Axial Compressor Design: Thermodynamics & Fluid Mechanics

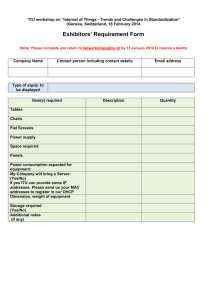

advertisement

Axial Compressor Design

Onur Tuncer

Istanbul Technical University

Faculty of Aeronautics and Astronautics

Department of Aeronautical Engineering

Maslak, Istanbul 34469

tuncero@itu.edu.tr

November 23, 2011

Outline

Introduction

Thermodynamics

Fluid Mechanics

Axial-Flow Compressor Blade Profiles

2-D Blade-to-Blade Flow

O. Tuncer (ITU)

Axial Compressor

November 2011

2 / 148

Introduction

Axial Flow Compressor Basics

Axial vs. Centrifugal Compressors

O. Tuncer (ITU)

Axial Compressor

November 2011

3 / 148

Introduction

Axial Flow Compressor Basics

Construction of an Axial Compressor

A stationary row of blades (stator) is followed by a rotating row of blades

(rotor).

A compressor stage is made up of a rotor and a stator.

O. Tuncer (ITU)

Axial Compressor

November 2011

4 / 148

Introduction

Basic Velocity Diagrams for a Stage

Polar Surface View of a Stage

The rotor row is rotating with a velocity U = ωr

Viewed in a reference frame rotating with the rotor, the upstream velocity

W is called the relative velovity.

The rotor deflects the flow such that the velocity in the stationary frame

of reference of the stator (the absolute velocity), C is properly aligned to

enter the stator row.

O. Tuncer (ITU)

Axial Compressor

November 2011

5 / 148

Introduction

Basic Velocity Diagrams for a Stage

Shrouded Stator Blades

O. Tuncer (ITU)

Axial Compressor

November 2011

6 / 148

Introduction

Basic Velocity Diagrams for a Stage

Guide Vane Velocity Triangles

O. Tuncer (ITU)

Axial Compressor

November 2011

7 / 148

Introduction

Basic Velocity Diagrams for a Stage

Velocity Triangle for a Rotor

O. Tuncer (ITU)

Axial Compressor

November 2011

8 / 148

Introduction

Basic Velocity Diagrams for a Stage

Velocity Triangle Calculations

Wθ = Cθ − ωr

The axial components of velocity are identical in both reference frames.

W z = Cz

The absolute

and relative velocities are,

q

2

C = Cz + Cθ2

q

W = Cz2 + Wθ2

The absolute β and relative β 0 flow angles are,

tan β = Cθ /Cz

tan β 0 = Wθ /Cz

O. Tuncer (ITU)

Axial Compressor

November 2011

9 / 148

Introduction

Similitude and Performance Characteristics

Similarity

Two turbomachines are completely similiar if the ratios of all corresponding

length dimensions, velocity components and forces are equal.

Equivalent Flow Rate Parameter

Q = ṁ/ρt

Local Axial Flow Velocity

Q = ṁ/ρt

Volume Flow Machines

ρ0 /ρt0 is a function of Cz 0. Therefore, unique velocity diagrams are

associated with a unique Q0 /A0 , yet can correspond to many values of

ṁ/A0 .

O. Tuncer (ITU)

Axial Compressor

November 2011

10 / 148

Introduction

Similitude and Performance Characteristics

An Equivalent Performance Map

O. Tuncer (ITU)

Axial Compressor

November 2011

11 / 148

Introduction

Similitude and Performance Characteristics

More on Similarity

I

True equivalent performance is obtained if working fluids obey the

perfect gas equation.

I

Similarity is also compromised if the compressors operate at

substantially different Reynolds numbers.

O. Tuncer (ITU)

Axial Compressor

November 2011

12 / 148

Introduction

Similitude and Performance Characteristics

More on Similarity

Alternative Equivalent Flow Parameters

√

√

Q/at0 ∝ ṁ Tt0 /Pt0 ∝ ṁ θ/δ

Sound

√ of speed is calculated by,

a = kRT

θ and δ relate inlet total conditions to some reference condition (most

often to standart atmospheric conditions).

θ = Tt0 /Tref

δ = Pt0 /Pref

The equivalent speed can be replaced by,

N/at0 ∝ N/

O. Tuncer (ITU)

p

√

Tt0 ∝ N/ θ

Axial Compressor

November 2011

13 / 148

Introduction

Similitude and Performance Characteristics

Efficiency

Previous figure only shows part of the information. However, it is

important to know how much work is necessary to drive the compressor.

η = ∆Hrev /∆H

Z

∆Hrev =

rev

O. Tuncer (ITU)

Axial Compressor

dP

ρ

November 2011

14 / 148

Introduction

Similitude and Performance Characteristics

An Equivalent Efficiency Map

O. Tuncer (ITU)

Axial Compressor

November 2011

15 / 148

Introduction

Stage Matching and Stability

Stage Matching and Stability

I

Each blade row achieves best performance for a specific inlet flow

angle, where losses are minimum.

I

The designer seeks to ”match” succeeding blade rows such that all

operate close to their optimum inlet flow angles, at a specific

operating condition (i.e. design point or match point)

I

At lower flow rates the characteristic has a positive slope which is

theoretically unstable. This severe unstable operation is commonly

called as surge.

I

In other cases abrupt stall might occur.

I

For higher flow rates no rise in pressure might occur. This is called

choke.

O. Tuncer (ITU)

Axial Compressor

November 2011

16 / 148

Introduction

Dimensionless Parameters

Dimensionless Parameters

Euler Turbine Equation

∆H = U(Cθ2 − Ctheta1 )

Total Enthalpy

1

H = h + C2

2

O. Tuncer (ITU)

Axial Compressor

November 2011

17 / 148

Introduction

Dimensionless Parameters

Dimensionless Parameters

Stage Work Coefficient

Ψ = ∆H/U 2 = (Cθ2 − Ctheta1 )/U

Stage Flow Coefficient

φ = Cz 1/U

Stage Reaction

R = (h2 − h1 )/(h3 − h1 )

O. Tuncer (ITU)

Axial Compressor

November 2011

18 / 148

Introduction

Dimensionless Parameters

Relationship Between φ, Ψ, R and Velocity Diagrams

50% Reaction Stages

tan β10 = −(Ψ/2 + R)/φ

tan β20 = (Ψ/2 − R)/φ

tan β1 = (1 − R − Ψ/2)/φ

tan β2 = (1 − R + Ψ/2)φ

O. Tuncer (ITU)

Axial Compressor

November 2011

19 / 148

Thermodynamics

First and Second Laws of Thermodynamics

First Law of Thermodynamics

I

Steady-state

I

Steady-flow

I

Open system

1 2

q̇ + ẇ = ṁ∆ u + C + P/ρ

2

Note that,

h ≡ u + P/ρ

O. Tuncer (ITU)

Axial Compressor

November 2011

20 / 148

Thermodynamics

First and Second Laws of Thermodynamics

Second Law of Thermodynamcis

Specific Entropy

ds =

dqrev

T

Second Law

∆s ≥ 0

Fundamental Thermodynamic Equation for Entropy

Tds = dh − VdP

O. Tuncer (ITU)

Axial Compressor

November 2011

21 / 148

Thermodynamics

Efficiency

An Enthalpy Entropy Diagram

O. Tuncer (ITU)

Axial Compressor

November 2011

22 / 148

Thermodynamics

Efficiency

Polytropic Efficiency

I

Polytropic efficiency is also known as small stage efficiency or true

aerodynamic efficiency.

I

Instead of using a path of constant entropy as the reversible path,

polytropic efficiency uses as path of constant efficiency defined by

ηP = ρ1 dP

dh .

