Uploaded by

roberto valencia

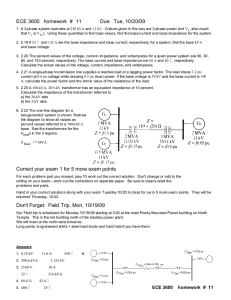

DAPPER Reference Manual: Electrical Engineering Analysis Software