Emergency Action Plan for the Solid Waste Management in Colombo

advertisement

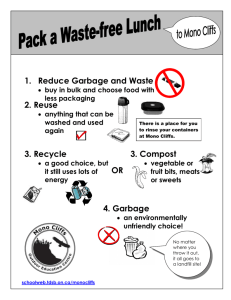

Proposed Emergency Solid Waste Management Plan for the Colombo Municipal Limits By Walkers Colombo Shipyard (Pvt) Ltd, Subsidiary of MTD Walkers PLC Dr. Sarath Obeysekara , Dr. Lalith Samarakkody Eng. Chamila Silva, Dr. Max Ikeda, This proposal is made as an Emergency Plan to cope up with the situation after the landslide that took place in the Meethotamulla Waste Dumpsite a couple of days ago, where the waste acceptance to the site has completely been stopped as of now. Furthermore the Government and Colombo Municipal Council have no alternative options rather than transporting the waste to the Karadiyana Waste Management Facility and Dompe Sanitary Landfill for the time being where there is inadequate land capacity at the aforesaid sites to accommodate the CMC volume of waste since the waste that generates from their respective Local Authorities are also massive in number. Moreover a serious Public Protest is anticipated in due course from the residents dwelling in Piliyandala and Dompe areas hence we would prefer to propose an immediate solution for the waste piling up at the CMC area to be managed in a most Acceptable, Human & Environmental friendly manner. In addition, a similar situation could be expected in Karadiyana dumpsite as well similar to the Meethotamulla site since the height of the mountain of dump is in the upward trend day by day due to the massive collection of waste at the aforesaid site. The vulnerable areas will be the Karadiyana Watte and Battiyawatte towards Bokundara area where the marshy lands have the tendency of pushing away from the mountain of dump as a result of it’s weight. This may cause danger even to the human lives. (Ref: Sri Lanka Airforce press release) Present Situation The statistics reveals that 775 MTS of Waste (as per JICA 2016 Survey, Annexure 1) generates daily in the Colombo Municipal Council area which exists 52% of Organic Waste currently dumped at the Meethotamulla Site. It is estimated that there is about 3 million tons of waste piled up at the aforesaid dump site since 2009 subsequent to the court order given for the closure of the Bluemendhal dump site. The current methodology of the CMC Waste Collection The Waste collection in CMC is currently conducted by using 90 Vehicles including 63 Compactor Trucks that were provided by JICA in the 1990s and collection area was divided into Six Districts. Waste Collection, Street Cleaning and Waste Transportation in the CMC limits are conducted by the outsourced two main private companies namely Carekleen and Abans in accordance to the waste management guidelines formulated by the CMC. The collection coverage is 100%, at the maximum. (Ref: JICA REPORT 2016) The Proposed Methodology & the Immediate Solution Step 1 – Diverting the Fresh Waste to a New Location (only for a period of Three Months) It is proposed to set up Four Bailing Plants initially having an output of 40 Bales per Plant per Hour, the approximate weight of a bale amounts to 0.5 MTS where the hourly output amounts to 40 Bails containing 20 Tons of MSW in it. Hence within a normal 8 hour shift, if assumes an efficiency of 70% man hours resulting a production of 112 bales from one machine. If Two Shifts per day are allocated, one plant could bale 224 MTS where 775 MTS could be accommodated per Day. It is mandatory to install Four Baling Plants with the wrapping facility to turn out a neat product that could be stored in a warehouse for any period until used for some purpose. The Baled & Wrapped Waste, in other words the Finished Product will be transported to a designated location to store until the commencement of the Waste to Energy (WTE) Project where it would be utilized as a resource. Meantime please note that we intend to include a Leachate Treatment Unit and an Odor Control System with adequate