Polytropic Head

∆Hp = ∆H − (sd − si )(Ttd − Tti )/ ln(Ttd /Tti )

Total to Polytropic Efficiency

ηP =

O. Tuncer (ITU)

∆Hp

∆H

Axial Compressor

November 2011

23 / 148

Thermodynamics

Fluid Equation of State Fundamentals

Fundamental Relations

Thermal Equation of State

P = P(ρ, T )

Calorific Equation of State

h = h(T , P)

u = u(T , P)

O. Tuncer (ITU)

Axial Compressor

November 2011

24 / 148

Thermodynamics

Fluid Equation of State Fundamentals

Ideal Gas Law

P = ρRT

R = Ru /M

Ru = 8314 Pa.m3 /(kmol.K )

O. Tuncer (ITU)

Axial Compressor

November 2011

25 / 148

Thermodynamics

Fluid Equation of State Fundamentals

A Pressure Enthalpy Diagram Schematic

O. Tuncer (ITU)

Axial Compressor

November 2011

26 / 148

Thermodynamics

The Calorific Equation of State

The Calorific Equation of State

∂h◦

=

∂T

◦ P

∂h

cv◦ (T ) =

∂T V

cp◦ (T )

For a thermally perfect gas,

cp◦ (T ) − cv◦ (T ) = R

◦

◦

T

Z

h (T ) = h (Tref ) +

u ◦ (T ) = u ◦ (Tref ) +

Tref

T

Z

cp◦ (T )dT

cv◦ (T )dT

Tref

O. Tuncer (ITU)

Axial Compressor

November 2011

27 / 148

Thermodynamics

Entropy and the Speed of Sound

Entropy and the Speed of Sound

Specific Entropy

◦

◦

Z

T

s (T , P) = s (Tref , Pref ) +

Tr ef

cp◦ (T )

− R ln(P/Pref )

T

Specific Entropy for a Calorifically Perfect Gas

s ◦ (T , P) = s ◦ (Tref , Pref ) + cp◦ ln(T /Tref ) − R ln(P/Pref )

O. Tuncer (ITU)

Axial Compressor

November 2011

28 / 148

Thermodynamics

Entropy and the Speed of Sound

Speed of Sound

Thermodynamic Relation for the Speed of Sound

◦

a =

∂P

∂ρ

=k

s

∂P

∂ρ

T

Ratio of Specific Heats

k = cp /cv

Speed of Sound for a Thermally Perfect Gas

a◦ =

O. Tuncer (ITU)

√

kRT

Axial Compressor

November 2011

29 / 148

Thermodynamics

The Thermal Equation of State for Real Gases

The Thermal Equation of State for Real Gases

General Thermal Equation of State for a Real Gas

P/(ρRT ) = z(T , P)

where z is the compressibility factor.

For ideal gases z = 1.

Parametric Equations

Simple two-parameter equations of state are a good choice for general

aerothermodynamic design and analysis.

O. Tuncer (ITU)

Axial Compressor

November 2011

30 / 148

Thermodynamics

The Thermal Equation of State for Real Gases

Redlich-Kwong Equation of State

Redlich-Kwong Equation

P=

a

RT

√

−

V − b V (V + b) Tr

where Tr = T /Tc is the reduced temperature and,

a = 0.42747R 2 Tc /Pc

b = 0.08664RTc /Pc

O. Tuncer (ITU)

Axial Compressor

November 2011

31 / 148

Thermodynamics

Thermodynamic Properties of Real Gases

Thermodynamic Properties of Real Gases

Departure Functions

I

Specification of the calorific equation of state, h◦ , u ◦ are limited to

state points where the fluid is thermally perfect.

I

For non-ideal fluids h and u are functions of P and T .

I

Thermodynamics properties of a non-ideal fluid are best accomplished

utilizing departure functions.

I

Departure functions are defined as the difference between the actual

value of a parameter and its value under conditions where the fluid is

thermally perfect.

O. Tuncer (ITU)

Axial Compressor

November 2011

32 / 148

Thermodynamics

Thermodynamic Properties of Real Gases

Departure Functions

Corresponding Specific Volume

V ◦ = RT /P ◦

If A=Helmholtz Energy

A − A◦ = −

Z

V

(P − RT /V )dV − RT ln(V /V ◦ )

∞

◦

s −s =−

∂(A − A◦ )

∂T

V

h − h◦ = (A − A◦ ) + T (s − s ◦ ) + RT (z − 1)

u − u ◦ = (A − A◦ ) + T (s − s ◦ )

O. Tuncer (ITU)

Axial Compressor

November 2011

33 / 148

Thermodynamics

Thermodynamic Properties of Real Gases

Redlich-Kwong Departure Functions

h−h

◦

s − s◦

a

V +b

−n

= PV − RT − (n + 1)Tr ln

b

b

V V −b+c

na −n

V +b

= −R ln

−

T ln

V◦

V

bT r

b

where, c = 0 and n = 0.5 for the original Redlich-Kwong equation of state.

O. Tuncer (ITU)

Axial Compressor

November 2011

34 / 148

Thermodynamics

Thermally and Calorifically Perfect Gases

Thermally and Calorifically Perfect Gases

When the fluid can be considered thermallyperfect (z = 1) and calorifically

perfect (cp , cv and k are constants), equation of state calculations are

greatly simplified.

Calculations for Enthalpy and Entropy

h = href + cp (T − Tref )

s = sref + cp ln(T /Tref ) − R ln(P/Pref )

O. Tuncer (ITU)

Axial Compressor

November 2011

35 / 148

Thermodynamics

Thermally and Calorifically Perfect Gases

Thermally and Calorifically Perfect Gases

Relation Between Total and Static Conditions

1

cp (Tt − T ) = C 2

2

T /Tref = (P/Pref )

k−1

k

= (ρ/ρref )k−1

Efficiency Calculations

k−1

ηad

=

ηp =

O. Tuncer (ITU)

(Ptd /Pti ) k − 1

Ttd /Tti − 1

k − 1 ln(Ptd /Pti )

k ln(Ttd /Tti )

Axial Compressor

November 2011

36 / 148

Thermodynamics

The Pseudo-Perfect Gas Model

The Pseudo-Perfect Gas Model

The concept is to use fictitious values of cp , cv and k in an otherwise

standart calorifically and thermally perfect gas model.

√

R̄ = R z1 z2

c¯p = (h2 − h1 )/(T2 − T1 )

c¯v

= (u2 − u1 )/(T2 − T1 )

k̄ = ln(P2 /P1 )/ ln(ρ2 /ρ1 )

O. Tuncer (ITU)

Axial Compressor

November 2011

37 / 148

Thermodynamics

Component Performance Parameters

Diffuser

Diffuser Efficiency

ηdiff =

∆had

∆h

Pressure Recovery Coefficient

cp =

O. Tuncer (ITU)

Pd − Pi

Pti − Pi

Axial Compressor

November 2011

38 / 148

Thermodynamics

Component Performance Parameters

Nozzle

Pressure Loss Coefficient

Nozzle Efficiency

ηnoz =

ω̄ =

Cd2 − Ci2

2 − C2

Cad

i

ηnoz = 1 −

∆Pt

1

2

2 ρC

Pti − Ptd

Pi − Pd

Pressure Loss

∆Pt

Pti − Ptd

=

= T ∆s

ρ

ρ

O. Tuncer (ITU)

Axial Compressor

November 2011

39 / 148

Thermodynamics

Gas Viscosity

Gas Viscosity

Dean and Stiel Model

1/6

ξ = Tc /

√

2/3

MPc

Low pressure fluid viscosity,

8/9

µ0 ξ = (3.4.10−4 Tr

, Tr ≤ 1.5

µ0 ξ = 0.001668(0.1338Tr − 0.0932)5/9 , Tr > 1.5

Then, the viscosity at any pressure can be defined by the following

departure function.

(µ − µ◦ )ξ = (1.08.10−4 )[exp(1.439ρr ) − exp(−1.111ρr1.858 )]

O. Tuncer (ITU)

Axial Compressor

November 2011

40 / 148

Fluid Mechanics

Flow in a Rotating Coordinate System

Flow in a Rotating Coordinate System

The analysis of the flow in the rotor blade rows is accomplished in a

coordinate system that rotates with the blade.

Wθ = Cθ − ωr

The axial and radial velocity components are independent of rotation.

Wz

= Cz

Wr

= Cr

Meridional Velocity Component

Wm =

O. Tuncer (ITU)

q

Wz2 + Wr2 = Cm

Axial Compressor

November 2011

41 / 148

Fluid Mechanics

Flow in a Rotating Coordinate System

Stream Surface and Natural Coordinate System

A stream surface is defined as a surface having no fluid velocity

component normal to it.

Schematic of a Stream Surface

Natural Coordinate System

(dm)2 = (dr )2 + (dz 2 )

O. Tuncer (ITU)

Axial Compressor

November 2011

42 / 148

Fluid Mechanics

Flow in a Rotating Coordinate System

Euler Turbine Equation

Consider the flow through a thin stream sheet (i.e. a thin annular passage

bounded by two stream surfaces). The torque τ acting on the fluid

between merional stations 1 and 2 is provided by the conservation of

angular momentum.

τ = ṁ(r2 Cθ2 − r1 Cθ1 )

The torque must balance the power input.

