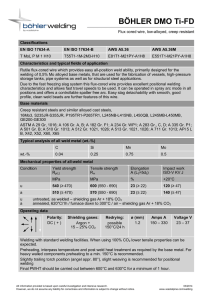

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/266616848 Evaluation of nitrogen influence on microstructure of duplex stainless steel laser welds Conference Paper · July 2014 DOI: 10.13140/2.1.1886.5928 CITATIONS READS 0 144 5 authors, including: Jozef Bárta Milan Marônek Slovak University of Technology in Bratislava Slovak University of Technology in Bratislava 19 PUBLICATIONS 17 CITATIONS 29 PUBLICATIONS 27 CITATIONS SEE PROFILE SEE PROFILE Miroslav Sahul Slovak University of Technology in Bratislava 18 PUBLICATIONS 16 CITATIONS SEE PROFILE All content following this page was uploaded by Jozef Bárta on 08 October 2014. The user has requested enhancement of the downloaded file. 65th Annual Assembly & International Conference of the International Institute of Welding 13th-18th July 2014, Seoul, Korea Evaluation of nitrogen influence on microstructure of duplex stainless steel laser welds Jozef Barta1, Milan Maronek2, Miroslav Sahul1, Katarina Bartova1, Erika Hodulova1 Institute of Production Technologies ,Faculty of Materials Science and Technology, Slovak University of Technology, Slovakia1 Institute of Production Technologies ,Faculty of Materials Science and Technology, Slovak Universiity of Technology, Slovakia 2 Abstract Welding of duplex stainless steel (DSS) by conventional welding methods is currently relatively well explored. A wide scale of filler materials as well as appropriate procedures for achievement of suitable weld joint microstructure with regard to its mechanical properties and corrosion resistance are available on the market. Welding of DSS by the laser and electron beam leads to faster cooling of weld metal. Therefore, there is insufficient time for transformation of delta ferrite to austenite, and thus the excess amount of ferrite in comparison to the base material is present in the final microstructure of weld metal. This disequilibrium can negatively influence the weld joint corrosion resistance. One of the possible ways to promote austenite formation in weld metal is application of the austenite supporting elements, either in filler materials or in protective gas. In case of welding without filler material, the addition of nitrogen to the protective gas seems to be eventual solution. The paper evaluates the influence of nitrogen as a protective atmosphere on promotion of austenite formation in the laser beam weld joints. The microstructure was examined by optical microscopy. The results revealed that welding in nitrogen shielding gas did not meet the required austenite and ferrite ratio, neither on the weld surface nor in the layers beneath. Keywords: duplex steel, laser beam welding, nitrogen, phase ratio 1. Introduction Duplex stainless steels (DSS), meaning those with a mixed microstructure of about equal proportions of austenite and ferrite, have existed for nearly 80 years. These materials are a family of grades combining good corrosion resistance with high strength and ease of fabrication. Their physical properties are between those of the austenitic and ferritic stainless steels but tend to be closer to those of the ferritic and to carbon steel. All DSS provide significantly greater strength than the austenitic grades while exhibiting good ductility and toughness. The typical yield strengths of several duplex stainless steels are compared with that of 316L austenitic stainless steel between room temperature and 300°C (570°F) in Figure 1 [1, 2]. Figure 1. Yield strengths comparison of several stainless steels [1] Yield strength of DSS at room temperature in the solutionannealed condition is more than double that of the standard austenitic stainless steels not alloyed with nitrogen. This may allow the design engineer to decrease the wall thickness in some applications [3]. The iron-chromium-nickel ternary phase diagram is a roadmap of the metallurgical behavior of the duplex stainless steels. A section through the ternary at 68% iron (Figure 2) illustrates that these alloys solidify as ferrite (α), some of which then transforms to austenite (γ) as the temperature falls to about 1000°C depending on alloy composition. Small changes in composition can have a large effect on the relative volume fraction of these two phases, as the phase diagram indicates. Beneficial effect of nitrogen, evidenced in Figure 2, is that it raises the temperature at which the austenite begins to form from the ferrite [1]. shielding gas containing, besides argon or helium, also 1% to 2 % of nitrogen [1, 2, 5]. Since there are no arc instabilities during laser beam welding, the aim of the paper was to use pure nitrogen as a shielding gas in order to maximize the austenite content in weld metal. 