be combined into one laboratory. Equipments: Careful planning is necessary while equipping the laboratory to effect proper utilisation of the equipments. Proper maintenance of equipments and storage of chemicals must be in the hands of responsible analyst. A need –based planning to acquire consumable materials like glassware, chemicals and reagents is in general more important than the procurement of frequently be checked using certain available or required standards. Preciseness of equipments can only be availed through regular maintenance and careful standardization or calibration on regular time period. The necessary different equipment’s used for the laboratory work under Sem-V (Civil) of Environmental Engineering are listed below with necessary information. Sr. No. Equipment Name Sr. No. Equipment Name 1. pH meter 11. Filtration Test Assembly 2. Turbidity Meter 12. Rectangular Hot Plate 3. B.O.D. Incubator 13. Magnetic Stirrer with Hot Plate 4. Hot Air Oven 14. Refrigerator 5. Digital Analytical Balance 15. High Volume Sampler (HVS) 6. COD Digestion Apparatus 16. Respirable Dust Sampler (RDS PM2.5) 7. Dissolved Oxygen Meter 17. PM2.5 & PM10 Combo Air Sampler 8. Spectrophoto Meter 18. Stack Monitoring Kit 9. Distillation Assembly 19. Flue Gas Analyser (Testo-350) TDS Meter 20. Sound Level Meter 10. Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 4 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 2 : Introduction to Standards, Sampling, Collection & Preservation of Samples Aim: Introduction to standards, sampling, collection and preservation of samples. 1. Standards The term standard can be defined as certain rules, principles or measurements established by the local or National/ International Authorities or legal agency and that is applicable/compelled to implement and remain binding officially to almost all the establishment of minimum standards of quality for public water supply is of fundamental importance in achieving the certain ideas like water should be free from pathogenic and harmful organisms, clear, palatable, free from undesirable taste and odour, neither corrosive nor scale forming and free from minerals which could produce undesirable physiological effects. There are certain primary standards which are related to human health and certain secondary standards which are related to protect human welfare. For water quality monitoring study, three standards are of interest: (a) Drinking water standards (b) Industrial Effluent standards (c) Sewage standards 1.1. Drinking Water Standards SR. NO. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Parameters Units Colour Odour Taste Turbidity pH value Total Hardness (as CaCO3) Iron Chlorides Residual free Chlorine Dissolved Solids Calcium Copper Manganese Sulphate Nitrate Fluoride Drinking Water (IS: 10500 – 1991) Hazen units NTU mg/L mg/L mg/L Desirable 5 Unobjectionable Agreeable 5 6.5 to 8.5 300 0.3 250 Maximum 25 10 No relaxation 600 1.0 1000 mg/L 0.2 - mg/L mg/L mg/L mg/L mg/L mg/L mg/L 500 75 0.05 0.1 200 50 1.0 2000 200 1.5 0.3 400 No relaxation 1.5 Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 5 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] SR. NO. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. Parameters Phenolic compounds Mercury Cadmium Selenium Arsenic Cyanide Lead Zinc Anionic detergents Chromium Polynuclear aromatic Hydrocarbons Mineral oil Pesticides Radioactive materials (a) Alpha emitters (b) Beta emitters Alkalinity Aluminium Boron Units Drinking Water (IS: 10500 – 1991) Desirable Maximum mg/L mg/L mg/L 0.001 0.001 0.01 0.002 No relaxation No relaxation mg/L 0.01 No relaxation mg/L mg/L mg/L mg/L mg/L 0.05 0.05 0.05 5 0.2 No relaxation No relaxation No relaxation 15 1.0 mg/L 0.05 No relaxation mg/L - - mg/L mg/L 0.01 Absent 0.03 0.001 Bq/L Pci/L - 0.1 0.037 mg/L mg/L mg/L 200 0.03 1 600 0.2 5 1.2. Industrial Effluent Standards SR. NO 1. 2. 3. 4. 5. 6. 7. 8. 9 10. 11. 12. 13. 14. 15. Parameters Units pH Temperature Color (pt. co. Scale) Total Suspended Solids Oil & Grease Phenolic Compound Cyanides Fluorides Sulphides °C Unit mg/L mg/L mg/L mg/L mg/L mg/L Ammonical Nitrogen Arsenic Total Chromium Haxavalent Chromium Copper Lead mg/L mg/L mg/L mg/L mg/L mg/L GPCB Permissible Limit 6.5 to 8.5 40 100 100 10 1.0 0.2 1.5 0.5 50 0.2 2.0 0.1 2.0 0.1 Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 6 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] SR. NO GPCB Permissible Limit Parameters Units mg/L mg/L mg/L mg/L mg/L mg/L 0.01 3.0 5.0 2.0 30 21. Mercury Nickel Zinc Cadmium BOD (3 Days at 27 °C) COD 22. 23. 24. 25. 26. 27. Chlorides Sulphates Total Dissolved Solids Insecticides/Pesticides Sodium Absorption Ratio Selenium mg/L mg/L mg/L mg/L 600 1000 2100 Absent 26 0.05 28. 29. 30. Boron mg/L Total Residual Chlorine Percent Sodium mg/L % 31 Bio Assay Test 2.0 1.0 60 90% Survival of fish after 96 hours in 100% effluent 16. 17. 18. 19. 20. - 100 1.3. Sewage Standard SR. NO. 1. 2. 3. 4. 5. 6. 7. Parameters pH Total Suspended Solids BOD COD NH4-N N-Total Total Coliform Units CPCB Permissible Limit mg/L mg/L mg/L mg/L mg/L (MPN/100ml) 6.5 to 9.0 Not More than 20 Not More than 10 Not More than 50 Not More than 5 Not More than 10 Less than 100 Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 7 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] 2. Sampling The objective of sampling is to collect a portion of water which is small enough in volume to be transported conveniently and handled in the laboratory while still representative of the characteristics of the water available in that water body. Water is a dynamic system. Its constituents vary with time 2.1. Planning of Sampling Ask yourself the purpose of study (?), what data are needed (?) and then select most suitable location that can provide the required information. Site location for river Upstream of the industrial and domestic discharge points Immediately downstream of industrial and domestic discharge points. At a place of abstraction for industrial use and public water supply. Base line stations where water is available in natural state. 2.2. Types of Samples Grab Samples Composite Samples Integrated Samples Grab Samples A sample collected at a particular time and place can represent only the composition of the source at that time and place. It shows only the prevailing conditions at the time of sampling and does not represent the average conditions. Sampling of water from sources such as wells, rivers, streams, lakes, oceans and reservoir for chemical, physical and bacteriological analysis. When a source is known to be constant over a considerable time period, in that case a single grab sample should be considered as representative. If the sources are known to vary with time, grab sample should be collected at suitable intervals of time and analyzed separately. The results can be documented in terms of mean, standard deviation, frequency, and duration of variations. When the source composition varies in space (in different locations), collect samples from appropriate locations. Composite Samples The term composite refers to a mixture of grab samples collected at the same sampling point at different times. A composite sample of 24 h period is considered standard for most of the determination. It provides more meaningful data than the grab samples. Sometimes a composite sample representing one shift or a shorter time period ora complete cycle of a period operation may be preferable. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 8 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Take at least 120-150mL of sample in each h, in some cases even at intervals of30 min (if composition varies within an hour) and mix at the end of samplingperiod or combine in a single bottle as collected. A final volume of 4-5 L is sufficient. Integrated Samples They represent the mixture of grab samples collected from different points simultaneously and mixed in equal volumes. Such samples are useful for rivers or streams that vary in composition across the width and depth. For collection of integrated samples, special sampling device is needed. Sample is collected at a known depth without disturbing the surface water. 2.3. Sample Container The sampling bottle may be made of either glass or plastic, usually polyethylene. It must be capable of being tightly sealed either by stopper or cap. The bottles should be soaked with 10% HCI for 24 h and then thoroughly cleaned and rinsed with distilled water. Cleaning solution; acid dichromate: Prepare a saturated water solution of potassium dichromate (K2Cr2O7). Add 32 mL of this K2Cr2O7 solution in 1L of concentrated H2SO4 (sp. gr. 1.84). 2.4. Sample Collection Wherever possible, the container should be rinsed 2 to 3 times with the sample to be examined. Sample where water is well mixed. Avoid large non-homogeneous matter such as leaves, rags, twigs and other floating material in the sample. Provide complete information about the source and the conditions under which the sample was collected. Sample preferably at 20cm depth in a shallow channel (Fig.1). Depths > 60 cm collect 2 samples at 20% and 80% below the surface. Sampling from dug wells and similar sources: Prepare the sampling device bottle with the help of a string and attach a weight at the bottom (Fig. 2). Fig. 1: Collecting a Sample from surface water Fig. 2: Collecting a Sample from dug well Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 9 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] 2.5. Transportation of Sample Sample containing bottles should be placed in a box for transportation to the laboratory. Sturdy, insulated wooden or plastic boxes will protect samples from sunlight, prevent the breakage of bottles and should allow a temperature of 4°C to be maintained during transport. 2.6. Labelling of Container Each sampling bottle must be provided with an identification label on which the following information is legibly and indelibly written (Given below Table). A Typical Label-Sheet of Container 1. Name of Study : 2. Sample No./Sample Station identification No. : 3. Source/location of sampling point 4. Date and time of collection : 5. Volume of sample : 6. Nature of collection : Grab/Composite sample 7. Given any preservative : Yes/No 8. Purpose of analysis : Drinking water/Effluent discharge 9. Field measured parameters : Temperature, pH, DO, or any other parameters 10. 11. 12. 13. 14. 15. Purpose of sampling (please tick which is applicable) Sample to be refrigerated and used for general analysis. Sample to be used for heavy metals analysis Sample to be refrigerated and used for bacteriological analysis. Brief details of weather any unusual condition was prevailing at the time of sampling. Name of the person and signature : : : : : : : Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 10 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] 3. Preservation of Sample Suggested chemical preservatives and recommended maximum storage times for samples for various analyses are summarized in below Table. Recommended Sample Volume (ml) Recommended Container Preservation Method Maximum Storage Time Acidity 100 P or G 40C 24 hours Alkalinity 200 P or G 40C 24 hours 1000 P or G 40C 6 hours 7 days Parameter BOD COD 100 P or G Analyses as soon as possible or add conc. H2SO4 to pH<2 Conductivity 500 P or G 40C 28 days Sulphate 100 P or G 40C 28 days Solids 100 P or G 40C 7 days Chlorine Residual 500 P or G Analyse Immedialy 0.5 hours Flouride 500 P Not required 28 days Hardness 100 P or G Add HNO3 to pH<2 6 months Nitrate 100 P or G 40C 48 hours Nitrite 200 P or G Analyse Immedialy -- pH 100 P or G --do-- 2 hours Temperature 100 P or G --do-- -- DO 300 G --do-- 6 hours Phosphate 100 G 100C 48 hours P or G Analyse same day, store in dark upto 24 hours 24 hours Turbidity 100 P-Plastic or G- Glass Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 11 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 3 : Presumptive Test for coliform bacteria Aim: To find the Most Probable Number (MPN) of bacterial density by Presumptive test. Theory: Coliforms are used as indicator organisms for fecal pollution in water. MPN is used to measure the optimum possibility of occurance of coliforms in the sample. Water is considered potable only if number of coliforms is not more than 3 per 100 ml of sample Reagent: Lauryl tryptose broth Beef extract 3 g, peptone 5 g, lactose 5 g and reagent grade distilled water 1 litre. Add these ingredients to reagent grade distilled water, mix thoroughly and heat to dissolve. pH should be 6.87.0 after sterilisation Computation of MPN: The number of positive finding of coliform group organisms resulting from the multiple portion decimal dilution planting should be computed as the combination of positives and recorded in terms of the Most Probable Number (MPN). The MPN for the variety of planting series are presented in table. The values are at the 95% confidence limit for each of the MPN determined. These values are prepared for 10, 1 and 0.1 mL combination. If the combination is 100, 10, 1mL, the MPN is 0.1 times the value in the table. If on the other hand a combination corresponding to 1, 0.1, and 0.01 mL is planted, record MPN as 10 times the value shown in the table. The MPN for combination not appearing on the table or for other combinations of tubes and dilutions, may be estimated by Thomas’ simple formula: MPN/100mL = Sample Collection: Sample Bottle – use sterilised bottles of glass or plastic of any suitable size and shape (preferably use 250 mL capacity). Plastic bottles are sterilised in autoclave at 1210C for 15 minutes. The non plastic bottles (glass) sterilised in hot air oven at 1700 C for 1 hour. Sample Presentation: If sample can not be analysed within 14 after collection use an ice cooler for storage during transport to the laboratory. In any case, the time elapsed between collection and analysis should not exceed 24 hr. Procedure: General: Clean and sterilise all the glasswares. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 12 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Presumptive Test: 1. Set up three separate series in a test rack, for each tubes three tubes marked as double strength (DS) and filled with 10 mL of double strength medium. Rest six tubes as single strength and added 10 mL of each single strength (SS) medium. 2. Sterlise the medium at 120°C. 3. Inoculate 10 ml aliquot of water sample to three tubes labelled double strength. Then 1 ml in 3 single strength tubes and lastly 0.1 mL in rest three single strength tubes. 4. Incubate all tubes for 48 hrs at 37°C, examine and if no gas is formed, repeat this test at the end of 48±3 hrs. 5. Record the presence or absence of gas formation at each examination of the tubes. Formation within 48±3 hrs of gas in any amount in the inverted fermentation tubes constitutes a positive presumptive test. Active fermentation may be shown by the continued appearance of small bubbles of gas throughout the medium outside the inner vial in the fermentation tubes. Observations and Results for Presumptive Test: Gas /Tubes showing +Ve result Sr. No. Double strength (10 mL) 1 2 1 3 3 Sample Single strength 1 mL 0.1 mL 2 1 3 2 Calculation: Case I: For three each of 10 mL, 1 mL and 0.1 mL sample concentration combinations MPN from the MPN table (Table 1) = .........