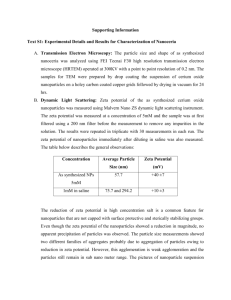

EFFECT OF ANNEALING ON CERIUM OXIDE THIN FILMS FABRICATED ON A SILICON SUBSTRATE AT DIFFERENT TEMPERATURE Project By: Ayesha khalid 921-FBAS-BsPHY/F15 Aqsa Zahoor 919-FBAS-BsPHY/F15 Supervisor: Dr. Rehana Riaz Assistant Professor Department of Physics Faculty of Basic and Applied Sciences International Islamic University, Islamabad (2019) International Islamic University, Islamabad Faculty of basic and applied sciences Department of Physics Ayesha khalid (921-FBAS-BsPHY/F15) ____________________ Aqsa Zahoor (919-FBAS-BsPHY/F15) ____________________ Thesis submitted to Department of Physics International Islamic University, Islamabad For the award of the degree of Bs Physics Signature: ____________________ (Chairperson, Department of physics) Final Approval It is certified that the work presented in this thesis entitled “Effect of annealing on cerium oxide thin films on a silicon substrate at different temperature ” by registration number 921FBAS-BsPHY/F15, 919-FBAS-BsPHY/F15 is of sufficient standard in scope and quality for the award of degree of BS Physics from International Islamic University, Islamabad. Committee Internal Examiner Dr. Shumaila Sajjad Assistant Professor Department of Physics International Islamic University, Islamabad ____________________ Supervisor Dr. Rehana Riaz Assistant Professor International Islamic University, Islamabad ____________________ Declaration of Originality We hereby declare that work & intellectual contents of this thesis “effect of annealing on cerium oxide thin films on silicon substrate at different temperature” are the product of our own work. This thesis has neither been published previously in any formwork and does not contain any material of published resources which could be treated as subject of international copyright law. We also declare that we understand the terms of copyright & plagiarism, and we will be held fully responsible for all the consequences in case of any violation of copyright’s law or plagiarism found in this thesis. Ayesha Khalid ____________________ (921-FBAS-BsPHY/F15) Aqsa Zahoor ____________________ (919-FBAS-BsPHY/F15) CERTIFICATE This is to certify that the work contained in this thesis entitled “effect Of annealing on cerium oxide thin films fabricated on silicon substrate at different temperature” has been carried out by Ayesha Khalid, Aqsa Zahoor under our supervision. In my opinion, this is fully adequate in scope and quality for the degree of BS Physics. Supervisor: Dr. Rehana Riaz Assistant Professor at Department of Physics International Islamic University, Islamabad. Signature: ____________________ DEDICATION This thesis is dedicated to our beloved parents and teachers for their love and support ACKNOWLEDGEMENT Foremost, we are grateful to Allah Almighty who has let us complete our work without any obstacles. Without His blessing it couldn’t have been possible. We would like to express our sincere gratitude to our Supervisor Dr. Rehana Riaz for the continuous support of our research, for her motivation and immense knowledge. Her guidance helped us in all the time of research and writing of this thesis. We would like to thank our Parents who were always supporting us in every step of this project. Abstract Thin films prepared by physical methods are currently attracting considerable attention, as they are relatively inexpensive, simple and convenient for large area deposition. Cerium oxide thin films were fabricated on a silicon substrate by mean of electron beam evaporation technique. The developed thin films were then post annealed at different temperature (200°C, 400°C and 700°C). Annealing proved to be very effective in changing the film structure. Structural, morphological, optical and electrical properties of CeO 2 have been explored through various analytical techniques, such as X-Ray Diffraction (XRD), Diffuse Reflectance Spectroscopy (DRS), and IV Characteristics. XRD data analysis revealed average crystallite size of the sample in the range of 50 nm-70 nm. DRS results shows that reflectance of light is maximum in near Infrared Region. The band gap varies from 3.2-5.9 eV. IV Characteristics analysis shows that the conductivity is highest at 400°C. Table of Contents CHAPTER 1 INTRODUCTION…………………………………………………………………………………………………………………. 1 1.1 Nanotechnology……………………………………………………………………………………………………………………………..1 1.2 Nanoscience …………………………………………………………………………………………………………………………………..1 1.3 Thin Films ……………………………………………………………………………………………………………….………………………2 1.3.1 Significance ……………………………………………………………………………………………….………………….2 1.4 Cerium……………………………………………………………………...........................................................................3 1.4.1 characteristics………………………………………………………...……………………………………………………..3 1.4.2 Compound of Cerium ……………………………………………………………………………………………………..4 1.5 Cerium Oxide……………………………………………………………………………………………………………….…….4 1.5.1 Electronic Properties………………………………………………………………………………………………..….,.5 1.5.2 Crystal Structure…………………….………………………………………….…………………………………….….…5 1.5.3 Microstructure…………………………………………………………………………………………………………..…..5 1.6 Application …...………………………………………………………………………………………………………….....…7 1.6.1 Catalytic Application….……………………………………………………………………………………………..….7 1.6.2 Photo Catalyst…………………..…………………………………………………………………………………….……8 1.6.3 Environmental Remediation ………………………………………….……………………………………….…….8 1.7 Nanoparticles ………………………………………………………………………………………………………………….8 1.8 Nanomaterials……………………….…………………………………………………………………………………………9 1.8.1 Bulk material and Nanoparticles………………………………………………………………………………….10 1.9 Applications…………………………..……………………………………………………………………………………….10 Chapter 2 Literature Review…………....………………………………………………………………………………….14 Chapter 3 Experimental Work………………………………………….…………………………………………………..24 3.2 Fabrication Technique……………………………………………………………………………………….…………….24 3.3 Procedure…………………………………………………………………………………………………………………….….24 3.3.1 Pallet Formation………………………………………………………………………………………………………….24 3.3.2 Substrate Cleaning……………………………………………………………………………………………………...24 3.4 Electron Beam Evaporation………………………………………………………………………………………………25 3.4.1 Working Principle………………………………………………………………………………………………………..26 3.4.2 Working………………………………………………………………………………………………………………..…….26 3.4.3 Advantages………………………………………………………………………………………………………………….27 3.4.4 Disadvantages……………………………………………………………………………………………………………..28 3.5 Annealing…………………………………………………………………………………………………………………………29 3.5.1 Stages………………………………………………………………………………………………………………………….29 3.5.2 Types Annealing………………………………………………………………………………………………………….29 3.5.3 Advantages of Annealing………………………………………………………………………………………….…31 3.5.4 Properties of Annealed material………………………………………………………………………………….31 3.6 Characterization Techniques……………………………………………………………………………………………32 3.6.1 Diffuse Reflectance Spectroscopy……………………………………………………………………………….32 3.6.1.1 Principle of Diffuse Reflectance……………………………………………………………………………….33 3.6.1.2 How Diffuse Reflectance …………………………………………………………………………………………34 3.6.2 X-Ray Diffraction…………………………………………………………………………………………………………..35 3.6.2.1 Principle……………………………………………………………………………………………………………………36 3.6.2.2 Bragg’s Law……………………………………………………………………………………………………………….37 3.6.2.3 Scherrer Equation……………………………………………………………………………………………………..39 3.6.2.4 Types…………………………………………………………………………………………………………………………39 3.6.2.5 Application of XRD……………………………………………………………………………………………………40 3.6.3 I-V Characteristics…………………………………………………………………………………………………………40 Chapter 4 Result And Discussion………………………………………………………………………………………….41 4.1 XRD Result And Discussion………………………………………………………………………………………………42 4.2 DRS Result And Discussion……………………………………………………………………………………………….45 4.2.1 Result For Reflectance………………………………………………………………………………………………….45 4.2.2 Band Gap Study……………………………………………………………………………………………………………47 4.3 I-V Characteristics Result And Discussion…………………………………………………………………………50 4.4 Conclusion……………………………………………………………………………………………………………………….52 References…………………………………………………………………………………………………………………………….54 List of figures Figure 1.1: Crystal Structure of CeO2……………………………...………...5 Figure 1.2: Application of Silver Nano Particles…………………………...12 Figure 3.1: Working of Electron Beam Evaporation………….……………26 Figure 3.2: Deposition of Sublimated Material…………………………….27 Figure 3.2.1: Perkin Elmer lambda 90……………………………………...32 Figure 3.2.2:Types Of Reflection………………. ………………………….33 Figure 3.3: X-Ray Diffraction………………………...…………………….36 Figure 3.3.1: Schematics of XRD……………………...…………...……….37 Figure 3.4 I-V Apparatus…………………………………………………...40 Figure 4.1: XRD graph for CeO2 thin film un- annealed …………………..42 Figure 4.2: XRD graph for CeO2 thin film annealed at 200°C……………..43 Figure 4.3: XRD graph for CeO2 thin film annealed at 400°C……………..43 Figure 4.4: XRD graph for CeO2 thin film annealed at 700°C……………..44 Figure 4.5: Graph of annealing temperature v/s crystallite size…………….44 Figure 4.6: DRS graph for CeO2 un-annealed thin film…………………….45 Figure 4.7: DRS graph for CeO2 thin film annealed at 200°C……………...46 Figure 4.8: DRS graph for CeO2 thin film annealed at 400°C……………...46 Figure 4.9: DRS graph for CeO2 thin film annealed at 700°C…..………….47 Figure 4.10: Band gap of un-annealed CeO2 thin film……….…………….48 Figure 4.11: Band gap of CeO2 thin film annealed at 200°C………………48 Figure 4.12: Band gap of CeO2 thin film annealed at 400°C………………49 Figure 4.13: Band gap of thin film annealed at 700°C…………………..…49 Figure 4.14: IV graph for un-annealed CeO2 thin film in light………......…50 Figure 4.15: IV graph for annealed CeO2 thin film at 200°C in light……....50 Figure 4.16: IV graph for annealed CeO2 thin film at 400°C in light……....51 Figure 4.17: IV graph for annealed CeO2 thin film at 700°C in light……....51 Figure 4.18: Graph of conductivity v/s annealing temperature…………......52 Chapter: 1 Introduction 1.1 Nanotechnology Nano is a Greek word means “dwarf”. At Nanoscales we have nanostructures made up of molecules or clusters of atoms or particles. Nanotechnology is a discipline which deals with the structures having size in nanometer range so we can say that applies methods from nanoscience to create products at Nano scale and make use of those unique properties that occur at such small dimensions. [1] In 1959, Richard Feynman became the first man to give the concepts involved in nanotechnology. He gave the talk at the American physical society at Caltech. It was basically how individuals might be able to manipulate atoms and molecules into smaller structures. Nanotechnology provides essential improvements in energy sector, semiconductor industry, biomedicines, optics and magnetic media and in many other fields. [2] ▪ Nanotechnology is the art and science of manipulating matter at Nano scale (down to 1/100000 the width of a human hair) to create new and unique materials and products with enormous potential to change the society. ▪ 1nm =1 billionth of a meter. [3] 1.2 Nanoscience Nanoscience is the study of phenomenon and manipulation of materials at atomic, molecular and macromolecular scales where properties differ significantly from those at a larger scale. [4] It is the study of materials that exhibits the remarkable properties functionality and phenomenon due to the influence of small dimensions. Nanoscience is not just the science of small, but the science in which materials with small dimensions show new physical phenomenon collectively called quantum effects which are size dependent and different from properties of macro scale materials. The main purpose of studying nanoscience is the control of material in extremely small Nano scale size range. Matters at the Nano scale exhibits unique properties and functions facilitate the establishment of exclusive Nano scale systems and devices that are valid in various fields such as biological, material and electrical sciences. [5] 1.3 Thin Film A thin film is a layer of material ranging from fractions of a nanometer (monolayer) to several micrometers in thickness. Thin films are created through a process called “deposition.” Deposition is a thin film coating process, which is achieved by modifying the four states of matter, solid, liquid, vapor and plasma. Thin film technology is based on three foundations: fabrication, characterization and applications. This can be accomplished through a variety of vacuum processes. [17] Conventional categories of vacuum deposition processes include: ✓ Chemical vapor deposition (CVD), ✓ Physical vapor deposition (PVD), ✓ Evaporation through vacuum