Aircraft Wing Stiffener Damage Detection via Strain & Deflection

advertisement

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 03, March 2019, pp. 155-171. Article ID: IJMET_10_03_016

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication

Scopus Indexed

DETECTION OF DAMAGE IN STIFFENERS OF

AIRCRAFT WING STRUCTURE BASED ON

INDUCED SKIN STRAINS AND LATERAL

DEFLECTIONS.

Dr. Hatem Hadi Obeid

Faculty of Engineering/ Department of Mechanical Engineering

University of Babylon

ABSTRACT

In this paper, the technique of structure health monitoring was applied to detect

damage occurrence in the stiffeners of wing structure. A wing structure of airfoil shape

according to digital NACA 0015 was considered for modelling the aerodynamic wing

shape. Finite element models of the wing structure were created included undamaged

and damage wing structures using high order eight nodes and six nodes shell elements.

The damaged wing models included damaged at the main spar at 20%, 40%,60% and

80% the distance than the root chord. A mathematical model was developed using high

order shell elements and programmed via MATLAB. The load cases were predicted

experimentally using wind tunnel test on a wood airfoil prototype such that the pressure

distributions through upper and lower wing skins measured at different attack angles.

The static solutions were achieved for each finite element model under action of

maximum pressure distribution at attack angle of 100. Strains distributions and lateral

deflections through lower skin were estimated. The results of strains through lower skin

showed occurring of climax in strain values initiated in the distribution at the location

of the damage for all the cases of damaged structures, which not appeared in the

undamaged wing structure. The results of lateral deformations through lower skin

showed indicating variations in the shape of the curves, such that the curve appeared

to be gradually increased the region between the chord and the damage. Semi to rapid

increasing in the lateral deformation occurred in region between the damage and the

end tip of wing. The difference in the behavior of the induced strains and lateral

deformation between undamaged and damaged wing structures is intended to a

technique predicting of the occurrence of the damage in the wing structure. The present

of a climax in the strain distribution lead to presence of damage near the climax value

of strain. Also, the indicating of variations in the shape of the lateral deformations of

skins semi or rapid increasing lead to presence of damage near the rejoin of that

variation. It is concluded the possibility of using the strain and deflection analysis for

the wing structure to investigate occurring damage in the structure due to variation in

the strains and lateral deflections between different damage locations.

http://www.iaeme.com/IJMET/index.asp

155

editor@iaeme.com

Dr. Hatem Hadi Obeid

Key Words: Wing structure, Structural health monitoring, finite element method,

structural analysis, airfoil pressure distributions, strain, stress, deflection, damage in

wing structure.

Cite this Article: Dr. Hatem Hadi Obeid, Detection of Damage in Stiffeners of Aircraft

Wing Structure Based On Induced Skin Strains and Lateral Deflections, International

Journal of Mechanical Engineering and Technology, 10(3), 2019, pp. 155-171.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3

1. INTRODUCTION

The Structural Health Monitoring of failures in aircraft and other flying equipment is very

important because its concerned with the safety of their users or the risks that may be occurred

due to falling on the ground. This analysis is applicable in wide range of engineering fields

spanning from mechanical, aerospace, military, building, to bridge and transportation

applications. Needs for prediction of failure in the aerospace structures are rapidly increasing

due to demands of enhance safety, reduce inspection time and cost but maintaining structural

function and uses. This field is also providing smart prognosis and diagnosis of failure

instantaneously. The deployment and development of structural health monitoring system is

required to ensuring the safe operation of any engineering structure or system. The execution

of the structural health monitoring is mainly considering the following processes: [1]

- Using sensors and instrumentation devices for sensing and tracing the interpretation of an

engineering system or structure under operational loads.

- Assessment the performance of the system or structure for any propagation of damages or

defects by the analysis of the measured values analytically or numerically.

- Indicating a notification or an alarm when the desired system parameters are exceeded.

