Substitutes for Soda Ash in the

Treatment of Boiler Feed Water

W. A. TANZOL4, R. L. REED, AND J. J. MAGUIRE

W. H. & L. D. Betz,

Philadelphia

Downloaded by CARGILL INC at 13:59:22:740 on June 18, 2019

from https://pubs.acs.org/doi/10.1021/ie50455a009.

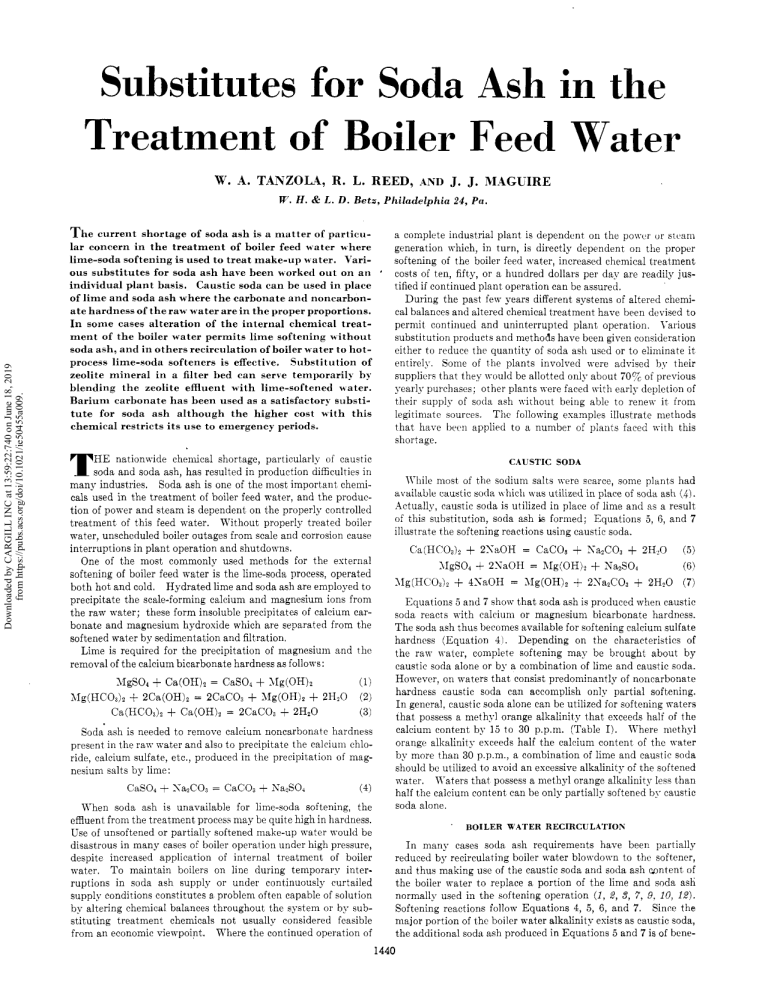

The

current

shortage of soda ash is a matter of particuin the treatment

lar concern

of boiler feed water where

lime-soda softening is used to treat make-up water.

Various

substitutes for soda ash have been worked out on an

individual plant basis. Caustic soda can be used in place

of lime and soda ash where the carbonate and noncarbonate hardness of the raw water are in the proper proportions.

In some cases alteration of the internal chemical treatof the boiler water permits lime softening without

ment

soda ash, and in others recirculation of boiler water to hotprocess lime-soda softeners is effective. Substitution of

zeolite mineral in a filter bed can serve temporarily bv

blending the zeolite effluent with lime-softened water.

Barium carbonate has been used as a satisfactory substitute

for soda ash although the higher cost with this

chemical restricts its use to emergency periods.

complete industrial plant is dependent on the power or steam

generation which, in turn, is directly dependent on the proper

softening of the boiler feed water, increased chemical treatment

costs of ten, fifty, or a hundred dollars per day are readily justified if continued plant operation can be assured.