sublimation, Occasionally, some combinations of these methods are just a few ways a thin film can be developed. The performance of thin film optical coatings (e.g. antireflective, or AR, coatings) is typically enhanced when the thin film coating consists of multiple layers having varying thicknesses and refractive indices. Similarly, a periodic structure of alternating thin films of different materials may collectively form a super lattice, which exploits the phenomenon of quantum confinement by restricting electronic phenomena to two dimensions. [18] 1.3.1 Significance Thin films science and technology plays an important role in the high-tech industries. Thin film technology has been developed primarily for the need of the integrated circuit industry. The demand for development of smaller and smaller devices with higher speed especially in new generation of integrated circuits requires advanced materials and new processing techniques suitable for future giga scale integration (GSI) technology. In this regard, physics and technology of thin films can play an important role to achieve this goal. The production of thin films for device purposes has been developed over the past 40 years. Thin films as a two-dimensional system are of great importance to many real-world problems. Their material costs are very small as compared to the corresponding bulk material and they perform the same function when it comes to surface processes. Thus, knowledge and determination of the nature, functions and new properties of thin films can be used for the development of new technologies for future applications. [19] 1.4 Cerium It is the most abundant rare earth metal. It is found in many minerals, including allanite or orthrite, monazite, bastnasite, cerite, and samarskite. Large deposits of cerium have been found in India, Brazil and Southern California. Cerium metal is obtained by thermal reduction techniques and produces very pure versions of the element. Cerium is a chemical element with the symbol Ce and atomic number 58. Cerium is a soft, ductile and silvery white metal that disappears when exposed to air, and is soft enough to be cut with a knife. Cerium is the second element in the lanthanide series, and although it often exhibits the characteristic +3 oxidation state of the series, it also exceptionally has a stable state of +4 which does not oxidize water. in the milli kelvin range at pressures above 20 kb. [20] 1.4.1 Characteristic Cerium is an inner transition metal (or lanthanide) that lies in period six of the periodic table, between lanthanum and praseodymium. It resembles iron in color and luster, but it is soft, malleable, and ductile. It tarnishes readily in the air. Only europium is more reactive than cerium among rare earth elements. The pure metal is likely to ignite if scratched with a knife. It oxidizes slowly in cold water and rapidly in hot water. It is rapidly attacked by alkali solutions and acids. In forming compounds, cerium has two common oxidation states, +3 and +4. The metal in the +3 oxidation state is referred to as cereous, that in the +4 oxidation state is called ceric. Cerium(IV) salts are orange red or yellowish, whereas cerium(III) salts are usually white. [21] 1.4.2 Compound of cerium Cerium(IV) oxide, ceric oxide, or ceria (CeO2): This pale yellow oxide is the most common compound of cerium. It is used in lapidary as "jeweler's rouge" and in ceramics to polish glass. It is also used in the walls of some self - cleaning ovens as a catalyst during the high-temperature cleaning process. Ceria can conduct ions (oxide ions) and electrons, and it is therefore called a "mixed ionic electronic conducting material." At temperatures above 500 °C, it becomes a predominantly ionic conductor and is potentially useful as an electrolyte in solid-oxide fuel cells (SOFCs). Cerium(III) chloride, cereous chloride, or cerium trichloride (CeCl3): serves as a starting material for the preparation of other cerium salts. In addition, it is a catalyst for certain reactions in organic chemistry. [22] Ammonium cerium(IV) nitrate or ceric ammonium nitrate (CAN) [(NH4)2Ce(NO3)6]: This orange-red compound is an oxidizing agent widely used in organic synthesis. It is also a standard oxidant used in quantitative analysis (titrations). Catalytic amounts of CAN in tap water can be used for the efficient synthesis of various quinoxaline derivatives, which in turn are useful for dyes, organic semiconductors, and DNA cleaving agents. Quinoxaline derivatives are also important components in antibiotics such as echinomycin and actinomycin. Cerium(IV) sulfate or ceric sulfate (Ce(SO4)4) is a common oxidizing agent used in quantitative analysis (titrations). [22] 1.5 Cerium oxide Cerium dioxide belongs to rare earth family and its abundance is greater than copper and tin. Due to high abundance ceria plays key role in various applications such as auto-exhaust catalyst, low temperature water gas shift (WGS) reaction, oxygen sensors, oxygen permeation membrane system, fuel cells glass-polishing material, electrochromic thin film application as well as biotechnology, environmental chemistry and medicine. [23] 1.5.1 Electronic properties In lanthanides series cerium is the second and reactive member. Cerium is electropositive in nature. It exists in two oxidation states, Ce+3 and Ce+4. Due to its electronic structure Ce+4 is considered as more stable oxidation state. There are two types of oxides of ceria ceria(CeO2) and equiaxed (Ce2O3). Ceria is used widely because it is more stable than Ce2O3. [24] 1.5.2 Crystal structure Cerium dioxide has face centered cubic crystal (FCC) structure. It consists of a simple cubic oxygen sub-lattice with the cerium ions occupying alternate cube centers. Cerium is at the centre of tetrahedron whose corners are occupied by oxygen atoms. [25] Fig:1.1 Crystal Structure of CeO2 1.5.3 Microstructure The microstructure of CeO2 has various shapes and sizes of films depending on the nature of substrate material, composition contents, deposition methods and parameters. This dependence result in epitaxial films or polycrystalline films of few nanometers to several hundred micrometers. The polycrystalline thin films have various sizes of grains that play an important role in the electrical conduction process due to the depletion region of low conductivity in the thin films. [26] Table:1.1 Properties of CeO2 Compound Formula CeO2 Compound Formula CeO2 Molecular Weight 172.12 Appearance White to Yellow Powder Melting Point 2340 °C (4240 °F) Boiling Point 3,500° C (6,332° F) Density 7.6 g/cm3 Solubility in H2O N/A Electrical Resistivity 4 10x Ω-m Specific Heat 390 J/kg-K Thermal Expansion 11 µm/m-K Young's Modulus 180 GPa Exact Mass 171.895 g/mol 1.6 Applications: Ceria is the technologically most important functional material so it has valuable uses in diverse fields. Some are discussed below: • Solid oxide fuel cells (SOFC) Ceria based ion conductors have resistance to carbon deposition and have capability of providing continuous supply of dry hydrocarbon fuels to anode. So it is used in solid oxide fuel cells for providing clean and reliable electric power. Ceria has reversible redox transition between Ce+3 and Ce+4. Due to this property ceria based ceramics have good ionic and electrical conductivity in the reducing atmosphere. Their excellent catalytic activities also result in oxygen-vacancy mechanism formation. No substantial change was observed in the electrochemical activity by keeping the ceria catalyzed reaction site density fixed as 2PB and the density of metal catalyzed reaction site (3PB) was varied by a factor of 16 and addition of metals did not put much impact on the electrochemical activities. Thus it is concluded that the rational design of ceria nanostructures promote electrochemical activities and thus provide a new route to achieve high performance. [27] 1.6.1 Catalytic applications Ceria is the important ingredient of the catalytic applications because of its property to uptake and release oxygen by reversible transition between Ce+3 and Ce+4. At low temperature ceria has the high oxygen storage capability during CO emission. Catalytic activity can be enhanced by using ceria of high surface area that provides a greater tendency to active species to contact with reactants, and therefore an enhanced catalytic performance can be expected. There are different reports that discuss various morphologies to evaluate the CO oxidation performance. For instance, nanotubes exhibit inner and outer surfaces that unadventurously provide active sites for the reactants adsorption that leads to better catalytic performance in CO oxidation. On the other hand, nano‐sized particles also exhibit high surface area, but demonstrate poor catalytic performance; while nanorods, with low surface area and larger diameter, were found to be more active in CO oxidation. [28] 1.6.2 Photo catalyst Visible light photocatalytic water splitting is an active source of renewable energy as well as water and air purification. A novel and efficient Au‐supported CeO2 nanoparticle‐based photocatalysts were fabricated and its visible light activities were reported by Primo et al. Ceria nanoparticles have excellent photocatalytic activity for generation of oxygen from water. [29] 1.6.3 Environmental Remediation Ceria has potential application for environmental remediation. Aromatic benzene is commonly found in urban ambient air and cause major environmental and health issues. CeO2 nanotubes show excellent photocatalytic activity towards the gas phase degradation of benzene when compared with commercial TiO2 at the reaction time of 22 hours. Ceria nanotube was maintained at 29 ppm even after 10 hours while ceria nanoparticles and TiO2 show un even photocatalytic behavior of benzene degradation. [30] 1.7 Nanoparticles According to International standards organization (ISO). [6] • Particles with a nominal diameter (such as geometric, aerodynamic, mobility, projected area) of 100 nm or less. • Ubiquitous in nature (smoke, dust) • Human exposures and accommodation nothing new • We cannot assume that nanomaterials are same as their bulk counterpart but also assume that they are more toxic • Every particle should be tested case-by-case basis. Various advantages of Nano sizing are mentioned below: • Decreased patient-to-patient variability • Enhanced solubility • Increased oral bioavailability • Increased rate of dissolution • Increased surface area • Less amount of dose requirement • More rapid onset of therapeutic action. 1.8 Nanomaterials Nanomaterials are materials which are characterized by an ultra fine grain size (< 50 nm) or by a dimensionally limited to 50 nm. Nanomaterials can be created with various modulation dimensionalities as defined by Richard W. Siegel: zero (atomic clusters, filaments and cluster assemblies), one (multi layers), and two (ultrafine-grained over layers or buried layers), and three (Nano phase materials consisting of equally nanometer sized grains). [7] Nano materials consisting of nanometer sized crystallites or grains and interfaces may be classified according to their chemical composition and shape (dimensionality),as discussed above. We can classify Nanomaterials in to four categories. [8] 1. Clusters or powders (MD=0) 2. Multi layers (MD=1) 3. Ultra fine grained over years or buried layers (where the layer thickness or the rod-diameters are 50 nm) (MD=2) 4. Nano materials composed of equiaxed Nano meter-sized grains (MD=3) The later 3 categories can be further grouped into four families: 1. In most simple case, all grains and interfacial regions have the same chemical compositions e.g. semi crystalline polymers. 2. As the second case, we classify materials with different chemical compositions e.g. quantum well structures are the best example of this family. 3. The third family includes all materials that have a different chemical composition of its forming matter e.g. ceramics of alumina with Gallium in its interface. 