2. Material properties Sheets with 1 mm thickness made of duplex stainless steel grade 2205 were used in the experiment. The typical chemical composition of 2205 DSS is provided in Table 1 [4]. Table 1 Typical chemical composition of 2205 duplex stainless steel [4] Grade C Cr Ni Mo N Mn Cu [%] [%] [%] [%] [%] [%] [%] 3.5–5.5 0.1–0.6 2205 0.03 22.0–24.0 Figure 2. Section through Fe-Cr-Ni ternary phase diagram at 68% iron content [1] 0.05–0.20 2.00 1.0–3.0 Mechanical properties measured in the direction parallel to the rolling direction are shown in Table 2. Table 2 Mechanical properties of DSS 2205 Duplex stainless steels have very good hot cracking resistance due to the high ferrite content; hot cracking is rarely a consideration when welding these steels. The problems of most concern in duplex stainless steels are associated with the Heat Affected Zone (HAZ), not with the weld metal. The HAZ problems are loss of corrosion resistance, toughness, or post-weld cracking [3]. Grade Proof strength Rp0.2 [MPa] Tensile strength [MPa] Elongation A5 [%] 2205 556 810 23 The microstructure of DSS 2205 documented in Figure 3 consisted of approximately equal amount of austenite and ferrite with typical elongated grains after rolling process. As a general rule, preheating is not recommended because it may be detrimental. Postweld stress relief is not needed for duplex stainless steels and is likely to be harmful because the heat treatment may precipitate intermetallic phases or alpha prime (475°C) embrittlement causing a loss of toughness and corrosion resistance [2]. Duplex stainless steels can tolerate relatively high heat inputs. Exceedingly low heat input may result in fusion zones and HAZ which are excessively ferritic with a corresponding loss of toughness and corrosion resistance. Exceedingly high heat input increases the danger of forming intermetallic phases. To avoid problems in the HAZ, the weld procedure should allow rapid cooling of this region after welding [1]. Laser beam welding produce very limited heat affected zones and rapid cooling that prevents intermetallic phase formation. However, the high cooling rate associated with these techniques can result in the excessive ferrite formation in the weld, so weld qualification of the procedure is critical when using these methods [3]. The most frequent way to prevent nitrogen diffusion from weld metal in standard welding methods is usage of Figure 3 Microstructure of duplex stainless steel 2205 3. Experiment The experiment was carried out with the solid state disc laser. The laser head was mounted on the Fanuc M-710iC/50 robotic arm for precise guidance of laser beam. The 65th Annual Assembly & International Conference of the International Institute of Welding 13th-18th July 2014, Seoul, Korea workplace is shown in Figure 4. Shielding gas was supplied by four parallel nozzles. The butt welds were made by laser beam welding of two duplex stainless steel sheets with the dimensions of 1x50x100 mm. The materials were fixed during welding in the fixture shown in Figure 5. Design of the welding fixture provided the possibility of both weld surface and weld root protection by shielding gas. Figure 4 Laser beam welding workplace Figure 5 Welding fixture design The specifications of welding equipment are provided in Table 3. Table 3 Specifications of welding equipment Welding source Maximum output power Welding optics Focal distance Laser beam spot diameter Focus position TRUMPF TruDisk 4002 2 kW TRUMPF D70 200 mm 200 µm On material surface The 99,998% nitrogen shielding gas was used in order to evaluate its influence on microstructural changes. The flow rate was constantly set to 16 l/min. Other welding parameters are provided in Table 4. Table 4 Welding parameters Specimen No. 30 35 40 45 50 30N 35N 40N 45N 50N Welding speed [mm/s] 30 35 40 45 50 30 35 40 45 50 Shielding gas Heat input [kJ/mm] – – – – – Nitrogen Nitrogen Nitrogen Nitrogen Nitrogen 0.033 0.029 0.025 0.022 0.02 0.033 0.029 0.025 0.022 0.02 Worthy of note is that the recommended heat input for DSS welding by arc welding methods is between 0.5 and 2.5 kJ/mm. Specimens for microstructural analysis were prepared by standard metallographic procedure (grinding, polishing and etching). Neophot 32 Optical microscope was used for microstructural analysis. 