-- Case II: For other combinations and dilutions MPN/100mL = Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 13 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 14 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 4 : Determination of pH & Conductivity for water & wastewater PH Aim: To determine the pH of the given sample. Theory: pH of aqueous solutions can be defined as negative logarithm of hydrogen ion concentration. pH values ranging from 0 to 7 are acidic, and from 7 to 14 are alkaline. The effect of pH on the chemical and biological properties of liquids makes its determination very important. It is used in several calculations in analytical work. The pH determination is usually done by electrometric method which is the most accurate method and free of interference. Environmental Significance: Determination of pH is one of the important objectives in biological treatment of the wastewater. In anaerobic treatment, if the pH goes below 5 due to excess accumulation of acids, the process is severely affected. Shifting of pH beyond 5 to 10 upsets the aerobic treatment of the wastewater. In these circumstances, the pH is generally adjusted by addition of suitable acid or alkali to optimize the treatment of the wastewater. pH value or range is of immense importance for any chemical reaction. A chemical shall be highly effective at a particular pH. Chemical coagulation, disinfection, water softening and corrosion control are governed by pH adjustment. Dewatering of sludges, oxidation of cynides and reduction of hexavalent chromium into trivalent chromium also need a favorable pH range. It is used in the calculation of carbonate, bicarbonate, CO2 corrosion, stability index and acid base equilibrium. Lower value of pH below 4 will produce sour taste and higher value above 8.5 a bitter taste. Higher values of pH hasten the scale formation in water heating apparatus and also reduce the germicidal potencial of chlorine. High pH induces the formation of trihalomethanes, which are causing cancer in human beings. Standard: pH of drinking water should be between 6.5 and 8.5 Requirements: pH Meter, Flask, Magnetic Stirrer, Funnel, Beaker, Wash Bottle Electrometric Method: The pH is determined by measurement of the electromotive force of a cell comprising an indicator electrode (an electrode responsive to hydrogen ions such as glass electrode) immersed in the test solution and a reference electrode or a combined electrode. The contact between the test solution and the reference electrode is usually achieved by means of a liquid junction. The emf of this cell is measured with pH meter. This is a high impedance electrometer calibrated in terms of pH. Reagents: Calibrates the electrode system against standard buffer solution of known pH. Buffer tablets having pH 4.0, 7.0 and 9.2 are available. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 15 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 16 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Reagents: pH 4, pH7, pH 9.2 Buffer Solutions: Dissolve buffer tablet of pH 4 in 100 ml of distilled water to get pH 4 buffer solution. Similarly other buffer solutions can be prepared by dissolving corresponding buffer tablets. Procedure: 1. 2. 3. 4. 5. Prepare buffers of pH 4, 7 and 9.2. Rinse the electrode thoroughly with distilled water. Standardize pH meter electrode with any two of these buffers. Dip the electrode in the sample for test. Let the reading on screen stabilize; note it as pH & temperature of your sample. Results: Sr. No. Date: Sample pH Temperature (°C) Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 17 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] CONDUCTIVITY Aim: To determine the Conductivity of the given sample Theory: Conductivity is the capacity of water to carry an electrical current and varies both with number and types of ions the solution contains, which in turn is related to the concentration of ionized substances in the water. Most dissolved inorganic substances in water are in the ionized form and hence contribute to conductance. Conductivity measurement gives rapid and practical estimate of the variations in the dissolved contents of water. Environmental Significance: Electrical conductivity measurements are often employed to monitor desalination plants. It is useful for detection of impurities in water. Used for quantitative measurement of ionic constituents dissolved in water, which are important for boiler feed water and cooling water etc.; Used for checking correctness of water analysis as there is a distinct relationship between conductivity and total dissolved solids (TDS). Conductivity data is useful in determining the suitability of water and wastewater for disposal on land. Irrigation waters up to 2 millisiemens/cm conductance have been found to be suitable for irrigation depending on soils and climatic characteristics. Requirements: Conductivity Meter, Flask, Beaker, Wash Bottle Reagents: 0.01 N, KCL solution: Dissolve 0.746 grams of potassium chloride in 1 liter of distilled water. Procedure: 1. Rinse the electrode thoroughly blot and dry. 2. Immerse the electrode in 0.01 N KCL solution and the conductivity should be 1413 micro mhos at 25°C Temperature. 3. Now the instrument is calibrated. 4. Remove the cell from KCL solution and wash it thoroughly with distilled water. 5. Immerse the electrode/cell in the unknown sample whose conductivity is to be determined. 6. Note down the instrument reading. If the cell constant is given on the cell itself, then the measured value of conductivity = Cell Constant C X Screen reading Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 18 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sr. No. Date: Sample Conductivity (mS/cm) Temperature (°C) Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 19 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 5 : Determination of Solids (suspended, dissolved and settleable) SUSPENDED SOLIDS Aim: To determine the Suspended solids present in water sample& waste water. Theory: The term TSS applies to the dry weight of the material that is removed from a measured volume of water sample by filtration through a standard filter. To achieve reproducibility and comparability of the results close attention of procedural details, especially filter characteristics and time and temperature of drying is required. Environmental Significance: They cut down light transmission through the water and so lower the rate of photosynthesis in aquatic flora. In less turbulent parts of river, some of the solids may sediment out, smothering life of the riverbed. The TSS determination is extremely valuable in the analysis of polluted water. It is a major parameter used to evaluate the strength of domestic wastewater and to determine the efficiency of treatment unit. Apparatus: Suction Flask, Filtration Apparatus, Aluminum Weighing Dishes, Desiccator, Beakers, Weighing Balance, Hot Air Oven, Filter Paper, Graduated Cylinder etc. Procedure: 1. 2. 3. 4. 5. 6. 7. 8. 9. Measure the empty weight of filter paper and note down reading. (Wi) Mix Sample well and pour into a graduated cylinder to the selected volume. (V) Apply suction to filter flask and seat filter with a small amount of distilled water. Pour selected volume into filtration apparatus. Wash with 3-successive 10-mL volume of distilled water, allowing complete drainage between washing, and continue suction for about 3 minutes after filtration is completed. Carefully remove the filter paper from filtration apparatus and transfer it to an weighing dish as a support. Dry for at least 1 hour at 103-105°C in a hot air oven. Cool in desiccator and weigh filter paper and record the reading (Wf) Repeat cycle of drying, cooling, desiccating and weighing until a constant weight is obtained, or weight change is less than 4% of previous weight or 0.5 mg, whichever is less. Duplicate determination should be within 5% of their average Observation: Sr. No. 1. Water Sample Particular Waste water Sample Initial Wight of Filter Paper in gm, (Wi) 2. 3. Final Wight of Filter Paper in gm, (Wf) Total Wight of Filter Paper in gm, (W) 4. Volume of Sample in ml, (V) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 20 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 21 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Calculation: Suspended solids in mg/L Date: = (Wf – Wi) x 1000000 V Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 22 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] TOTAL DISSOLVED SOLIDS Aim: To determine the Dissolved solids present in water sample & waste water. Theory: A well-mixed, measured portion of sample is filtered through a standard glassfibre filter and the filtrate portion is evaporated to dryness at 180 ± 2 °C and that gives the amount of total dissolved solids. The reason for higher temperature used is to remove all mechanically occluded water. Where organic matter is generally very low in concentration, the losses due to higher drying temperature will be negligible. Environmental Significance: They A high content of dissolved solids elevates the density of water, influences osmoregulation of freshwater organisms, reduces solubility of gases (like oxygen) and reduces utility of water for drinking, irrigation and industrial purposes. TDS concentration beyond 500 mg/L, decreases palatability and may cause gastrointestinal irritation. Apparatus: Suction Flask, Filtration Apparatus, porcelain dish, Desiccator, Beakers, Weighing Balance, Hot Air Oven, Filter Paper, Graduated Cylinder etc. Procedure: 1. Take a clean porcelain dish/beaker which has been washed and dried in a hot air oven at 103-105 °C for one hour. 2. Now weigh the empty porcelain dish/beaker in analytical balance. (Wi) 3. Mix sample well and pour into a funnel with filter paper. Filter a known volume of a well-mixed sample in the above beaker. (i.e. 100 mL, 200 mL or 500 mL) (V) 4. Note: Choose the sample volume to yield 10 to 200 mg of dried residue. If more than 10 minutes are required for complete filtration, decrease the sample volume. 1. Evaporate the sample in a hot air over at180 ± 2 °C after the whole water is evaporated, cool the evaporating dish/beaker in a desiccator and take the final weight (Wf). 2. Total solids = (Suspended solids) + (Dissolved solids). Observation: Sr. No. Particular Water Sample 1. Initial Wight of Beaker in gm, (Wi) 2. Final Wight of Beaker in gm, (Wf) 3. Total Wight of Beaker in gm, (W) 4. Volume of Sample in ml, (V) Waste water Sample Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 23 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 24 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Calculations: Total Dissolved solids in mg/L Sr. No. Date: Sample No. = (Wf – Wi) x 1000000 V Dissolved Solids (A) Suspended Solids (B) Total Solids (A+B) Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 25 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] SETTLEABLE SOLIDS Aim: To determine the Settleable solid in given sample Theory: The term settleable solids are applied to the solids in suspension that will settle, under quiescent conditions, because of the influence of gravity. Only the coarser suspended solids with a specific gravity sufficiently greater than that of water settle. Sludge is accumulation of settleable solids. Settleable solids may be determined and reported on either a volume (mL/L) or a weight (mg/L) basis. Environmental Significance: To determine the need for and design of primary settling tank. To determine the efficiency of sedimentation units. To study the physical behaviour of waste streams entering natural water bodies. Volumetric Method: Apparatus: The volumetric test requires only an Imhoff cone Procedure: 1. Fill an Imhoff cone to the l-L mark with a well-mixed sample). 2. Settle for 4S-min, gently agitate sample near the sides of the cone with a rod or by spinning, settle 15 min longer, and record volume of settleable solids in the cone as mL/L. 3. If the settled matter contains pockets of liquid between large settled particles, estimate volume of these and subtract from volume of settled solids. 4. The practical lower limit of measurement depends on sample composition and generally is in the range of 0.1 to 1.0 mL/L. where a separation of settleable and floating materials occurs, do not estimate the floating material as settleable matter. 5. Replicates usually are not required. Results: Report the results as mL of settleable solids/L (volumetric method). Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 26 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Gravimetric Method: Apparatus: Measuring Cylinder Procedure: 1. Determine the total suspended solids (TSS) as given above (page 20). 2. Determination of non-settleable solids is as follows. Take 1 L measuring cylinder and pour about 1 L of sample (Note: the minimum depth of sample should be 20 cm). Let stand quiescent for 1h and, without disturbing the settled or floating material, siphon 2S0mL from center of measuring cylinder at a halfway between the surface of the settled material and the liquid surface. Determine total suspended solids (mg/L) of this supernatant liquor. These are the non-settleable solids. Calculation Settleable Solids, mg/L = TSS, mg/L - Non-settleable Solids, mg/L Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 27 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 6 : Determination Hardness Acidity, Alkalinity and ACIDITY Aim: To determine the acidity present in water & Wastewater sample Theory: Acidity of water is its quantitative capacity to neutralize a strong base to a designated pH. Acidity of water is significant in many water supply systems, because acidity influences certain chemical and biological process in water. Acidity of water is due to Hydrogen ions (H+) present in a sample of water. As a result, dissociation of Hydrogen ions is neutralized by titration with standard solution of a strong base in presence of an indicator. Dissolved Carbon dioxide is usually the major acidic component of surface water. Acidity is usually determined by titration with 0.02N solution of Sodium Hydroxide. The amount of Sodium Hydroxide required for the sample to reach the pH 4.5 in a measure of Methyl orange acidity and amount to reach pH 8.3 is a measure of total acidity.. Environmental Significance: Acidity is interferes in the treatment of water. Carbon dioxide is of important considerations in determining whether removal by aeration or simple neutralization with lime / lime soda ash or NaOH will be chosen as the water treatment method. The size of the equipment, chemical requirements, storage spaces and cost of the treatment all depends on the carbon dioxide present. Aquatic life is affected by high water acidity. The organisms present are prone to death with low pH of water. High acidity water is not used for construction purposes. Especially in reinforced concrete construction due to the corrosive nature of high acidity water. Water containing mineral acidity is not fit for drinking purposes. Industrial wastewaters containing high mineral acidity is must be neutralized before they are subjected to biological treatment or direct discharge to water sources. Apparatus: Titration Stand with Burette, Conical Flask, Beaker, Measuring Cylinder, Pipette, Funnel, Wash Bottle etc. Reagents: 0.02 N NaOH Solution: Dissolve 0.8 grams of NaoH in 1 liter of distilled water. Phenolphthalein Indicator: Dissolve 0.5 gm of Phenolphthalein Indicator in 500 ml95% of ethyl alcohol. Add 500 mL distilled water. Methyl orange Indicator: Dissolve 0.5 g of Methyl orange Indicator & dilute to 1000 ml with distilled water. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 28 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Procedure: A. Methyl Orange Acidity 1. Take suitable volume of sample (25, 50 or 100 mL) in a Conical flask.(V) 2. Add 2 drops of methyl orange and see the colour. If color turns yellow, methyl orange acidity is absent. If colour turns orange, titrate with 0.02 N NaOH till colour changes to faint orange. Characteristic of pH 4.3-4.4. Note the volume of NaOH required (A). B. Phenolphthalein Acidity 1. Take suitable volume of sample (25, 50 or 100 mL) in a Conical flask.(V) 2. Add 2-3 drops of phenolphthalein indicator, If the sample turns pinks color it means that, phenolphthalein acidity is absent and stop the experiment. 3. If there is no color change, the titrate with 0.02N Standard NaOH solution till faint pink color appears indicating pH 8.3. The end point is colorless to faint pink color.Note additional volume of NaOH required (B). Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 29 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Observation: 1. Titrant : 2. Indicators : Phenolphthalein and Methyl Orange Indicator 3. End Point : a) Yellow to Faint Orange b) Colorless to Faint Pink Color Table: 1 Mineral Acidity: (Methyl Orange Indicator) Sr. No. Burette Reading (ml) Volume of Sample (ml) (V) Initial Volume of NaOH (ml) (A) Final Table: 2 Phenolphthalein Acidity: (Phenolphthalein Indicator) Sr. No. Burette Reading (ml) Volume of Sample (ml) (V) Initial Volume of NaOH (ml) (B) Final Calculations: Mineral Acidity as CaCO3 in mg/L Volume of NaOH (A) x N x 50 x 1000 = V Phenolphthalein Acidity as CaCO3 in mg/L Total Acidity as CaCO3in mg/L = = Volume of NaOH (B) x N x 50 x 1000 V Volume of NaOH (A) + (B) x N x 50 x 1000 ml of sample Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 30 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 31 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sample Used Date: Mineral Acidity (mg/L) Phenolphthalein Acidity (mg/L) Total Acidity (mg/L) Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 32 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] ALKALINITY Aim: To determine the Alkalinity present in water sample Theory: Alkalinity of water is its quantitative capacity to neutralize a strong acid to a designated pH. Alkalinity is significant in many uses and in treatment of natural acid and wastewater. It is significant in determining suitability of water for drinking as well as irrigation purpose. Alkalinity measurements are used in interpretation and control of water and wastewater treatment process. Alkalinity is primarily due to salts of weak acids and bicarbonates. Major part of alkalinity is because of the action of Carbon dioxide on basic materials. Environmental Significance: Alkalinity is important for fish and aquatic life because it protects or buffers against rapid pH changes. Higher alkalinity levels in surface waters will buffer acid rain and other acid wastes and prevent pH changes that are harmful to aquatic life. Large amount of alkalinity imparts bitter taste in water. The principal objection of alkaline water is the reactions that can occur between alkalinity and certain in waters. The resultant precipitate can corrode pipes and other accessories of water distribution systems. Wastewaters containing excess caustic (hydroxide) alkalinity are not to be discharged into natural water bodies or sewers. Alkalinity as carbonate and bicarbonate of saline water is very important in tertiary recovery processes for recovering petroleum. Alkaline water offers better wetting to the formation rock and improve oil release. As an additional benefit, ions that provide alkalinity absorb on rock surfaces occupying adsorption sites and decrease the loss of recovery chemical by adsorption. The alkalinity value is necessary in the calculation of carbonate scaling tendencies of saline waters. The alkalinity acts as a pH buffer in coagulation and lime-soda softening of water. In wastewater treatment, alkalinity is an important parameter in determining the amenability of wastes to the treatment process and control of processes such as anaerobic digestion, where bicarbonate alkalinity, and any fraction contributed by volatile acid salts become considerations. Apparatus: Titration Stand with Burette, Conical Flask, Beaker, Measuring Cylinder, Pipette, Funnel, Wash Bottle etc. Reagents: 0.02N H2SO4: 3 mL. Conc. H2SO4 in 1 L distilled water toget 0.01 N H2SO4. Take 100 mL 0.01 N H2SO4 + 500 mL distilled water Phenolphthalein Indicator: Dissolve 0.5 gm of Phenolphthalein Indicator in 500 ml95% of ethyl alcohol. Add 500 mL distilled water. Methyl orange Indicator: Dissolve 0.5 g of Methyl orange Indicator & dilute to 1000 ml with distilled water. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 33 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Procedure: A. 1. 2. 3. Phenolphthalein Alkalinity: Take suitable volume of sample (25, 50 or 100 mL) in a conical flask. Add 2-3 drops of phenolphthalein indicator. If the sample turns pink in colour, then titrate with 0.02 NH2SO4, till the pink colour disappears. Note the volume of acid required as (A). 4. If the pink colour does not exist it indicates that, phenolphthalein Alkalinity is absent. Then continue the titration with Methyl Orange indicator. B. Methyl Orange Alkalinity: 1. Add 2-3 drops of methyl orange to the same flask; continue titration till colour becomes orange. Note down volume of H2SO4 consumed as ‘B’. 2. If there is no pink colour after adding phenolphthalein, continue according to step 3. 3. Calculate alkalinity in mg/l as; Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 34 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Observation: 1. Titrant : 2. Indicators : Phenolphthalein and Methyl Orange Indicator 3. End Point : a) Pink to Colourless b) Yellow to Faint Orange Color Table: 1 Phenolphthalein Alkalinity: (Phenolphthalein Indicator) Sr. No. Volume of Sample (ml) (V) Burette Reading (ml) Initial Final Volume of H2SO4 (ml) (A) Table: 2 Methyl orange Alkalinity: (Methyl Orange Indicator) Sr. No. Burette Reading (ml) Volume of Sample (ml) (V) Initial Final Volume of H2SO4 (ml) (B) Calculations: Phenolphthalein Alkalinity as CaCO3 in mg/L = Methyl Orange Alkalinity as CaCO3 in mg/L = Total Alkalinity as CaCO3 in mg/L = Volume of H2SO4 (A) x N x 50 x 1000 V Volume of H2SO4 (B) x N x 50 x 1000 V Volume of H2SO4 (A) + (B) x N x 50 x 1000 V Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 35 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 36 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Alkalinity Relationship (P and T) The values obtained from Phenolphthalein and Total alkalinity determination for a given sample of water are used to estimate three forms of alkalinity shown below. Results of Titration Hydroxide Alkalinity/Caustic Alkalinity as CaCO3 Carbonate Alkalinity as CaCO3 Bicarbonate Alkalinity as CaCO3 P=0 0 0 0 P<1/2 T 0 2P T-2P P=1/2T 0 2P 0 P>1/2 T 2P-T 2(T-P) 0 P=T T 0 0 Where: P: Phenolphthalein Alkalinity, T: Total Alkalinity Results: Sample Used Phenolphthalein Alkalinity (mg/L) Methyl Orange Alkalinity (mg/L) Total Alkalinity (mg/L) Hydroxide Alkalinity Carbonate Alkalinity Bicarbonate Alkalinity Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 37 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] HARDNESS Aim: To determine the hardness of given sample of water or waste water. Theory: Originally hardness of water is a measure of soap consuming capacity to produce foam or lather. Also produce scale in hot water pipes, heaters, boilers and other units, precipitated chiefly by Calcium and Magnesium ions commonly present in water. Also may be precipitated by ions of other polyvalent metals such as Aluminium, Iron, Strontium, Zinc and by Hydrogen ions. Calcium and Magnesium ions are usually present in significant concentrations in natural water. Hardness of water varies from place to place. Surface waters are soften than the ground water, due to the dissolved salts of Carbonates, Bicarbonates, Chlorides, Sulphate, Nitrates of Calcium and Magnesium. Temporary hardness is mainly due to Carbonate and Bicarbonate of Calcium and Magnesium. Permanent hardness is mainly due to Sulphate and Chlorides. A small amount of dye Eriochrome Black –T is added to hard water containing Calcium and Magnesium ion, the solution will become wine red. EDTA is then added as a titrant. Complexes of Calcium and Magnesium are formed after sufficient EDTA has been added. The solution turns from Wine Red to Blue. This is the end point of titration, a pH value of 10.2 is usually maintained. The degree of hardness of drinking water has been classified in terms of the equivalent CaCO3 concentration as follows: Soft: 0 - 60 mg/L. Medium: 60 - 120 mg/L. Hard: 120 -180 mg/L Very hard: > 180 mg/L. Environmental Significance: Scales are formed as inner coating of the pipelines prevents corrosion. Absolutely soft waters are corrosive and dissolve the metals. More cases of cardio vascular diseases are reported in soft water areas. Hard water is useful to growth of children due to the presence of calcium. Hard waters cause excessive consumption of soap used for cleaning purpose. Sodium soaps react with multivalent metallic cations to form a precipitate, thereby lose their surfactant properties. Lathering doesn’t take place until all hardness ions precipitate out. This precipitate adheres to surfaces of tubes, sinks, dish washer and may stain clothing. Scales formed mainly due to carbonate hardness act as insulations and cause enormous loss of fuel in boiler. Scales deposited mainly due to increase in pH to 9 at which bicarbonates are converted as carbonates are formed in distribution mains reducing their carrying capacity. Apparatus: Titration Stand with Burette, Conical Flask, Beaker, Measuring Cylinder, Pipette, Funnel, Wash Bottle etc. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 38 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Reagents: Standard EDTA solution 0.01 M (0.02N): Dissolve 3.723 gm EDTA disodium salt and dilute to 1000 ml distilled water. Eri0chrome black T indicator: Mix 0.5gm dye with 100 gm NaCI to prepare dry powder. or 0.5 gm of indicator in 100 ml of Ethyl Alcohol. Ammonia Buffer solution: Dissolve 16.9gmAmmonium Chloride (NH4CI) in 143 ml of Ammonium Hydroxide (NH4OH). Add 1.25 gm magnesium salt of EDTA and dilute to 250 ml with distilled water. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 39 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Procedure: 1. Take well mixed suitable volume of sample (25, 50 or 100 mL) in a conical flask (V). Select a sample volume that requires less than 15 mL EDTA titrant and complete titration within 5 minutes, measured from time of buffer addition. 2. Add 1-2 ml of Ammonia buffer solution. Usually 1-2 mL buffer solution is sufficient to give a pH of 10.0 to 10.1 and mix well. 3. Add a pinch of Eriochrome black T and titrate with standard EDTA (0.01 M) till wine red colour changes to blue colour. Note down the Volume of EDTA required. (A). 4. Run a reagent blank with distilled water. Note the volume of EDTA consumed (B). 5. Calculate the volume of EDTA required by sample; C = (A-B) Observation: 1. Titrant : 2. Indicators : Eriochrome Black T Indicator 3. End Point : Wine Red to Blue Sr. No. Volume of Sample; V (ml) Burette Reading of Sample; A (ml) Initial Final Total Burette Reading of Blank; B (ml) Initial Final Total Volume of EDTA (ml) (C=A-B) Calculations: Total Harness as CaCO3 in mg/L = Volume of EDTA (C) x N x 50 x 1000 V Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 40 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sample No. Date: Total Hardness as CaCO3 (mg/L) Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 41 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 7 : Determination of fluoride and nitrate FLUORIDE Aim: To determine the fluoride in water sample. Theory: Fluorides is more common in ground water than in surface water. The main sources of fluoride in ground water are different fluoride bearing rocks. In rare instances the fluoride concentration of naturally occurring water may approach 10 mg/L. Such water should be defluoridated. A fluoride concentration of approximately 1 mg/L in drinking water effectively reduces dental caries or tooth decay without any harmful effect on health. The actual concentration of fluoride in drinking water depends on the air temperature, because ambient air temperature influences the amount of water that people drink. Apparatus: 1. Spectrophotometer for use at 570 nm, providing a light path of at least 1 cm or longer. 2. Nessler’s tubeswith capacity of 100 mL REAGENTS: 1. Stock fluoride solution (0.221 gm/L):Dissolve 221.0 mg 2. 3. 4. 5. 6. 7. sodium fluoride (NaF) in distilled water and dilute to 1000 ml. 1 ml = 100 µg. Standard fluoride solution:Dilute 100 ml stock fluoride solution to 1000 ml with distilled water. (1 ml = 10µgF) SPADNS solution:Dissolve 958 mg SPADNS, [sodium 2 – (parasulfophenylazo)-1,8dihydroxy-3,6-napthalene disulfonate] in distilled water and dilute to 500 ml. This solution is stable for 1 year if protected from sunlight. Zirconyl-acid reagent:Dissolve 133 mg zirconyl chloride octahydrate (ZrOCl2·8H2O) in about 25 ml distilled water. Add 350 ml conc. HCl and dilute to 500 ml with distilled water. Acid Zirconyl-SPADNS reagents:Mix equal volumes of SPADNS solution and zirconyl acid reagent. The combined reagent is stable for at least 2 years. Reference solution:Add 10 ml SPADNS solution to 100 ml distilled water. Dilute 7 ml conc HCl to 10 ml and add to the diluted SPADNS solution. The resulting solution, used for setting the instrument reference point (zero) of the spectrophotometer. This solution is very stable and may be reused indefinitely. Sodium Arsenite Solution: Dissolve 5.0 gm NaAsO2 and dilute to 1000 mL wih distilled water. (Caution: Sodium arsenite is toxic avoid ingestion). Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 42 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Procedure: Preparation of standard curve: 1. Prepare fluoride standards in the range of 0 to 1.40 mg/L by diluting appropriate quantities of standard fluoride solution to 50 mL with distilled water (Given below Table). 2. In each 50 mL of Nessler tube, add 10 mL mix solution (or 5 mL of SPANOS and 5 mL zirconyl acid reagent). Mix well. Take absorbance immediately of the bleached colour at 570 nm using reference solution for setting zero absorbance. 3. Plot standard graph between concentration and absorbance (optical density). Preparation of Fluoride standard solutions [Fluoride Stock Solution 1 mL = 10 µg F (Final Volume: 50 mL)] F Stock Solution in mL F in µg Distilled Water in mL F conc, mgF/L 1 10 49 0.2 2 20 48 0.4 4 40 46 0.8 6 60 44 1.2 8 80 42 1.6 Fluoride estimation in sample: 1. Take 50 mL filtered sample and add 10 mL of mix solution, mix well and read the absorbance immediately of the bleached colourat 570 nm using reference solution for setting zero absorbance. (Advice: After adding the mix solution take reading immediately) 2. If sample contain residual chlorine, remove it by adding NaAs02 solution; [1 drop(0.05mL)=0.l mg CI)]. Note: Sodium arsenite concentration of 1300 mg/L produce an error of 0.1 mg/L at 1 mgF/L). 