4. The fourth family includes all Nano materials formed by Nano meter sized grains (layers, rods or equiaxed crystallites) dispersed in a matrix of different chemical composition e.g. nanometer sized Ni3Al precipitate dispersed in a nickel matrix generated by annealing a supersaturated NiAl solid solution are an example of such alloys. These materials have created a high interest in recent years by virtue of their unusual mechanical, electrical, optical and magnetic properties. Some of the incredible properties of nano particles are: • Tiny size • Incredible surface area per unit mass • Light weight Strong. [9] 1.8.1 Bulk material and nanoparticles Bulk materials the big material which we see around us, possess continuous macroscopic physical properties. The same applied to micron sized materials. But when particle assume nanoscale dimensions classical physics are no longer capable of describing their behavior (movement, energy etc.). The same materials at Nano scale can have properties (optical, mechanical, electrical etc) which are very different from properties of material has at the macro scale (bulk). [10] Bulk material has following properties and has following applications. [11] • Single magnetic domain (magnetic recording) • Small mean free path of electrons in a solid (special conductors) • Size smaller then wavelength (light or heat absorption, scattering) • High and selective optical absorption of metal particles (colures, filters, solar absorbers, photovoltaic, photographic material and phototropic materials • Formation of ultra fine pores due to superfine agglomeration of particles (molecular filters) • Uniform mixture of different kinds of super fine particles (R & D of new materials) • Grain size too small for stable dislocation (high strength and hardness of metallic materials). 1.9Applications Nanomaterials and Nanotechnology have great demand these days. They are having numerous applications in field of medicine, drugs, diagnostic and tissue engineering etc. • Catalysis Substance catalysis advantages especially from nanoparticles, due to the incredibly huge surface place to quantity rate. The program prospective of nanoparticles in catalysis varies from energy mobile to catalytic converters and photo catalytic gadgets. Catalysis is also essential for the development of substances. Jewelry nanoparticles are now being regarded in the next creation of automobile catalytic converters because the very high place of nanoparticles could decrease the quantity of platinum needed. However, some issues have been brought up due to tests indicating that they will automatically burn if methane is combined with the normal air. [12] • Filtration A strong influence of nano chemistry on waste-water therapy, air filtration and energy storage gadgets is to be expected. Technical or chemical techniques can be used for efficient filtration techniques. One class of filtration techniques is based on the use of walls with appropriate hole sizes, whereby the liquid is pushed through the tissue layer. [10] Nano porous walls are appropriate for an analog filtration with extremely small skin pores smaller than 10 nm (“Nano filtration”) and may be consisting of Nano tubes. Nano filtration is mainly used for the removal of ions or the separating of different liquids. On a larger scale, the tissue layer filtration technique is named ultra filtration, which works down to between 10 and 100 nm. One important field of application for ultra filtration is medical reasons as can be found in kidney dialysis. Attractive nanoparticles offer an efficient and reliable method to remove metal pollutants from spends H2O by making use of magnetic separating techniques. Low-cost nanostructure separating walls techniques have been shown to be efficient in producing safe and clean H2O in majority of folks. [13] • Agriculture Food is provided to humans by agriculture, directly and indirectly. The world’s population is increasing rapidly, it is the need of hour to use modern technology like nanotechnology in the field of agriculture and food. The applications of nanotechnology are in all stages of production, processing, storing, packaging, and transport of agricultural products. We can reduce environmental pollution by the production of pesticides and chemical fertilizers by using the nanoparticles and nano capsules. The use of nanotechnology in agricultural products increases the ability to control delivery, absorption and more effective and environmentally friendly and production of nano-crystals to increase the efficiency of pesticides for application of pesticides with lower dose. Nano particles that have entered into the arena of controlling plant diseases are nanoforms of carbon, silver, silica and alumina-silicates. [14] • Nano silver Silver nano particles have very high antimicrobial effects. A disease rose powdery mildew caused by Sphaerothecapannosa Var rosae is common disease of both green house and outdoor grown roses. The effect of this disease is leaf distortion, leaf curling, early defoliation and reduced flowering. Double capsulized nano silver prepared by chemical reaction of silver ion with aid of physical method, reducing agent and stabilizers are highly stable and very well dispersive in aqueous solution. Nano silver particles reduce unwanted microorganisms in planter soils and hydroponics systems and are perfect plant growth stimulator. [15] Fig:1.2 Application of Silver Nano-Particles • Nano Alumino-Silicate Nano-alumina silicate is used in the formulation of nano sized pesticides. The nano alumina silicate is easily picked by insect hairs. They are environmentally safe pesticides and is used in targeted delivery of chemicals into plants. • Nanoelectronics As the need for speed of operation in computer and communication technology continues to drive the search for further miniaturization of integrated circuits, the characteristic structure sizes of integrated circuits will have fallen to about 20 nanometers. Quantum effects are decisive at this scale and this will present both new problems and new opportunities. Nano-electronic research focuses on two main areas – solid-state quantum-effect device and molecular electronic device. These devices can be divided into three distinct categories: ✓ Resonant tunneling devices ✓ Single-electron transistors ✓ Quantum dots To obtain the maximum benefits from these devices will require reliable mass fabrication of features with widths of between 5 and 10 nanometers. It is probable that the employment of hybrid devices combining quantum-effect and bulk-effect components will allow the densities of microelectronic logic circuits to be increased by orders of magnitude as an intermediate stage on the way to the development of pure nano-electronic circuitry required. [16] Chapter: 2 Literature review In recent years, much effort has been focused primarily on the development of new synthetic routes for preparing nanostructure cerium oxide due to their potential uses in many applications, e.g. highstorage capacitor devices, buffer layers for conductors, fuel cells, polishing materials, UV blocks and, optical devices Several methods, such as chemical vapor deposition, physical vapour deposition (PVD electrochemistry, templates, photo induced conversion, biological synthesis. Among them, owing to the great advantages of simple process, easy scale-up and low cost, cheap the precipitation technique has attracted. Numerous techniques have been proposed to fabricate and synthesize nano-sized CeO2 has particles with promising control of properties. While some hopeful results have been achieved, the development of simple and cost - effective synthetic and fabrication processes for CeO2 (cerium- oxide) based nanomaterials are still enviable and essential for improving the properties and many applications. Otsuka, et al. in (1983) explain a fundamental behaviour of the CeO2/sub 2/ in its reduction by hydrogen and carbon monoxide and in the oxidation by water and carbon dioxide is described. It is believed that CeO2 works as an oxidation catalyst by its redox mechanism. The effects of solid additives on the rates of reduction and oxidation of the oxide are also described briefly. Lunxiang Yin et al. (2002) prepared cerium oxide (CeO2) nanoparticles sonochemically , by using cerium nitrate and azodicarbonamide as starting materials, and ethylenediamine or tetraalkylammonium hydroxide as additives. The additives have a strong effect on the particle size and particle size distribution. CeO2 nanoparticles with small particle size and narrow particle size distribution are obtained with the addition of additives; while highly agglomerated CeO2 nanoparticles are obtained in the absence of additives. Monodispersed CeO2 nanoparticles with a mean particle size of ca. 3.3 nm are obtained when tetramethylammonium hydroxide (TMAOH) is used as the additive and the molar ratio of cerium nitrate/azodi carbinamine /TMAOH is 1/1/1. Blue shifts of the absorption peak and the absorption edges of the products are observed in the UV-Vis absorption spectra as a result of the quantum size effect. The samples have been characterized using powder XRD, TEM, DLS, and absorption spectra. Ultrasound radiation is a new route for the preparation of cerium oxide nanoparticles. Small particle size and narrow particle size distribution are obtained when additives are used in the synthetic process. Blue shifts of the absorption peaks are observed. Further work on the synthesis of CeO2 nanoparticles with different precipitation agents is in progress now. [31] Zhang, et al in (2004) fabricated ultrafine CeO2 powders from a solution of cerium(III) nitrate by a two-stage precipitation process. Precipitated cerium hydroxide gel was reacted in boiling basic solutions. Amorphous cerium hydroxide gel crystallized to CeO2·nH2O (n < 2) during the lowtemperature hydrothermal treatment, and this process was effective to dehydrate the adsorbed water and decrease the hydrogen bonding effect leaving a weakly agglomerated powder. The preparation was calcined at 600°C to obtain urea. In order to avoid agglomerating during drying and calcining, sodium hexametaphosphate was introduced. The resulting powders are highly crystalline and weakly agglomerated. The objective of this work was to develop an economically feasible precipitation method that is suitable for a large scale production of ceria oxide powders. For this purpose, a two stage homogeneous precipitation was utilized to produce the cerium hydroxide. In order to avoid agglomerating during drying and calcining, anion surfactant was introduced to solve this problem. The resulting ceria oxide powders are highly crystallite. The weakly agglomerated state of the ceria powder, the fine particle size under 30nm, and the narrow size - distribution are characteristics which make the powder suitable for a variety of ceramic forming processes. [32] GAO, Feng, et al in (2006) investigated microwave hydro thermal method for synthesis of rare cerium oxide nanoparticles and nanorods. This approach combines the advantages of both hydrothermal and microwave heating techniques. It is facile, rapid, energy-saving, and environmentally-benign and leads to high-yields. The average sizes of the obtained CeO2 nanoparticles could be adjusted from ∼1.6 nm to ∼20 nm. Moreover, by changing cerium source and adjusting the amount of the added ammonia water, CeO2 nanorods could be synthesized under microwave-assisted conditions for the first time. No calcination process or surfactant is required in our experiments for both CeO2 nanoparticles and nanorods. The ultraviolet and visible (UV-vis) spectra show the obvious size-dependence of the position of the absorbance peak. The Brunaur Emmett Teller (BET) nitrogen adsorption indicates that these nanoparticles and nanorods have high specific surface areas, which are needed for potential applications in many fields. Compared with conventional hydrothermal method, microwave-assisted hydrothermal method shows its advantages of rapidity, convenience and perhaps cost-effectiveness and could be extended to the synthesis of other nanoparticles and nanorods. [33] NIU, et al 5 in (2007) stated that cerium oxide (CeO2) nanoparticles protect cells in culture from lethal stress, but no protection in vivo has been reported. Cardiac-specific expression of monocyte chemoattractant protein (MCP)-1 in mice causes ischemic cardiomyopathy associated with activation of endoplasmic reticulum (ER) stress. The aim of this study was to assess the effects of CeO2 nanoparticles on cardiac function and remodelling as well as ER stress response in this murine model of cardiomyopathy. CeO2 nanoparticles protect against the progression of cardiac dysfunction and remodelling by attenuation of myocardial oxidative stress, ER stress, and inflammatory processes probably through their auto regenerative antioxidant