During the past few years different systems of altered chemical balances and altered chemical treatment have been devised to

permit continued and uninterrupted plant operation. Various

substitution products and methods have been given consideration

either to reduce the quantity of soda ash used or to eliminate it

entirely. Some of the plants involved were advised by their

suppliers that they would be allotted only about 70% of previous

yearly purchases; other plants were faced with early depletion of

their supply of soda ash without being able to renew it from

The following examples illustrate methods

legitimate sources.

that have been applied to a number of plants faced with this

shortage.

a

'

nationwide chemical shortage, particularly of caustic

soda and soda ash, has resulted in production difficulties in

THE

many industries. Soda ash is one of the most important chemicals used in the treatment of boiler feed water, and the production of power and steam is dependent on the properly controlled

treatment of this feed water. Without properly treated boiler

water, unscheduled boiler outages from scale and corrosion cause

interruptions in plant operation and shutdowns.

One of the most commonly used methods for the external

softening of boiler feed water is the lime-soda process, operated

both hot and cold. Hydrated lime and soda ash are employed to

precipitate the scale-forming calcium and magnesium ions from

the raw water; these form insoluble precipitates of calcium carbonate and magnesium hydroxide which are separated from the

softened water by sedimentation and filtration.

Lime is required for the precipitation of magnesium and the

removal of the calcium bicarbonate hardness as follows:

+ Ca(OH)2

+ Mg(OH)2

2CaC03 + Mg(OH)2 + 2H,0

Mg(HC03)2 + 2Ca(OH)2

2CaC03 + 2H20

Ca(HC03)2 + Ca(OH)2

MgSCh

=

CaS04

=

=

CAUSTIC SODA

While most of the sodium salts were scarce, some plants had

available caustic soda which was utilized in place of soda ash (4).

Actually, caustic soda is utilized in place of lime and as a result

of this substitution, soda ash is formed; Equations 5, 6, and 7

illustrate the softening reactions using caustic soda.

Ca(HC03)2 + 2XaOH

CaC03 + Xa2C03 + 2H.0

2XaOH

Mg(OH), + Xa2S04

MgS04 +

Mg(HC03)2 + 4XaOH

Mg(OH)2 + 2Xa2C03 + 2H20

=

=

CaC03 + Xa2S04

(5)

(6)

(7)

Equations 5 and 7 show that soda ash is produced when caustic

soda reacts with calcium or magnesium bicarbonate hardness.

The soda ash thus becomes available for softening calcium sulfate

hardness (Equation 4). Depending on the characteristics of

the raw water, complete softening may be brought about by

caustic soda alone or by a combination of lime and caustic soda.

on waters that consist predominantly of noncarbonate

hardness caustic soda can accomplish only partial softening.

In general, caustic soda alone can be utilized for softening waters

that possess a methyl orange alkalinity that exceeds half of the

calcium content by 15 to 30 p.p.m. (Table I). Where methyl

orange alkalinity exceeds half the calcium content of the water

by more than 30 p.p.m., a combination of lime and caustic soda

should be utilized to avoid an excessive alkalinity of the softened

Waters that possess a methyl orange alkalinity less than

water.

half the calcium content can be only partially softened by caustic

soda alone.

However,

(1)

(2)

(3)

remove

CaS04 + Xa2C03

=

=

calcium noncarbonate hardness

present in the raw water and also to precipitate the calcium chloride, calcium sulfate, etc., produced in the precipitation of magnesium salts by lime:

Soda ash is needed to

24, Pa.

(4)

When soda ash is unavailable for lime-soda softening, the

effluent from the treatment process may be quite high in hardness.

Use of unsoftened or partially softened make-up water would be

disastrous in many cases of boiler operation under high pressure,

despite increased application of internal treatment of boiler

To maintain boilers on line during temporary interwater.

ruptions in soda ash supply or under continuously curtailed

supply conditions constitutes a problem often capable of solution

by altering chemical balances throughout the system or by substituting treatment chemicals not usually considered feasible

from an economic viewpoint. Where the continued operation of

BOILER WATER

RECIRCULATION

In many cases soda ash requirements have been partially

reduced by recirculating boiler water blowdown to the softener,

and thus making use of the caustic soda and soda ash content of

the boiler water to replace a portion of the lime and soda ash

normally used in the softening operation {1, 2, S, 7, 9, 10, 12).