The base on parameters or criteria that the structural health monitoring system executed are

varied depending on the nature of the system responses or performance. Although the

importance of structural health monitoring but their researches are relatively young if compared

to other engineering fields, thus most of the researches have been conducted at universities or

research and development centers of companies.

The applications of structural health monitoring in engineering fields included different

problems such detection of damage in steel structure, aerospace, concrete structures, precast

concrete, box girders in railroads, composite materials, dikes and pipelines of water and

wastewater. Also, evaluation bridge deflection; stress or strain analysis in petroleum pipes, dam

structures, or suspension bridge cables. In addition to more complicated problems such as

detection of impact effects in wind turbine blades and water leaks. The vibration of high-rise

reinforced structures such as towers can be evaluated and assessment.

In this paper the structural health monitoring is applied for detection failure at the stiffeners

of aircraft wing structure. The performance of an aircraft structure can be characterized by

various factors, essentially the response (i.e. strain mapping, shape determination etc.) due to

applied loading that can be evaluated by health monitoring technique [2]. Finite element method

is powerful to be used to modelling the wing structure for estimation the effects in the structures

due to the applied loading. The most wing structural stiffness comes from the interior stiffeners.

The stiffeners included main, auxiliary spars and ribs. Having stiffeners (spars and ribs) attaing

structure increases the load resistance of the structure without further increasing in the weight.

To further reduce the weight, a certain arrangement of stiffener on structure is being necessary

to increase the rigidity with less material. The construction of both stiffeners and outer skin

gives the overall wing structural stiffness. The response of wing structure into the loading

http://www.iaeme.com/IJMET/index.asp

156

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

depending mainly on the overall stiffness of wing. Then the present of damage in any location

in the stiffeners will be affecting on the response of the wing to the applied loading.

2. FINITE ELEMENT MODELLING

2.1. Geometric Parameters:

In this work, a wing structure of a guided aircraft laboratory prototype was modelled via finite

element method. Different finite element models were created each represent a case of damage

in spar. The purpose of these finite element models is performing static analysis under action

of static load and obtain strains induced in the skins and the lateral deformation at the tip of

wing. Then the health monitoring technique is applied to estimate relations between damage of

stiffeners and the static induced strains and deformations. The geometry configurations and

dimensions are illustrated in figure (1), such that the wing consisting of upper and lower skins,

spars and ribs. The wing stiffeners are constructed as eight spars and ten ribs connected for

giving the wing structure the required stiffness. The four digits symmetrical NACA 0015 airfoil

was used as an aerodynamic shape for the considered wing. The (00) number of the NACA

indicating that it has no camber. The (15) number of the NACA indicates that the airfoil has a

“thickness to chord length ratio” of 15% as shown in figure (2). The equation describing the

geometric shape of a NACA 0015 foil is [4,5]:

(1)

x: is the location along chord from ranged (0 to 100%).

y(x) is the half thickness at any location x .

t: is maximum thickness of the wing as a fraction of the chord.

The chords of the wing structure were assigned as 1m and 0.4m at the root and tip

respectively with length 1.75m.

http://www.iaeme.com/IJMET/index.asp

157

editor@iaeme.com

Dr. Hatem Hadi Obeid

2.2. Mesh Generation of wing structure:

In order to study the effect of damage that occurred in the spars, finite elements models were

created for each damage case. The damage was assumed to be as a cut in the connection of the

main spar which is located at the maximum thickness of wing, such that it assumed that the

damage occurred at five locations in the spar nearest to the maximum wing thickness. High

order SHELL 8-node quadrilateral element and 6-nodes triangular element ware selected for

the generation finite element model of the wing structures. Figure (3) is shown the high order