capacities in order to mitigate the Water and Air pollution that could take place during the process. Mobile Baling Plant Step 2 ( at the 4th Month it’s proposed to commence the Separation & Classification Plant) Since it is mandatory to obtain necessary Government Approvals and Permits to set up the Classification, RFP and RDF plants, a temporary facility has installed to handle the newly delivered MSW during the construction period. The process of segregation at the temporary installed facility is as follows. Initially the MSW is pre-classified into Steel, Lighter Fraction (mainly food waste, paper, plastic sheets and textiles), Heavier Fraction (mainly wood, plastic lump, miscellaneous inflammable) and Large Lump (mainly non-flammable). The Lighter Fraction and Heavier Fraction will be compacted into cubic bales reducing the volume to 1/2 -1/4 of the original volume of MSW. The Lighter Fraction bales will be plastic-film wrapped for odor protection and piled up by fork-lift trucks in a smaller area. (Refer to Appendix 1 for the preliminary process scheme) Appendix 1 As per the appendix 5 it is possible to separate 52% of Organic Waste (401MTS per Day) to 80MTS of Organic Compost per day. Rest of the valuable recyclable items could be sent for the process of recycling. Appendix 2 (JICA SURVEY – 2016) Land allocation 1. Option 1 Sri Lanka Land Reclamation and Development Corporation ( SLLDC) –holds a land bank near Colombo. In Muthurajawela SLLRDC has developed a 400 acre area as an Industrial Park by reclaiming a marsh with Sea Sand in 1996 after obtaining Environment Clearance from the relevant authorities and now fully occupied by various companies as Fuel and Gas Storage, Ware Housing and Power Generation projects. SLLRDC lately obtained an environment clearance to reclaim 200 more acres between the buffer zone and the 400 acre developed plot and now ready to offer to investors for various industries. SLLRDC has also pumped over 2.5 million Cubic Meters of Sea Sand which is now stock piled next to the 200 acre plot and being sold to retail buyers. This stock pile of sand can be used to reclaim the 200 acres and offer to investors, and SLLRDC has advertised the land calling for offers. Government can initiate an action plan to remove the OLD GARBAGE which has already being partially composted lying in the southern part of the Meethotamulle Dump using trucks to the 200 acre plot for reclamation . It is advisable to use part of the available sand to lay a 1-2 feet layer in the marshy layer of 200 acres prior to dumping of the OLD GARBAGE and fresh layer of either sand or earth ( being excavated in many building sites in Colombo) can be used to cover the garbage payers one by one . SLLRDC has a large fleet of equipment and trucks which are idling and the workforce can undertake this work. It is anticipated that removal of the OLD GARBAGE can be completed within 1 year. = 3,000,000 Assume a 6 Wheel Dump Truck carry 10 MTS of Decayed Waste with Soil (If it Clears Meethotamulla land within 1 year) 3,000,000 Loads / 365 days = 821 Loads Per Day Land which is cleared in Meethotmualle dump could be used for installing a Garbage Sorting Ware House and compacting unit for further transportation either for incineration or for degasifying else where. Part of the 200 acre land can be used for installation of the incineration plant which can be the source to generate steam for power generation. Proposed land plot to be Reclaimed & developed By SLLRDC Actual Example It can be witnessed in Maldive Island how garbage is carried by landing crafts to an area closed to the city and over 500 acres has been reclaimed by dumping garbage and covering with sea sand . This newly generated land is now an Industrial Estate in Male, Maldives has very stringent environment rules & regulations and yet they opted to do above to solve the problem. Therefore reclaiming the land observing proper guidelines