Softening reactions follow Equations 4, 5, 6, and 7. Since the

major portion of the boiler water alkalinity exists as caustic soda,

the additional soda ash produced in Equations 5 and 7 is of bcne1440

INDUSTRIAL

November 1947

Table I.

Applicability

Raw Water Characteristics'

.

VjCa + (15-30 p.p.m.

3

XI unethyl orange

Table II.

Hardness

CaCOj,

as

as

180

120

60

20

0

32

60

3d

10

Complete

0

16

4

Boiler

Water

With Recirculation^

Lime-soda

Raw softened Boiler

180

120

60

20

0

120

35

10

32

60

0

16

4

CaCOj,

p.p.m.

Phenolphthalein

Methyl

Softening

Partial

Complete

CaCOj.

Without Recirculation3

Lime-soda

Raw softened Boiler

p.p.m.

Sulfate

as

Analyses with and without

Recirculation

Ca as CaCOj, p.p.m.

XIg as CaCOj, p.p.m.

Alkalinity

alkalinity) and Ca

orange

as SO4

Chloride

120

3o

10

630

700

o38

154

60

CHEMISTRY

336

374

538

154

60

as Cl

19

Phosphate as PO*

7.3

10.1

11.7

7.3

10.1

11.5

pH

a

Lime requirement, 147 p.p.m. on raw water; soda ash, 106 p.p.m. on

raw water.

6.5 %> boiler water blowdown (69,500 pounds per million pounds

BARIUM CARBONATE

Barium carbonate was considered an emergency substitute

for soda ash. Lime-barium softening for reducing the sulfate

concentration is a process of historical interest but is in use, to the

authors’ knowledge, at only one plant in this country (-5, 6, 8, It).

Barium carbonate was applied during the soda ash shortage, not

with the primary intention of reducing the sulfate content of the

treated water, but rather to obtain the advantage of the sod urn

carbonate produced as a by-product of sulfate removal:

+ BaCO,

CaSO, + BaCOs

MgSO, + BaCO,

MgCOs + Ca(OH)2

Xa2S04

•steam).

Lime requirement, 132 p.p.m, on raw water; soda ash, $4 p.p.m. on

water.

raw

6.5% system blowdown (139,000 pounds per million pounds

steam, of which 69,500 pounds are returned to softener).

b

tit in the removal of noncarbonate hardness as illustrated by

Equation 4.

Table II shows the normal balances maintained on a hot process

softener and the resulting boiler water characteristics, as well as

the balances utilizing boiler water recirculation to the softener to

bring about a reduction in soda ash requirements. As a result of

recirculation, the reduction in lime requirements was approximately 10% and in soda ash requirements, 21%. A normal balance was maintained on the softener, and all factors of the boiler

water balance remained the same with the exception of boiler

water alkalinity. The reduction of boiler water alkalinity is a

direct result of consuming it in the softening process. In many

cases reduction in boiler water alkalinity is a desirable feature to

minimize carry-over that may result from excessive boiler water

alkalinity; boiler water is often recirculated solely for this purpose.

In general, the application of boiler water recirculation to waters

that, consist predominantly of carbonate hardness brings about

a greater percentage saving in soda ash than is covered by the

case cited.

Noncarbonate hardness waters involve only a minor

percentage savings in the soda ash requirements.

ZEOLITE

=

=

CaZ + 2XaHCO

MgZ + Xa2S04

=

=

BaSO, + Na.CO,

BaSO, + CaCO,

BaSO, + CaSO,

(10)

CaCO, + Mg(OH)2

(13)

(11)

(12)

Blending of Zeolite Softened Water Prior

Lime-Soda Softening (in Parts per Million)

Table III.

to

ZeoliteSoftened

Raw?

Hardness as CaCOj

Ca as CaCOj

Xlg

as

CaCOj

Alkalinity

CaCOj

Phenolphthalein

Blended b

Lime-Soda

Softened

121

20

84

37

16

4

0

160

110

50

4

0

130

30

0

130

30

130

30

32

60

30

12

12

12

12

as

Xlethyl orange

Sulfate as SO<

Chloride as Cl

Chemical requirements: lime, 149 p.p.m.; soda ash, 68 p.p.m.

b

75% raw water, 25% zeolite-softened. Chemical requirements:

137 p.p.m.;

soda ash, 27 p.p.m.;

salt, 140 p.p.m.

a

Table IV.