ẇ = ωτ = ω ṁ(r2 Cθ2 − r1 Cθ1 )

Euler Turbine Equation

H2 − H1 = ω(r2 Cθ2 − r1 Cθ1 )

O. Tuncer (ITU)

Axial Compressor

November 2011

43 / 148

Fluid Mechanics

Flow in a Rotating Coordinate System

Rothalpy

Total enthalpy change is produced by a transfer of mechanical energy

between the fluid and the rotating blade row.

I = H − ωrCθ

For a stationary blade row, I = H.

Aerodynamic analysis of axial compressors involve the solution of

conservation equations in both rotating (rotors) and stationary (stators)

coordinates.

The relationship between relative total enthalpy H 0 in a rotating, and

absolute total entalhalpy in a stationary coordinate system.

1

1

h = H0 − W 2 = H − C 2

2

2

O. Tuncer (ITU)

Axial Compressor

November 2011

44 / 148

Fluid Mechanics

Flow in a Rotating Coordinate System

Rothalpy (Continued)

The relative velocity W ,

W =

q

Wm2 + Wθ2

Total enthalpies,

1

1

H 0 = H − ωrCθ + (ωr )2 = I + (ωr )2

2

2

Since I is constant on the stream surface, above equation allows the

calculation of H 0 at all points on a stream surface when one value is

known, e.g. at the inlet.

O. Tuncer (ITU)

Axial Compressor

November 2011

45 / 148

Fluid Mechanics

Adiabatic Inviscid Compressible Flow

Adiabatic Inviscid Compressible Flow

Vector Form of Momentum Equation in a Rotating Coordinate Frame

~

~

1~

DC

DW

~ )+ω

= − ∇P

+ 2(~

ωx W

~ x(~

ω x~r )

=

Dt

ρ

Dt

where,

~

~

DW

∂W

~ .∇)

~

~ W

=

+ (W

Dt

∂t

Hence the momentum equation in rotating coordinates is,

~

~

∂W

∇P

~ .∇)

~ + 2(~

~ )+ω

~ W

+ (W

ωx W

~ x(~

ω x~r ) =

∂t

ρ

O. Tuncer (ITU)

Axial Compressor

November 2011

46 / 148

Fluid Mechanics

Adiabatic Inviscid Compressible Flow

Vector Form of Continuity and Energy Equations

∂ρ ~

~ )=0

+ ∇.(ρW

∂t

1 ∂P

∂I

~ .∇)I

~ =0

−

+ (W

∂t

ρ ∂t

O. Tuncer (ITU)

Axial Compressor

November 2011

47 / 148

Fluid Mechanics

Adiabatic Inviscid Compressible Flow

Governing Equations in Natural Coordinates

∂ρ 1 ∂r ρWm ∂ρWθ

+

+

+ κn ρWm = 0

∂t

r

∂m

∂θ

Wm Wθ ∂Wm sin φ

1 ∂P

∂Wm

+ Wm

+

−

[Wθ + ωr ]2 = −

∂t

∂m

r ∂θ

r

ρ ∂m

∂Wθ

∂Wθ

Wθ ∂Wθ

Wm sin φ

1 ∂P

+ Wm

+

+

[Wθ + 2ωr ] = −

∂t

∂m

r ∂θ

r

r ρ ∂θ

κm Wm2 +

cos φ

1 ∂P

[Wθ + ωr ]2 =

r

ρ ∂n

∂I

1 ∂P

∂I

Wθ ∂I

−

+ Wm

+

=0

∂t

ρ ∂t

∂m

r ∂θ

O. Tuncer (ITU)

Axial Compressor

November 2011

48 / 148

Fluid Mechanics

Adiabatic Inviscid Compressible Flow

Governing Equations in Natural Coordinates

The curvature of the stream sheet κm and the normal of the surface κn

are related to the angle φ as follows.

∂φ

∂m

∂φ

1 ∂b

=

∂n

b ∂m

κm = −

κn =

Parameter b is the thickness of the stream sheet bounded by two stream

surfaces.

O. Tuncer (ITU)

Axial Compressor

November 2011

49 / 148

Fluid Mechanics

Adiabatic Inviscid Compressible Flow Applications

Adiabatic Inviscid Compressible Flow Applications

I

To determine the flow in the meridional plane

I

Blade-to-blade flow solutions

I

Hub to shroud flow solutions

I

Quasi three dimensional analysis

O. Tuncer (ITU)

Axial Compressor

November 2011

50 / 148

Fluid Mechanics

Boundary Layer Analysis

Boundary Layer Analysis

The basic premise of boundary layer theory is that the viscous effects are

confined to a thin layer close to the physical surfaces bounding the flow

passages.

I

I

Blade surface boundary layers play an important role in viscous losses

and stall or boundary layer seperation.

Endwall boundary layers can produce substantial viscous blockage

effects that significantly affect compressor performance.

O. Tuncer (ITU)

Axial Compressor

November 2011

51 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Two-Dimensional Boundary Layer Analysis

I

Two-dimensional boundary layer analysis is a useful approximation in

blade design.

I

Two dimensional blade sections designed between the hub and tip are

stacked together to create the actual three dimensional compressor

blade.

Boundary Layer Equations

Basic conservation of mass and momentum provide the governin equations

for two dimensional boundary layer flow over an adiabatic wall.

∂ρbu ∂ρbv

+

=0

∂x

∂y

u

O. Tuncer (ITU)

∂u

∂u 1 ∂P

1 ∂τ

+v

+

=

∂x

∂y

ρ ∂x

ρ ∂y

Axial Compressor

November 2011

52 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Integral Form of Boundary Layer Analysis

Integrating the conservation of mass across the boundary layer and

applying the Liebnitz rule to interchange the order of integration and

differentiation yields.

∂

∂x

Z

δ

bρudy = bρe ue

0

∂δ

∂

− bρe ve =

[bρe ue (δ − δ ∗ )]

∂x

∂x

Displacement Thickness

∗

Z

δ

[ρe ue − ρu]dy

ρe ue δ =

0

It is a fictitious thickness used to correct the mass balance relative to the

inviscid flow solution.

O. Tuncer (ITU)

Axial Compressor

November 2011

53 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Integral Form of Boundary Layer Analysis (Continued)

Momentum Thickness

ρe ue2 θ =

Z

ρu[ue − u]dy

Combining displacement and momentum thicknesses yields,

Z

δ

ρu 2 dy = ρe ue2 [δ − δ ∗ − θ]

0

If the free stream conditions are applied within the boundary layer with no

flow in the thickness δ ∗ , and no momentum in the thickness θ, momentum

conservation will be corrected for viscous effects. This is the basis of

integral boundary layer analysis method.

O. Tuncer (ITU)

Axial Compressor

November 2011

54 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Integral Form of Boundary Layer Analysis (Continued)

Integrating the momentum equation across the boundary layer. Further

noting that P = Pe across the boundary layer,

∂

∂x

Z

0

δ

bρu 2 dy − ρe ue2

∂δ

∂Pe

+ ρe ue ve + δ

= −τw

∂x

∂x

Arranging and manipulating this statement one arrives at the well-known

momentum integral equation.

1 ∂bρe ue2 θ

∂ue

+ δ ∗ ρe ue

= τw

b ∂x

∂x

O. Tuncer (ITU)

Axial Compressor

November 2011

55 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Flow Entrainment into the Boundary Layer

The momentum integral equation is valid for both laminar and turbulent

boundary layers.

Laminar boundary layer analysis usually employs specific boundary layer

flow profile assumptions to permit direct integration of the momentum

integral equation.

Turbulent boundary layer analysis usually employs several empirical models

for solution, which may include specific boundary layer flow profile

assumptions.

Usually turbulent boundary layer analysis employs a second conservation

equation (i.e mass, energy, moment of momentum).