3. If the transmission fall beyond the range of the standard curve, repeat the procedure using a smaller sample. Calculation: The ratio B/C applies only when a sample is diluted to a volume B, and a portion C taken from it for colour development. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 43 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sample No. Date: Fluoride in mg/L Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 44 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] NITRATE Aim: To determine the nitrates present in water Theory: Nitrate reacts with phenol disulphonic acid and produce a nitro-derivative which in alkaline solution develops colour due to rearrangement of its structure. The yellow colour follows Beer’s law and is proportional to the concentration of nitrate present in the sample. Apparatus: Spectrocolorimeter or spectrophotometer having a range of 300-700nm. Nessler's tubes: capacity, 100 mL Water bath Beakers: capacity, 100 Reagents: Standard silver sulfate: Dissolve 4.40 gm Ag2SO4 in distilled water and dilute to 1000 mL; 1 mL = 1 mg Cl. Phenol disulfonic acid (PDA): Dissolve 25 gm white phenol in 150 mL conc. H2SO4, Add 75 mL fuming H2SO4 (15 % free SO3)' stir well and heat for 2 h on water-bath. If fuming sulfuric acid is not available, add additional 85 mL conc. H 2SO4 to the 150 mL H2SO4, stir well and heat for 2 h. Ammonium hydroxide: Concentrated Potassium hydroxide (12 N): Dissolve 673 gm KOH in distilled water and make up to 1000 mL with distilled water. Stock nitrate solution: Dissolve 721.8 mg anhydrous potassium nitrate and dilute to 1000 mL with distilled water; 1 mL = 100 µg NO3-N Standard nitrate solution: Evaporate 50 mL stock nitrate solution to dryness on water-bath. Dissolve residue in 2 mL PDA reagent and dilute to 500 mL. 1 mL = 10 µg N. EDTA: Weigh 50 gm EDTA and make a paste with 20 mL distilled water. Add 60 mL NaOH and mix well. Aluminium hydroxide: Dissolve 125 gm potash alum in 1000 mL. Heat to 60°C and add 55-60 mL NaOH and allow to stand for 1 h. Decant the supernatant and wash the precipitate a number of times till it is free from CI or nitrite. Procedure: I. Pre-treatment of sample 1. Colour removal: If the sample has a colour in excess of 10units, add 3 mL aluminium hydroxide to 150 mL of sample. Stir well and allow to settle for a few minutes. Filter and use the filtrate discarding the first portion of the filtrate. 2. Nitrite removal: (a) Generally nitrite occurs along with ammonia and gets eliminated in the routine test due to decomposition of nitrite and NH 4+ to N2 (b) Oxidise NO2-~ to NO3; under acidic condition using KMnO4 (c) Add sulfamic acid to the sample to suppress nitrite interference. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 45 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] 3. Chloride removal: Determine the chloride content of the sample and precipitate out it as AgCI by using silver sulphate solution at the rate of 1 mL to remove 1 mg of chloride. One should be very careful while adding AgSO4 because excess Ag will precipitates as silver oxide when alkali is added to the sample. II. Colour development 1. Neutralize the clarified sample to pH 7.0. 2. Take a suitable aliquot of the sample in a beaker and evaporate to dryness on water bath. 3. Dissolve the residue using glass rod with 2 mL phenol disulfonic acid (PDA) reagent. Dilute to the original volume and transfer to a Nessler tube. 4. Add 8-l0 mL 12 N KOH. If turbidity is developed add the EDTA reagent drop wise till it dissolves. Filter and make up to 100 mL. 5. Prepare blank in the same way using distilled water instead of sample. 6. Read the colour developed at 410 nm with a light path of 1 cm. Record nitrate nirogen in mg/L from the standard graph. 7. Prepare calibration curve using suitable aliquots of standard nitrate in the range of 0 to 1 mg NIL following the above procedure. Calculation: 1. Construct a standard curve by plotting the nitrate-nitrogen in mg/L against absorbance. 2. Obtain sample concentration directly from the standard curve. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 46 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sample No. Date: Nitrate in mg/L Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 47 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 8 : Determination Chloride and Residual Chlorine CHLORIDE Aim: To determine the chloride content of the given water sample by Mohr's method Theory: Chloride in the form of Chlorine ion is one of the major inorganic anions. The salty taste produced by Chloride concentration is variable and dependent on the chemical composition of water. The Chloride is higher in wastewater than in raw water. Along the sea costal, Chloride may be present in high concentrations because of intrusion of salt water into the water and sewage system. In this method, slightly alkaline solution is used. Potassium chromate can indicate the end point of Silver nitrate titration of Chloride as quantitatively precipitated before red Silver chromate is formed. Environmental Significance: Chlorides associated with sodium (Sodium Chloride) exert salty taste when its concentration is more then 250 mg/L. These impact a salty taste to water. Chlorides are generally limited to 250 mg/L in water supplies intended for public water supply. In many arrears of the world where water supplies are scarce, sources containing as much as 2000 mg/L are used for domestic purposes without the development of adverse effect, once the human system becomes adapted to the water. It can also corrode concrete. Magnesium chloride in water generates hydrochloric acid after heating which is also highly corrosive and creates problem in boilers. Chloride determinations in natural waters are useful in the selection of water supplies for human use. Chloride determination is used to determine the type of desalting apparatus to be used. Chloride determination is used to control pumping of ground water from locations where intrusion of seawater is a problem. Apparatus: Titration Stand with Burette, Conical Flask, Beaker, Measuring Cylinder, Pipette, Funnel, Wash Bottle etc. Reagents: Standard Silver nitrate titrant (0.0141 N): Dissolve 2.395 gm of silver nitrate in distilled water and dilute to 1000 ml. Standardize against 0.0141 N sodium chloride solution. Standard sodium chloride solution (0.0141 N): Dissolve 824 mg of sodium chloride (Dried) in distilled water and dilute to 1 litre. 1 ml = 500 µg of chloride. Potassium chromate indicator solution: Dissolve 50 gm of potassium chromate in a little distilled water. Add few drops of silver nitrate solution until a definite red precipitate is formed. Let it stand for 12 hour, filter and dilute to 1 litre with distilled water. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 48 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Procedure: 1. Take well mixed suitable volume of sample (25, 50 or 100 mL) in a conical flask (V). 2. Add 1ml of potassium Chromate indicator. The colour of the solution turns to yellow colour. 3. Titrate against Standard silver Nitrate solution till colour change from yellow to brick red. 4. Note the Burette volume of silver Nitrate added (A) 5. For better accuracy, titrate distilled water (blank) in the same manner. Note the burette volume of silver Nitrate added for distilled water (B). 6. Calculate the volume of EDTA required by sample; C = (A-B) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 49 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Observation: 1. Titrant : 2. Indicators : Potassium Chromate Solution 3. End Point : Yellow to Brick Red Sr. No. Volume of Sample; V (ml) Burette Reading of Sample; A (ml) Initial Final Total Burette Reading of Blank; B (ml) Initial Final Total Volume of AgNO3 (ml) (C=A-B) Calculations: ( ) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 50 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Results: Sample Date: Chloride in mg/L Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 51 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] RESIDUAL CHLORINE Aim: To determine the Residual Chlorine present in water Chlorine will liberate free iodine from potassium iodine (Kl) solutions at pH 8 or less. The liberated iodine is titrated with a standard solution of sodium thiosulphate (Na 2S2O3) with starch as the indicator. The liberated iodine is directly proportional to the concentration of chlorine present in sample. Titrate at pH 3 to 4 because the reaction is not stoichiometric at neutral pH due to partial oxidation of thiosulphate to sulphate. Select a sample volume that will require not more than 20mL 0.01N sodium thiosulphate. For residual chlorine concentration of 1 mg/L or less, 100mL sample for chlorine range 110 mg/L, 500ml for chlorine above 10mg/L and proportionally less as per chlorine concentration. Apparatus: Titration Stand with Burette, Conical Flask, Beaker, Measuring Cylinder, Pipette, Funnel, Wash Bottle etc. Reagents 1. Acetic acid, conc. (glacial) 2. Potassium iodide, Kl, crystals 3. Standard sodium thiosulphate, 0.01N: Dissolve 2.482gm Na2S2O3.5H2O in 1L freshly boiled distilled water. 4. Starch indicator solution: Prepare slurry by adding small quantity of water to 1.0 gm starch powder. Add 100 mL boiling water to it and continue boiling for a few minutes until solution becomes clear. The solution is cooled and preserved with 1.25gm salicylic acid or a few drops of toluene or chloroform. Procedure: 1. 2. 3. 4. 5. 6. Volume of sample: Select volume that will require not more than 20 ml. 0.01N Na 2S2O3 and not less than 0.2 ml for the starch-iodide end point. For a chlorine range of 1 to 10 mg/L, take 200 ml of chlorinated water sample in a conical flask (V). Add 5 ml Acetic Acid and mix well. To acidify the sample. It is used to reduce the pH between 2 and 4 in the conical flask. Add about 1 gm potassium Iodide (KI) measured using the spatula and dissolved it by thoroughly mixing it with stirring rod.Perform the titration quickly, since Iodine liberate faster. Titrate the solution with standard Na2S2O3 solution until the yellow colour of librated iodine is almost faded out. (Pale yellow colour appears) Add 1 ml of starch solution, the yellow colour changes to dark blue colour, continue the titration until the blue colour disappears. Note Down the volume of titrant used (A). In many cases residual chlorine is very low and starch needed to be added before starting up the titration. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 52 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Observation: 1. Titrant : 2. Indicators : Starch Solution 3. End Point : : Blue to Colorless Sr. No. Volume of Sample (ml) (V) Burette Reading (ml) Initial Final Volume of Na2S2O3 (ml) (A) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 53 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Calculation: ( ) Results: Sample No. Date: Residual Chlorine in mg/L Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 54 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 9 : Ambient air quality measurement using High Volume sampler PARTICULATE MATTER (PM2.5) Aim: Sampling of Particulate matter (PM2.5) in ambient air and the determination of its concentration. Reference: CPCB Guidelines Volume-I Method: - Gravimetric Method Principle: Air with dust enters in the sampler through circular omni directional inlet reaches to impactor where all particles having size more than 10 microns are removed and retained. Now air having particles less than 10 microns further proceed and pass through WINS impactor which is well shaped. A filter dipped in impaction oil is kept in the well where particles hit at a specific velocity (maintained by top critical hole of WINS impactor). This results in separation of particles above 2.5 micron to 10 micron. Only particles having size 2.5 micron and below proceed further and accumulated on PTFE membrane filter. Accumulated dust on filter is obtained by weight difference while total volume of air sampled is given by the difference of final and initial DG readings. PM 2.5 dust concentration can be calculated simply by dividing weight of dust by volume of air sampled. The lower detection limit of PM2.5 dust is about 2μg/m3 which depends upon the accuracy of the digital balance. A sensitive digital balance with minimum detection of 0.00001 g is basic need for measurement of accumulated dust. If 6 digit balance (recommended by USEPA) is available one can measure weight more accurately and thus PM2.5 values. through filters. Instrument/Equipment: 1. Analytical balance 2. Sampler : Combo PM10 and PM2.5 Sampler with size selective inlet for PM2.5 and automatic volumetric flow control 3. Filter Jacket 4. Inmector oil/grease 5. Calibrated flow-measuring device to control the airflow at 16.67 l/min Absorbing Media: - Filter Media – A Glass fibre filter of 47 mm size and supported filter paper 37 mm size. Procedures: 1. Filter inspection: Inspect the filter for pin holes using a light table. 2. Loose particles should be removed with a soft brush. Apply the filter identification number or a code to the filter if it is not a numbered. 3. Condition the filter in conditioning room maintained within 20-30° C and 40-50% relative humidity or in an airtight desiccator for 24 hours. 4. Take initial weight of the filter paper (Wi) before sampling. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 55 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] 5. Place the filter paper in the sampling system securely and tighten the screws of the bracket. 6. Note down the initial dry gas meter reading and time. 7. Start the sampler and adjust flow rate as per guidelines. 8. At the end stop the pump, note down final dry gas meter reading and time. 9. Remove filter cassette from the filter holder and store in filter carrier immediately and transfer it to desiccators as early as possible. 10. Condition the filter after sampling in conditioning room maintained within 20 30° C and 40-50% relative humidity or in an airtight desiccator for 24 hours. 