not to pollute the area for Industrial Purpose is the ideal short term solution for above problem. RECLAIMED LAND IN MALE USING GARBAGE Waste Separation Relevant Ministries must declare the orders to L/As that the residential garbage which is not segregated will not be collected by the garbage collectors. Residential garbage must be segregated as biodegradable waste, non-biodegradable waste and plastic or glass in order for it to be collected, L/As must Strictly follow the regulations. Model of a separation Bin Fund Allocation 1. Government via Treasury and also from CMC offers funds should be made available to SLLRDC to carry out the above work. 2. Special supplementary budget should be approved by the government 3. UDA would allocate funds which has allocated for the Puttlam Waste Management Project. Collateral from the Government & the Responsibility 1. The land reclaimed by above means can be offered to Investors who may come with an investment plan to generate power using the raw garbage which can be transported after compacting and bailing 2. Provide land for Mix Development Projects 3. Provide tax concessions for the importation of Machinery/Balers/Separation Plant 4. Provide approval and permissions with short term 5. Waste Separation at source must be a mandatory 6. Tipping Fee should be paid at the rate of Rs.1000 Per Ton from CMC to the Project Company 7. Excavation of the existing dump site should be done by the SLLRDC and cost will be borne by UDA Action Plan and Time Schedule Month 1 Month 2 Month 3 Month 4 week 4 week 3 week 2 week 1 week 4 week 3 week 2 week 1 week 4 week 3 week 2 week 1 week 4 week 3 week 2 week 1 Description Civil Construction Procurement Civil Construction Obtain approvals Importing of machines Installing utility supply Commissioning a Commissioning of Waste classification plant Reclaim the SLLRDC land Monitoring and Evaluation Monthly Progress monitoring meeting must be organized with the participation of the following officers Army commander, Navy Commander, IGP, Secretary to Ministry of Megapolis, Minister of Megapolis, Chief Minister /WP, The Mayor of Colombo, Division secretary Wattala,, Hon Minister John Amaratunge, Chairman CEA, Chairman RDA, Chairman SLLRDC, Chairman UDA, Director - WMA /WP, Attorney General –AG, Director –State TV stations.GA Gampaha & Colombo. Secretary Wattala PS & MC, MOH Wattala. E Project Expenditure Total Project Cost : US $ 8,909,458.57 Rs. 1,363,147,160.00 Capital Expenditure Fully Automated Plant (FOB) 2 76,800.00 Amount (US$) 153,600.00 Manual Plant (FOB) 2 38,000.00 76,000.00 11,628,000.00 Wrapping Plant (FOB) 4 4,780.00 19,120.00 2,925,360.00 Wheal Loader with 4 45,000.00 180,000.00 27,540,000.00 Conveyor Belt systems 4 33,000.00 132,000.00 20,196,000.00 Single Roll Crusher (20-30/H) 8 10,000.00 80,000.00 12,240,000.00 Generator 400 Kw 1 30,000.00 30,000.00 4,590,000.00 temporary Classification Unit 4 30,000.00 120,000.00 18,360,000.00 vehicle 2 33,000.00 66,000.00 10,098,000.00 Crew Cab 1 30,000.00 30,000.00 4,590,000.00 Waste Water Treatment Unit 1 30,000.00 132,000.00 20,196,000.00 Office 13,071.90 2,000,000.00 Civil & Foundation 32,679.74 5,000,000.00 Utility Supply System 52,287.58 8,000,000.00 1,116,759.22 170,864,160.00 Description QTY Rate (US$) TOTAL Rs 23,500,800.00 Recurrent Expenditure Description US $ RS Wrapping Material (per Annum) 326,797.39 50,000,000.00 Salaries 203,529.41 31,140,000.00 Fuel 32,679.74 5,000,000.00 Electricity 94,117.65 14,400,000.00 water 13,071.90 2,000,000.00 6,535.95 1,000,000.00 20,000.00 3,060,000.00 5,000.00 765,000.00 6,000.00 918,000.00 78,431.37 12,000,000.00 196,078.43 30,000,000.00 130,718.95 20,000,000.00 6,679,738.56 1,022,000,000.00 7,792,699.35 1,192,283,000.00 telephone Transportation & sea freight Installation Civil & Foundation Ordure Control Engineering & Project Management Operation Cost for bailing Transportation of Bales (200 Trucks/4 Trips)