properties. [34] Uzma Qureshi, et al in 2009 deposited two series of composite thin films on glass by aerosol assisted chemical vapour deposition (AACVD)—nanoparticulate cerium dioxide and nanoparticulate cerium dioxide embedded in a titanium dioxide matrix. The films were analysed by a range of techniques including UV–visible absorption spectroscopy, X-ray diffraction, scanning electron microscopy and energy dispersive analysis by X-rays. The AACVD prepared films showed the functional properties of photocatalysis and super-hydrophilicity. The CeO2nanoparticle thin films displaying photocatalysis and photo-induced hydrophilicity almost comparable to that of anatase Titania. [35] Kuen-Song in 2010 provides a comprehensive overview of the recent progress of research work toward developing new one dimensional (1-D) ceria (CeO2) nanomaterials. The review has been classified into three parts: the preparation procedures with identification of the existing different dimensional ceria nanomaterials, the formation mechanisms, and an analysis of their applications. From literature survey, it is inaugurated that the fundamental structures of the ceria nanomaterials constructively dominate their properties and applications. In addition, this work will also provide a perspective on the future technical trends for the development of different dimensional CeO2 nanomaterial Ceria nanomaterials have received attraction in the past decade due to their effective applications in the fields of environmental protection and in semiconductor industries. Onedimensional ceria nanostructures have reached such potential owing to their size, shapes and crystallographic behaviours. Due to their preparation procedure and preparation mechanism, different 1-D ceria nanostructures can be accomplished. To improve the properties of the ceria nanomaterials in terms of environmental and other issues, an enormous amount of reaction mechanisms and preparation procedures have been developed. So far, correlations between the details of ceria nanomaterial preparation and the mechanisms of the 1-D nanomaterial have not been established. Therefore, an overview of several 1-D ceria nanomaterials like nanorod, nanowire/nanofiber, nanotube etc., and the preparation mechanisms and applications are provided in the present work, and should facilitate the choice of the right type of ceria for a specific application, as well as to provide a better understanding for designing new ceria based materials with the desired properties. [36] Elaheh K , et al in 2011 stated that Ceria (CeO2) is a technologically important rare earth material because of its unique properties and various engineering and biological applications. A facile and rapid method has been developed to prepare ceria nanoparticles using microwave with the average size 7 nm in the presence of a set of ionic liquids based on the bis (trifluoromethyl sulfonyl) imide anion and different cations of 1-alkyl-3-methyl-imidazolium.The structural features and optical properties of the nanoparticles were determined in depth with X-ray powder diffraction, transmission electron microscope, N2 adsorption–desorption technique, dynamic light scattering (DLS) analysis, FTIR spectroscopy, Raman spectroscopy, UV–vis absorption spectroscopy, and Diffuse reflectance spectroscopy. The energy band gap measurements of nanoparticles of ceria have been carried out by UV–visible absorption spectroscopy and diffuse reflectance spectroscopy. The surface charge properties of colloidal ceria dispersions in ethylene glycol have been also studied. To the best of our knowledge, this is the first report on using this type of ionic liquids in ceria nanoparticle synthesis. This is the first report on using this type of ionic liquids used in this work in ceria synthesis. The method is found to be convenient, rapid, cost-effective, and efficient. No surfactant was used. This is the first paper on determining the band gap of ceria nanoparticles using diffuse reflectance spectroscopy. [37] L.Yang X, et al in 2011 Nanostructured CeO2 films were prepared by cathodic electrolytic deposition (ELD) and electrophoretic deposition (EPD). Benzoic acid has been utilized for the dispersion and charging of CeO2 nanoparticles for EPD. The kinetics of ELD and EPD was investigated. Electrodeposition method has been developed for the deposition of poly (2-vinyl pyridine) (PVP) films. The thickness of the films was varied in the range of 0.1– 3 μm. The deposition mechanism was based on the pH increase in the cathodic reactions, electrophoresis of the protonated PVP macromolecules, neutralization of their charge and film formation at the cathode surface. The deposition yield was studied by the quartz crystal microbalance method. Two electrochemical strategies were developed for the fabrication of composite PVP-CeO2 films, which were based on the electrodeposition of PVP and ELD or EPD of CeO2. The composite films were studied by electron microscopy, X-ray diffraction, thermogravimetric and differential thermal analysis. The CeO2 content in the composite films was varied by the variation of bath composition. The deposition methods allowed the fabrication of crack-free PVP-CeO2 films, which provided corrosion protection of stainless steel substrates in aqueous NaCl solutions. Sharadha Thakur et al in 2013 reported a simple and rapid microwave-assisted method for synthesizing cerium oxide (CeO2) nanoparticles for the fabrication of high-performance humidity sensors. The humidity-sensing investigation reveals that the sensor based on CeO2 nanoparticles exhibits a high and linear response within the entire relative humidity (RH) range of 11–97% at an operating frequency of 60 Hz. The corresponding impedance changes by approximately three orders of magnitude within the entire humidity range from 11% to 97%. The response and recovery times are approximately 3 and 16 s, respectively. Additionally, the sensor exhibits a rapid and reversible response characterized by a very small hysteresis (∼1%RH), excellent repeatability, long term stability and a broad range of operation (11–97%RH). The Nyquist impedance plots of the sensor at different RHs were used to elucidate the sensor's humidity-sensing mechanism via an electrical equivalent circuit. The experimental results provide a possible method for the rapid synthesis and fabrication of high-performance humidity sensors based on CeO2 nanoparticles. [39] Soumen Das, et al in 2013 reported that promising results have been obtained using cerium (Ce) oxide nanoparticles (CNPs) as antioxidants in biological systems. CNPs have unique regenerative properties owing to their low reduction potential and the coexistence of both Ce3+/Ce4+ on their surfaces. Defects in the crystal lattice due to the presence of Ce3+ play an important role in tuning the redox activity of CNPs. The surface Ce3+:Ce4+ ratio is influenced by the microenvironment. Therefore, the microenvironment and synthesis method adopted also plays an important role in determining the biological activity and toxicity of CNPs. The presence of a mixed valance state plays an important role in scavenging reactive oxygen and nitrogen species. CNPs are found to be effective against pathologies associated with chronic oxidative stress and inflammation. CNPs are well tolerated in both in vitro and in vivo biological models, which make CNPs well suited for applications in nanobiology and regenerative medicine. [40] Chen et al synthesized nanocrystalline cerium oxide particles by the precipitation method and the influences of reaction temperature and atmosphere on the character of cerium oxide were investigated. Although CeO2 particles prepared by the precipitation technique have been extensively studied, most of the previous reports were focused on effects of cerium precursors, ligands and additives reaction media. Less information was reported on the influences of reaction temper Ceria oxide nanoparticles with 200-300 nm in diameter were successfully synthesized by a facile precipitation method in the presence of the difference precipitant. In this paper cerium oxide (CeO2) nanoparticles with 200-300 nm in diameter were synthesized via a precipitation method using ammonia water and oxalic acid as precipitant, respectively. The as-prepared CeO2 nanoparticles were characterized by means of diff errant techniques including X-ray, scanning electron microscopy and FT-IR. The effect of calcine temperature and precipitant on the crystal size and morphology were discussed. The results showed that the shape of CeO2 nanoparticles prepared is strongly dependent on the precipitant. The average particle size as well as the crystallite size increased with increasing the calcine temperature. The structure of the nanoparticles was fluorite -type structure in the samples Ceria oxide nanoparticles with 200-300 nm in diameter were successfully synthesized by a facile precipitation method in the presence of the difference precipitant. From the present results, the shape of CeO2 nanoparticle prepared are strongly dependent on the precipitant. The structure of the synthesized CeO2 nanoparticles were determined by means of XRD. The fluorite type structure in all the samples. [41] Majid Darroudi in 2014 by use of food-directed and natural products for the synthesised different nanoparticles (e.g., metal and metal oxide) by using food directed or natural products ,that was of enormous interest to modern nanoscience and nanotechnology. We have developed a facile and green chemistry method with bio-directed, and low cost materials for the synthesis of cerium oxide nanoparticles (CeO2-NPs) using honey. In this method, the conversion of cerium cations into CeO2NPs was achieved via a sol–gel process in aqueous honey solutions. The synthesized CeO2-NPs were characterized by the following title: UV–vis spectroscopy, field emission scanning electron microscopy (FESEM), Fourier transform infrared spectroscopy (FT-IR), thermogravimetric (TGA– DTA) analysis, Energy dispersive spectrum (EDS), and powder X-ray diffraction (PXRD). Spherical CeO2-NPs were synthesized at different calcination temperatures and FESEM imaging along with its corresponding particles size distribution indicated the formation of nanoparticles in size of about 23 nm. The PXRD analysis revealed fluorite cubic structure for CeO2-NPs with preferential orientation at (111) reflection plane. In vitro cytotoxicity studies on neuron 2A cells , a dose dependent toxicity with non-toxic effect of a concentration below about 25 µg/mL was illustrated. The synthesis of CeO2-NPs in aqueous honey solutions was found to be comparable to those obtained from conventional reduction methods that use hazardous materials proving to be an excellent alternative for the preparation of CeO2-NPs, using food and bio-derived materials. [42] M. Farahmandjoua, et al in 2016 Synthesised cerium oxide (CeO2) nanoparticles by new and simple co-precipitation method. The cerium oxide nanoparticles were synthesized using cerium nitrate and potassium carbonate precursors. Their physicochemical properties were characterized by high resolution transmission electron microscopy (HRTEM), scanning electron microscopy (SEM), X-ray diffraction (XRD), energy dispersive spectroscopy (EDS), and Fourier transform infrared spectroscopy (FTIR) and UV-Vis spectrophotometer. XRD pattern showed the cubic structure of the cerium oxide nanoparticles. The average particle size of CeO2 was around 20 nm as estimated by XRD technique and direct HRTEM observations. The surface morphological studies from SEM and TEM depicted spherical particles with formation of clusters. The sharp peaks in (FTIR) spectrum determined the existence of Ce-O stretching mode and the absorbance peak of UV-Vis spectrum showed the bandgap energy of 3.26 eV. CeO2 nanoparticles have been successful synthesized using Chemical precipitation of cerium nitrate hexahydrate and potassium carbonate. XRD spectra showed cubic fluorite structure of CeO2 identified using the standard data. SEM images indicated that with increasing temperature the morphology of the particles changes to the sphere-like shaped with less agglomeration. TEM results exhibited the spherical CeO2 nanoparticles with a diameter in the range size of 40-80 nm. FTIR data exhibited the presence of Ce-O stretching mode of CeO2. The Ceria nanoparticles showed a strong UV-vis absorption at 500 nm with a well-defined absorption