∂

[bρe ue (δ − δ ∗ )] = bρe ue E

∂x

Entrainment Function

E=

O. Tuncer (ITU)

∂δ

ve

−

∂x

ue

Axial Compressor

November 2011

56 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Axisymmetric Three-Dimensional Boundary Layer Analysis

The governing equations for axisymmetric three-dimensional boundary

layer flow in a rotating coordinate system in natural coordinates are,

1 ∂ρWm ∂ρWy

+

=0

r ∂m

∂y

∂Wm

∂Wm sin φ

1

∂Pe

∂τm

2

Wm

+ Wy

−

(Wθ + ωr ) =

fm −

−

∂m

∂y

r

ρ

∂m

∂y

∂Wθ

∂Wθ

sin φ

1

∂τθ

Wm

+ Wy

+

Wm (Wθ + 2ωr ) =

fθ −

∂m

∂y

r

ρ

∂y

Body force terms,

fme = ρe Wme

fθe = ρe Wme

O. Tuncer (ITU)

∂Wme

∂Pe

sin φ

+

−

ρe (Wθe + ωr )2

∂m

∂m

r

∂Wθe

sin φ

ρe Wme ∂rCthetae

+

ρe Wme (Wθe + 2ωr ) =

∂m

r

r

∂m

Axial Compressor

November 2011

57 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Integral Form of Axisymmetric Three Dimensional

Boundary Layer Equations

Boundary layer equations are converted into integral form in the same

manner as described earlier. The resulting integral equations are,

∂

[r ρe Wme (δ − δ1∗ )] = r ρe We E

∂m

∂

∂Wme

2

[r ρe Wme

θ11 ] + δ1∗ r ρe Wme

∂m

∂m

− ρe Wθe sin φ[Wθe (δ2∗ + θ22 ) + 2ωr δ2∗

= r [τmw + fme vm ]

∂ 2

∂Wθe

∗

[r ρe Wme Wθe θ12 ] + r δ1 ρe Wme r

+ sin φ(Wθe + 2r ω)

∂m

∂m

= r 2 [τθw + fθe vθ ]

O. Tuncer (ITU)

Axial Compressor

November 2011

58 / 148

Fluid Mechanics

Two-Dimensional Boundary Layer Analysis

Mass, Momentum and Force Defects

ρe Wme δ1∗

Z

δ

(ρe Wme − ρWm )dy

=

0

2

ρe Wme

θ11 =

Z

δ

ρWm (Wme − Wm )dy

0

Z

δ

ρWm (Wθe − Wθ )dy

ρe Wme Wθe θ12 =

0

ρe Wθe δ2∗

Z

δ

=

(ρe Wθe )dy

0

2

ρe Wθe

θ22

Z

δ

ρWθ (Wθe − Wθ )dy

=

0

Z

vm fme

δ

(fme − fm )dy

=

0

Z

vθ fθe

O. Tuncer (ITU)

δ

(fθe − fθ )dy

=

0

Axial Compressor

November 2011

59 / 148

Axial-Flow Compressor Blade Profiles

Basic Airfoil Geometry

Blade Camber Angle

θ = χ1 + χ2

O. Tuncer (ITU)

Axial Compressor

November 2011

60 / 148

Axial-Flow Compressor Blade Profiles

Cascade Nomenclature

Cascade Nomenclature

Cascade Solidity

σ = c/s

Stagger Angle γ

O. Tuncer (ITU)

Axial Compressor

November 2011

61 / 148

Axial-Flow Compressor Blade Profiles

Cascade Nomenclature

Cascade Nomenclature (Continued)

κ1 and kappa2

The angles between slopes to the camberline and the axial direction, at

the leading and trailing edges respectively.

Incidence Angle

i = β 1 − κ1

Deviation Angle

δ = β2 − κ2

Angle of Attack

α = β1 − γ

O. Tuncer (ITU)

Axial Compressor

November 2011

62 / 148

Axial-Flow Compressor Blade Profiles

Cascade Nomenclature

Notes on Cascade Nomenclature

I

This cascade nomenclature is directly applicable to blades based on

well-defined camberlines such as the circular arc and parabolic arc

camberlines (typical of British practice).

I

American practice is based on NACA airfoils, which typically have

infinite camberline slopes at the leading and trailing edges. A suitable

approximate reference is needed to define κ, χ, θ, i and δ. Common

practice is to use an equivalent circular arc camberline as a reference.

I

Construction of blades from the base camberline and profile is

occasionally a source of confusion. When imposing a profile on a

blade with camber, the thickness distribution data should be

interpreted in terms of dimensionless distance along the camberline

rather than along the chord line.

O. Tuncer (ITU)

Axial Compressor

November 2011

63 / 148

Axial-Flow Compressor Blade Profiles

Cascade Nomenclature

Dimensionless Data for Axial Flow Compressor Blades

O. Tuncer (ITU)

Axial Compressor

November 2011

64 / 148

Axial-Flow Compressor Blade Profiles

NACA 65-Series Profile

NACA 65-Series Profile

I

The NACA 65-series blades are derived from NACA aircraft wing

airfoils for approximately uniform loading.

I

NACA 65-series airfoils are designated by their lift coefficients and

maximum thickness to chord ratio. The lift coefficient in tenths first

appear in parentheses followed by the thickness to chord ratio.

O. Tuncer (ITU)

Axial Compressor

November 2011

65 / 148

Axial-Flow Compressor Blade Profiles

NACA 65-Series Profile

NACA 65-12 and Equivalent Circular Arc Camberline

Profiles

Relation between the effective camber angle and the lift coefficient.

tan(θ/4) = 0.1103Cl0

O. Tuncer (ITU)

Axial Compressor

November 2011

66 / 148

Axial-Flow Compressor Blade Profiles

Circular Arc Camberline

Circular Arc Camberline

Commonly used in conjunction with the British C.4 profile. Also the

camberline used for double circular arc profile.

O. Tuncer (ITU)

Axial Compressor

November 2011

67 / 148

Axial-Flow Compressor Blade Profiles

Circular Arc Camberline

Circular Arc Camberline (Continued)

c/2 = Rc (sin(θ/2)

yc = −Rc cos(θ/2)

y = yc +

p

Rc − x 2

2y (0)/c = [1 − cos(θ/2)]/ sin(θ/2) = tan(θ/4)

O. Tuncer (ITU)

Axial Compressor

November 2011

68 / 148

Axial-Flow Compressor Blade Profiles

Parabolic Arc Camberline

Parabolic Arc Camberline

Parabolic arc camberline is also used with British C.4 profile and with

others as well.

The parabolic arc allows a more general blade loading style than the

circular arc. Front, mid and rear loaded blades are all possible. This

loading can be changed by changing the location of maximum camber.

O. Tuncer (ITU)

Axial Compressor

November 2011

69 / 148

Axial-Flow Compressor Blade Profiles

Parabolic Arc Camberline

Parabolic Arc Camberline (Continued)

The point of maximum camber is located at x = a, y = b.

The basic constraints are,

y (0) = 0

y (c) = 0

y (a) = 0

y 0 (a) = 0

The camberline is generated using the general second-order equation.

√

Ax 2 + 2 AE xy + By 2 + Cx + Dy + E = 0

Note that one of the coefficients is arbitrary.

x2 +

O. Tuncer (ITU)

c − 2a

(c − 2a)2 2

c 2 − 4ac

xy +

y

−

cx

−

y =0

b

4b 2

4b

Axial Compressor

November 2011

(1)

70 / 148

Axial-Flow Compressor Blade Profiles

Parabolic Arc Camberline

Parabolic Arc Camberline (Continued)

To evaluate the blade angles the derivative of the previous expression at

x = 0 and x = c can be used.

tan χ1 = 4b/(4a − c)

tan χ2 = 4b/(3c − 4a)

Parabolic arc camberline in terms of camber and the ratio a/c

q

b/c = [ 1 + (4 tan θ)2 [a/c − (a/c)2 − 3/16] − 1]/(4 tan θ)

Note that,

0.25 < a/c < 0.75s

O. Tuncer (ITU)

Axial Compressor

November 2011

71 / 148

Axial-Flow Compressor Blade Profiles

British C.4 Profile

British C.4 Profile

I

One of the several profiles in the British C series.

I

With respect to NACA-65 series, C.4 is thicker towards the leading

edge.

I

Maximum thickness at 30% chord.

I

Less effective at higher Mach numbers but higher structural integrity.

I

C.7 profile has more use in compressors and quite similiar to

NACA-65 series.

O. Tuncer (ITU)

Axial Compressor

November 2011

72 / 148

Axial-Flow Compressor Blade Profiles

British C.4 Profile

Designation of C Series Profiles

I

C-series profiles are designated by a code giving tb , profile, θ,

camberline and a/c.

I

10C4/20P40 is a 10% thick C.4 profile with 20◦ camber angle using a

parabolic arc camberline with a/c = 0.4.

I

10C4/20C50 similiar but with a circular arc camberline.

Note: Well established empirical performance prediction models exist

for C.4 profiles.

O. Tuncer (ITU)

Axial Compressor

November 2011

73 / 148

Axial-Flow Compressor Blade Profiles

Double Circular Arc Profile

Double Circular Arc Profile

Double circular arc profiles are constructed with both surfaces formed by

circular arcs, that blend with a nose radius r0 applied both at the leading

and trailing edgrs.

