Site Menu

weibull.com home

Reliability HotWire

Issue 130, December 2011

Hot Topics

Box-Behnken Designs for Optimizing Product Performance

Design of Experiments (DOE) is a set of techniques that revolve around the study of the influence of different variables on the outcome of a

controlled experiment. Generally, the first step is to identify the independent variables or factors that affect the product or process, and then

study their effects on a dependent variable or response. In this article, we will give an example on how to use Box-Behnken Designs in

DOE++ to determine the settings of factors that would result in the optimum value of the response.

Background

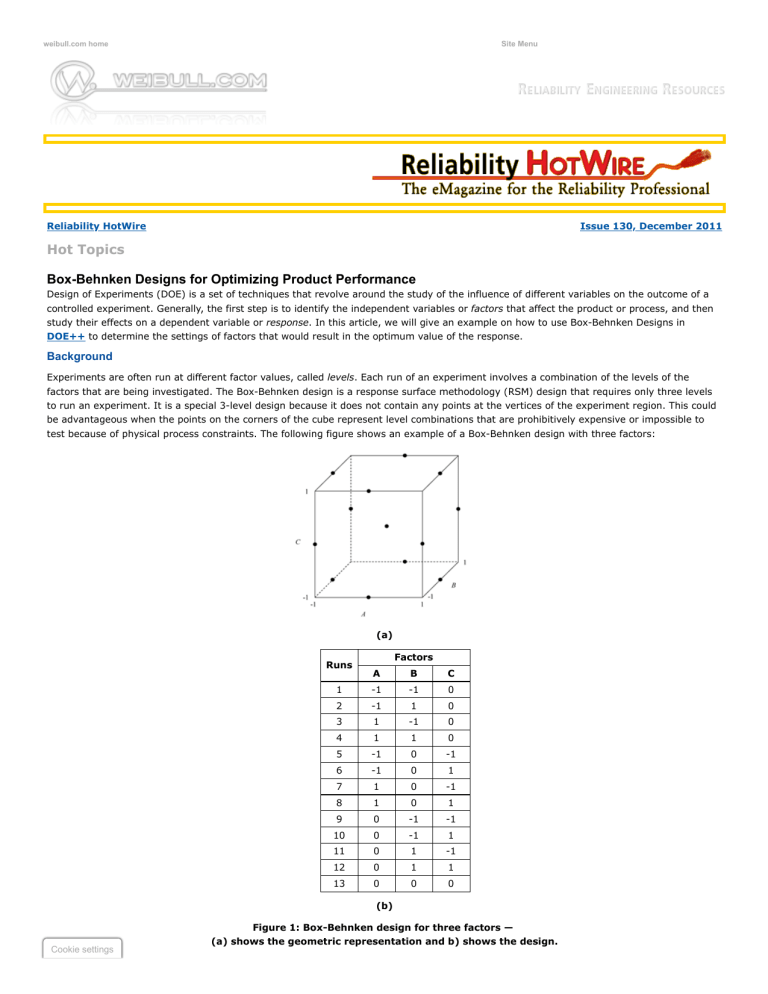

Experiments are often run at different factor values, called levels. Each run of an experiment involves a combination of the levels of the

factors that are being investigated. The Box-Behnken design is a response surface methodology (RSM) design that requires only three levels

to run an experiment. It is a special 3-level design because it does not contain any points at the vertices of the experiment region. This could

be advantageous when the points on the corners of the cube represent level combinations that are prohibitively expensive or impossible to