Blending

of

Lime-Soda Effluent

Raw

plants faced with the need for reducing soda ash

requirements had enough filters and filtering capacity to permit

conversion of one of the filters to a zeolite softening unit, operated

In the zeolite softening process calcium

on the sodium cycle.

and magnesium hardness is removed in exchange reactions with

sodium ions substituted for the calcium and magnesium:

=

=

As reaction 10 shows, sodium carbonate is formed by the reaction between barium carbonate and sodium sulfate present in

the raw water. The sodium carbonate is then available for use

in accordance with reaction 4. In addition, as reactions 11, 12,

and 13 show, calcium sulfate and magnesium sulfate can be removed without the use of soda ash.

SOFTENING

A few of the

Ca(HCO,)$ + Na»Z

MgSOi + Xa2Z

1441

In some of the plants employing batch cold-process lime-soda

softeners with gravity filters, consideration was given to converting one of the gravity filters to a gravity zeolite softener and

blending the effluents of both softening processes to produce a

water as illustrated in Table IV. The quantity of soda ash saved

by this procedure ivas in proportion to the amount of water softened by the zeolite unit. Since only 75% of the make-up water

was softened by the lime-soda process, a direct saving of 25% in

soda ash was achieved.

Degree of

Caustic soda

Caustic soda

Caustic soda

and lime

M > VsCa 4- 30 p.p.m.

ENGINEERING

Caustic Soda

of

Treatment

< i/2Ca

=

AND

Hardness as CaCO,

Ca as CaCOj

Xlg as CaCOj

Alkalinity as CaCOj

Phenolphthalein

Xlethyl

orange

Zeolite Softened Water

(in Parts per Million)

Lime-Soda

Softened

220

160

60

35

25

0

45

80

100

Zeolite

Softened

lime,

with

Blended'1

4

28

0

100

35

85

80

30

10

80

80

80

Sulfate as SO4

30

30

30

Chloride as Cl

3

75% cold lime-soda softened, 25% zeolite-softened.

8;

(9;

Reaction 8 shows that the bicarbonate hardness is converted to

sodium bicarbonate. When the zeolite softened water is blended

with the raw water, the resulting characteristics are such that

the hardness becomes totally carbonate. Table III shows the

make-up of the blended water and the resulting softened water,

which brought about a saving of 8% in lime and 60% in soda

ash. At the same time the external chemical treatment cost

was slightly lower with this treatment than was obtained by the

normal procedure. By softening increased percentages of the

raw water by the zeolite process, the use of soda ash could be

totally eliminated.

where the natural sodium sulfate content of the

insufficient to produce the desired sodium carbonate excess required in the softener effluent, it· was necessary

to feed sodium sulfate to the softener and thereby produce soda

ash directly in accordance with reaction 10.

Theoretical efficiency in the use of barium carbonate to produce soda ash has not been obtained in either laboratory test or

full scale plant operation. Barium carbonate can be used in both

hot· and cold softening, but its action is more efficient in the hot

(Table V).

Table V illustrates hot process tests in which normal softening

action is obtained with theoretical quantities of lime and soda

In

raw

some

cases

water

was

INDUSTRIAL

1442

Table V.

Results

of

Raw

AND

ENGINEERING

Laboratory Tests on Hot

with

Barium Carbonate

and

ments

100

Barium carbonate

Sodium sulfate

Amounts used, p.p.m,

172

Soda ash

Barium carbonate

Sodium sulfate

Analysis, p.p.m.

Hardness as CaCOt

Ca as CaCOt

Mg as CaCOt, p.p.m.

Alkalinity as CaCOt

Phenolphthalein

Methylorange

Sulfate as SO4

Chloride as Cl

0

Conditions of test:

Conditions of test:

100

100

172

200

100

100

100

100

100

100

150

150

150

...

100

100

100

172

172

200

24

21

172

172

172

370

223

370

334

555

334

38

23

15

248

168

80

170

172

4

3

26

34

30

164

46

64

30

...