∆xU = (RU − r0 ) sin(θU /2) = c/2 − r0 cos(θ/2)

O. Tuncer (ITU)

Axial Compressor

November 2011

74 / 148

Axial-Flow Compressor Blade Profiles

Double Circular Arc Profile

Double Circular Arc Profile (Continued)

∆yU = Ru − y (0) − tb /2 + r0 sin(θ/2) = RU − d

d = y (0) + tb /2 − r0 sin(θ/2)

The Phythagorean theorem applied to the right triangle requires,

[RU − r0 ]2 = [RU − d]2 + [c/2 − r0 cos(θ/2)]2

Ru =

d 2 − r02 + [c/2 − r0 cos(θ/2)]2

2(d − r0 )

The leading and trailing edge radii are constructed about their centers at

y = r0 sin(θ/2) and x = ±[c/2 − r0 cos(θ/2)] to blend with the circular arc.

O. Tuncer (ITU)

Axial Compressor

November 2011

75 / 148

Axial-Flow Compressor Blade Profiles

NACA A4 K6 63-Series Guide Vane Profile

NACA A4 K6 63-Series Guide Vane Profile

This vane has excellent flow guidance and a wide incidence operating

range.

The camberline is developed by combining a front-loaded A profile with

Cl0 = 0.4 and a uniform loaded K profile with Cl0 = 0.6, which is

designated as the A4 K6 camberline corresponding to Cl0 = 1. This

geometry is combined with the 6% thick NACA-63 series profile as the

base guide vane geometry. Similiar to 65 series blades, the camberline

coordinates can be scaled directly by lift cooefficient to alternate

camberlines. The thickness distribution can be scaled as well.

O. Tuncer (ITU)

Axial Compressor

November 2011

76 / 148

Axial-Flow Compressor Blade Profiles

NACA A4 K6 63-Series Guide Vane Profile

NACA A4 K6 63-Series Guide Vane Profile (Continued)

The general vane designation is 63 − (Cl0 A4 K6 )nn , where nn is the

maximum thickness as percent of chord.

The leading and trailing edge camberline slopes are infinite. An equivalent

parabolic arc camberline can be used to provide viable definitions of

leading and trailing edge blade angles.

tan θ =

O. Tuncer (ITU)

291.5cl0

468.75 − (5.83Cl0 )2

Axial Compressor

(2)

November 2011

77 / 148

Axial-Flow Compressor Blade Profiles

Controlled Diffusion Airfoils

Controlled Diffusion Airfoils

I

I

I

I

I

I

I

Standart blade profiles are used extensively for axial compressors.

These are well-understood, reliable and can yield excellent

performance if properly applied.

However, many investigators have explored alternatives offering better

Mach number range and efficiency.

This is possible by specifying Mach number distributions on the

surface.

A continuous acceleration along the suction surface and near the

leading edge to avoid boundary layer separation or premature

separation.

The peak Mach number should not exceed 1.3 in order to avoid

shock-wave induced separation.

Carefully controlled deceleration along the suction surface from the

peak Mach number to avoid turbulent boundary layer separation

ahead of the trailing edge.

A nearly constant Mach number distribution on the pressure surface.

O. Tuncer (ITU)

Axial Compressor

November 2011

78 / 148

Axial-Flow Compressor Blade Profiles

Controlled Diffusion Airfoils

Controlled Diffusion Airfoils (Continued)

O. Tuncer (ITU)

Axial Compressor

November 2011

79 / 148

Axial-Flow Compressor Blade Profiles

Blade Throat Opening

Blade Throat Opening

Minimum distance between adjacent blades.

Governs the onset of local flow choking within the blade passage.

O. Tuncer (ITU)

Axial Compressor

November 2011

80 / 148

Axial-Flow Compressor Blade Profiles

Blade Throat Opening

Blade Throat Opening for NACA-65 Series Blades

Stagger Angle Parameter

1.5

1.5

φ = γ(1 − 0.05Cl0

) + 5Cl0

−2

Throat Opening to Pitch Ratio

√

√

o/s = [1 − tb σ/c) cos φ] σ

O. Tuncer (ITU)

Axial Compressor

November 2011

81 / 148

Axial-Flow Compressor Blade Profiles

Blade Throat Opening

Extended Throat Opening Correlation

O. Tuncer (ITU)

Axial Compressor

November 2011

82 / 148

Axial-Flow Compressor Blade Profiles

Blade Throat Opening

Staggered Blade Geometry

Once the camberline and profile coordinates are generated along the

chord, the geometry of the staggered blade in the cascade is obtained by a

simple rotation of coordinates to the stagger angle γ.

The staggered blade inlet and discharge angles are given by,

κ1 = χ1 + γ

κ2 = γ − χ2

θ = κ1 − κ2

For circular arc or NACA 65 series equivalent circular arc approximation.

χ1 = χ2 = θ 2

γ = (κ1 + κ2 )/2

O. Tuncer (ITU)

Axial Compressor

November 2011

83 / 148

2-D Blade-to-Blade Flow

Two-Dimensional Blade-to-Blade Flow Through Cascades

of Blades

I

Offers a very natural view of cascade fluid dynamics to make it easier

for designers to develop an understanding of the basic flow processes

involved.

I

Inviscid blade-to-blade flow analysis addresses the general problem of

two dimensional flow on a stream surface in an annular cascade.

I

Two dimensional boundary layer analysis can be used to approximate

viscous effects.

I

Ignores secondary flows.

I

Loses accuracy when significant flow separation is present.

O. Tuncer (ITU)

Axial Compressor

November 2011

84 / 148

2-D Blade-to-Blade Flow

The Blade-to-Blade Flow Problem

The Blade-to-Blade Plane Flow

O. Tuncer (ITU)

Axial Compressor

November 2011

85 / 148

2-D Blade-to-Blade Flow

The Blade-to-Blade Flow Problem

The Blade-to-Blade Plane Stream Sheet

O. Tuncer (ITU)

Axial Compressor

November 2011

86 / 148

2-D Blade-to-Blade Flow

Coordinate System and Velocity Components

Coordinate System and Velocity Components

Convenient to use a coordinate transformation into new coordinates (ξ, η)

such that blade surfaces correspond to η = constant.

Z

m

dm

0 cos β

η = [θ − θ0 ]/[θ1 − θ0 ]

ξ =

O. Tuncer (ITU)

Axial Compressor

November 2011

87 / 148

2-D Blade-to-Blade Flow

Coordinate System and Velocity Components

Coordinate System and Velocity Components

r ∂θ

tan β =

∂m

O. Tuncer (ITU)

= tan β0 + [tan β1 − tan β0 ]η

η

Axial Compressor

November 2011

88 / 148

2-D Blade-to-Blade Flow

Coordinate System and Velocity Components

Coordinate System and Velocity Components

The following equations relate velocity components to the more usual Wm

and θ components.

Wξ = Wm cos β + Wθ sin β

Wq = Wθ cos β − Wm sin β

Wm = Wξ cos β − Wq sin β

Wθ = Wq cos β + Wz sin β

O. Tuncer (ITU)

Axial Compressor

November 2011

89 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Potential Flow in the Blade-to-Blade Plane

Assumptions,

I

Steady-state

I

Inviscid

I

Adiabatic

I

Rothaply and entropy constant on the flow plane.

Conservation of Mass

"

2∆m

ρbWq

cos β

−

m,η−∆η

ρbwq

cos β

#

+2∆η[(SρbWm )m−∆m,η −(SρbW

m,η+∆η

where,

S = r (θ1 − θ0 )

O. Tuncer (ITU)

Axial Compressor

November 2011

90 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Conservation of Mass (Continued)

Taking the limit,

Continuity

∂ ρbWq

∂(SρbWm

+

=0

∂η cos β

∂m

Irrotational flow in the stream surface requires that the component of

absolute vorticity normal to the stream sheet to be zero.

~ ) = ~en .[∇x(

~ + r ω~eθ )] = 0

~ C

~ W

~en .(∇x

Stokes Theorem

I

~ .d~r =

W

C

O. Tuncer (ITU)

Z

~ )]da = −

~ W

[~en .(∇x

A

Z

~ ω~eθ )]da

~en .(∇xr

A

Axial Compressor

November 2011

91 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality (Continued)

Applying to control volume,

"

2 ∆m

Wξ

cos β

−

m,η−∆η

Wξ

cos β

#

m,η+∆η

+ 2 ∆η[(SWθ )m−∆m,η − (SWθ )m+∆m,η ] = 4∆η∆m

S ∂r 2 ω

r ∂r

Taking the limit,

Wξ

∂

∂(SWθ )

+ 2Sω sin φ

=

∂η cos β

∂m

where φ is the stream sheet angle w.r.t the axial direction.

sin φ =

O. Tuncer (ITU)

∂r

∂m

Axial Compressor

November 2011

92 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Stream Function

A strem function Ψ is defined by,

ṁ

∂Ψ

0 − ρb(Wθ − Wm tan β)

∂m

ṁ

Ψ

= SρbWm

∂η

ṁ is the stream sheet mass flow rate.