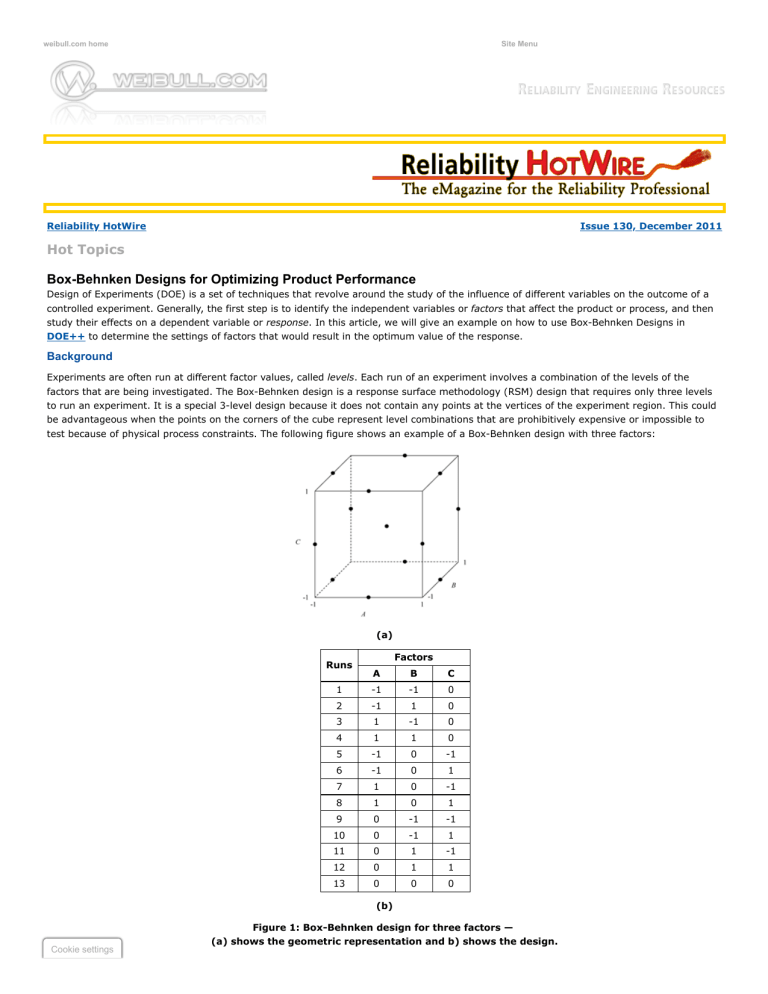

test because of physical process constraints. The following figure shows an example of a Box-Behnken design with three factors:

(a)

Runs

Factors

A

B

C

1

-1

-1

0

2

-1

1

0

3

1

-1

0

4

1

1

0

5

-1

0

-1

6

-1

0

1

7

1

0

-1

8

1

0

1

9

0

-1

-1

10

0

-1

1

11

0

1

-1

12

0

1

1

13

0

0

0

(b)

Figure 1: Box-Behnken design for three factors —

Cookie settings

(a) shows the geometric representation and b) shows the design.

Example

Fungal contamination of grains during the post-harvest period has been a recurring health hazard. To remedy the situation, a UV-light system

is being used to inactivate the fungal spores of Aspergillus niger in corn meal [1]. Three factors in the UV-light process will affect the results:

treatment time (number of pulses), distance from the UV strobe and input voltage for the UV lamp. The following table shows the initial

settings.

Factor

Name

Units

A

Time

s

Low Level High Level

20

B

Distance

cm

3

13

C

Voltage

v

2000

3800

100

The response is a log10 reduction of the fungal spores. The goal of the experiment is to determine the UV-light settings that will maximize the

reduction of the fungal spores.

Create the Experiment Design

Let us create a 15 run Box-Benhken design with three center points. In DOE++, create a project and add a standard folio that uses the BoxBenhken design. Use the settings shown next.

Click the Factor Properties button and enter the initial settings of the UV-light system, as shown next

The following data sheet shows the resulting design table and the corresponding effect of the different UV-light settings on the reduction of

fungal spores. The effects are recorded in the "Response 1" column.

Cookie settings

Note that the values in the "Run Order" column are randomly generated; therefore, the run order you obtain for the test design may be

different from the one shown in the example. To continue working with this example, sort the data by standard order (by selecting the

corresponding option in the Sort area on the control panel), and then enter the response values in the order shown in the picture.

Analysis and Results

To analyze the data, first specify the effects (combination of factors) to include in the analysis. To do this, click the Select Effects icon on the

control panel. In the Effects window, select all of the effects (i.e., full quadratic effect of factors), as shown next.

On the Options page of the control panel, enter 0.1 in the Risk Level (Alpha) field, and in the Test Terms area, select the Individual

Terms option. Next, return to the Main page of the control panel and click the Calculate icon.

The following data sheet displays the resulting ANOVA table, which shows that effects A, C, AC and AA are significant. Also, the P value for

factor B is 0.1481, which is close to the risk level 0.1. Therefore, the effect of factor B could also be included in the final model.

To create the final model, click the Select Effects icon on the control panel again. In the Effects window, click the Select Significant Effects

button and then select to include only effects A, B, C, AC and AA, as shown next.

Cookie settings

On the control panel, click Calculate to recalculate the results. The Regression Information table of the final model displays the coefficients

for the parameters in the final model, as shown next.

This model can be used to determine the optimum settings of the UV-light system.

Optimization

Click the Optimization Settings icon on the control panel. On the Response Settings page, use the settings shown next.

On the Factor Settings page, set the range of each factor as shown next. The ability to define a range allows you to set the limits of each

factor within which the optimal settings should fall.

Click OK to close the window and plot the optimal solution, as shown next.

Cookie settings

Therefore, the optimal settings are A = 100 s, B = 3 cm and C = 3800 v. Under these settings, the expected logarithmic transformation of the

reduction is 4.9. To confirm this conclusion, it would be necessary to conduct an experiment using these settings.

Reference

[1] Jun, S., Irudayaraj, J., Demirci, A., and Geiser, D., "Pulsed UV-light treatment of corn meal for inactivation of Aspergillus niger spores,"

International Journal of Food Science and Technology, vol. 38, no. 8, pp. 883-888, 2003.

Copyright ® 2011 ReliaSoft Corporation, ALL RIGHTS RESERVED

The weibull.com reliability engineering resource website is a service of HBM Prenscia.

Copyright © 1992 - 2019 HBM Prenscia Inc. All Rights Reserved.

About weibull.com | About HBM Prenscia | Third Party Privacy Notice | Website Notice | Cookie Notice

Cookie settings