SHELL 8-Node element parameters and degrees of freedom. The upper and lower skins were

discretized into ten divisions, to be generate one hundred shell elements at each skin. The spars

and ribs were discretized into ten divisions in order to connected with both and skins element

at the contracted nodes to maintain continuous element connections as shown in figure (4). The

thickness of all of skins, spars and ribs were assigned to 0.4 mm. Aluminum 2024 alloy -T3

was used as the material of all parts their mechanical properties are shown in table (1). [7]

3. DEFINITION OF THE ELEMENT COORDINATE SYSTEMS [8,9,10]

For the typical shell elements as shown in Figure (3), the external faces (surfaces) of the element

are curved, while the thickness is generated by straight lines. Many coordinate sets employed

in the formulation of degenerated shell element. These coordinate systems are described in the

following sections.

3.1. Global Coordinate System - (Xi)

It is the global Cartesian coordinate system, used to describe the wing geometry in the space.

The coordinates and deflections of nodes can be described using this coordinates system. In

addition to describe the assembled global stiffness matrix and assembled force vector. The

following notation is used:

Xi

(I=1,3) and X1 =X , X2=Y , X3=Z

,

U i (I=1,3) and U1=U, U2 =V, U3=W

(i=1,3) is a unit vector in the X i direction.

This system is used to define global stiffness matrix and applied force vector and in the

structure geometry, as well as nodal coordinate and displacements are referred to this system.

Xi

http://www.iaeme.com/IJMET/index.asp

158

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

3.2. Nodal Coordinate System (V1f , V2f , V3f )

This system type can be established at each nodal point as shown in Figure (3) with origin

located at reference surface (shell mid-surface), V3f is a vector formulated from nodal

coordinate of shell surfaces at node f,

V3 f X f Yf Zf top X f Yf Zf bot

T

V3 f X ftop X fbot ,

The unit vector

V3 f

hf

V3 f

V

V3 f

hf

x

3f

T

2

can normalize from the vectorV3f, thus:

V3yf

V3zf T

3

ΔX

2

1f

ΔX2 f ΔX3 f

2 1/ 2

2

4

i 1,2,3

ΔX if X iftop X ifbot

5

The vector V 3f is the direction of “normal” at the node f, which is not necessarily

perpendicular to the mid-surface at f.

The vector V2f is normal to plane of vectors V1f and V3f: V2f = V1f V3f .

The mathematical characteristic of vector V1f is perpendicular to V3f and parallel to the

global X – Z plane, thus: V1f V3f

x

, V1fy 0.0

z

Or, if the vector is in the Y-direction

V

V1fx V3fz

V1fz -V3fx

, V1fy 0.0

,

x

3f

V3fz 0.0

,

V1fz -V3fx

3.3. Curvilinear Coordinate System ( )

The description of this system is established by the definition of three coordinates, each one has

its characteristic as shown in Figure (3). The coordinate is an intrinsic coordinate through

thickness direction. coordinate is defined as a function of V , the -direction is considered

normal to the shell mid-surface. It is assumed that the curvilinear coordinate varies between (1 and +1), which represent the top and bottom surfaces of the element respectively. The two

other coordinates are ξ, η which are curvilinear coordinate in the middle plane of the shell

element and are also assumed to vary between (-1 and +1) which represent the faces of the

element.

3f

3.4. Local Coordinate System ( X

'

i

or X ' , Y ' , Z '

)

This system is a cartesian coordinate system defined at the sampling points wherein stresses

'

and strains are to be calculated. The direction Z is taken perpendicular to the mid-surface (

'

constant ), X ' and Y ' tangent it as shown in Figure (3). The vectors V1' , V2' , V3 define X ' ,Y ' and Z '

direction of mid-surface respectively, and it should be noted that,

x

ξ

y

ξ

ξ

z

ξ

,

x

η

y

η

η

z

η

x

ξ

y

V1 ξ

ξ

z

ξ

,

http://www.iaeme.com/IJMET/index.asp

,

159

x X

ξ

η

y Y

V3 ξ η

ξ η

z Z

ξ x η

6

editor@iaeme.com

Dr. Hatem Hadi Obeid

'

[T] = V1 ,

V 1'

,V ,V

'

2

'

3

V 2'

,

V 3'

: unit vectors on

7

X ' ,Y ' and Z '

.