peak at 380 nm and finally the direct band gap was determined about 3.26 eV. [43] Fahima Char goo, et al in 2017 stated that CeO2 nanoparticles (NPs) have promising approaches as therapeutic agents in biology and medical sciences. The physicochemical interactions of the NP with target cells. Recently, CeO2-NPs have been synthesized through several bio-directed methods applying natural and organic matrices as stabilizing agents in order to prepare biocompatible CeO2NPs, thereby solving the challenges regarding safety, providing the appropriate situation for their effective use in biomedicine. This review discusses the different green strategies for CeO2-NPs synthesis, their advantages and challenges that are to be overcome. In addition, this review focuses on recent progress in the potential application of CeO2-NPs in biological and medical fields. Exploiting biocompatible CeO2-NPs may improve outcomes profoundly with the promise of effective neurodegenerative therapy and multiple applications in nanobiotechnology. Properties of CeO2-NPs, such as size, agglomeration status in liquid, and surface charge, play important roles in the ultimate. [44] Jazmin Calvache-MuñozFabiola, et al in 2017 synthesized cerium oxide (ceria,) using a modified polymer complex process (modified Echini) , while varying the pH of the system. This methodology made it possible to obtain, in a reproducible and controlled was, nanoparticles of ceria (< 100 nm) of a high chemical purity at low temperatures. The precalcined cerium solid obtained at350°C was characterized using differential thermal analysis (DTA), thermogravimetric analysis (TG) and IR (infra-red) spectroscopy. Very little organic phase was found in the respective spectra, indicating that the inorganic phase, cerium oxide, is predominant. Carbonaceous residues still present in the solids were removed by heating at temperatures above 500°C and the samples obtained were characterized using X-ray diffraction (XRD IR, UV–visible absorption and diffuse reflectance spectroscopies, and Transmission Electron Microscopy (TEM). The diffractograms of the samples showed that the only crystalline phase present was CeO2. From the results of UV-visible absorption and diffuse reflectance spectroscopy, two important energy values were obtained, 3.8 eV and 3.4 eV. These could be attributed to the energy gap value (3.8 eV) and to a possible “mid-gap” (3.4 eV). Furthermore, on increasing the synthesis pH, a reduction in particle size results, the particle being between 10 and 20 nm, with a spheroidal shape. By looking at the different stages of the synthesis process, a mechanism is proposed to explain how nanoparticles of ceria are formed. [45] M. A. Majeed Khan, et al in (2017) explored the microstructural, optical and photo catalytic properties of undoped and 5% Zn doped CeO2 nanocrystals (NCs) through various analytical techniques, viz. powder x-ray diffraction (PXRD), x-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), UV-visible, Raman and photoluminescence (PL) spectroscopy. XRD data analysis revealed face centered cubic (FCC) crystal symmetry of the samples with average crystallite size in the range of 19 – 24 nm. XPS results confirmed that the Zn ions exist in +2 states and successfully incorporated into the CeO2 matrix. Internal structure and morphology observed by TEM exhibited almost uniform cubical shape of the particles of average size ~20–26 nm. The energy band gap of undoped and Zn doped CeO2 NCs had a direct transition of 3.46 eV and 3.57 eV respectively as estimated by the optical absorption data. The increase in the band gap revealed blue shift of absorption edge due to the quantum confinement effects. The NCs exhibited an inherent luminescence emission peak at ~408 nm in PL spectra. Improvement in the photo catalytic activity was observed for Zn incorporated sample attributed to the enhanced light absorption or/and fall in charge recombination rate between CeO2 and Zn. In summary, undoped and Zn doped CeO2 NCs have been studied to explore their structural, optical and photo catalytic properties through various techniques like XRD, XPS, TEM/HRTEM, Raman, UV-visible and photoluminescence (PL) spectroscopy. Average grain size estimated from the Williamson–Hall analysis, Debye–Scherer equation and TEM image analysis are very close to each other. The analysis of XRD data and Raman spectroscopy established highly pure, single phase and cubic fluorite structure of the samples, and slightly increase in lattice parameter was also observed with the reduction in crystallite size. The effect of band gap tuning was observed in UV-visible absorption spectra of CeO2 NCs with Zn incorporation. A blue shift in the absorption was observed in CeO2 NCs compared to its bulk counterpart, as well as for Zn doped CeO2 sample. It was also demonstrated that the crystallinity and luminescence properties of the nanocomposite increased significantly after Zn doping. Finally, Zn doped CeO2 NCs exhibit superior photo catalytic performance compared to undoped NCs for the degradation of methylene blue dye under visible light. [46] Fang Jian Lin, et al stated that (2015) the structure of doped ceria plays an important role in its chemical reactivity and catalytic performance. However, for the majority of the dopants studied, whether a monophasic solid solution is formed or not is typically determined only by standard X-ray diffraction (XRD). In-depth structural characterization is lacking. In this paper we have prepared Zn-doped ceria nanocrystals exhibiting twice the oxygen storage capacity (OSC) of pure ceria. X-ray photoelectron spectroscopy (XPS) shows that the material is chemically inhomogeneous with zinc enrichment in the surface layer. X-ray fluorescence (XRF) reveals significant compositional in homogeneity of the material after annealing in air at 1300°C for 24 h. The standard structural characterization of this material using room temperature XRD and transmission electron microscopy (TEM) fails to reveal its correct phase composition. Based on clear evidence from in situ high temperature XRD we show that, after calcinations at 500°C, the material is not monophonic: X-ray amorphous ZnO is present within the material. The amorphous ZnO crystallizes at 800°C and undergoes second-stage incorporation at even higher temperatures. This second-stage incorporation is not complete after annealing and trace amounts of ZnO remain according to synchrotron-based XRD. Our work provides valuable insight into the incorporation mechanism of zinc into the ceria lattice, and in particular, raises some doubts on the phase compositions reported in many previous studies on doped ceria. In summary, we have synthesized Zn-doped ceria nanocrystals that exhibit twice the OSC of pure ceria. It is shown by XPS that these materials are chemically inhomogeneous on the nanometer scale, with zinc enrichment at the surface. After annealing at 1300 °C the spatial distribution of zinc on the micrometer scale becomes also inhomogeneous. Our work also shows that a combination of commonly applied characterization techniques (such as room temperature XRD and TEM) is not sufficient to determine the correct. [47] Chapter: 3 Experimental work 3.1 Fabrication technique Manufacturing process in which sample is fabricated from raw materials instead of being assembled from ready-made components or parts. 3.2 Chemicals Cerium oxide Ethanol or methanol Acetone or isopropyl alcohol 3.3 Procedure Cerium oxide powders were weighed on balance machine and mixed by ratio of 99.9 % cerium oxide 3.3.1. Pallet Formation Zinc doped cerium oxide pallet with dimension 2g was made in carver hydraulic press. Holder of carver press was cleaned using ethanol, methanol can also be used. Grinded mixture of nanoparticles was put on the holder and then set into the caver presser. Pressure of about 15000 pounds was applied twice for few minutes (2 or 3 minutes). [48] 3.3.2 Substrate Cleaning Silicon wafers (substrate) were washed with detergent. Then they were set into the sonicate and were sonicated in acetone for 10 to 15 minutes. Then wafers were soaked into the DI water and sonicated again. After cleaning they were left for drying. After drying substrate, pallet was set into the electron beam chamber for development of thin film. We use two techniques for fabrication of CeO2 thin films: 1. Electron Beam Evaporation 2. Annealing 3.4 Electron Beam Evaporation The physical meaning of electron beam evaporation is that there will be a process of evaporation of which a change of phase will occur from liquid to vapor and this evaporation activity will be done by the beam of electrons. [49] Electron Beam Evaporation is a form of Physical Vapor Deposition in which an electron beam from a charged tungsten filament is bombarded on the target material to be used as a coating to evaporate and convert it to a gaseous state for deposition on the material to be coated. The process takes place in a high vacuum chamber. Atoms or molecules in a vapor phase then precipitate and form a thin film coating on the substrate. It is a Thermal Evaporation process, and Sputtering are the two most common types of Physical Vapor Deposition or PVD. In vacuum chamber, thermal energy of atoms or molecules is less than 1 eV and can be used to coat a substrate positioned above the evaporating material at the average working distances of 300 mm to 1 meter. Since thermal energy is so low, the pressure in the chamber must be below the point where the mean free path is longer than the distance between the electron beam source and the substrate. The mean free path is the average distance an atom or molecule can travel in a vacuum chamber before it collides with another particle thereby disturbing its direction to some degree. This is typically around 3.0 x 10-4 Torr or lower. The main reason to run an e-beam evaporation process at the high end of the pressure range is to allow a wide beam ion beam source to be employed simultaneously for film densification or other property modification and wide beam ion beam sources do not typically operate below 1x10-4 Torr. Evaporation without ion beam assist can be done at any pressure below this although the process always increases the pressure due to outgassing of some things within the vacuum chamber. [50] 3.4.1 Working Principle Electron beam evaporation is a process of evaporation in which evaporated material is deposited on the substrate by using beam of electrons to evaporate the desired material to form thin film. The work chamber and the beam generating system are evacuated to enable generation and unimpeded propagation of electron beams. When the beam hits the evaporate, the kinetic energy is converted into heat (useful energy and evaporation) and losses encountered are back scattered electrons, secondary electrons, thermionic electrons and X-radiation. [51] 3.4.2 Working The electron beam is produced by a hot filament which is represented by the symbol of resistor. The process of the evaporation is taken place in a high vacuum area to allow molecules to move freely in the chamber and hence condense on all surfaces including the substrate on the principle of evaporation. Fig: 3.1 working of electron beam evaporation a) Heating of filament The first stage is a process of heating filament. The hot filament is heated to produce a beam of electrons by applying thermionic emission. Thermionic emission is a procedure of discharging of electrons the hot filament. Sufficient amount of energy is required to overcome the attractive force that holds the electron together. The electrons move randomly once they get excited. b) Heating of target In second stage the targeted material is heated. The source of the heating is the beam of electrons that is produced from stage one. Excited electrons move randomly in the high vacuum area without any force of attraction to it. In order to use effectively beam of electron must have certain path. For this purpose two magnets are used. The first magnet is a focusing magnet that is used to attract the electrons towards it right. The deflecting magnet is used to deflect the route of the beam of electrons towards the material to be evaporated. The material will be heated up to a boiling point, by the principle of evaporation. At boiling point, the molecules evaporated material will collide and transfer energy to each other and thus the liquid would turn into vapor. Therefore, the evaporated material is now be able to move freely in the high vacuum area. c) Deposition The third stage is the deposition of the evaporated material on the substrate (silicon). Evaporate move towards the substrate and attach on it. The material evaporate which is now in form of vapor. [52] Fig: 3.2 deposition of sublimated material 3.4.3 Advantages [53] I. The minimum deposition rate is 1 nm per minute and the maximum rate is few micrometers per minute. II. The material utilization efficiency is high relative to other methods, and the process offers structural and morphological control of films. III. Due to the very high deposition rate, this process has potential industrial application for wear-resistant and thermal barrier coatings in aerospace industries, hard coatings for cutting and tool industries, and electronic and optical films for semiconductor industries and thin-film solar applications. IV. V. Electron beam evaporation has high film deposition rate. It creates less surface damage from the impurity atom and produce the films of high purity. VI. There is the less chance for substrate to be heated unintentionally. 