11. Take final weight of the filter paper (Wf) Calculation: Concentration of PM2.5 in µg/m3 PM2.5 = (Wf-Wi) x 106/V Where: Wi : Initial mass of the conditioned filter before sample collection (gm) Wf : Final mass of the conditioned filter after sample collection (gm) 6 10 : Unit conversion factor for grams (gm) to micrograms (μg) V : Volume of air sampled (m3) [V= Final Dry Gas Meter Reading – Initial Dry Gas Meter Reading] Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 56 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] PARTICULATE MATTER (PM10) Aim: Sampling of Particulate matter (PM10) in ambient air and the determination of its concentration. Reference: IS 5182 (Part 23): 2006/CPCB Guidelines Volume-I Method: - Gravimetric Method Principle: Air with dust enters the sampler through circular inlet and passed through the impactor where all particles size more than 10 microns are removed. Particles equal or less than 10 micron passed through impactor. Design of impactor has been done for a cut off at 10 micron at flow rate 2.3 m3/hr. Particles greater than 10 microns hit on greased metallic surface and remains on the surface while dust less than 10 microns follow trajectory and reach to pre weighted filter paper where it accumulated. Accumulated dust on filter paper is obtained by weight difference while total volume of air sampled is given by difference of final and initial DG reading. PM 10 dust concentration calculated simply by dividing weight of dust by volume of air passed through filters. Instrument/Equipment: 1. Analytical balance 2. Sampler : Combo PM10 and PM2.5 Sampler with size selective inlet for PM10 and automatic volumetric flow control 3. Filter Jacket 4. Calibrated flow-measuring device to control the airflow at 16.67 l/min Absorbing Media: - Filter Media – A Glass fibre filter of 47 mm size. Procedures: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Filter inspection: Inspect the filter for pin holes using a light table. Loose particles should be removed with a soft brush. Apply the filter identification number or a code to the filter if it is not a numbered. Condition the filter in conditioning room maintained within 20-30° C and 40-50% relative humidity or in an airtight desiccator for 24 hours. Take initial weight of the filter paper (Wi) before sampling. Place the filter paper in the sampling system securely and tighten the screws of the bracket. Note down the initial dry gas meter reading and time. Start the sampler and adjust flow rate as per guidelines. At the end stop the pump, note down final dry gas meter reading and time. Remove filter cassette from the filter holder and store in filter carrier immediately and transfer it to desiccators as early as possible. Condition the filter after sampling in conditioning room maintained within 20 30° C and 40-50% relative humidity or in an airtight desiccator for 24 hours. 11. Take final weight of the filter paper (Wf) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 57 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Calculation: Concentration of PM10 in µg/m3 PM10 = (Wf-Wi) x 106/V Where: Wi : Initial mass of the conditioned filter before sample collection (gm) Wf : Final mass of the conditioned filter after sample collection (gm) 6 10 : Unit conversion factor for grams (gm) to micrograms (μg) V : Volume of air sampled (m3) [V= Final Dry Gas Meter Reading – Initial Dry Gas Meter Reading] Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 58 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] SULFUR DIOXIDE (SO2) Aim: Measurement of Sulphur dioxide concentration in ambient air. Reference: IS 5182 (Part 2): 2001/CPCB Guidelines Volume-I Method: - Improved West and Gaeke method Principle: Sulphur dioxide is absorbed from air in a solution of potassiumtetrachloromercurate (TCM). A dichlorosulphitomercurate complex which resists oxidation by the oxygen in the air is formed. This complex is stable to strong oxidants such as ozone and oxides of nitrogen and therefore the absorber solution may be stored for some time prior to analysis. The complex is made to react with pararosaliniline and methylsulphonic acid. The absorbance of the solution is measured by means of a suitable spectrophotometer. APPARATUS & GLASSWARES: Gaseous Pollutant Sampler Glass Impingers Spectrophotometer Volumetric flasks Pipettes Burette REAGENTS: Distilled Water Absorbing Reagent (Potassium Tetrachloromercurate–TCM-0.04M): Dissolve 10.86 gm mercuric chloride, 0.066 gm EDTA, and 6.0 gm potassium chloride in distilled water and bring to the mark in a 1 liter volumetric flask. The pH of this reagent shall be approximately 4.0 but it has been shown that there is no appreciable difference in collection efficiency over the range of pH 5to 3. The absorbing reagent is normally stable for 6 months. If a precipitate forms, discard the reagent after recovering the mercury. CAUTION: - Highly poisonous if spilled on Skin. Flush off with water immediately Sulphamic Acid (0.6%): Dissolve 0.6 gm of Sulphamic acid in 100 mL of distilled water. Prepare fresh, when needed. Formaldehyde Solution (0.6%): Dilute 5 mL of formaldehyde solution (36 to 38 %) to 1 liter with Distilled water. Prepare fresh, when needed. Stock Iodine Solution (0.1 N):Take 12.7 gm of iodine in a 250 mL beaker; add 40 gm of potassium iodide and 25 mL of water. Stir to dissolve completely, then dilute to 1 liter with distilled water. Iodine Solution (0.01 N): Dilute 50 mL of stock solution to 500 mL with distilled water. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 59 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Starch Indicator Solution: Triturate 0.4 gm of soluble starch and 0.002 gm of mercuric iodide preservative with a little water and add the paste slowly to 200 mL boiling water. Continue boiling until the solution clear, cool and transfer to a glass stoppered bottle. Stock Sodium Thiosulphate Solution (0.1 N):Take 25 gm of sodium thiosulphate pentahydrate in a beaker, add 0.1 gm of sodium carbonate, and dissolve using boiled distilled water making the solution up to final volume of 1 liter. Allow the solution to stand one day before standardizing To standardize accurately weigh, to the nearest 0.1 mg, 1.5 gm of primary standard potassium iodate dried at 180°C, dissolve and dilute to 500 mL in a volumetric flask. Take 50 mL of iodate solution by pipette into a 500 mL iodine flask, add 2 g of potassium iodide and 10 mL (1:10) hydrochloric acid and stopper the flask. After 5 min titrate with stock thiosulphate solution to a pale yellow color. Add 5 mL starch indicator solution and continue the titration until the blue color disappears. Calculate the normality of the stock solution. The normality of sodium thiosulphate solution, N is calculated as follows: N= Where: V : Volume in mL of Sodium thiosulphate solution used M : Mass in gm of Potassium iodate Sodium Thiosulphate Solution (0.01 N): Dilute 100 mL of the stock thiosulphate solution to 1 liter with freshly boiled distilled water. Standardized sulphite Solution for preparation of working sulphate-TCM Solution: Dissolve 0.30 g of sodium meta bisulphite (NaHSO 3) or 0.40 gm of sodium sulphite (Na2SO3) in 500 mL of freshly boiled and cooled distilled water. Sulphite solution is unstable, it is therefore important to use water of the highest purity to minimize this instability. This solution contains the equivalent of 320-400 μg/mL of SO2. The actual concentration of the sulphite solution is determined by adding excess iodine and back titrating with standard sodium thiosulphate. To standardize pipette out 50 mL of the 0.01 N iodine solution into each of two 500 mL iodine flask A (blank) and B (sample). To flask A add 25 mL of distilled water and into flask B measure 25 mL of sulphite solution. Stopper the flask and allow to react for 5 min. Titrate with standardized 0.01 N thiosulphate, to a pale yellow color. Then add 5 mL of starch solution and continue the titration until the blue color disappears. Working sulphite- TCM Solution: Take 2 mL of the standard sulphite solution into 100 mL volumetric flask to dilute with 0.04 M TCM. Preparation of stock Para Rosaniline Solution: Dissolve 0.5 gm of para rosaniline chloride in 100 mL distilled water. Keep it for 2 days and filter the solution. The filtrate solution is stable for 3 months, if stored in refrigerator. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 60 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Working Para Rosaniline Solution: Add 15 mL concentrated hydrochloric acid to 10 mL stock para rosaniline solution and dilute to 250 mL with distilled water in a 250 mL volumetric flask. It may be stored at room temperature in an amber colored bottle for one to two weeks, if stored in a refrigerator. PROCEDURES: Sampling: Assemble the sampling apparatus at the sampling site.Procedures are described for short-term (30 minutes, 1 hour, 4 hours long-term (24 hours) sampling. 30 minutes, 1 hour, 4 hours Sampling: insert a midget impinger into the sampling system. Add 10 ml of TCM solution to the impinger (30 ml TCM solution for 4 hours sampling) Collect sample at the rate of 1 l/min for 30 min, or 0.5 l/min for 1 hour and 4 hours using either a rotameter. 24 hours Sampling: Place 50 ml of TCM solution in a larger absorber and collect the sample at 0.2 l/min for 24 hour from midnight to midnight. Shield the absorbing reagent form direct sunlight during and after sampling by covering the impinger with aluminium foil to prevent deterioration. Start sampling only after obtaining an flow rate. Ensure packing of ice around bubbler for low temperature to improve absorption efficiency. Record the exact sampling time by recording initial time (t i) and final time (tf) of sampler. Measure and record the flow rate (fi) before the sampling and flow rate (ff) after the sampling. Recorded the atmospheric pressure and temperature. Remove the stopper the impinger. If the sample has to be stored for more then a day before analysis, keep it at 5° C in a refrigerator; during hot weather, sampling is to not recommended unless it is possible to refrigerate the samples. After sampling measure the volume of sample and transfer to a sample storage bottle. Mark identification number on sample storage bottle and transport to the laboratory for analysis. Sample Preparation: 30-Minutes and 1-Hour Sample: Transfer the sample quantitavely to a 25 ml volumetric flask using about 5 ml of distilled water for rinsing. Delay the analysis for 20 min to allow any ozone to decompose. 24-Hour Samples: Dilute the entire sample to 50 ml with absorbing solution. Measure 5 ml of the sample into a 25 ml volumetric flask by pipette for chemical analysis. Bring volume to 10 ml with absorbing reagent. Delay analysis for 20 min to allow any ozone to decomposes. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 61 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Analysis: For each set of determinations prepare a reagent blank by adding 10 ml of unexposed TCM solution to a 25 ml volumetric flask. Prepare a control solution by measuring 2 ml of working sulphite-TCM solution into a 25 ml volumetric flask by pipette. To each flask containing sample or control solution or reagent blank, add 1 ml of 0.6% sulphamic acid and allow to react for 10 min to destroy the nitrite resulting from oxides of nitrogen. Add 2 ml of 0.2% formaldehyde solution and 5 ml of pera rosaniline solution. Start a laboratory timer that has set for 30 min. Determine the absorbance of the sample, reagent blank, and control solution at 560 nm using cells with a 1 cm path length. Calibration: Preparation of Calibration Curve: Measure 0.5 ml, 1.0 ml, 1.5 ml, 2.0 ml, 2.5 ml, 3.0 ml, 3.5 ml and 4.0 ml of working sulphite TCM solution in 25 ml volumetric flask. Add sufficient TCM solution to each flask to bring the volume to approximately 10 ml. Then add the remaining reagents as described in the procedure for analysis. A reagent blank with 10 ml absorbing solution is also prepared. Read the absorbance of each standard and reagent blank. Standard Curve: Plot Plot a curve absorbance (Y axis) versus concentration (X axis). Draw a line ofbest fit and determine the slope. The reciprocal of slope gives the calibrationfactor (CF). CALCULATION: Volume of Air Sampled: Convert the volume of air sampled to the volume in liter at the reference conditions of 25° C and 760 mm Hg.: Vn = V Where: Vn : Volume of air at 25 °C and 760 mm Hg V : Volume of air sample, (m3) P : Barometric Pressure, (mm Hg) t :Temperature of air sampled, (°C) Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 62 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Concentration of Sulphite Solution: ( ) C= Where: C : SO2 concentration in µg/ml V1 : Volume of thiosulthate for blank (ml) V2 : Volume of thiosulthate for sample (ml) V : Volume of standard sulphite solution (25 ml) SO2 Concentration in Air Sample: Calculate SO2 as µg per cubic meter of air as follows: (A – Ao) × 103× B 3 SO2 (µg/m ) = D Vr Where: A : Sample absorbance, (µg) Ao : Reagent blank absorbance, (µg) 103 : Conversion of factor to cubic meters Vr : The sample corrected to 25 C and 760 mm Hg B : Calibration factor, /absorbance unit D : Dilution factor: for 30 min and 1 hr samples, D=1; for 24-hr samples, D=10 Conversion of µg/m3into ppm SO2 (ppm) = (SO2µg/m3) ×3.82 × 10-4 Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 63 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] NITROGEN DIOXIDE (NO2) Aim: Measurement of Nitrogen dioxide concentration in ambient air. Reference: IS 5182 (Part 6): 2006/CPCB Guidelines Volume-I Method: - Modified Jacob and Hochheiser Method Principle:Ambient nitrogen dioxides are collected by bubbling air through a solution of Sodium hydroxide and sodium arsenite. The concentration of nitrite ion (NO2) produced during sampling is determined colorimetrically by reacting the nitrite ion with phosphoric acid, sulphanilamide and N-(1-naphtyl)-ethylenediamine di-hydrochloride (NEDA) and measuring the absorbance of the highly colored azo-dye at 540 nm. APPARATUS & GLASSWARES: - Gaseous Pollutant Sampler Glass Impingers Spectrophotometer Volumetric flasks Pipettes Burette REAGENTS: Distilled Water Absorbin Reagents: Dissolve 4.0 g of sodium hydroxide in distilled water, add 1.0 g of sodium Arsenite, and dilute to 1000 ml with distilled water. Hydrogen Peroxide, 30 percent Hydrogen Peroxide Solution: Dilute 0.2 ml of 30% hydrogen peroxide to 250 ml with distilled water. This solution may be used for one month, if, refrigerated and protected from light. N-(1-Naphthyl)-ethylenediamine Di-hydrochloride (NEDA): A 1%aqueous solution should have only one absorption peak at 320 nm over the range of 260-400 nm. NEDA showing more than one absorption peak over this range is impure and should not be used NEDA Solution: Dissolve 0.5 g of NEDA in 500 ml of distilled water. This solution is stable for one month, if refrigerated and protected from light. Phosphoric Acid, 85 percent Sodium Arsenite Sodium Hydroxide Sodium Nitrate: Assay of 97 percent NaNO2 or greater. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 64 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Sodium Nitrate Stock Solution (1000 µg NO2/ml):Dissolve 1.5 gm of desiccated sodium nitrate in distilled water and dilute to 1000 ml such that a solution containing 1000 µg NO2/ml is obtained. The amount of NaNO2 to be used if the assay percent is less than 100 percent , is calculated as follows: G = 1.500/A Where: G: Amount of NaNO2 in gm 1.500: Gravimetric Conversion factor A: Assay percent (should be 97 or greater) Note: This stock solution can be stored for six weeks, if refrigerated. Sodium Nitrate Solution (10 µg NO2/ml): Pipette 5 ml of the stock solution into a 500 ml volumetric flask and dilute to volume with distilled water. Sodium Nitrate Solution (1 µg NO2/ml): Pipette 25 ml of the solution into a 250 ml volumetric flask and dilute with absorbing reagent solution, prepare fresh daily. Sulphanilamide: Melting point 165 to 167°C Sulphanilamide Solution: Dissolve 20.0 gm of sulphanilemide in 700 ml of distilled water. Add with mixing 50 ml of 85 percent phosphoric acid and dilute to 1000 ml. [Note: This solution is stable for one month, if refrigerated.] PROCEDURES: Sampling: Assemble the sampling apparatus at the sampling site. Place 30 ml of absorbing solution in an impinger and sample for four hour at the flow rate of 0.2 to 1 L/min. Connect the calibrated flow meter, set the flow rate as per method, measure the flow rate before sampling. Start sampling only after obtaining an initial flow rate of 1 liter per minute. Ensure packing of ice around bubbler for low temperature to improve absorption efficiency. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 65 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Record the exact sampling time by recording initial time (ti) and final time (tf) of sampler. Measure and record the flow rate (fi) before the sampling and flow rate (ff) after the sampling. Seal the collected samples after making it up to 30 ml using distilled water. Mark identification number on sample collection bottle and transport to the laboratory for analysis. Analysis: Pipette out 10 ml of the collected sample into 50 ml volumetric flask. Now. Add 1 ml of hydrogen peroxide solution, 10 ml sulphanilamide solution, and 1.4 ml of NEDA solution using pipette, with through mixing after the addition of each reagent and make up to 50 ml with distilled water. Prepare a blank in the same manner using 10 ml of un-exposed absorbing reagent. After a 10 min colour development interval, measure and record the absorbance at 540 nm against the prepared reagent blank. Use distilled water; not the reagent blank, as the optical reference. Determine NO2 from the calibration curve. Calibration: Preparation of Standard: Prepare calibration curve using 1 µg/ml working standards in accordance with the above analytical procedure. Pipette 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 12, 15, 20 ml of working standard solution (sodium Nitrate Solution,1 µg NO2/ml) in 50 ml volumetric flask. Pipette out 10 ml absorbing solution in one volumetric flask as a blank and pipette out 10 ml absorbing solution to all other volumetric flask. Now add 1 ml of hydrogen peroxide solution, 10 ml sulphanilamide solution, and 1.4 ml of NEDA solution using pipette, with through mixing after the addition of each reagent and make up to 50 ml with distilled water. Take optical density at lamda 540 nm on spectrophotometer. Standard Curve: Plot Plot a curve absorbance (Y axis) versus concentration (X axis). Draw a line of best fit and determine the slope. The reciprocal of slope gives the calibration factor (CF). Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 66 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] CALCULATION: Air Volume: Calculate the volume of air drawn for sample as follows: fi + ff Va= × (tf –ti) × 60 × 10-3 2 Where: Va : Volume of air sample, (m3) fi : Air flow rate before sampling, (LPM) ff : Air flow rate after sampling, (LPM) ti :Initial time, (Hr) tf : Final time, (Hr) 10-3: Conversion of litre to m3 60 : Conversion of hours to min NO2 Concentration in Analyzed Sample: Determine µg NO2/ml graphically from the calibration curve or compute from the slope and intercept values. NO2 Concentration in Air Sample: Calculate NO2 as µg per cubic meter of air as follows: (As – Ab) × CF × D × Vs 3 NO2 (µg/m ) = V × 0.82 × Vt Where: As : Absorbance of sample, (µg) Ab : Absorbance of reagent blank, (µg) CF : Calibration factor D : Dilution factor (D:1for no dilution, D:2 for 1:1 dilution) Va : Volume of air sample (m3) Vs : Volume of sample (ml) Vt : Volume of aliquot taken for analysis (ml) 0.82: Sampling efficiency Conversion of µg/m3into ppm NO2 (ppm) = (NO2µg/m3) ×5.32 × 10-4 Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 67 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 10 : Exhaust Gas Analysis for Air Pollutants PARTICULATE MATTER (PM) Aim: Measurement of Particulate Matter from stationary sources. Reference: IS 11255 (Part 1): 1985 Principle: The determination of the particulate concentration consist essentially of Sampling isokinetically a measured amount of gas from the flue and separating the particles from the gas and hence determining the particulate concentration. APPARATUS: - Stack Monitoring Kit Sampling Probe Suction Pump Nozzle Pitot Tube Thimble Thimble Holder Stack Monitoring: Flue gases in chimney are the mixture of hot gases and particulates. Flue gas mixture from such stacks is sucked using Yash Stack Sampler at Iso Kinetic flow rates this results extraction of representative mixture of flue gases which passes immediately after their suction through a thimble (a kind of filter where several gram of particulates can be accumulated without being lost while sampling) particulate free hot gases are divided into two parts before bubbling through impinger where water and absorbing solution are kept. Distribution of hot gases is controlled by the needle valve of two capacities rotameter. Major part is cooled just by passing them through a large capacity impinger where chilled water is placed while gases at the rate of 2 lpm are taken directly into 120 mL impingers where absorbing solutions are kept. All impingers are kept in ice tray where ice is absorbing solutions are kept. All impingers are kept in ice tray where ice is packed to ensure effective cooling and better absorption. Moisture of gases is removed before passing cool gases through rotameter with the help of silica gel impinger bottle. A thermocouple and digital pyrometer have been provided to measure the stack gas temperature. A standard S-type pitot tube is used to measure the velocity of flue gases in the stack. Differential pressure generated across the Pitot tube ends is measured on a digital manometer filled in the panel of stack monitor. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 68 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] The stack gas velocity (in m/s) can be calculated at prevailing conditions using Barnauli equation given below. V= K √ Where, V : Velocity of flue gas in chimney m/s K : Pitot calibration constant G : Gravitational constant 9.81 m/s2 ΔP : Differential pressure in m of Wc Dm : Density of manometer fluid in kg/m3 (for water 1000 kg/m3, red oil800 kg/m3) Ds: Stack gas density in kg/m3 at stack temperature and at stack absolute pressure. The stack gas density is a function of the molecular weight of gases comprising the flue gas, the static pressure inside the dust/chimney and the temperature of flue gas. Therefore find out static pressure flue gas composition of stack gases including moisture to find out density of stack gases. However, in most of the common situations the molecular weight of stack gas is practically the same as that of air while the static pressure is close to atmospheric pressure. Hence stack gas density can be approximated by following relation where significant errors are not expected. This is true if moisture content is not more then 2-3%. Ds = Where Da is density of atmospheric air at ambient temperature Ta (273+25°C) and Ts is the temperature of stack gas. Both Ta and Ts are in degrees Kelvin. Da = 1.25 kg/m3, at (273+25) °K Thus Ds = ( ) ( ) Substituting in relation (1) we have; V= K √ V = K √( V=K√ ( ) (Where P is in meter) (Where P is in millimeter) or V = 0.229 √ Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 69 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Aerodynamic drag along the stack wall, damper vanes, right angle bends, side entry ducts etc., cause variation in the flow rate across the cross- section of the duct/chimney. Hence air velocity measurements must be carried out at number of traverse point. Traverse points can be decided based on diameter of stack. Travers Point Multiples to Determine Minimum Numbers of Traverse Point Required When Port Hole Is Made At the Stack as Per Requirement: Inside Diameter of Stack or Duct (m) Number of Points I.D. ≤ 0.3 0.3 ≤ I.D. ≤ 0.6 4 8 12 20 0.6 ≤ I.D. ≤ 1.2 1.2 ≤ I.D. ≤ 2.4 2.4 ≤ I.D. ≤ 5 32 The velocity measure at each point is used to calculate ISOKINETIC sampling rate needed for sampling at monitored traverse point for a nozzle at known temperature. A set of three nozzles with different diameter is provided. The rate of sampling which would achieve isokinetic condition for a nozzle of cross area An is given by relation below: Where, Qs : Rate of sampling from stack in LPM V : Stack gas velocity in m/sec An : Area of Nozzle in m2 60 : Conversion factor second to minute 103 : Conversion factor m3 to liter Dia. of Nozzle Cross-Sectional area in m2 1/8 1/4 3/8 0.0000079132 0.0000316531 0.00007122 However stack gases cool down as they pass through the sampling train and the rate of flow indicated by the flow meter must correspondingly be corrected as per gas laws. It is assumed a seen that if ice is used in cold box and stack temperature is 100-250° C. Temperature at rotameter inlet is seen 25˚ C ± 2° C. Therefore, ( ) Where, Q’s = Iso kinetic sampling rate to be set in flow meter in lpm where it is assumed that the flue gases will cool down up to 25° C when reaching to rotameter. Since the flow meter of stack gases varies across the cross- section of the duct/chimney, the particulate concentration too is likely to vary and must be sampled at different traverse points with corresponding change in sampling rate to maintain isokinetic conditions. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 70 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] In fact there could also be a pressure drop across the sampling train so that for an exact measurement of flow rate, correction for both pressure and temperature must be made. Sampling train in has been designed for minimal pressure loss requiring no pressure correction. However, the ESS100 system provides a vacuum gauge and a pyrometer to measure the pressure and temperature of sampled flue gas at the point of flow measurement so that appropriate correction can be applied by using following equation ( Where, Vstd Vm Pstd Pm Pbar Tm : : : : : : ) Volume of dry gas through the sampling train (25°C, 760 mm Hg) Volume calculated by sampling rate and time (Qs x t) Standard pressure (760 mm of Hg) Static pressure in sampling train (mm of Hg) Barometric pressure at the metering point (mm of Hg) Temperature of gas at dry gas meter condition (°C) Dust Concentration ( Where, Wi Wf Vstd Date: ) : Initial weight of thimble (gm) : Initial weight of thimble (gm) : Volume of dry gas through the sampling train (25°C, 760 mm Hg), Nm3 Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 71 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] SULPHUR DIOXIDE (SO2) Aim: Measurement of sulphur dioxide emission from stationary sources. Reference: IS 11255 (Part 2): 1985 Method: Thorin Method Principle: A gas sample is extracted from the sampling point in the stack. The acid mist, including sulphur trioxide, is separated from the sulphur dioxide and the sulphur dioxide fraction is measured by the barium thorin titration method. APPARATUS: Apparatus for Sampling Probe: Chemical resistant glass, 5 to 6 mm ID, with a heating system to prevent condensation and filtering medium to remove particulate matter including Sulphuric acid mist. Dust Trap: For low dust concentration (up to 1 g/m3N ) are a standard large impinger with glass wool packed in top to prevent acid mist carry over. For high dust concentrations, use an appropriate thimble. Impingers: Three standard large impingers Drying Tube: Packed with 1-3 mm size indicating type silica gel, or equivalent, to dry the sample. Valve: Needle valve or equivalent, to adjust flow rate accurately in the range of 2-5 l/min. Pump: Leak-free, vacuum type. Rotameter: Rotameter or other suitable device, to measure flow rate in the range of 0-10 l/min. Dry Gas Meter: Sufficiently accurate to measure the sample volume within 1 percent. Apparatus for Sample Recovery Glass Wash Bottles: Two. Polyethylene Storage Bottles: To store impinger samples. Apparatus for Sample Analysis Pipettes: 5 ml and 10 ml sizes (0.1 ml division) and 25 ml (0.2 ml division) Volumetric Flasks: 50 ml, 100 ml & 1000 ml. Burettes: 5 ml and 50 ml. Long-necked Flask: 125 ml. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 72 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] REAGENTS: Reagents for Sampling: Water-Deionized or Distilled: Deionized water is preferable for sharp end points. Iso-propanol, 80 Percent: Mix 80 ml of iso – propanol with 20 ml of distilled H2O. Hydrogen Peroxide (3%): Dilute 100 ml of 30 percent hydrogen peroxide to 1000 ml with distilled water. [Prepare fresh daily.] Reagent for Sample Recovery Water-Deionized or Distilled: Deionized water is preferable for sharp end points. Iso-propanol, 80 Percent: Mix 80 ml of iso – propanol with 20 ml of dist. H2O Reagent for Sample Analysis Water-Deionized or Distilled: Deionized water is preferable for sharp end points. Iso-propanol, Thorin Indicator: Dissolve 0.20 g in 100 ml distilled water. Barium Perchlorate (0.01 N): Dissolve 1.95 g of barium perchlorate Ba (ClO4)2. 3H2O in 200 ml distilled water and, dilute to 1 litre with iso-propanol. Standardize with sulphuric acid. Barium chloride may be used. Sulphuric Acid, Standard (0.01 N): Standardize to ± 0.0002 N against 0.01 N NaOH which has previously been standardized against potassium acid phthalate (primary standard grade). PROCEDURES: Preparation of Collection Train: Pour 15 ml of 80 percent iso-propanol into the impinger and 15 ml of 3 percent hydrogen peroxide into each of the first two impingers. Leave the final impinger dry. Check the sampling train for leakage at the sampling site by plugging the probe inlet and pulling a vacuum corresponding to 250 mm mercury column. A leakage rate not in excess of 1 percent of the sampling rate is acceptable. Carefully release the probe inlet plug and impingers and add more ice during the run to keep the temperature of the gases leaving the last impinger at 20°C or less. Sample Collection: Adjust the sample flow rate in the range 2 to 5 litres/minutes. To begin sampling, position the tip of the probe at the first sampling point and start the pump. At the conclusion of each run, turn off the pump and record the final readings. Remove the probe from the stack and disconnect it from the train. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 73 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Sample Recovery: Disconnect the impingers after purging. Discard the contents of the mist impinger (with the glass wool). Pour the contents of the other impingers into a polyethylene shipment bottle. Rinse the three midget impingers and the contacting tube, with distilled water and add these washings to the same storage container. Sample Analysis: Transfer the contents of the storage container to a 50 ml volumetric flask. Dilute to the mark with deionized, distilled water. Pipette a 10 ml aliquot of this solution into a 125 ml erlenmeyer flask. Add 40 ml of iso-propanol and two to four drops of thorin indicator. Titrate to a pink end point using 0.01 N barium perchlorate. Run a blank with each series of samples. CALCULATION: Dry Gas Volume: Correct the sample measured by the dry gas meter to normal conditions (298 K and 101 kPa) by using the following equation. V (TN)× (P) VN = (T) × (PN) Where: VN : Volume of gas sample through the dry gas meter (normal condition), (m3) V : Volume of gas sample through the dry gas meter (meter condition), (m3) TN : Absolute temperature at normal conditions (298 K) T : Average dry gas meter temperature (K) P : Absolute meter pressure (kPa) PN : Absolute pressure at normal conditions (101 kPa) Flow rate × Time V= 1000 Sulphur Dioxide Concentration: Calculate the concentration of sulphur dioxide using the following equation. 