3.5. Geometry of Elements [10]

To obtain the formulation of the coordinates of any point within the element, it is simpler to

divide the general formulation of coordinate in two parts. The first part is to establish the term

of formulation, which represents the intercept of the “normal” with the mid-surface. If there is

a node (f) at the “normal” at =0 surface and this “normal” has a top and bottom nodes at

=+1 and =-1 surfaces respectively, the coordinates of node (f) can be obtained as follows:

X 'f

1

X'f top X'f bot

2

,

X f

1

Yf 2

Z f

X f

Yf

Z f

top

X f

Yf

Z f

bot

8

Since node (f) is in the mid-surface (at =0 surface), the two dimensional interpolation

function N f , can be applied from Table (2) , to obtain relationship between the Cartesian

point and the curvilinear coordinate as follows:

X i N f , X if

n

f 1

9

The second part is to establish the second term of the general formulation, which defines

the position of the point along this “normal”. But to establish that, it is necessary to define

arbitrary point (p) on the “normal” at node (f), therefore the vector V3f which represents the

thickness of the shell hf, can be written ass:

X f

X f

h f V3 f Yf Yf

Z

Z

f top

f bot

10

The distance between the arbitrary point (p) and the node f (at mid-surface) can be written as follows:

Unit Distance

Since the

hf ζ

= 2

hf V

11

i

3f

means the coordinates of the arbitrary point, the equation (11) can be rewritten with

the application of the two-dimensional interpolation function N f ξ, η from Table () so that:

n

ζ

X i N f ξ, η V3i f

2

f 1

12

The general formulation of the coordinate defines the geometry of the shell element which

represents the rotations between the coordinate ( ξηζ ) and coordinates (X, Y, Z). It is

obtained by the summation of the previous two parts (equation (8) & equation (12)) so that:

http://www.iaeme.com/IJMET/index.asp

160

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

n

X i N f (, )

f 1

n

1 ζ

X if top N f (, ) 1 ζ X if bot

2

2

f 1

X

X

n

ζ hf

n

Y

N

(

,

)

Y N f (, )

f

2

f

1

f

1

Z

Z

mid

V

V

V

x

3f

y

3f

z

3f

13

is the elemental Cartesian coordinate, ( X 1 X , X 2 Y , X 3 Z ), n: is the number of nodes

per element, hf is the element thickness at node f, i.e. the respective “normal” length, Xif is

the Cartesian coordinate of nodal point f, and N f ( , ) is the two dimensional interpolation

functions. ( ζ =constant) at nodal point f.

Xi

3.6. Displacement Field [10]

Each node of the high order element has five degrees of freedom representing the displacement

along local coordinates. It is assumed that the strains in the directions to the mid-surface is

assumed to be negligible. The deflections through the element mid surface can be defined by

the three displacements (u,v,w), and two rotations of the nodal vector V3f about orthogonal

directions normal to it. One of the two orthogonal directions is represented by unit vector V 1 f

and the corresponding rotation ( α 1 f ). The other directions is V 2 f and the corresponding rotation

is ( α 2 f ), and it is the displacements ( δ1 f , δ 2 f ) of a point at unit distance (h) from node f on the

“normal” resulted from the two rotations ( α 1 f , 2f ) are calculated as follows:

α1f

δ1 f

h

α2f

δ1 f h α 1 f

or

δ2f

h

h

where

δ2f h α2f

or

hf

2

14

, δ1 f

is the displacement in the direction of V 1 f , δ 2 f is the displacement

in the negative direction of V 2 f . Equation (13) can be written as follows:

δ1 f h α 1 f

δ

α

2f

2f

15

The global displacement can be found from:

u N u

n

i

f

f 1

i

οf

N f u 'οf

i

mid

16

i

f

u i : the nodal displacement through element thickness. u : nodal displacement through

i

u'

Cartesian coordinate. f :nodal displacement through “normal” of the cross product of

rotations 1f and 2 f .

i

Since;

u οf δ1' f δ '2 f

17

'

'

'

where the corresponding displacement components ( 1f , 2f ) of u f can be calculated as

follows:

1' f

i

hf

1f V 1f

2

and

1' f

i

hf

1f V 1f

2

http://www.iaeme.com/IJMET/index.asp

18

161

editor@iaeme.com

Dr. Hatem Hadi Obeid

Since the global displacement can be found as shown before in equation (16) as the

i

simulation of the mid-surface nodal displacement ( u f ) and the relative displacements are

'i

caused by the rotations of the normal ( u f ), then the element displacement field can be

expressed by:

u if u iοf

i

i

ζ . hf

(V 1 f α 1 f V 2 f α 2 f )

2

19

V1xf

uf n

u

n

y

ζ

h

f

v N f ξ, η v f N f ξ, η

V1zf

2 V

f 1

w

f 1

1f

w f

V

α1f

V

α

V 2 f

x

2f

y

2f

z

2f

20

The contribution to the global displacement from a given node f in the general form and for

complete element is:

u i N f ξ, η, ζ Sf

n

f 1

Nf

u

v 0

w

0

Nf

Sf

0

0

Nf

0

0

Nf

ζ hf x

V1f

2

ζ hf y

Nf

V1f

2

ζ hf z

Nf

V1f

2

Nf

21

ζ hf x

V2 f

2

ζ hf y

Nf

V2 f

2

ζ hf z

Nf

V2 f

2

Nf

uf

vf

w f

α1 f

α

2 f

22

is the shape function matrix of the degenerated shell element.

is transformation matrix of the displacement vector at node f of shell element

u f , v f , w f , 1f , 2f T .

3.7. State of Stress [10]

The stress and strain components for the shell assumption of zero local stress through shell mid'

'

surface along Z -direction ( z 0 ) and using Hooks law enables the stresses vector to be

reduced to following five stress components,

σx

σ

y

σ τ x y Dε ε ο

τ x z

τ

yz

'

'

' '

' '

23

' '

is the initial strain vector.

is the strain vector.

[D] is the elasticity matrix given by,

0

0

1 ν 0

0

0

E ν 1 0

0

0

G

0

0

D

1 ν 2 0 0 0 K 1G

0

0 0 0

0

K 2 G

24

G: modulus rigidity, E: modulus of elasticity, : Poisson’s ratio,

K1, K2 is the shear correction factors.

http://www.iaeme.com/IJMET/index.asp

162

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

3.8. State of Strains [10]

The normal strain in the Z ' -direction ( z ) is neglected. Therefore, the general vector of green

strains it will be reduced to the following five components,

'

u

x

v

y

u v

y x

u w

z x

v w

z y

'

'

ε

ε

ε

'

x'

'

y'

x'y'

x 'z'

'

'

'

'

'

'

'

yz

'

'

'

'

'

'

'

25

'

'

'

The local derivatives above of the displacement components u , v and w in the local

'

coordinates system ( X 1 ) can be obtained as:

u'

x'

u'

'

y

u'

'

z

v'

x'

v'

y'

v'

z'

w'

u

x

x'

w '

T u

'

y

y

u

w'

z

z'

v

x

v

y

v

z

w

x

w

y

w

z

26

[ ] is the transformation matrix given by,

x

x'

y

[ ] '

x

z

'

x

u

x

u

y

u

z

v

x

v

y

v

z

x

ξ

x

[J]

η

x

ζ

x

y'

y

y'

z

y'

x

z'

y

'

z

z

z'