248

168

176

174

16

14

68

80

2

2

13

52

30

22

0

6

16

16

6

12

12

0

38

128

164

44

96

164

100

30

164

100

30

30

40

30

24

80

164

164

164

164

164

1-hour retention, 20( 0 F. 1.0-liter samples.

4-hour retention, 80° F., 1.0-liter samples.

Lime alone is effective in precipitation of magnesium, but

obviously additional softening power is required to reduce the

calcium content. Using theoretical quantities of barium carbonate and sodium sulfate as substitutes for soda ash yields

reasonably satisfactory results, with reduction in calcium to 55

p.p.m. as calcium carbonate. Further improvement in lowering

the hardness of the treated water is obtained with additional

barium carbonate and sodium sulfate.

Table V also shows the results of cold process tests with the

same raw water.

Application of theoretical quantities of barium

carbonate and sodium sulfate does not achieve the same degree

of hardness removal as secured at higher temperatures. Increased quantities of barium carbonate and sodium sulfate show

steadily decreased calcium contents of the softened water, but

these data indicate that this process 15 considerably less efficient

at lower temperatures, possibly as a result of lower barium carbonate solubility at lower temperatures.

The insoluble barium sulfate precipitate formed in these reactions is removed along with the calcium carbonate and magnesium hydroxide through sedimentation and filtration as in

normal lime-soda softener operation. Inasmuch as barium salts

are toxic, qualitative barium determinations were conducted on

the softener effluent, and the efficiency of filtration was also

checked closely to make oertain> of the removal of the finely

divided barium sulfate precipitate. Only small traces of barium

ash.

were

The

Cold Processes

11

for this condition

reason

has not been closely investigated but was possibly due to

insoluble barium sulfate

coating on the barium carbonate particles. In addition,

100 100 100 100 100

100

slightly larger lime charges

Í0Ó 10Ó 150 2ÓÓ 250

300

were

required, of the order

100 150 150 200 250

300

of approximately 10%. In

172 172 172 172 172

172

general, reasonably good agree370 370

740 925 1110

ment is observed between labo223 334 334 466

670

ratory and field tests on the

112 118

66

96

60

56

hot process use of barium car105 101

42

33

31

17

19

24

25

27

bonate.

26

26

26

36

48

54

The use of barium carbonate

38

40

52

36

74

92

in place of soda ash does not

112 176 152 192 248

296

164 164 164 164 164

164

require alteration of normal

softener control procedures, so

no disadvantage has been encountered in this phase of operation. Lime control can be

established on the basis of maintaining certain residual hydrate

alkalinity values, and barium carbonate.can be regulated to develop optimum excess carbonate alkalinity concentrations. Determinations for excess sodium sulfate would not be imperative

since experience proved that the feed of this material, if required,

could be adjusted in direct ratio to the barium carbonate charges.

Some state health authorities consider the barium-containing

sludge to be a health hazard and will not permit it to be dumped

in waterways. Potential users of barium carbonate process who

must discharge sludge to streams and rivers should seek information concerning the attitude of their state health authorities

before installing the process.

Treated waters

% of theoretical requireSoda ash

Vol. 39, No.

an

Raw

Treated waters

CHEMISTRY

Table VI.

Results of Field Tests with

(in Parts per Million)

Raw

Hardness as CaCOt

Ca as CaCOt

Mg as CaCOt

Alkalinity as CaCOt

Phenolphthalein

Methyl

orange

Sulfate as SO*

Chloride as Cl

a

Theoretical

b Theoretical

c

10% excess

d 10% excess

Water

No. Ia

188

122

66

50

40

10

0

26

40

24

8

48

152

8

lime and barium

lime; 50% excess

lime; 25% excess

lime; 40% excess

-Soft*

No. 2»

38

28

the

Hot Process

Efflu

No. 3C No. 4d

mer

No. 5d

22

16

14

2

14

12

2

34

32

26

40

28

30

50

24

30

52

36

8

8

8

8

10

16

carbonate; no sodium sulfate,

barium carbonate; no sodium sulfate.

barium carbonate and sodium sulfate.

barium carbonate and sodium sulfate.

observed.

During initial application of barium carbonate to plant operation, the raw make-up water to the softener was depended upon to

supply the amount of sulfate required for barium precipitation.