3.4.4 Disadvantages [54] I. EBPVD is a line-of-sight deposition process when performed at a low enough pressure roughly less than 10−4 Torr .At pressures of roughly 10−4 Torr (1.3×10−4 hPa) or higher, significant scattering of the vapor could takes place such that surfaces not in sight of the source can be coated. The slow transition from line-of-sight to scattered deposition is determined not only by pressure or mean free path but also by source-to-substrate distance. II. This process is only suitable for coating the outer surface of complex geometries due to the translational and rotational motion of the shaft. This process cannot be used to coat the inner surface of complex geometries. III. Due to the degradation filament in the electron gun results in a non-uniform evaporation rate. IV. Difficult to be controlled incapable of doing surface cleaning, harder to improve the step coverage and could cause x-ray damages by the electron beam evaporation. 3.5 Annealing Annealing is a heat treatment in metallurgy and materials science. It alters the physical and sometimes chemical properties of a material to increase its ductility by reducing its hardness and making it more workable. In annealing process material is heated above its recrystallization temperature for particular time and then cooling. [55] 3.5.1Stages There are three stages of the annealing process: [56] 1. Recovery 2. Recrystallization and 3. Grain growth • Recovery The first stage is recovery, and it results in softening of the metal through removal of primarily linear defects called dislocations and the internal stresses they cause. Recovery occurs at the lower temperature stage of all annealing processes and before the appearance of new strain-free grains. The grain size and shape do not change. [57] • Recrystallization In the recrystallization stage new strain-free grains nucleate and grow to replace those deformed by internal stresses. [58] • Grain growth If annealing is continue after recrystallization, and then grain growth occurs. In grain growth, the metal loses substantial part of its original strength due to coarsen of microstructures that can however be regained with hardening. [59] 3.5.2 Types of Annealing There are various types of annealing. 1. Full Annealing The purpose of full annealing is to originate a uniform and stable microstructure that most closely resembles the metal's phase diagram equilibrium microstructure. We get relatively low levels of hardness, yield strength and ultimate strength with high plasticity and toughness. For example involves steel is heated to 30 to 50 degrees Centigrade above the critical temperature of steel and maintaining the temperature for a specified period of time, then allowing the material to slowly cool down inside the furnace itself without any forced means of cooling to attain equilibrium microstructure . But in some cases it is air cooled. Hot Worked sheets, forgings, and castings made from medium and high carbon steels need full annealing. 2. Process Annealing It is also called intermediate annealing. It restores some of the ductility to a product being coldworked without breaking. This process is mainly suited for low carbon steel. The steel is heated up to a temperature just below the lower critical temperature of steel. It is difficult to work on cold worked steel because there is increased hardness and decrease ductility. These characteristics are improved by Process annealing. This is mainly carried out on cold rolled steel like wire drawn steel, etc. 3. Stress Relief Annealing Internal stresses are produced in large castings or welded structures during their manufacture and uneven cooling that causes brittleness at isolated locations and sudden breakage or failure of the material. The material is heated about 650 degrees centigrade to relief stress. The temperature is maintained constantly for a few hours and allowed to cool down slowly. 4. Spheroids Annealing This is a process for high carbon and alloy steel in order to improve their machinability. The process tends to improve the internal structure of the steel. This can be done by two methods: a. The material is heated just below the lower critical temperature about 700 Degrees centigrade and the temperature is maintained for about 8 hours and allowed to cool down slowly. b. Heating and cooling the material alternatively between temperatures just above and below the lower critical temperature. 5. Isothermal Annealing This is a process where is steel is heated above the upper critical temperature. This causes the structure of the steel to be converted rapidly into austenite structure. The steel is then cooled to a temperature below the lower critical temperature about 600 to 700 Degree Centigrade. This cooling is done using a forced cooling means. The temperature is then maintained constant for a specified amount of time in order to produce a homogenous structure in the material. This is mainly applicable for low carbon and alloy steels to improve their machinability. 6. Short cycle annealing Short cycle annealing is used for turning normal ferrite into malleable ferrite. It consists of heating, cooling and then heating again from 4 to 8 hours. 3.5.3 Advantages of Annealing The following are some of the advantages of annealing. [60] · It softens the steel. · It enhances and improves the machinability of steel. · It increases the ductility of steel · It enhances the toughness of steel · It improves the homogeneity in steel · The grain size of the steel is refined a lot by annealing · It prepares the steel for further heat treatment 3.5.4 Properties of annealed material • Bend with pressure • Deformed easily than Hardened Metals • Low hardness, yield strength, tensile strength of the steel • Annealing induce ductility • Homogenized structure 3.6 Characterization Techniques The aim is to give a basic knowledge of experimental techniques used for characterization of structural and electronic properties in materials science. To develop experimental skills and abilities for critical analysis and scientific reporting. The techniques that we have done are: • DRS • XRD • I-V 3.6.1 Diffuse Reflectance Spectroscopy Infrared spectroscopy can be used to determine solid, liquid or gas samples. Here we talk about the assessment of solids, especially powder samples, through diffuse reflection. Fig: 3.2.1 Perkin Elmer lambdas 950 The optical phenomenon known as diffuse reflectance is commonly used in the UV-visible, nearinfrared (NIR), and mid-infrared (sometimes called DRIFT or DRIFTS) regions to obtain molecular spectroscopic information. It is usually used to obtain spectra of powders with minimum sample preparation. A reflectance spectrum is obtained by the collection and analysis of surface-reflected electromagnetic radiation as a function of frequency (v, usually in wave numbers, cm) or wavelength (usually in nanometers, nm). [61] • Two different types of reflection can occur 1- Regular or specular reflection usually associated with reflection from smooth, polished surfaces like mirrors 2- Diffuse reflection associated with reflection from so-called mat or dull surfaces textured like powders. Fig: 3.2.2 Types of reflection 3.6.1.1 Principle of the Diffuse reflection When light shines on a powder it participates, it is reflected at random, as shown in figure. Some of the lights experience specular reflection on the surface of the powder. Due to the type of powder forms, it is reflected in many directions, unlike the light reflected by a mirror. The rest of the light is refracted upon entering the dust, where it is scattered due to internal reflection, reflection from the surfaces of other dust grains or periodic access to refraction in the dust. Some quantity of this scattered light is transmitted to the air. [62] As diffuse reflected light reflects or permeates the dust, it weakens if the powder penetrates. This leads to a diffuse reflected range, such as the transmission range. On the other hand, in regions where the dust has an intense penetration, most of the diffuse reflected light in long paths of light is consumed, so that only the diffuse reflected light that comes out of the short-light paths is sent back in the air. On the contrary, in the weak absorption bands, part of the light is not absorbed even in the long light paths and this diffuse reflected light is emitted to the air, which results in peaks stronger than the transmission spectrum. In diffuse reflectance spectrum, the absorbed wave number positions are the same as the transmission spectrum. However, the relative intensity between the peaks differs from the transmission spectrum because weak peaks in the transmission spectrum become comparatively stronger in the diffuse reflectance spectrum. The so-called k-m function (f (r∞)) derived from Kubelka-Munk is used for comparison with transmission spectra or chemical tests. (3.1) Where, R∞ is the absolute reflectance, K is the absorption coefficient, and S is the dispersion coefficient. However, due to the difficulty of measuring the absolute reflectance R∞, in practice, the comparative reflectance r∞ with respect to a standard powder such as KBr or KCl, of which K is almost zero (0) in the range of real measurement. (3.2) The light transmitted to the air from the powder contains specular reflection light, as well as diffuse reflected light. The specular reflection light must be shortened to obtain a more defined diffuse reflectance range. To achieve this, the particle size must be reduced. It is said that reducing the particle size to a size equivalent to the wavelength decreases the proportion of specular reflection light and maximizes dispersion efficiency. The particle shape and the quality of the packaging are other important factors, besides the particle size. The samples are generally not measured immediately, but in a diluted form at an appropriate concentration (1% to 10%) in a standard powder KBr or KC 3.6.1.2 How Diffuse Reflectance Works Diffuse reflectance relies upon the focused projection of the spectrometer beam into the sample where it is reflected, scattered and transmitted through the sample material (shown below). The back reflected, diffusely scattered light (some of which is absorbed by the sample) is then collected by the accessory and directed to the detector optics. Only the part of the beam that is scattered within a sample and returned to the surface is considered to be diffuse reflection. Some powders may be analyzed by diffuse reflectance as neat samples (coal samples, soil samples, diffuse coatings on a reflective base). Usually, the sample must be ground and mixed with a non- absorbing matrix such as KBr. The sample to matrix ratio is generally between 1 to 5% (by weight). Diluting ensures a deeper penetration of the incident beam into the sample which increases the contribution of the scattered component in the spectrum and minimizes the specular reflection component. The specular reflectance component in diffuse reflectance spectra causes changes in band shapes, their relative intensity, and, in some cases, it is responsible for complete band inversions (Restorable bands). Dilution of the sample with a non-absorbing matrix minimizes these effects. [63] 3.6.2 X-Ray Diffraction: • Definition Scattering of X-rays by the atoms of a