Velocity components are given by,

Wm =

Wθ =

O. Tuncer (ITU)

ṁ ∂Ψ

Sbρ ∂η

ṁ tan β ∂Ψ ∂Ψ

−

bρ

S ∂η

∂m

Axial Compressor

November 2011

93 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function

Introducing stream function into the vorticity equation

=

∂ ṁ(1 + tan2 β) ∂Ψ ṁ tan β ∂Ψ

−

∂η

Sbρ

∂η

bρ ∂m

∂ ṁ tan β ∂Ψ ṁS ∂Ψ

−

+ 2Sω sin φ

∂m

bρ ∂η

bρ ∂m

This equation can be simplified into,

A

∂2Ψ

∂Ψ

∂2Ψ

∂Ψ

∂2Ψ

+

C

+E

= 2Sω sin φ

−

2B

+D

∂η 2

∂η∂m

∂m2

∂η

∂m

where,

O. Tuncer (ITU)

Axial Compressor

November 2011

94 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Boundary Conditions

On the blade surfaces,

Ψ(m, 0) = 0

Ψ(m, 1) = 1

O. Tuncer (ITU)

Axial Compressor

November 2011

95 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Boundary Conditions (Continued)

Periodic boundary conditions on the sides,

Ψ(m, η + 1) = Ψ(m, η) + 1

ρ(m, η + 1) = ρ(m, η)

Wm (m, η + 1) = Wm (m, η)

Wθ (m, η + 1) = Wθ (m, η)

Uniform flow at the upstream and downstream boundaries (This requires

Ψ vary linearly in the tangential direction.

Another choice is to require constant flow angle. If the geometry of the

side boundaries coincide with the local flow angles.

∂Ψ

∂Ψ

= cos β

=0

∂ξ

∂m

O. Tuncer (ITU)

Axial Compressor

November 2011

96 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Boundary Conditions (Continued)

Periodic boundary conditions on the sides,

Ψ(m, η + 1) = Ψ(m, η) + 1

ρ(m, η + 1) = ρ(m, η)

Wm (m, η + 1) = Wm (m, η)

Wθ (m, η + 1) = Wθ (m, η)

Uniform flow at the upstream and downstream boundaries (This requires

Ψ vary linearly in the tangential direction.

Another choice is to require constant flow angle. If the geometry of the

side boundaries coincide with the local flow angles.

∂Ψ

∂Ψ

= cos β

=0

∂ξ

∂m

O. Tuncer (ITU)

Axial Compressor

November 2011

97 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Kutta Condition

Typically β will be assigned to vary uniformly along the side boundary

from the upstream boundary flow angle to the blade leading edge angle,

and analogously for the downstream boundary.

Upstream and downstream flow angles depend upon each other. A

prediction of the downstream flow angle for any upstream flow condition is

required. Therefore an additional constraint is needed.

[W (m, 0)]te = [W (m, 1)]te

Iterative adjustment of the discharge flow angle is needed until the above

condition is met.

O. Tuncer (ITU)

Axial Compressor

November 2011

98 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Finite Difference Approximations

For interior points,

∂Ψ

∂m

∂Ψ

∂η

∂2Ψ

∂m2

∂2Ψ

∂m∂η

O. Tuncer (ITU)

=

=

=

Ψi+1,j − Ψi−1,j

2∆m

Ψi,j+1 − Ψi,j−1

2∆η

Ψi+1,j − 2Ψi,j + Ψi−1,j

(∆m)2

=

Axial Compressor

November 2011

99 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Finite Difference Approximations

For points at the boundary,

∂Ψ

∂m

∂Ψ

∂η

∂Ψ

∂m

∂Ψ

∂η

O. Tuncer (ITU)

=

=

=

=

4Ψi+1,j − 3Ψi,j − Ψi+2,j

2∆m

4Ψi,j+1 − 3Ψi,j − Ψi,j+2

2∆η

3Ψi,j − 4Ψi−1,j + Ψi−2,j

2∆m

3Ψi,j − 4Ψi,j−1 + Ψi,j−2

2∆η

Axial Compressor

November 2011

100 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Algebraic Form of the PDE for Interior Points

Ψi,j

+ Ãi,j Ψi−1,j + B̃i,j Ψi+1,j + C̃i,j Ψi,j−1 + D̃i,j Ψi,j+1

+ Ẽi,j [Ψi+1,j+1 − Ψi+1,j−1 − Ψi−1,j+1 + Ψi−1,j−1 ] = Q̃i,j

where,

O. Tuncer (ITU)

Axial Compressor

November 2011

101 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Irrotationality in Terms of Stream Function (Continued)

Coefficients

Ãi,j

=

B̃i,j

=

C̃i,j

=

Ei,j

Ci,j

− 2∆m

(∆m)2

− 2A

2Ci,j

i,j

+ (∆m)

2

(∆η)2

Ci,j

Ei,j

+ 2∆m

(∆m)2

− 2A

2Ci,j

i,j

+ (∆m)

2

(∆η)2

Ai,j

Di,j

− 2∆η

(∆η)2

− 2A

2Ci,j

i,j

+ (∆m)

2

(∆η)2

O. Tuncer (ITU)

Axial Compressor

Di,j

Ai,j

+ 2∆η

(∆η)2

− 2A

2Ci,j

i,j

+ (∆m)

2

(∆η)2

Bi,j

2∆m∆η

2Ai,j

2Ci,j

+ (∆m)

2

(∆η)2

D̃i,j

=

Ẽi,j

=

Q̃i,j

= −

2sω sin φ

2Ai,j

(∆η)2

+

2Ci,j

(∆m)2

November 2011

102 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Solution Procedure

I

A relaxation technique or a matrix method can be used for solution.

I

After each solution for the stream function density field must be

updated. Rothalpy is constant on the stream sheet,

1

1

1

h = H 0 − W 2 = I + (r ω)2 − W 2

(3)

2

2

2

Since entropy is also constant, all thermodynamic properties can be

calculated from (h,s). Density can be calculated using an appropriate

equation of state.

I

As long as the flow is subsonic this lagging density solution offers very

good numerical stability and rapid convergence.

I

If the flow is transonic or supersonic other solution procedures are

needed as the PDE is no longer elliptic in nature.

I

Stability of numerical solution is significantly influenced by the grid

structure.

O. Tuncer (ITU)

Axial Compressor

November 2011

103 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Leading Edge Grid Structure

O. Tuncer (ITU)

Axial Compressor

November 2011

104 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Potential Flow Results

O. Tuncer (ITU)

Axial Compressor

November 2011

105 / 148

2-D Blade-to-Blade Flow

Potential Flow in the Blade-to-Blade Plane

Transonic Potential Flow Results

O. Tuncer (ITU)

Axial Compressor

November 2011

106 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis

Motivation

The real purpose of the linearized method is its use in a

quasi-three-dimensional flow analysis, where blade to blade flow analyses

are conducted on several stream sheets and must be repeated many times.

Linearization of the Stream Function

Ψ(m, n) = a(m)[η − η 2 ] + η 2

This is tantamount to assuming ρbWm vary linearly with η.

Note that W = Wξ on the blade surface.

W1

W0

−

=

β1

cos β0

O. Tuncer (ITU)

Z

0

1

∂SWθ

+ 2Sω sin φ

∂m

Axial Compressor

November 2011

107 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis (Continued)

The velocity normal to the blade surfaces must be zero,

W =

Wm

1 ṁ ∂Ψ

=

cos β

cos β Sbρ ∂η

Combining,

W1

cos β1

W0

cos β0

=

=

ṁ(2 − a)

Sbρ cos2 β1

ṁa

Sbρ cos2 β0

SWθ = ṁ[tan β(a − 2aη + 2η) − a0 S(η − η 2 )]/(bρ)

where the prime denotes total derivative w.r.t. m.

O. Tuncer (ITU)

Axial Compressor

November 2011

108 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis (Continued)

In order to simplify the analysis we define,

u(m, η) = ṁ tan β/(bρ)

v (m, η) = ṁS/(bρ)

Differentiating the previous eqaution and substituting new variables,

∂SWθ

∂u

∂v 0

=

(a − 2aη − 2η) + (1 − 2η)ua0 − (va00 +

a )(η − η 2 )

∂m

∂m

∂m

O. Tuncer (ITU)

Axial Compressor

November 2011

109 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis (Continued)

Using truncated Taylor series expansion for any function F (η), for values

at 0, 0.5, and 1, a three-point difference approximation to the integral is

obtained.