Sulfate removal taking place during this process decreases the

dissolved solids of the softener effluent, which is beneficial in

numerous

applications. Further analyses revealed that 100%

of the natural sulfate content of the raw water did not react with

the barium carbonate, but rather a sulfate residual of 20-40

p.p.m. as SO, remained in the softener effluent. Consequently,

not enough carbonate w-as produced to yield as complete noncarbonate hardness removal as desired. Barium carbonate fed

considerably in excess of theoretical requirements failed to produce further sulfate or hardness reduction. Excess barium carbonate feed without the sulfate available for precipitation was

simply wasted, since this material remained in an insoluble, inert

form.

Table VI illustrates the results obtained in field tests with

barium carbonate in conjunction with a hot process lime-soda

softener, having a capacity of 10,000 gallons per hour and operating at 218° F. Somewhat greater than theoretical quantities

of barium carbonate were required, varying from 25-40%.

Assuming reaction 10 to proceed at 100% theoretical efficiency,

the cost of the soda ash thus produced is 6.2 cents per pound.

This cost is based on 3.25 cents per pound for barium carbonate

of 98% purity and sufficient natural sulfate content of the raw

water to complete the reaction. Where sodium sulfate must be

supplied for the reaction, based on a cost of 2.1 cents per pound

for this chemical, the cost of thus producing soda ash is 9.0 cents

per pound. Where higher than theoretical quantities of barium

carbonate and sodium sulfate are necessary, the cost of producing

soda ash is correspondingly increased.

All applications proved that barium carbonate gave as great a

hardness reduction as possible with the conventional use of

soda ash. Obviously, operating chemical costs increased as a

result of the cost of barium carbonate in comparison with soda

ash and also the necessity of employing sodium sulfate in a large

number of cases. However, the use of barium carbonate enables

normal softening operations to be maintained during emergency

periods when the soda ash supply may be inadequate, and thereby

permits continuous operation without fear of interrupted pro-

duction.

INDUSTRIAL

November 1947

AND ENGINEERING

ACKNOWLEDGMENT

The authors wish to thank J. W. Polsky, who conducted the

majority of the laboratory tests, and also express appreciation

to W. H. & L. D. Betz for permission to present these data.

LITERATURE

CITED

(1) Baker, Combustion, 12, 31-4 (1940).

(2) Betz, Handbook of Industrial Water

547 (1945).

(3) Flickinger, Power, 85, 115-20 (1941).

Conditioning, Chap. IS, p.

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

CHEMISTRY

1443

Heiskell, Ibid., 90, 747-9 (1946).

Hundesshagen, Z. offentl. Chem., 24, 159-67, 175-86 (1918).

Leick, Vom Wasser, 7, 197-205 (1933).

Maguire and Tomlinson, Combustion, 11, 26-32 (1939).

Mehring, Chem. & Met. Eng., 21, 629-32 (1919).

Paris. Chaleur & industrie, 5, 277-9 (1924).

Paris, Chimie & industrie, 4, 722-30 (1920).

Rodman, Chem. & Met. Eng., 35, 221-3 (1928).

Sperry, Combustion, 10, 27-33 (1939).

Received September 6, 1947. Presented before the Division of Water,

Sewage, and Sanitation Chemistry at the 112th Meeting of the American

Chemical Society, New York, X, Y.

Butanol-Acetone Fermentation

of Wood Sugar

REID H. LEONARD AND W. H. PETERSON

GEORGE J. RITTER

University of Wisconsin, Madison, Wis.

United States Forest Products Laboratory, Madison, Wis.

Wood hydrolyzates were fermented with Clostridium

The wood

butylicum No. 39 to butanol and acetone.

species and method of hydrolysis affect the fermentability

of the liquors. Very mild or very vigorous conditions of

by the Madison wood sugar process as described by Harris and

Beglinger (4). These samples were neutralized to pH 4.2 with

lime at 138° C. (4, 7). The oak sample represented the first

25% of the hydrolyzate received from the digester, and the

Douglas fir liquor was from a normal run.

hydrolysis do not produce an easily fermentable solution.

Complete utilization of sugar could be obtained up to 3%

concentrations.