crystal that produces an interference effect so that the diffraction pattern gives information on the structure of the crystal or the identity of a crystalline substance. X-ray diffraction (XRD) is a powerful non-destructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientation, and other structural parameters, such as average grain size, crystallinity, strain, and crystal defects. X-ray diffraction peaks are produced by constructive interference of a monochromatic beam of X-rays scattered at specific angles from each set of lattice planes in a sample. The peak intensities are determined by the distribution of atoms within the lattice. Consequently, the X-ray diffraction pattern is the fingerprint of periodic atomic arrangements in a given material. [64] Fig: 3.3 X-Ray Diffraction 3.6.2.1 Principle XRD analysis is based on constructive interference of monochromatic X-rays and a crystalline sample. The X-rays are generated by a cathode ray tube, filtered to produce monochromatic radiation, collimated to concentrate, and directed toward the sample. The interaction of the incident rays with the sample produces constructive interference (and a diffracted ray) when conditions satisfy Bragg’s Law N λ =2d sin θ (3.3) This law relates the wavelength of electromagnetic radiation to the diffraction angle and the lattice spacing in a crystalline sample. The characteristic x-ray diffraction pattern generated in a typical XRD analysis provides a unique “fingerprint” of the crystals present in the sample. When properly interpreted, by comparison with standard reference patterns and measurements, this fingerprint allows identification of the crystalline form. [65] Fig: 3.3.1 Schematics of XRD 3.6.2.2 Bragg’s law Bragg diffraction (also referred to as the Bragg formulation of X-ray diffraction) was first proposed by Lawrence Bragg and his father William Henry Bragg in 1913 in response to their discovery that crystalline solids produced surprising patterns of reflected X-rays in contrast to that of, say, a liquid. [66] ➢ Bragg’s condition Bragg diffraction occurs when radiation, with a wavelength comparable to atomic spacings, is scattered in a specular fashion by the atoms of a crystalline system, and undergoes constructive interference. For a crystalline solid, the waves are scattered from lattice planes separated by the interplanar distance d. When the scattered waves interfere constructively, they remain in phase since the difference between the path lengths of the two waves is equal to an integer multiple of the wavelength. The path difference between two waves undergoing interference is given by 2dsin θ, where θ is the scattering angle. The effect of the constructive or destructive interference intensifies because of the cumulative effect of reflection in successive crystallographic planes of the crystalline lattice (as described by Miller notation). This leads to Bragg's law, which describes the condition on θ for the constructive interference to be at its strongest. [74] Fig: 3.16 Bragg diffraction (Two beams with identical wavelength and phase approach a crystalline solid and are scattered off two different atoms within it. The lower beam traverses an extra length of 2dsinθ. Constructive interference occurs when this length is equal to an integer multiple of the wavelength of the radiation.) ➢ Mathematical form n λ =2d sin θ(3.4) (3.4) Where n is a positive integer and λ is the wavelength of the incident wave Bragg's law, as stated above, can be used to obtain the lattice spacing of a particular cubic system through the following relation: [67] (3.5) where α is the lattice spacing of the cubic crystal, and h, k, and ℓ are the Miller indices of the Bragg plane. Brags law become; (3.6) 3.6.2.3 Scherrer equation The Scherrer equation, in X-ray diffraction and crystallography, is a formula that relates the size of sub-micrometer particles, or crystallites, in a solid to the broadening of a peak in a diffraction pattern. It is named after Paul Scherrer. It is used in the determination of size of particles of crystals in the form of powder. The Scherrer equation can be written as: [68] (3.7) where: г is the mean size of the ordered (crystalline) domains, which may be smaller or equal to the grain size K is a dimensionless shape factor, with a value close to unity. The shape factor has a typical value of about 0.9, but varies with the actual shape of the crystallite; ʎ is the X-ray wavelength β is the line broadening at half the maximum intensity (FWHM), after subtracting the instrumental line broadening, in radians. ϴ is the Bragg angle. The Scherrer equation is limited to nano-scale particles. It is not applicable to grains larger than about 0.1 to 0.2 μm, which precludes those observed in most metallographic and cerographic microstructures. It is important to realize that the Scherrer formula provides a lower bound on the particle size. The reason for this is that a variety of factors can contribute to the width of a diffraction peak besides instrumental effects and crystallite size; the most important of these are usually inhomogeneous strain and crystal lattice imperfections. [69] 3.6.2.4 Types: • Identification analysis: XRD analysis for identification purposes, according to Ph. Eur. 2.9.33., using a standard scan program over the interval: 2°-60° 2Θ. • Quantitative analysis: Quantification of crystalline or amorphous content in a sample is determined by use of a calibration line, relating peaks intensities to crystalline sample content. • XRD Test This test method is performed by directing an x-ray beam at a sample and measuring the scattered intensity as a function of the outgoing direction. Once the beam is separated, the scatter, also called a diffraction pattern, indicates the sample’s crystalline structure. The Rietveld refinement technique is then used to characterize the crystal structure which most likely provided the observed pattern. 3.6.2.5 Applications of XRD X-Ray diffraction is primarily used for: [78] ✓ Identification of crystalline material (used for regulatory purposes or during development) ✓ Identification of different polymorphic forms ✓ Identification of miller indices ✓ Distinguishing between amorphous and crystalline material ✓ Quantification of the percent crystallinity of a sample ✓ For non-ambient structural analysis ✓ For stability studies 3.6.3 IV-Characteristics I-V curve or current-voltage characteristic is a graphical representation of the relationship between the voltage applied across an electrical device and the current flowing through it. It is one of the most common methods of determining how an electrical device functions in a circuit. Current-Voltage characteristics curves can be used to plot the operation of any electrical or electronic component from resistors, to amplifiers, to semiconductors and solar cells. I-V characteristic curves are generally used as a tool to determine and understand the basic parameters of a component or device and which can also be used to mathematically model its behavior within an electronic circuit. But as with most electronic devices, there are an infinite number of I-V characteristic curves representing the various inputs or parameters and as such we can display a family or group of curves on the same graph to represent the various values. [70] Figure 3.4: IV apparatus. Chapter 4 Result and discussion After the thin film fabrication, characterizations were done to study about their structural, morphological and optical properties. 4.1 XRD result and discussion This technique is used to study the phase identification of a crystalline material which is annealed at different temperatures of 200°C, 400°C and 700°C for 1 hour. The graphs of intensity v/s 2θ are shown below where intensity is the arbitrary units. un-annealed thin film, it shows three peaks of cerium oxide having(111),(311) and (200) crystalline plane . Thin film which is annealed at 200°C, it shows five peaks of cerium oxide having (111), (311), (220) and (222) crystalline plane. Thin film which is annealed at 200°C, it shows four peaks of and cerium oxide having (111), (220), (002), (222) and (331) crystalline plane. Thin film which is annealed at 700°C, it shows four peaks of cerium oxide having (111), (222), (311) and (222) crystalline plane respectively. (111) 200 150 50 (200) 100 (311) Intensity (a.u) 250 0 20 40 60 80 2θ (Degree) Figure: 4.1 XRD result of un-annealed CeO2 thin film. 0 20 (222) (220) (311) (111) Intensity (a.u) 500 450 400 350 300 250 200 150 100 50 0 40 60 2θ (Angle) 80 (331) (002) (222) 500 450 400 350 300 250 200 150 100 50 0 (111) Intensity (a.u) Figure 4.2 : XRD results of CeO2 thin film annealed at 200°C. 0 20 40 60 80 100 2θ (degree) Figure 4.3: XRD results of CeO2 thin film annealed at 400°C. 100 300 200 150 (311) 100 (222) (222) Intensity (a.u) 250 50 0 0 20 40 60 80 100 2θ (degree) Figure 4.4: XRD result of CeO2thin film annealed at 700°C. Annealing temperature v/s crystallite size Crystallite size start increasing from 25°C to700°C we have the highest crystallite size 80 Crystallite sise (nm) 70 60 50 40 30 20 10 0 0 100 200 300 400 500 600 700 Temperature ̊C Figure 4.5: Graph of crystallite size and annealing temperature 800 4.2 DRS result and discussion This technique is used to study the reflectance of a crystalline material which is annealed at different temperatures of 200°C, 400°C and 700°C for 1 hour. sample which is un-annealed is almost 5% reflector of UV light and are then reflecting 25% of light in visible region and in infrared region its reflection is 45%. sample which is annealed at 200°C is almost 40% reflector of UV light and is then reflectance of light in visible region is very less which show absorbance and in infrared region its reflection is 25%. sample which is annealed at 400°C is almost 20 % reflector of UV light and is then reflection decreases in visible region from 400 nm to 800 nm and in infrared region its reflection is 30%. the sample which is annealed at 700°C is almost 20% reflector of UV light and is then reflecting constantly light in visible region and in infrared region its reflection is 32%.The Dip between 200 nm – 400 nm at all temperature 25°C,20 °C,400°C and at 700°C which shows absorption in the region. Reflectance % 4.2.1 Result for Reflectance 50 45 40 35 30 25 20 15 10 5 0 0 200 400 600 800 1000 1200 1400 Wavelength (nm) Figure 4.6: DRS result for reflectance v/s wavelength for un-annealed CeO2 thin film. 45 40 Reflectance % 35 30 25 20 15 10 5 0 0 200 400 600 800 1000 1200 1400 Wavelegth (nm) Figure 4.7: DRS result for reflectance v/s wavelength for annealed CeO2 thin film at 200°C. 35 30 Reflectance % 25 20 15 10 5 0 0 200 400 600 800 1000 1200 1400 Wavelength (nm) Figure 4.8: DRS result for reflectance v/s wavelength for annealed CeO2thin film at 400°C. 35 Reflectance % 30 25 20 15 10 5 0 0 200 400 600 800 1000 1200 1400 Wavelength (nm) Figure 4.9: DRS result for reflectance v/s wavelength for annealed CeO2 Thin film at 700°C. 4.2.2 Band gap study Following graphs show band gap energy of cerium oxide thin films in different regions. at room temperature Band gap lies in visible region and band gap energy is 3.2 eV. after annealing At 200 ˚C gradually increase in Bandgap and band gap energy is 5.9 eV. At 400 ˚C Bandgap decreases Slightly and band gap energy is 5.2 eV. with increase in temperature at 700°C band gap decreases and the band gap energy is 4.2 eV. 9.00E+12 8.00E+12 7.00E+12 (αhν) 2 6.00E+12 5.00E+12 4.00E+12 3.00E+12 2.00E+12 1.00E+12 0.00E+00 0 1 2 3 4 5 6 Bandgap Energy(eV) Figure 4.10: DRS result for (αhν) 2 v/s energy for un-annealed CeO2 thin film. 3.5E+33 3E+33 (σhѵ)2 2.5E+33 2E+33 1.5E+33 1E+33 5E+32 0 0 1 2 3 Bandgap Energy(eV) 4 5 6 7 Figure 4.11: DRS result for (αhν) 2 v/s energy for annealed CeO2 thin film at 200°C. (αhν)2 0.000018 0.000016 0.000014 0.000012 0.00001 0.000008 0.000006 0.000004 0.000002 0 0 1 2 3 4 5 6 7 Bandgap energy (eV) Figure 4.12: DRS result for (αhν) 2 v/s energy for annealed CeO2 thin film at 400°C. 1.20E+07 1.00E+07 (σhѵ)2 8.00E+06 6.00E+06 4.00E+06 2.00E+06 0.00E+00 0 1 2 3 4 Bandgap energy (ev) 5 6 Figure 4.13: DRS result for (αhν) 2 v/s energy for annealedCeO2 thin film at 700°C. 7 4.3 IV Characteristics result and discussion This technique is used to study the electrical behavior of a crystalline material which is annealed at different temperatures of 200°C, 400°C and 700°C for 1 hour. The graphs of current v/s voltage are shown below 4.50E-01 Current (A) 3.50E-01 2.50E-01 1.50E-01 5.00E-02 -2.00E-01 0.00E+00 2.00E-01 4.00E-01 6.00E-01 8.00E-01 1.00E+00 1.20E+00 Voltage (v) Figure 4.14: IV curve result for current v/s voltage for un-annealed CeO2 thin film. 3.50E-06 Current (A) 3.00E-06 2.50E-06 2.00E-06 1.50E-06 1.00E-06 5.00E-07 0.00E+00 2.00E-01 4.00E-01 6.00E-01 8.00E-01 1.00E+00 1.20E+00 Voltage (v) Figure 4.15: IV curve result for current v/s voltage for annealed CeO2 thin film at 200°C. 3.50E-06 3.00E-06 Current (A) 2.50E-06 2.00E-06 1.50E-06 1.00E-06 5.00E-07 0.00E+00 0.00E+00 2.00E-01 4.00E-01 6.00E-01 Voltage (V) 8.00E-01 1.00E+00 1.20E+00 Figure 4.16: IV curve result for current v/s voltage for annealed CeO2 thin film at 400°C. 6.60E-06 5.50E-06 Current (A) 4.40E-06 3.30E-06 2.20E-06 1.10E-06 0.00E+00 -2.00E-01 0.00E+00 -1.10E-06 2.00E-01 4.00E-01 6.00E-01 8.00E-01 1.00E+00 1.20E+00 Voltage (V) Figure 4.17: IV curve result for current v/s voltage for annealed CeO2 thin film at 700°C. Annealing temperature v/s conductivity 30 Conductivity 25 20 15 10 5 0 0 100 200 300 400 500 600 700 800 Temperature Figure 4.18: Graph of annealing temperature and conductivity in light. Figure 4.18 shows that conductivity is highest at 400°C.In light, conductivity is more due to the photons. 