Z

1

F (η)dη = (F0 + 4F̄ + F1 )/6

0

where overbar denotes the function value at η = 0.5. Therefore,

Z

0

1

∂SWθ

dη = [au00 + u0 a0 + 4ū 0 − v̄ a00 − v̄ 0 a0 + u10 (2 − a) − u1 a0 ]/6

∂m

Combining,

a00 + Aa0 + Ba = C

where A,B, and C are functions of m only.

O. Tuncer (ITU)

Axial Compressor

November 2011

110 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis (Continued)

A(m) = [v̄ 0 − u0 + u1 ]/v̄

B(m) =

u10 − u00

v0

6

v1

+

−

v̄

v̄ S 2 cos2 β1 cos2 β0

C (m) =

2u10 + 4ū 0 + 12ω sin φ

12v1

−

2

v̄

v̄ S cos2 β1

O. Tuncer (ITU)

Axial Compressor

November 2011

111 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Analysis (Continued)

Leading Edge Boundary Condition

The leading edge boundary condition follows from the known inlet angular

momentum supplied by the upstream flow, Wθ,in .

Integrating Wθ across the passage at the leading edge,

a0 + a[u1 − u0 ]/v̄ =

Kutta Condition

Kutta condition is used as the trailing edge boundary condition (i.e.

W0 = W1 ).

a = 2cosβ0 /[cos β1 + cos β0 ]

O. Tuncer (ITU)

Axial Compressor

November 2011

112 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Solution Method

I

The governing equations are cast into matrix form, Ax = B.

I

Matrix A is in tri-diagonal form. Except for the equation at the

leading edge point.

I

Gas density field update is lagging the velocity field. Same procedure

as before.

O. Tuncer (ITU)

Axial Compressor

November 2011

113 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Tri-Diagonal Systems

Tri-diagonal systems commonly arise in the solution of many engineering

problems. Ordinary matrix inversion for a tri-diagonal system with n

unknowns requires O(n3 ) operations. Such an approach is unnecessarily

computationally intensive. “Thomas Algorithm”only requires O(n)

operations. A tri-diagonal system can be written as,

ai xi−1 + bi xi + ci xi+1 = di , with, a1 = 0, cn = 0

This system can be cast into matrix Ax = b form with,

b1 c1 0 · · ·

0 0

x1

a2 b2 c2 · · · 0 0

x2

b3

c3 0

A = 0 a3

, x = .. , b =

.

..

..

0 ...

.

. 0

xn

0 0

···

an bn

d1

d2

..

.

dn

Note that in matrix A all entries are zero except the ones in the diagonal,

the super-diagonal and the sub-diagonal.

O. Tuncer (ITU)

Axial Compressor

November 2011

114 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Thomas Algorithm

The solution of this system is performed in two steps as per the Thomas

Algorithm. First step involves modifying the coefficient vectors.

(c

1

i =1

ci0 = b1 ci

i = 2, 3, · · · , n − 1

0 a

bi −ci−1

i

d1

i =1

b

0 a

di0 = d1i −di−1

i

b −c 0 a i = 2, 3, · · · , n − 1

i

i

i−1

After the new coefficients are obtained solution is reached through back

substitution.

(

i =n

dn0

xi =

0

0

di − ci xi+1 i = n − 1, n − 2, · · · , 1

O. Tuncer (ITU)

Axial Compressor

November 2011

115 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Listing 1: Source Code to Implement the Thomas Algorithm

i n t Thomas ( const double ∗a , const double ∗b , double ∗ c

double ∗d , double ∗x , i n t n ) {

int i ;

/∗ Mo di fy t h e c o e f f i c i e n t s . ∗/

c [ 0 ] /= b [ 0 ] ;

d [ 0 ] /= b [ 0 ] ;

f o r ( i = 1 ; i < n ; i ++){

double i d = 1 . 0 / ( b [ i ] − c [ i − 1 ] ∗ a [ i ] )

c [ i ] ∗= i d ; /∗ L a s t v a l u e i s r e d u n d a n t

d [ i ] = (d [ i ] − d [ i − 1]∗ a [ i ])∗ id ;

}

/∗ Back s u b s t i t u t i o n ∗/

x [ n − 1] = d [ n − 1 ] ;

f o r ( i = n − 2 ; i >= 0 ; i −−)

x [ i ] = d [ i ] − c [ i ]∗ x [ i + 1 ] ;

return 0;

}

O. Tuncer (ITU)

Axial Compressor

November 2011

116 / 148

2-D Blade-to-Blade Flow

Linearized Potential Flow Analysis

Linearized Potential Flow Results

O. Tuncer (ITU)

Axial Compressor

November 2011

117 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method

I

Potential flow method has limitations in terms of Mach number.

I

Time marching method provides a more general solution capability.

I

It is applicable to subsonic, transonic and supersonic flows.

I

Suggested first by von Neumann and Richtmayer (1950).

I

Solution is accomplished using the same velocity components and

coordinate system.

I

The governing equations are solved in their full unsteady form.

I

Solution is advanced in time until variations is time become negligible.

O. Tuncer (ITU)

Axial Compressor

November 2011

118 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method (Integral form of Conservation

Equations)

Mass

Z

V

∂ρ

dV +

∂t

Z

~ .~n)dA = 0

ρ(W

A

Momentum

Z

V

~

∂ρW

dV +

∂t

Z

~ (W

~ .~n)dA +

ρW

Z

A

Z

P~e (~e .~n)dA =

A

~f dV

V

Energy

Z Z

Z

∂H 0 ∂P

~ .~n)dA =

~ )dV

ρ

−

dV +

ρH 0 (W

ρ(~f .W

∂t

∂t

V

A

V

O. Tuncer (ITU)

Axial Compressor

November 2011

119 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method (Integral form of Conservation

Equations)

~e is the unit vector along w

~.

~f is a body force used to account for the Coriolis and centrifugal

acceleration terms in the rotating curvilinear system.

Equations in conservative form,

Sb

Sb

∂ρWm

∂t

+

=

O. Tuncer (ITU)

∂ρ

∂

∂

+

[SbρWm ] +

[bρQ] = 0

∂t

∂m

∂η

∂

∂bP

∂

[Sb(ρWm2 + P)] − tan β

+

[bρQWm ]

∂m

∂η

∂η

1

∂Sb

SBρ sin φ(Wθ + r ω)2 + P

r

∂m

Axial Compressor

November 2011

120 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method (Integral form of Conservation

Equations)

Sb

∂ρWθ 1 ∂

∂

∂

+

[Sb(ρWm (Wθ +r ω)]+ [b(QWθ +P)] = r ω

[SbρWm ]

∂t

r ∂m

∂η

∂m

Sb

∂(ρI − P)

∂

∂

+

[SbρWm I ] +

[bρQI = 0

∂t

∂m

∂η

Q is a special velocity component to conserve properties at the constant η

boundaries of the control cell.

Q = Wq / cos β = Wθ − Wm tan β

O. Tuncer (ITU)

Axial Compressor

November 2011

121 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method (Integral form of Conservation

Equations)

Note that Q = Wq = 0 on the blade surface. For these points there is only

Wξ component of velocity.

Applying the integral momentum equation in the ξ-direction.

Sb

∂ρWξ

∂t

∂

∂

[Sb(ρWm Wξ + P cos β)] +

[bρQWξ ]

∂m

∂η

∂

[Sb cos β] + Sbρ sin φ cos βr ω 2

= P

∂m

+

Wm = Wξ cos β

Wθ = Wξ sin β

O. Tuncer (ITU)

Axial Compressor

November 2011

122 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Method (Boundary Conditions)

I

On the blades velocity normal to the surface is zero.

I

For side boundaries outside the blade passage periodic boundary

conditions are used (as before)

I

Upstream and downstream boundary conditions are rather tricky.

I

O. Tuncer (ITU)

Axial Compressor

November 2011

123 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Unsteady Characterisctics

dm

dt

dm

dt

dm

dt

O. Tuncer (ITU)

= Wm + a

= Wm − a

= Wm

Axial Compressor

November 2011

124 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Subsonic Upstream Boundary

At t + ∆t one of the characteristics is inside the domain.

A logical choice for the computed dependant variable is density.

P, Wm from equation of state and rothalpy (if entropy is known).

At the upstream boundary specify Wθ , Pt , Tt .

O. Tuncer (ITU)

Axial Compressor

November 2011

125 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Supersonic Upstream Boundary

All characteristics outside the solution domain.