Solvent yields ranged from 24 to 38% of

the sugar fermented.

fermentation of wood hydrolyzates by butanol-acetone

is difficult. Sjolander, Langlykke, and Peterson

(10) conducted butanol-acetone fermentations on hydrolyzates

prepared by a method similar to the Scholler process and obtained a fermentable medium after precipitation of metals at

pH 10, neutralization, and clarification with Norite decolorizing

carbon. In the present paper other types of hydrolyzates have

been studied, and attempts have been made to simplify the pretreatments for fermentation.

Two cultures had previously been selected for wood sugar fermentations: Cl. felsineum Carbone No. 41 by Sjolander et al.

(10) for hydrolyzates and Cl. butylicum (Fitz strain) No. 39

by Wiley et al. (11) for sulfite waste liquor fermentation. These

two cultures, as well as Cl. butylicum No. 37, Cl. beijerinckii

No. 67, and Cl. butylicum No. 69, were compared on wood hydrolyzate, and No. 39 was selected as the most suitable organism.

Fermentations were conducted with cultures transferred three

to five times from the spore stock. Nutrients were supplied

by 1% malt sprouts and 0.1% (NHtRHPO». A trace of reduced

iron was added to the media before autoclaving. From 0.1 to

0.3% calcium carbonate was added to the media after inoculation. Inoculum was produced on glucose-malt sprouts medium

and used after 12 to 20 hours at 8% of the fermentation volume.

Determination of reducing sugars was made by the method of

Shaffer and Somogyi (9); furfural by a colorimetric method (1);

ethanol and butanol by Johnson’s procedure (6); and acetone by

Goodwin’s method (3). Volatile acids were determined by

titration of 11 volumes of distillate from 1 volume of sample.

Hydrolyzates of maple and spruce were prepared in a rotary

digester similar to that described by Plow et al. (8). Maple

sawdust was hydrolyzed by 3% sulfuric acid with an acid-wood

ratio of 1:1 at 181° C. for 30 minutes. A milder hydrolysis of

maple and of spruce was made with 1.8% acid, ratio 1:1 at

173° C. for 5 minutes. Oak and Douglas fir were hydrolyzed

THE

bacteria

FACTORS AFFECTING

FERMENTATION

It was first desirable to repeat the results of Sjolander et al.

In their work the amount of decolorizing carbon was not stated,

and it was found that with maple hydrolyzate, following their

procedure, 10 to 20 grams of Norite decolorizing carbon per 100

ml. were required to duplicate their fermentation results. Fermentation of high temperature maple hydrolyzate prepared

in this manner showed that 92% of the sugar in a 4.04 grams per

100 ml. solution was fermented in 5 days. The quantity of decolorizing carbon was found to be important; the use of 1 gram

per 100 ml. resulted in the fermentation of 25% of the sugar,

5

grams gave 64%, 10 grams gave 72%, and 20 grams gave 93%.

After the furfural was removed from the sample, the quantity of

carbon required was decreased to less than 5 grams per 100 ml.

The pH was found to be important, since 1 gram of carbon at pH

2.0 gave 17% fermentation, while 1 gram at pH 6.8 gave 51%.

The difficulty found with maple wood hydrolyzates was also

found with spruce, Douglas fir, and oak. The fermentations

were characterized by a long induction period and a slow sugar

utilization. In some samples much of the inhibition could be

accounted for by the presence of furfural—for example, the

°

maple hydrolyzate made at 181 C. contained from 0.5 to 0.8

gram of furfural per 100 ml. On synthetic medium 0.1% furfural decreased the fermentation by 15%. Hydrolyzates containing more than 0.1% furfural stopped the development of

the bacteria completely. Furfural was removed easily by distillation or by passing the liquor through a steam stripping colWhen furfural was added back to the stripped liquor,

umn.

the fermentations were not inhibited to the same extent as initially. This indicated that substances other than furfural were

removed by the distillations.

When the concentration of the inhibitory substances was decreased by dilution of the liquor, the extent of fermentation was

improved. Complete fermentation of sugars in wood hydrolyzates was usually obtained at about 3% concentration. With

glucose-malt sprouts medium 5% concentration was about the

maximum quantity which could be completely fermented with