4.4 Conclusion Uniform cerium oxide thin films prepared by e-beam evaporation and then annealed at different temperatures show change in structural, optical and electrical properties when characterized by XRD, DRS and IV characteristics. Temperature affects the structure of thin films as much as annealing. At room temperature we get cerium oxide peak at 28°C. As the temperature was increased to 200°C and then cerium oxide peak started to decrease as we increase the temperature. At 700°C we have the least crystallite size because of breaking of bonds at high temperature. Crystallite size varying from 50 nm-73 nm was calculated by Debye Scherer formula. As temperature increase, there is activation in cerium oxide molecules. DRS analysis shows that by changing the temperature the band gap shifts from 3.2 eV-5.9 eV (visible to infrared region). Thin films annealed at different temperatures are good absorber of visible light and good reflector of ultraviolet and IR light. IV analysis (in light) shows as shift towards ohmic behavior as the temperature increases. Conductivity of the annealed thin films was highest at 400°C. By studying all the properties of cerium oxide nanoparticles, we concluded that we can use them in different optoelectronic devices, in photo catalytic activities and in biomedical. References 1. Drexler, K. Eric (1992). Nanosystems: Molecular Machinery, Manufacturing, and Computation. New York: John Wiley & Sons. ISBN 978-0-471-57547-4. 2. Wolfram, Stephen (2002). A New Kind of Science. Wolfram Media, Inc. p. 1193. ISBN 9781-57955-008-0. 3. "Nanotechnology Information Center: Properties, Applications, Research, and Safety Guidelines". American Elements. Retrieved 13 May 2011. 4. Drexler, K. Eric (1986). Engines of Creation: The Coming Era of Nanotechnology. Doubleday. ISBN 978-0-385-19973-5. 5. Analysis: This is the first publicly available on-line inventory of nanotechnology-based consumer products". The Project on Emerging Nanotechnologies. 2008. Archived from the original on 5 May 2011. Retrieved 13 May 2011. 6. "ISO/TS 80004-2: Nanotechnologies — Vocabulary — Part 2: Nano-objects". International Organization for Standardization. 2015. Retrieved 18 January 2018. 7. Buzea, Cristina; Pacheco, Ivan; Robbie, Kevin (2007). "Nanomaterials and Nanoparticles: Sources and Toxicity". Biointerphases. 2 (4): MR17–MR71. arXiv:0801.3280. 8. "ISO/TS 80004-2:2015 - Nanotechnologies — Vocabulary — Part 2: Nano-objects". International Organization for Standardization. 2015. Retrieved 8 January 2018. 9. Ramsden, J.J. (2011) Nanotechnology: An Introduction, Elsevier, Amsterdam. 10. Reversible Thermoelectric Nanomaterials T. E. Humphrey and H. Link Phys. Rev. Lett. 94, 096601 – Published 9 March 2005. 11. Bond, J.E.; Wintz, S. "Blending and control systems technologies for cement raw materials revisited - PGNA analyzer application review - An example from Lafarge's Davenport plant in Buffalo, Iowa USA" 53rd Cement Industry Technical Conference, 2011. Conference Record IEEE-IAS/PCA, May 2011, 18 pp. 12. PierluigiBarbaro, Francesca Liguori, ed. (2010). Heterogenized homogeneous catalysts for fine chemicals production : materials and processes. Dordrecht: Springer. ISBN 978-90-4813695-7. 13. Raymond D. Letterman (ed.)(1999). "Water Quality and Treatment." 5th Ed. (New York: American Water Works Association and McGraw-Hill.) ISBN 0-07-001659-3. 14. International Journal of Engineering Research and General Science Volume 3, Issue 1, January-February, 2015 ISSN 2091-2730 314 www.ijergs.org nano fertilizers and nano sensors – an attempt for developing start agriculture Dr. G. N. Rameshaiah1, JPallavi2 ,S Shabnam3. 15. Graf, Christina; Vossen, Dirk L.J.; Imhof, Arnout; van Blaaderen, Alfons (July 11, 2003). "A General Method To Coat Colloidal Particles with Silica". Langmuir. 19 (17): 6693–6700. doi:10.1021/la0347859. 16. "Samsung Mass Producing 128Gb 3-bit MLC NAND Flash". Tom's Hardware. 11 April 2013. Retrieved 21 June 2019. 17. P.H. Li, P.K. Chu, in Thin Film Coatings for Biomaterials and Biomedical Applications, 2016. 18. Physical properties of thin‐film field emission cathodes with molybdenum cones Journal of Applied Physics 47, 5248 (1976). 19. G. Korotchenkov (2013). "Thin metal films". Handbook of Gas Sensor Materials. Integrated Analytical Systems. Springer. pp. 153–166. ISBN 978-1-4614-7164-6. 20. Meija, J.; et al. (2016). "Atomic weights of the elements 2013 (IUPAC Technical Report)". Pure and Applied Chemistry. 88 (3): 265–91. doi:10.1515/pac-2015-0305. 21. Jones, Adrian P., Frances Wall, and C. Terry Williams, eds. 1996. Rare Earth Minerals: Chemistry, Origin and Ore Deposits. The Mineralogical Society Series. London: Chapman and Hall. ISBN 0412610302 22. Cotton, F. Albert, and Geoffrey Wilkinson. 1980. Advanced Inorganic Chemistry. 4th ed. New York: Wiley. ISBN 0471027758 23. Klaus Reinhardt and Herwig Winkler (2000). "Cerium Mischmetal, Cerium Alloys, and Cerium Compounds". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: WileyVCH. 24. Structure-dependent electronic properties of nanocrystalline cerium oxide films P. Patsalas, S. Logothetidis, L. Sygellou, and S. Kennou, Phys. Rev. B 68, 035104 – Published 7 July 2003 25. Cerium; Crystal Structure and Position in The Periodic Table. Börje Johansson et/al; Article number: 6398 (2014). 26. Microstructural characteristics of cerium oxide conversion coatings obtained by various aqueous deposition methods; B.Y.Johnson et/al, Materials Characterization (2005). 27. Solid oxide fuel cells (SOFCs): a review of an environmentally clean and efficient source of energyABStambouli, E TraversaRenewable and sustainable energy reviews 6 (5), 433-455 28. Published: 06 January 2000Reverse microemulsion synthesis of nanostructured complex oxides for catalytic combustionAndrey J. Zarur& Jackie Y. Ying Naturevolume 403, pages65–67 (2000) 29. Preparation, characterization, photocatalytic properties of titania hollow sphere doped with ceriumJournal of Hazardous MaterialsVolume 178, Issues 1–3, 15 June 2010, Pages 517-521 30. Assessing exposure, uptake and toxicity of silver and cerium dioxide nanoparticles from contaminated environmentsGaiser et al; licensee BioMed CentralPublished: 21 December 2009 31. Sonochemical Synthesis of Cerium Oxide Nanoparticles—Effect of Additives and Quantum Size Effect et.al Lunxiang Yin Journal of Colloid and Interface Science Volume 246, Issue 1, 1 February 2002, Pages 78-84 32. Preparation of discrete nanosize ceria powder panel FanZhang Shi-Ping Yang Ceramics International Volume 30, Issue 6, 2004, Pages 997-1002 33. Fast Synthesis of Cerium Oxide Nanoparticles and Nanorods Feng Gao1, Qingyi Lu Journal of 34. Nanoscience and Nanotechnology Vol.6, 3812–3819, 2006 35. Cardioprotective effects of cerium oxide nanoparticles in a transgenic murine model of cardiomyopathy Article in Cardiovascular Research 73(3):549-59 · March 2007 36. Applied Surface Science Volume 256, Issue 3, 15 November 2009, Pages 852-856 Nanoparticulate cerium dioxide and cerium dioxide–titanium dioxide composite thin films on glass by aerosol assisted chemical vapour deposition Uzma Qureshi Charles W.DunnillIvanP.Parkin 37. Synthesis, Characterization, and Application of 1-D Cerium Oxide Nanomaterials: A Review 38. Kuen-Song Lin and SujanChowdhuryReceived: 8 July 2010 / Revised: 18 August 2010 / Accepted: 19 August 2010 / Published: 13 September 2010 39. Fabrication of cerium oxide nanoparticles: Characterization and optical propertiesElahehK.GoharshadiabSaraSamieeaPaulNancarroJournal of Colloid and Interface ScienceVolume 356, Issue 2, 15 April 2011, Pages 473-480 40. The Influence of Electrophoretic Deposition for Fabricating Dye-Sensitized Solar Cell Et.al Jung-Chuan Chou, Shen-Chang LinReceived 9 May 2014; Revised 18 August 2014; Accepted 18 August 2014; Published 28 August 2014Journal of NanomaterialsVolume 2014, Article ID 126053 41. Rapid synthesis of cerium oxide nanoparticles with superior humidity-sensing performanceSharadaThakurPradipPatilSensors and Actuators B: ChemicalVolume 194, April 2014, 42. Catalytic Properties and Biomedical Applications ofCerium Oxide NanoparticlesCarlWalkey a, SoumenDasb, SudiptaSealb, Joseph ErlichmancReceived 00th January 2012,Accepted 00th January 2012 43. SYNTHESIS AND CHARACTER OF CERIUM OXIDE (CeO2)NANOPARTICLES BY THE PRECIPITATION METHODReceived –: 2013-12-05Accepted –: 2014-03-25 44. Food-directed synthesis of cerium oxide nanoparticles and their neurotoxicity effects et.al MajidDarroudiCeramicsInternationalVolume 40, Issue 5, June 2014, Pages 7425-7430 45. FARAHMANDJOU, M.; ZARINKAMAR, M. and FIROOZABADI, T.P.. Synthesis of Cerium Oxide (CeO2) nanoparticles using simple CO-precipitation method. Rev. mex.fis. [online]. 2016, vol.62, 46. Int J Nanomedicine. 2017 Feb 20;12:1401-1413. doi: 10.2147/IJN.S124855. eCollection 2017.Cerium oxide nanoparticles: green synthesis and biological applications.Charbgoo F1, Ahmad MB2, Darroudi M 47. Cerium oxide nanoparticles: Synthesis, characterization and tentative mechanism of particle formation et.al JazmínCalvache-MuñozColloids and Surfaces A: Physicochemical and Engineering AspectsVolume 529, 20 September 2017, Pages 146-159 48. Mechanical Alloying Technology, Institute of Materials Processing”. 49. FatinFatihah Binti Zahari (2011/2012) “Electron Beam Evaporation EEN3016”. 50. Matt Hughes (15 June 2016) “Semicore Equipment, Inc.” 51. “Journal of vacuum science & technology. A, Vacuum, surfaces, and films an official journal of the American Vacuum Society”. 52. Madou, M. J et al (2002) "Fundamentals of Microfabrication: The science of Miniaturization" 2nd Ed., CRC Press (2002), p. 135–6. 53. Movchan, B. A. (2006). "Surface Engineering". 54. Wolfe, D.; J. Singh (2000). "Surface and Coatings Technology”. 55. Van Vlack, L. H. (1985). Elements of Materials Science and Engineering. Addison-Wesley. 56. Verhoeven, J.D. Fundamentals of Physical Metallurgy, Wiley, New York, 1957. 57. Verhoeven, J.D. et al (1975) “Fundamentals of Physical Metallurgy” Wiley, New York. 58. Arne K. Dahle (2018) “Heat Treatment of Aluminium Alloys”, in Reference Module in Materials Science and Materials Engineering. 59. E.A. StarkeJr et al (2001) “Aluminium Alloys: Thermal Treatmentsin Encyclopedia of Materials: Science and Technology”. 60. H.U. Kunzi (2002) “Fiber Fracture” 61. Finmeccanica et al (2008) “Leonardo DRS, formerly DRS Technologies, Inc., is a US-based defense contractor. Previously traded on the NYSE”. 62. S.T. Misture et al. (2001) “Encyclopedia of Materials: Science and Technology” 63. A.K. Chatterjee, (2001) “Handbook of Analytical Techniques in Concrete Science and Technology”. 64. Bragg, W.H.; Bragg, W.L. (1913). "The Reflexion of X-rays by Crystals". 65. H. P. Myers (2002). Introductory Solid State Physics. 66. "x-ray diffraction, Bragg's law and Laue equation" 67. P. Scherrer, GöttingerNachrichten Gesell., Vol. 2, 1918. 68. A.K. Singh (ed.), "Advanced X-ray Techniques in Research And Industries", IosPr Inc, 2005. 69. Bish et al. (1989) “Modern Powder Diffraction”. 70. Charles et al (2019) “Extraction of Schottky diode parameters from forward current‐voltage characteristics”.