0.032× (V-Vb) × N × Vso/ Va SO2 (gm/Nm3) = VN Where: V : Volume of barium perchlorate titrate used for sample, (ml) Vb : Volume of barium perchlorate titrate used for blank, (ml) N : Normality of barium perchlorate titrate VSO :Total solution volume of sulpher dioxide (50 ml) Va :Volume of sample aliquot titrted(10 ml) VN : Volume of gas sample through the dry gas meter (Normal Condition) (m3) Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 74 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] NITROGEN DIOXIDE (NO2) Aim: Measurement of Nitrogen dioxide emission from stationary sources. Reference: IS11255 (Part 7): 2005 Principle :A grab sample is collected in a dilute sulphuric acid-hydrogen peroxide absorbing solution, and the nitrogen oxides, except nitrous oxide, are measured colorimetrically using the phenoldisulphonic acid(PDS) procedure. APPARATUS: Apparatus for Sampling Probe: Borosilicate glass tubing sufficiently heated to prevent water condensation and equipped an in-stack or out-stack filter to remove particulate matter (a plug of glass wool is satisfactory for this purpose). Collection Flask: Two litre borosilicate round bottom flask, with short neck and 24/40 standard taper opening, protected against implosion or breakage. Flask Valve: T-bore stopcock connected to a 24/40 standard taper joint. Temperature Gauge: Dial type thermometer or other temperature gauge, capable to measuring 1˚C on intervals from -5 to 50˚C. Vacuum Line: Tubing capable of with standing a vacuum of 75 mm Hg absolute pressure, with ‘T’ connection and T-bore stopcoke. Vacuum Gauge: U-tube manometer, 1 m high, with 1 mm divisions, or other gauge capable of measuring pressure to within ± 2.5 mm Hg. Pump: Capable of evacuating the collection flask to a pressure equal to or less than 75 mm Hg absolute. Sueeze Bulb: one way Stopcoke Barometer: Mercury, aneroid, or other barometer capable of measuring atmospheric pressure to within 2.5 mm Hg. Porcelain Evaporating Dishes: 175 to 250 mt capacity with lip for pouring, one for each sample and each standard. Steam Bath: Low temperature ovens or thermostatically controlled-hot plates kept below 70°C. Policeman Porcelain: One for each sample and each standard Graduated Cylinder: 100 ml with 1 ml divisions. Spectrophotometer: To measure absorbance at410nm. pH Meter& pH Paper Analytical Balance Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 75 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] REAGENTS: Absorbing Solution: To prepare the absorbing solution, cautiously add 2.8 ml concentrated H2SO4 to 1000 ml of distilled water. Mix well and add 6 ml of 3 percent hydrogen peroxide solution, freshly prepared from 30 percent hydrogen peroxide solution. [Note: The absorbing solution should be used within 1 week of its preparation. Do not expose to extreme heat or direct sunlight.] Sodium Hydroxide (1 N): Dissolve 40 gm NaOH in distilled water and dilute to 1000 ml. Fuming Sulphuric Acid: 15 to 18 percent by weight free sulphur trioxide. [Note: Highly corrosive, handle with care] Phenol: White solid. Sulphuric Acid: Concentrated 95 percent minimum assay. Potassium Nitrate: Dried at 105°C to 110°Cfor a minimum period of 2 h just prior to preparation of standard solution. StandardKNO3Solution: Dissolve 2.198 gm dried potassium nitrate (KNO3) in distilled water and dilute to 1000 ml with distilled water in a 1000 ml volumetric flask. Working Standard KNO3Solution: Dilute 10 ml of the standard solution to 100 ml with distilled water. One millilitre of the working standard solution is equivalent to 100 μg nitrogen dioxide (NO2). Phenoldisulphonic Acid Solution: Dissolve 25 gm of pure white phenol in 150 ml concentrated sulphuric acid on a steam bath. Cool, add 75 ml fuming sulphuric acid, and heat at 100°C for 2 h. Store in a dark, stoppered bottle. PROCEDURES: Sampling: Pipette 25 ml of absorbing solution into a sample flask, retaining a sufficient quantity for use in preparing the calibration standards. Insert the flask valve-stopper into the flask with the valve in the 'purge' position. Assemble the sampling train and place the probe at the sampling point. Make sure that all fittings are tight and leak-free and that all ground glass joints have been properly greased with a high vacuum, high temperature chlorofluorocarbon based stopcock grease. Turn the flask valve and the pump valve to their 'evacuate' position. Evacuate the flask to 75 mm Hg absolute pressure, or less. Evacuation to a pressure approaching the vapour pressure of water at the existing temperature is desirable. Turn the pump valve to its ‘vent’ position and tum off the pump. Check for leakage by observing the manometer for any pressure fluctuation. Any variation greater than 10 mm Hg over a period of 1 minute is not acceptable, and the flask is not to be used until the leakage problem is corrected. Pressure in the flask is not to exceed 75 mm Hg absolute at the time sampling is commenced. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 76 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Record the volume of the flask and valve (Vi), the flask temperature (Ti) and the barometric pressure. Tum the flask valve counter clockwise to its 'purge' position and do the same with the pump valve. Purge the probe and the vacuum tube using the squeeze bulb. If condensation occurs in the probe and the flask area, heat the probe and purge until the condensation disappears. Next, tum the pump valve to its 'vent' position. Turn the flask valve clockwise to its ‘evacuate’ position and record the difference in the mercury levels in the manometer. The absolute internal pressure in the flask (Pi) is equal to the barometric pressure less the manometric reading. Immediately tum the flask valve to the 'sample' position and permit the gas to enter the flask until pressures in the flask and sample line (that is duct, stack) are equal. This will usually require about 15 s; a longer period indicates a 'plug' in the probe, which must be corrected before sampling is continued. After collecting the sample, turn the flask valve to its 'purge' position and disconnect the flask from the sampling train. Shake the flask for at least 5 min. If the gas being sampled contains insufficient oxygen for the conversion of NO to NO2 then oxygen shall be introduced into the flask by one of the following three methods: 1) Before evacuating the sampling flask, flush with pure cylinder oxygen, then evacuate flask to 75 mm Hg absolute-pressure less; 2) Inject oxygen into -the flask after sampling; or 3) Terminate sampling with minimum 50 mm Hg vacuum remaining in flask, record the final pressure and vent the flask to atmosphere until the flask pressure is equal to the atmospheric pressure. Sample Recovery: Let the flask-set for a minimum of 16 h and then shake the contents for 2 min. Connect the flask to mercury filled U-tube manometer. Open the valve-from the flask to the manometer and record the flask temperature (Tf), the barometric pressure, and the difference between the mercury levels in the manometer. The absolute internal pressure in the flask (Pr) is the barometric pressure less the manometer reading. Transfer the contents of the flask to a leak-free polyethylene bottle. Rinse the flask twice with 5 ml portions of distilled water and add the rinse water to the bottle. Adjust the pH to between 9 and 12 by adding sodium hydroxide (l N), dropwise (about 25 to 35 drops). Check the pH by dipping a stirring rod into solution and then touching to the pH test paper. Remove as little material as possible during this step. Mar-k the height of the liquid level so that the container can be checked for leakage after transport. Label the container to clearly identify its contents. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 77 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Sample Analysis: Note the level of the liquid in container and confirm whether or not any sample was lost during shipment; note this on analytical data sheet. Immediately prior to ana1ysis, transfer the contents of the shipping container to a 50 ml volumetric flask and rinse the container twice with 5 ml portions of distilled water. Add the rinse water to the flask and dilute to the mark with distilled water; mix thoroughly. Pipette a 25 ml aliquot into the porcelain evaporating dish. Return any unused portion of the sample to the polyethylene storage bottle. Evaporate the 25 ml aliquot to dryness on a steam bath and allow to cool. Add 2 ml phenoldisulphonic acid solution to the dried residue and triturate thoroughly with a polyethylene policeman. Make sure the solution contacts all residue. Add 1 ml distilled water and four drops of concentrated sulphuric acid. Heat the solution on a steam bath for 3 min with occasional stirring. Allow the solution to cool, add 20 ml distilled water, mix well by stirring and add concentrated, ammonium hydroxide, drop wise, with constant stirring, until the pH is 10 (as determined by pH paper). If the sample contains solids, these shall be removed by filtration as follows: Filter through Whatman No. 41 or equivalent into a 100 ml volumetric flask, rinse the evaporating dish with three 5 ml portions of distilled water; filter these three rinses. Wash the filter with at least three 15 ml portions of deionized, distilled water. Add the filter washings to the contents of the volumetric flask and dilute to the mark with distilled water. If the solids are absent, transfer the solution directly to the 100 ml volumetric flask and dilute to the mark with distilled water. Mix the contents of the flask thoroughly and measure the absorbance at the 410 nm wavelength used for the standards using the blank solution as a zero reference. Dilute the sample and the blank with equal volumes of distilled water. Determination of Calibration Curve: Add 0 ml, 2 ml, 4 ml, 6 ml and 8 ml of KNO3 working standard solution (1 ml = 100g of NO2) to a series of fine 50 ml volumetric flasks. To each flask, add 25 ml absorbing solution, 10 ml distilled water and sodium hydroxide (1 N) drop wise until the pH is between 9 and12 (about 25 to 35 drops each). Dilute to mark with distilled water. Mix thoroughly and Pipette 25 ml aliquot of each solution into a separate porcelain evaporating dish. Beginning from evaporation step follow the analysis procedure as given in above until the solution has been transferred to the 100-ml volumetric flask and dilute to mark. Measure the absorbance of each solution at 410 nm wavelength on a spectrophotometer. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 78 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Plot the absorbances of the solutions ordinates against the concentration. A linear relationship is obtained. Calculate the calibration factor (Kc) by taking the reciprocal of the slope of the line. CALCULATION: Sample Volume Corrected to Standard Conditions: Carry out the calculations as given below: Vsc = (Tstd/Pstd) (Vt-Va) (Pf/Tf-Pi/Pi/Ti) = K1 (Vt-25) (Pf/Tf-Pi/Ti) Where: Pf :Final absolute pressure of flask, (mmHg) Pi :Ininal absolute pressure of flask, (mmHg) Pstd : Standard absolute pressure of flask, (760 mmHg) Tf : Final absolute temperature of flask (K) Ti :Iniinal absolute temperature of flask (K) Tstd : Standard absolute temperature of flask (298.15 K) Vsc :Sample volume at standard conditions (ml) K1 : 0.392 K/mm Hg Vt : Volume of flask and valve (ml) Va : Volume of absorbing solution (25 ml) NO2 Concentration Corrected to Standard Conditions: Carry out the calculations as given below: ( ) Where: As : Absorbance of the sample Ab : Absorbance of the blank C : Concentration of NOx as NO2, corrected to standard conditions, mg/Nm3 F : Dilution factor (that 25/5, 25/10, etc) required only, if sample dilution was needed to reduce the absorbance into the range of calibration Kc : Spectrophotometer calibration factor 2 : 50/25 the aliquot factor [Note: If other than 25 ml aliquot is used for analysis, the factor 2 must be replaced by corresponding factor] Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 79 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 11 : Measurement of Noise at Different Sources using Sound Meter Aim: Measurement of Noise at Different Sources using Sound Meter Theory: Noise level measurement procedure are processes which are followed while monitoring sound level or acoustic energy level in specified area. These days annoying noise levels have started to become a major threat to public health. Noise in simple terms can be defined as unwanted or unpleasant sound which disturbs the environment and has a significant impact on the quality of life. We all very well know how exposure to high noise level can result in hearing impairment, headache, sleep disturbance and impaired task performance. Why Noise Monitoring is required? Compliance with noise regulation Hearing loss prevention Noise control Community Annoyance To find out the location or place or areas where noise is high than the TLV and problematic Workers or people are complaining about noise or are affected Noise Measurement Three techniques are used to measure noise in the work place and community environment (1) Personal sound exposure meter or also known as dosimeter (2) Sound Level Meter (3) Tape recorders, data recorders and level recorders Types of Noise: Steady or Continuous Noise: It is uninterrupted noise that varies less than 5 dB-A during the period of measurement eg Noise from house hold fan , boiler in a power house, lathes, diesel engine ,grinder etc Impulsive or Impact noise :When source causes vibration for a short time eg firing from the gun or hammer Intermittent/Fluctuating Noise: Large workshop number of machines are in operation, noise levels varies from time to time or dentists drilling Selection of instrument, sampling duration and scale To measure noise level, the most extensively used instrument is a Sound Level Meter (SLM) which commonly is known as a noise meter. After selection of instrument, selection of sampling duration and scale is must. With these it is also necessary to consider the parameters which we need to measure like; Lmax, Lmin, Leq, etc. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 80 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Sound Level Meter . Sound level meter SLM consist of a microphone, electric circuit and digital display. Microphone detects and reads minimal air pressure changes and convert them into electric signals. These signals are processed by electric circuits and converted into decibels. SLM can read noise level for one location at a time. While measuring noise levels it is held in an arm’s length at the ear height. It does not matter whether microphone is point towards source. Sound level monitor must be calibrated before and after use. Every sound level meter has two modes and those are SLOW and FAST. It is the response rate which SLM averages before showing on screen. For workplace noise level monitoring it should be taken as SLOW. Sound Level Meter Information required for noise survey/monitoring Location and Nature of work (Sketch of the measurement site, including size of the room, machine dimensions etc.) Nature of work process and task No of workers working in noisy area Current control including protection devices (e.g. Personal Protection devices like ear plugs or ear muffs) Community noise monitoring is required? If yes, Status of Community monitoring, whether higher than permissible level? Type of sound level meter Operating condition during the measurement and job description Results of the noise assessment Date of assessment or monitoring Name and signature of the person conducting the monitoring. Noise Level measurement Procedure Must be check the battery full before goes onside monitoring. Switch ON of equipment and wait for one minute. SLM has two modes of operation selection via the menu key. Two mode:(1) In continuous Mode (2) In Recording Mode In continuous Mode: For only onsite observation. In Recording Mode: For recording the data in sound level meter. Select the appropriate mode of sound level. Set the slow or fast time as per site condition. Slow time is applicable for normal measurement. Fast time is applicable for specific measurement of noise like moving train, heavy traffic etc. Adequate Distance (1 to 3 meter) maintain between source and equipment. Take reading for at least one minute at one location. Number of reading can take for one minute intervals. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 81 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Monitoring period should be decided in such a manner that one reading is available after one minute of monitoring at one location. When we change the location, off the machine and again Switch ON of equipment. Place of the Instrument Many factors need to be taken into account when measuring because sound levels vary at different heights above ground level. They will also vary depending on the distance between the measurement point and facades and obstacles. These are some important factors for doing monitoring: a. Away from facades b. Away from obstacles c. With the microphone 1.2 - 1.5 meter above ground level d. Monitoring inside Industrial facility distance from source shall be 1.5 meter Monitoring Locations The locations for monitoring to assess the ambient noise levels shall be mix up of all zones i.e. Residential, Commercial and Industrial to find the variations with different zones. The monitoring schedule carried out on working days and weekend to differentiate the noise levels between normal days to weekend days. The Sampling locations should be sufficient enough provide representative samples for the project. Comparison with Noise standards Once we get the monitoring records then we can compare them with standards to understand if noise levels are exceeding the standards and if they are then by how much. In India, the standards extensively used are prescribed by Central Pollution Control Board (CPCB). Noise level Measurement Standards Limits or noise level standards defined by pollution control board during Day time for Residential Noise < 55 dB and Limits during Night time for Residential Noise < 45 dB In industry, there are of two types Sound Monitoring & testing or Noise Level Measurement: (A) Ambient Noise level Monitoring & (B) In-plant Noise level Monitoring A) Ambient Noise level standards Ambient Noise level Monitoring or Noise pollution Measurement within industrial zone at ambient conditions.(e.g. Near Main Gate, Near Canteen, Near Manufacturing plant etc.) As per Central Pollution control Board (as per Factory act 1948). Limits or acceptable noise level during Day time for Ambient Noise < 75 dB and Limits during Night time for Ambient Noise < 70 dB. B) In-plant Noise level Standards In-plant Noise level means Sound level measurement allocated in the plant. As per Central Pollution control Board (as per Factory act 1948) Limits for In-plant Noise level < 90 dB. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 82 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] The below table shows the Noise level Monitoring standards prescribed by Central Pollution Control Board (CPCB). Noise Pollution (Regulation & Control) Rules 2000 under the provision of the Environment (Protection) Act, 1986. These rules provides standards in respect of noise for different areas/zones of a city/town Area code Category of area/Zone Limits in db (A) Day Time Night Time (A) Industrial area 75 70 (B) Commercial area 65 55 (C) Residential area 55 45 (D) Silence zone 50 40 Day time Night time : 6:00 AM to 10:00 PM : 10:00 PM to 6:00 AM Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 83 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Field Data Sheet of Noise Monitoring Sampling Client Name : Address : Details of Sample Collection: Sampling Instrument Date of Sampling Sampling Done By Noise Monitoring Results Sr. No. Date: Sample Location Name Unit Observed Value Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 84 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Practical No. 12 : Characterization of Municipal Solid Waste (Physical and Chemical) SOLID WASTE CHARACTERISATION Physical and chemical composition of solid wastes vary depending on sources and types of solid wastes. The nature of the deposited waste in a landfill will affect gas and leachate production and composition by virtue of relative proportions of degradable and nondegradable components, the moisture content and the specific nature of the biodegradable element. The waste composition will effect both the bulk gases and the trace components. Physical Composition: Information and data on the physical composition of solid wastes are important in the selection and operation equipment and facilities, in assessing the feasibility and resources and energy recovery and in the analysis and design of disposal facilities. Waste composition, moisture content, waste particle size, waste density, temperature and pH are important as these affect the extent and rate of degradation of waste. These are determined on components of solid wastes. Determination of Characteristics in the Field: Solid wastes are complex, multiphase mixtures. Because of the heterogeneous nature of solid wastes, determination of composition is not easy. Statistical procedures are difficult and usually procedures based on random sampling techniques are used to determine composition. To obtain a sample for analysis the waste is reduced to about 100 kg by coning and quartering. Moisture Content: The moisture content of solid wastes usually is expressed as the weight of moisture unit weight of wet or dry material. In the wet-weight method of measurement, moisture in a sample is expressed as a percentage of the wet weight of the material; in dry-weight method, it is expressed as a percentage of the dry weight of the material. equation form, the wet-weight moisture content is expressed as follows: per the the In a b 100 a Moisture content (%) = where a = initial weight of sample as delivered b = weight of sample after drying Typical data on the moisture content for the solid waste components are given in Table 1. For most municipal solid wastes, the moisture content will vary from 15 to 40 percent, depending on the composition of the wastes, the season of the year, and the humidity and weather conditions, particularly rain. Most micro-organisms including bacteria require a minimum of approximately 12% moisture for growth. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 85 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Table 1: Determination of Moisture Content for Solid Wastes Component Percent Wight Moisture Percentage 15 40 4 3 2 0.5 0.5 12 2 8 6 1 2 4 70 6 5 2 10 2 10 60 20 2 3 2 3 8 Food Waste Paper Cardboard Plastics Textiles Rubbers Leather Garden Trimmings Wood Glass Tin Cans Nonferrous Metals Ferrous Metals Dirt, Ashes, Bricks etc. Density: Density data are often needed to assess the total mass and volume of water that must be managed. Unfortunately, there is little or no uniformity in the way solid waste densities have been reported in the literature. Often, no distinction has been made between uncompacted or compacted densities. Typical densities for various wastes as found in containers are reported by source in Table 2. Table 2: Typical Densities of Municipal Solid Wastes by Source Density, Kg/m3 Source Residential (uncompacted) Rubbish Garden Trimmings Ashes Residential (Compacted) In compactor Trucks In landfill (normally compact) In landfill (well compacted) Residential (after processing) Baled Shredded, uncompacted Shredded, compacted Commercial-industrial (uncompacted) Food waste (wet) Combustion rubbish Non combustion rubbish Range Typical 150-300 100-250 1100-1400 130 100 750 300-750 600-850 1000-1250 300 450 600 1000-1800 200-450 1100-1800 700 200 750 800-1600 80-300 300-600 550 120 300 Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 86 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Because the densities of solid wastes vary markedly with geographic location, season of the year, the length of time in storage, great care should be used in selecting typical values. Municipal solid wastes as delivered in compaction vehicles have been found to have a typical value about 300 kg/m3. Particle Size and size distribution: The size and size distribution of the component materials in solid wastes are an important consideration in the recovery of materials, especially with mechanical means such as trommel screens and magnetic separators. The size of a waste component may be defined by one or more of the following measures: Sc l l w Sc 2 l wh Sc 3 S c l w h 3 1 S c l w 2 1 Where Sc = size of component, in (mm) L = length, in (mm) W = width, in (mm) H= height, in (mm) The major means of controlling particle size is through shredding. Shredding increases homogeneity, increases the surface area/volume ratio and reduces the potential for preferential liquid flow paths through the waste. Particle size will also influence waste packing densities, and particle size reduction (by shredding) could increase biogas production through the increased surface area available to degradation by bacteria. But the smaller particles allow higher packing density which decrease water movement, bacterial movement and the bacterial access to substrate. Field Capacity The field capacity of solid waste is the India amount of moisture that can be retained in a waste sample subject to the downward pull of gravity. The field capacity of waste materials is of critical importance in determining the formation of leachate in landfills. Water in excess of the field capacity will be released as leachate. The field capacity varies with the degree of applied pressure and the state of decomposition of the waste. A field capacity of 30 percent by volume corresponds to 30 in/100 in. The field capacity of uncompacted commingled wastes from residential and commercial sources is in the range of 50 to 60 percent. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 87 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Chemical Composition: Information on the chemical composition of solid wastes is important in evaluating alternative processing and recovery options. For example, consider the incineration process. Typically, wastes can be thought of as a combination of semimoist combustible and non-combustible materials. If solid wastes are to be used as fuel, the four most important properties to be known are: 1. Proximate analysis a. Moisture (loss at 105 0C for 1 h) b. Volatile matter (additional loss on ignition at 950 0C) c. Ash (residue after burning) d. Fixed carbon (remainder) 2. Fusing point of ash 3. Ultimate analysis, percent of C (carbon), H (hydrogen), O (oxygen), N (nitrogen), S (Sulphur), and ash 4. Heating value. A proximate analysis for the combustible components of municipal solid wastes as discarded is presented in Table 3. Table 3: Typical Proximate Analysis for Municipal Solid Wastes Component Value, percent Typical Moisture 20 Volatile Matter 53 Fixed Carbon Glass, Metal, Ash 7 20 Fusing Point of Ash The fusing point ash is defined as that temperature at which the ash resulting from the burning of waste will form a solid (clinker) by fusion and agglomeration. Typical fusing temperature for the formation of clinker from solid waste range from 2000 to 2200 0F (1100 to 1200 0C). Ultimate Analysis of Solid Waste Components The ultimate analysis of a waste component typically involves the determination of the percent C (carbon), H (hydrogen), O (oxygen), N (nitrogen), S (sulphur), and ash. Because of the concern over the emission of chlorinated compounds during combustion, the determination of halogens is often included in an ultimate analysis. The results of the ultimate analysis are used to characterise the chemical composition of the organic matter in MSW. They are also used to define the proper mix of waste materials to achieve suitable C/N ratios for biological conversion processes. Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 88 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Energy Content of Solid Waste Components The energy content of the organic components in MSW can be determined (1) by using a full scale boiler as a calorimeter, (2) by using a laboratory bomb calorimeter, and (3) by calculation, if the elemental composition is known. Because of the difficulty in instrumenting a full-scale boiler, most of the data on the energy content of the organic components of MSW are based on the results of bomb calorimeter tests. Essential Nutrients and Other Elements Where the organic fraction of MSW is to be used as feedstock for the production of biological conversion products such as compost, methane, and ethanol, information on the essential nutrients and elements in the waste materials is of importance with respect the microbial nutrient balance and in assessing what final uses can be made of the materials remaining after biological conversion. Representative data on the ultimate analysis of typical municipal waste components are presented in Table 4. If Btu values are not available, the approximate Btu value can be determined as below. Btu/lb = 145.5C + 620(H – O) = 41S where C = carbon, percent H = hydrogen, percent O = oxygen, percent S = sulphur, percent Chemical compositions of Municipal Solid waste dumps of three cities are summarised in Table 5. Table 4: Typical Data on Ultimate Analysis of the Combustible Components in Municipal Solid Wastes Percent by Weight (Dry Basis) Component Carbon Hydrogen Oxygen Nitrogen Sulphur Ash Food Waste 48.0 6.4 37.6 2.6 0.4 5.0 Paper 43.5 6.0 44.0 0.3 0.2 6.0 Cardboard 44.0 5.9 44.6 0.3 0.2 5.0 Plastics 60.0 7.2 22.8 - - 10.0 Textiles 55.0 6.6 31.2 4.6 0.15 2.5 Rubbers 78.0 10.0 - 2.0 - 10.0 Leather 60.0 8.0 11.6 10.0 0.4 10.0 Garden Trimmings 47.8 6.0 38.0 3.4 0.3 4.5 Wood 49.5 6.0 42.7 0.2 0.1 1.5 Dirt, Ashes, Bricks etc. 26.3 3.0 2.0 0.5 0.2 68.0 Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 89 [ENVIRONMENTAL ENGINEERING LABORATORY MANUAL] Table 5: Overall Chemical Analysis (in %) Location Madras Foreshore Otteri Organic Matter 21.40 46.30 48.40 Carbon 12.40 26.80 28.00 Nitrogen 0.44 0.32 0.48 Phosphorus 0.24 0.87 0.74 Potash 0.19 0.15 0.22 10.10 22.80 30.00 6.90 7.10 6.90 Moisture pH Future Changes in Composition In terms of solid waste management planning, knowledge of future trends in the composition of solid wastes is of great importance. For example, if a paper recycling program were instituted on the basis of current distribution data and if paper production were to be eliminated in the future, such a program would more than likely become a costly “white elephant”. Although this case is extreme, it nevertheless illustrates the point that future trends must be assessed carefully in long-term planning. Another important question is whether the quantities are actually changing or only the reporting system has improved. Treatment methods: Suitability of various treatment methods depends on physical and chemical characteristics of waste. The method of treatment is decided based on moisture content, organic matter and total solids. Date: Signature of Faculty Department of Civil Engineering, Darshan Institute of Engineering & Technology-Rajkot Page 90