All dependant variables must be assigned when Wm > a on an upstream

boundary.

O. Tuncer (ITU)

Axial Compressor

November 2011

126 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Subsonic Downstream Boundary

At t + ∆t one of the characteristics is inside the domain.

Specify discharge static static pressure as the boundary condition.

O. Tuncer (ITU)

Axial Compressor

November 2011

127 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Supersonic Downstream Boundary

All characteristics inside the solution domain.

All dependent variables can be computed from the solution without any

boundary condition specification.

O. Tuncer (ITU)

Axial Compressor

November 2011

128 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Numerical Stability

I

No Kutta condition is needed!

I

Specifiying more boundary conditions WILL NOT PRODUCE A

VALID SOLUTION. WILL CAUSE THE SOLUTION TO DIVERGE!!!

I

Explicit solution scheme numerically unstable.

I

Stabilizing terms (like artificial viscosity) is needed in governing

equations if an explicit solution is sought.

O. Tuncer (ITU)

Axial Compressor

November 2011

129 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Stability Analysis

ut = v (ξ, η, t) + µ(ξ) uξξ + µ(η) uηη

For a stable solution the coefficients must satisfy the following conditions.

µ(ξ) ≥

µ(η) ≥

µ(ξ) ≥

µ(η) ≥

O. Tuncer (ITU)

1

(|Wm | + a)2 ∆t

2

1

(|Wθ | + a)2 ∆t

2

1

[(|Wξ | + a) cos β]2 ∆t

2

1

[(|Wq | + a)/ cos β]2 ∆t

2

Axial Compressor

November 2011

130 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Stability Analysis (Continued)

If the grid structure is highly skewed and node spacing in the tangential

direction is much finer than the meridional direction an additional

meridional stabilizing term can be added.

1

µ(ξ) → µ(ξ) [(|Wθ | + a) sin2 β(∆m)/(S∆η)]2 ∆t

2

O. Tuncer (ITU)

Axial Compressor

November 2011

131 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Stability Analysis (Continued)

CFL Criterion

∆tmax

≤

∆tmax

≤

∆m

|Wm | + a

∆S∆η

|Wθ | + a

Actual time step is,

∆t = µ0 ∆tmax

A rule-of-thumb is,

0.1 ≤ µ0 ≤ 0.9

O. Tuncer (ITU)

Axial Compressor

November 2011

132 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Stability Analysis (Continued)

If the time derivative is approximated by a forward time derivative,

u(ξ, η, t + ∆t) = u(ξ, η, t) + [v (ξ, η, t) + µ(ξ) uξξ + µη uηη ]∆t

I

Stabilizing terms second order w.r.t ∆t

I

Dynamic terms of the original PDE are first order w.r.t ∆t

I

Start with a large time step a the beginning

I

Reduce the time step as the solution converges

O. Tuncer (ITU)

Axial Compressor

November 2011

133 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Time Marching Solution Results

O. Tuncer (ITU)

Axial Compressor

November 2011

134 / 148

2-D Blade-to-Blade Flow

Time Marching Method

Transonic Time Marching Solution Results

O. Tuncer (ITU)

Axial Compressor

November 2011

135 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Blade Surface Boundary Layer Analysis

Motivation

I

Quantify viscous effects

I

Predict flow seperation

I

Predict the level of total pressure loss

Momentum Integral Equation

1 ∂bρe ue2 θ

∂ue

+ δ ∗ ρe ue

= τw

b ∂x

∂x

O. Tuncer (ITU)

Axial Compressor

November 2011

136 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis (Continued)

Momentum Thickness

ρe We2 θ

Z

ρW (We − W )dy

=

Displacement Thickness

∗

Z

δ

(ρe We − ρW )dy

ρe We δ =

0

Skin Friction Coefficient

Cf =

O. Tuncer (ITU)

τw

1

2

2 ρe We

Axial Compressor

November 2011

137 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Boundary layer initially laminar, soon transitions into turbulence.

Universal Boundary Layer Profile

W

= C1 η + C2 η 2 + C3 η 3 + C4 η 4

We

Z

1 y ρ

δ 0 0 ρe

Z δ

ρ

=

0 ρe

η =

δ0

O. Tuncer (ITU)

Axial Compressor

November 2011

138 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Shape Factor

Λ=

ρ2e (δ 0 )2 dWe

ρw µ dx

Matching Edge Conditions

C1 = 2 + Λ/6

C2 = −Λ/2

C3 = Λ/2 − 2

C4 = 1 − Λ/6

O. Tuncer (ITU)

Axial Compressor

November 2011

139 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Momentum Thickness

Λ

Λ2

θ

37

−

−

=

δ0

315 945 9072

Energy Thickness

δE

=

δ0

Z

0

δ

ρW

W2

798048 − 4656Λ − 758Λ2 − 7Λ3

1 − 2 dy =

ρe We

We

4324320

Velocity Thickness

δW

=

δ0

O. Tuncer (ITU)

Z

0

δ

ρW

W

3

Λ

FWe2

−

+

1−

dy =

ρ e We

We

10 120 2cp Te

Axial Compressor

November 2011

140 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Velocity Thickness

Λ 3

Λ

Λ 2

+ 17.8063

F = 0.232912 − 0.831483

+ 0.650584

100

100

100

Enthalpy Thickness

For adiabatic walls with Pr = 1

δh

=

δ0

Z

0

δ

ρW

ρe We

h

− 1 dy =

he

Displacement Thickness

δ ∗ = δh + δw

O. Tuncer (ITU)

Axial Compressor

November 2011

141 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Following parameters introduced for convenience,

b0 =

ρe

T0

= t

ρ

Te

2

θ

ρe θ2 dWe

K = Λ 0 = b0

δ

µ dx

Gruschweitz (1950) shows that,

1

µ

Λ

cf =

1

+

2

ρe We δ 0

6

37

Λ

Λ2

K=

−

−

315 945 9072

O. Tuncer (ITU)

Axial Compressor

2

Λ

November 2011

142 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Transition Criteria

<θ =

ρ e We θ

> 250

µ

Once boundary layer transitions into turbulence different methods are

needed.

Method of Head (1958)

Originally developed for incompressible boundary layers.

∂

[bρe We (δ − δ ∗ )] = bρe We E

∂x

Empirical relations are needed for E and cf as a function of θ and (δ − δ ∗ ).

O. Tuncer (ITU)

Axial Compressor

November 2011

143 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Shape Factors

H1 ≡ (δ − δ ∗ )/θ

H = δ ∗ /θ

Kinematic Shape Factor

Recommended by Green (1968)

1

Hk =

θ

δ

Z

0

ρ

ρe

W

1−

We

dy

For adiabatic walls with Pr = 1

H = (Hk + 1)Tt0 /Te − 1

O. Tuncer (ITU)

Axial Compressor

November 2011

144 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Aungier 2003 recommends,

Hk = 1 + [0.9/(H1 − 3.3)]0.75

E = 0.025(Hk − 1)

Skin friction coefficient correlation of Ludwieg and Tillmann (1950)

commonly used for incompressible turbulent boundary layer analysis.

cf ,inc = 0.246exp(−1.561Hk )Reθ−0.268

Green’s correction to it,

cf = cf ,inc

O. Tuncer (ITU)

Axial Compressor

November 2011

145 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

At the transition (laminar to turbulent) point,

(δ − δ ∗ )turb = (δ − δ ∗ )lam

θturb = θlam

From Gruschwitz (1950) profiles,

δ − δ∗ = δ0

7

Λ

+

10 120

Seperation Criterion for Turbulent Boundary Layers

Hk ≥ 2.4

O. Tuncer (ITU)

Axial Compressor

November 2011

146 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis of Grushwithz (1950)

Useful to predict total pressure loss coefficient for the cascade from the

B.L. data at the trailing edge.

Total pressure loss coefficient based on cascade inlet velocity (Lieblein and

Roudebush, 1956), where the summation is carried out for the boundary

layers on both blade surfaces.

This loss coefficient can be used to estimate the rotor efficiency.

cos βin 2 2Θ + (∆∗ )2

cos βout

(1 − ∆∗ )2

P

θ

Θ=

S cos βout

P ∗

δ

∗

∆ =

S cos βout

∆Pt

ω̄ =

=

(Pt − P)in

Loss coefficients are approximate, since the analysis method ignores

secondary flows.

O. Tuncer (ITU)

Axial Compressor

November 2011

147 / 148

2-D Blade-to-Blade Flow

Blade Surface Boundary Layer Analysis

Boundary Layer Analysis Results

O. Tuncer (ITU)

Axial Compressor

November 2011

148 / 148