27

u

w

ξ

x

w

u

J 1

η

y

u

w

z

ζ

y

ξ

y

η

y

ζ

v

ξ

v

η

v

ζ

z

ξ

z

η

z

ζ

w

ξ

w

η

w

ζ

28

[J] is Jacobian matrix

29

The transpose of the Jacobian matrix results from equation (12) can be expressed as follow:

X f

h

T

[J] Yf N f , N f, 0 f

2

f 1

Z f

n

V3xf

V3xf

hf y

y

V3f 0 0 N f

V3f N f , N f, 0

2 z

V z

3f

V3f

30

n is the number of node per element,

hf is the element thickness at node f, and

N f ,

N f ,

N f ,

;

N f ,

http://www.iaeme.com/IJMET/index.asp

31

163

editor@iaeme.com

Dr. Hatem Hadi Obeid

are the derivatives of the global displacements referred to the curvilinear coordinates are

obtained from equation (18), such as

u

. . .etc.

hf x

hf x

u

N f , u f

V1 f N f , 1f

V2 f N f , 2f

f 1

2

2

n

32

The strain matrix B can be formulated from equations (21), (29) and (31) as:

B

33

where, δ u , v , w , α1 , α 2

T

a

i

0

bi

0

[B]= ci

0

bi

ai

ci

0

34

0

eiV 1 y

- eiV 2 x

0 (eiV i1 x diV i 1 y) (- eiV i 2 x diV i 1 y)

bi (giV i 1 y eiV i 1 z) (- giV i 1 y eiV i 2 z)

ai (diV i 1 z giV i 1 x) (- diV i 2 z giV i 2 x)

diV i1 x

0

- diV i 2 x

i

i

35

ai J Ni, ζ J Ni, η

bi J Ni, ζ J Ni, η

ci J Ni, ζ J Ni, η

di hi (aiz , J *31 Ni)

2

ei hi (biz , J *23 Ni)

2

g i hi (ciz , J *23 Ni)

2

*

11

*

21

*

12

*

31

*

22

*

32

Consequently, it is used in the calculation of the stiffness matrix [K] using the midcoordinate rule. Hence [K] can be defined as follows:

1 1 1

[K] [B]T [D][B] Jξ, η, ζ dζ dξ d η

1 1 1

36

Then K can be written as summing up the contribution of each layer at the gauss points,

1 1

2 Δh j

nL

[K] [B j ]T [D j ][B j ] Jξ, η, ζ

dξ dη

h

j

1

1 1

37

[K] : stiffness matrix, [D] : elasticity matrix, [Bj]: strain-displacement matrix.

J(, , )

is the determinant of the Jacobian matrix for layer ( j ).

h j

is the thickness of the jth layer.

nL is the total number of layers.

e

In the same way, the internal force vector { f } can be determined as follows:

{f e } [B]T {} J dV

38

v

2 Δh j

nL 1 1

{f e } [B j ]T {σ j } J(ξ(η, ζ)

dξ dη

h

j1 1 1

39

e

{f }

{ j }

: is current stress vector,

: is the internal force vector.

It should be noted that, it is essential in nonlinear analysis to determine the internal force

vector (or equivalent nodal forces) at the end of each iteration. The transformation to the local

coordinates system ( X Y ) using the following relation:

'

'

[Ds' ] [S]T [Ds ][S]

http://www.iaeme.com/IJMET/index.asp

40

164

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

l2

2

m

[S] 2lm

0

0

m2

l2

2lm

0

0

lm

lm

l 2 m2

0

0

0

0

0

l

m

0

0

0

m

l

41

3.7. Boundary conditions

The wing is clamped through the root chord such that all the degrees of freedom of the regarded

nodes are fixed to be zeros. While all other nodes are freely to be of three translations and three

rotations along the corresponding local coordinates.