4. Results As anticipated, the microstructural analysis revealed mostly ferritic structure of weld metal. The specimens produced using nitrogen as a shielding gas showed a weld shape typical for laser beam welding, unlike the specimens welded without shielding gas (Figure 6). Weld joint did not show any abnormalities or porosity. Weld metal contained mostly columnar ferritic grains with little amount of austenite segregated on the ferritic grain boundaries. Figure 5 Macrostructure of weld joints nitrogen (left), no shielding gas (right) Examples of the weld metal microstructure with and without nitrogen shielding gas for specimens No. 35 and 35N are shown in Figures 5 and 6 respectively. Results revealed low amount of the austenite present at the ferritic grain Specimen No. 45 45N 50 50N boundaries. The specimens welded without shielding gas showed ferritic grain coarsening in comparison to the specimens welded with nitrogen shielding gas. Shielding gas – Nitrogen – Nitrogen Heat input [kJ/mm] 0.029 0.025 0.022 0.02 Ferrite content [%] 91,1 90,6 90,6 87,5 Published research papers indicated that nitrogen addition to shielding gas may help obtain balanced phase ratio in common arc welding processes. Based on the research results, this information was not proved in case of laser beam welding. 5. Conclusion Figure 5 Microstructure of weld metal in specimen No. 35 The attained results showed that nitrogen shielding gas had minimum influence on the austenite content in weld metal of laser beam welds. Suitable solution may lie in the application of filler metal enriched by the elements promoting austenite formation, e.g. nickel. On the other hand, surpisingly, lower heat input caused higher austenite content. This discrepancy is therefore the subject of further research. Further research will be also focused on the modification of heat input for example by the application of subsequent laser beam pass in order to prolong the weld metal cooling time. Acknowledgement This research was supported by Slovak Research and Development Agency using financial support no. APVV0248-12. Figure 6 Microstructure of weld metal in specimen No. 35N Quantitative image analysis was performed on the micrographs taken from the weld bead in order to determine the volume fraction of ferrite and austenite. Determination of the phase volume fractions was done by the manual point count method on the micrographs taken at 500x magnifications minimum, in accordance to ASTM E-562 standard. Weld metal of the specimens welded with different heat input showed similar microstructure with the minimum content of austenite as illustrated in Table 5. References [1] [2] [3] [4] Table 5 Results of the ferrite content measurement Specimen No. 30 30N 35 35N 40 40N View publication stats Shielding gas – Nitrogen – Nitrogen – Nitrogen Heat input [kJ/mm] 0.033 0.029 0.025 0.022 0.02 0.033 Ferrite content [%] 95,6 92,4 92,8 92 92,8 91,1 [5] Practical Guidelines for the Fabrication of Duplex Stainless Steel, 2009, Available from: http://www.worldstainless.org/Files/issf/nonimagefiles/PDF/Practical_Guidelines_for_the_Fabrication_of_Duplex_Stai nless_Steels.pdf, Accessed: 2014-05-15 How to Weld Type 2205 Code Plus Two® Duplex Stainless Steel, Available from: http://www.outokumpu.com/SiteCollectionDocuments/ Datasheethow-to-weld-2205-hpsa-imperial-outokumpu-en-americas.pdf, Accessed: 2014-03-28 El-Batahgy, A.M., Khourshid, A.F., Sharef, T.: Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel. In Materials Sciences and Applications, 2, pp.14431451, 2011, DOI:10.4236/msa.2011.210195 Pettersson, C.O., Fager, S.A..: Welding practice for the Sandvik duplex stainless steels SAF 2304, SAF 2205 and SAF 2507. Available from: http://www2.sandvik.com/sandvik/0140/internet/se01280.nsf/0/ecd13 2de31b33bd085256bd5006d666b/$FILE/Welding%20Practice%20fo r%20Sandvik%20Duplex.pdf, Accessed: 2014-02-08 How to weld duplex stainless steel. Available from: https://www.engineersaustralia.org.au/sites/default/files/shado/Divisi ons/Sydney%20Division/How_to_weld_Duplex_Stainless_Steel_Mec hanical16April09.pdf, Accessed: 2013-11-27