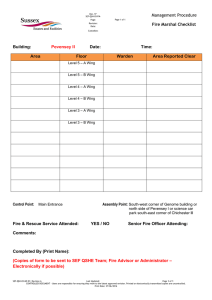

3.8. EXPERIMENTAL PREDICTION OF PRESSURE DISTRIBUTION:

In order to predict the load that applied on the wing structure, a prototype for the airfoil was

manufactured using wood material according to the digital naca number 0015. Then the

prototype was amounted in the wind tunnel section as shown in figure (5). Its required to

measure the pressure distribution through the airfoil, thus twelve manometers were used for this

purpose. The wind tunnel is flowing air at 50 m/s over the airfoil. The airfoil was mounted with

different attack angles (0 to 10 degrees). Figures (6),(7) showed the pressure distributions

through upper and lower skins with different attack angles. The net pressure distribution is equal

to the difference between the pressures through upper and lower skins. The pressure distribution

was measured for each attack angle which is represent the effect of aerodynamic lifting of the

wing.

http://www.iaeme.com/IJMET/index.asp

165

editor@iaeme.com

Dr. Hatem Hadi Obeid

3.9. STATIC ANALYSIS [10]

Static analysis solution has been included the calculation of the effects of the applied load under

steady loading conditions on a structure. The pressure distributions through upper and lower

skins were applied as normal pressures on the elements. The static analysis is governing by the

following equilibrium equation:

K q F

42

The above equilibrium equation is solved by jacobi iterative method to obtain the

displacement [q] vector.

4. RESULTS AND DISCUSION

Naman Jain [11,12] was created a Finite element code to solve shell structure under action of

static loads. In this work, a development was achieved for using Naman Jain code to generate

stiffened shell structure using quadrilateral eight nodes shell element and triangular six nodes

shell element. Jacobi iterative method was used to solve equation (42) to obtain the

deformations along global coordinates. Then the deformations transformed using equation (41)

to the local coordinates. The local deformations were transformed into global coordinates x,y

and z directions. The strains were estimated through local coordinates and substituted in the

stress strain relations to obtain elemental stresses through local coordinates. The first run

included the healthy structure that did not subjected into damage. Figure (8) showed the safe

strains induced in the lower skin along the intersection of the skins and main spar. Its noted that

the strains in the healthy wing were decreased gradually in the rejoins moved away than the

wing chord. The same behavior was noted in the strains induced in the upper and lower skins.

Figure (9) showed the safe lateral deformations induced in the lower skin along the intersection

of the skins and main spar. The lateral deformations of both the lower and upper skins at the

intersection of skins with main spar were approximately coincident. Also, the lateral

deformations were increased gradually in the rejoins moved away than the wing chord. A

similar behavior was noted in the study of Salu Kumar Das and Sandipan Roy [13]. The second

run included the static solution of the finite element model subjected to damage at the main spar

at the location apart 20% than the chord. The damage simulated as a cut in the element

connection of the spar and skins. The strain distributions are illustrated in figure (10), where

noted that a climax is initiated in the distribution at the location of the damage. In addition to

variation in the shape of the distribution of the strains in the rejoin between the damage and the

end tip of the wing. Figure (11) showed the distribution of the lateral deformations of the lower

skin at the intersection of the main spar with skins. The distribution indicated that there are two

shapes, the first shape in the rejoin between the chord and the damage where the distribution

was gradually increased. The second shape is between the damage and the end tip of the wing,

where the distribution appeared to be semi gradually comparative with the first region. This is

behavior due to the present of damage at the location 20% than the chord. In which the stiffness

if reduced rapidly at that location. So, this behavior can be used as a key to detect the damage

location. The other runs were executed for the finite element models that included the damages

at the locations apart than the chord by 40%, 60% and 80%. The behavior of the strain

distribution indicates a decreasing towards the end tip of the wing such that initiated a sudden

climax at the location of the damage as shown in figures (12, 14, and 16). The behavior of the

lateral deformations indicated variations the shape of the curve, such that the curve appeared to

be gradually increased the region between the chord and the damage. Semi to rapid increasing

in the lateral deformation occurred in region between the damage and the end tip of wing as

shown in figures (13, 15, and 17).

http://www.iaeme.com/IJMET/index.asp

166

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

http://www.iaeme.com/IJMET/index.asp

167

editor@iaeme.com

Dr. Hatem Hadi Obeid

http://www.iaeme.com/IJMET/index.asp

168

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

http://www.iaeme.com/IJMET/index.asp

169

editor@iaeme.com

Dr. Hatem Hadi Obeid

CONFLICT OF INTERESTS

Declare that there is no “conflict of interests” regarding the publication of this paper.

ACKNOWLEDGMENTS

My thankful for the assistance from the staff of post graduate laboratory at Department of

Mechanical Engineering ,College of Engineering, Babylon University ,Iraq.

DATA AVAILABILITY

All data concerned with the fixation and performing the test of pressure distributions

through wing in wind tunnel are available in the author and can be obtained via mailing.

The codes of the finite element analysis can be obtained after publication of the research

and can be contacting with author for this purpose.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

Structural Health Monitoring for Civil Structures: From the Lab to the Field, Piervincenzo

Rizzo, Yi Qing Ni, and Jinying Zhu Volume 2010, Article ID 165132.

Experimental modal analysis and dynamic strain fiber Bragg gratings for structural health

monitoring of composite antenna sub-reflector, Aikaterini Panopoulou, S. Fransen's,

Vicente Gomez-Molinero, Vassilis Kostopoulos

E.N. Jacobs, K.E. Ward, & R.M. Pinkerton. NACA Report No. 460, "The characteristics of

78 related airfoil sections from tests in the variable-density wind tunnel". NACA, 1933.

Fundamentals of aerodynamics", John D. Anderson,Jr, third ed, chap 4

Moran, Jack (2003). An introduction to theoretical and computational aerodynamics. Dover.

p. 7. ISBN 0-486-42879-6.

Payne, Greg (8 Jul 1994), NACA 6, 7, and 8 series, archived from the original on April 27,

2009

An experimental investigation into the high velocity penetration resistance of CFRP and

CFRP/aluminium laminates, Ming-ming Xu, Guang-yan Huang, Yong-xiang Dong, Shunshan Feng, Composite Structures, Volume 188, 15 March 2018, Pages 450-460.

The Finite Element Method Using MATLAB, Second Edition 2nd Edition, Young W.

Kwon, Hyochoong Bang,

Programing the Finite Element Method with Matlab, Jack Chessa, 3rd October 2002

William Weaver, Jr. and Paul R. Johnston,"Finite Element Programs for Structural

Analysis", Standford University, Printice-Hall Inc, N. J., 1984.

http://www.iaeme.com/IJMET/index.asp

170

editor@iaeme.com

Detection of Damage in Stiffeners of Aircraft Wing Structure Based On Induced Skin Strains and

Lateral Deflections

[11]

[12]

[13]

MATLAB Code for Structural Analysis of 2-D Structures Subjected to Static and SelfWeight Loading Conditions, Naman Jain, International Journal of Trend in Research and

Development, Volume 4, 2017.

EFFECT OF HIGHER ORDER ELEMENT ON NUMERICAL INSTABILITY IN

TOPOLOGICAL OPTIMIZATION OF LINEAR STATIC LOADING STRUCTURE, N

AMAN JAIN, Journal of Theoretical and Applied Mechanics, Sofia, Vol.48 No.3 (2018)

pp. 78-94.

Finite element analysis of aircraft wing using carbon fiber reinforced polymer and glass

fiber reinforced polymer, Salu Kumar Das , Sandipan Roy, 2nd International conference on

Advances in Mechanical Engineering (ICAME 2018), IOP Conf. Series: Materials Science

and Engineering 402 (2018) 012077.

http://www.iaeme.com/IJMET/index.asp

171

editor@iaeme.com