ANALYSIS OF PHYSICAL MODEL RUBBER WEIR CONTAIN WATER AS MOTION WEIR FOR FLOOD AND ROB HANDLING

advertisement

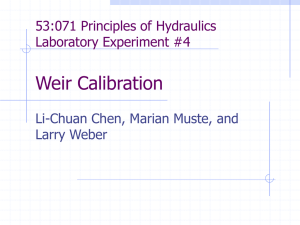

International Journal of Civil Engineering and Technology (IJCIET) Volume 10, Issue 04, April 2019, pp. 219-227, Article ID: IJCIET_10_04_024 Available online at http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=10&IType=04 ISSN Print: 0976-6308 and ISSN Online: 0976-6316 © IAEME Publication Scopus Indexed ANALYSIS OF PHYSICAL MODEL RUBBER WEIR CONTAIN WATER AS MOTION WEIR FOR FLOOD AND ROB HANDLING Fatchur Roehman* Civil Engineering Department, Universitas Sultan Fatah, Jalan Raya Katonsari No 19 Demak, Central Java 59516, Indonesia Slamet Imam Wahyudi and M. Faiqun Niam Civil Engineering Department, Universitas Islam Sultan Agung, Jalan Raya Kaligawe, Semarang KM. 4, Po Box 1054/SM, Central Java 50112, Indonesia Corresponding author * ABSTRACT The aim of this study is to evaluate the existing conditions of flood and rob disasters, prepare closed circuit water canals for experiments, analyze the characteristics of water-filled rubber weirs so that weir models can be used as appropriate technology, and carry out stability analysis on currents. The research method used several variations of model simulations to find a correlation between upstream water level elevation and a simulated elevated water level elevation. The variables studied are weir loads, mud, earthquake and hydrostatic stresses. The laboratory test results obtained that the elevation is obtained in the safety factor of 1.603 and the downstream elevation is found to be a safety factor of 1.597 in the condition of the flood face. Key words: Model; Weir Contain Water; Flood; Rob; Safety Factor. Cite this Article: Fatchur Roehman, Slamet Imam Wahyudi and M. Faiqun Niam, Analysis of Physical Model Rubber Weir Contain Water as Motion Weir for Flood and Rob Handling. International Journal of Civil Engineering and Technology, 10(04), 2019, pp. 219-227 http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=10&IType=04 1. INTRODUCTION Flood control and rob rubber dams filled with water are immediately resolved. The material used is an appropriate technology so that the public is easy to get and operations [3]. In order for the community to participate in helping guard the dams that have been made so that the surrounding settlements and roads are not flooded [17; 19]. \http://www.iaeme.com/IJCIET/index.asp 219 editor@iaeme.com Fatchur Roehman, Slamet Imam Wahyudi and M. Faiqun Niam The aim of the study was to evaluate the conditions of flood and rob disasters, tomake closed circuit water canals for experiments, to analyze the characteristics of water-filled rubber weirs by making four weir shape patterns, discharge stability analysis in weir models in the laboratory. 2. LITERATURE REVIEW Rubber weir is a relatively new type of hydraulic structure compared to sluice gates, weirs are made of high-strength fabric attached to rubber that forms a rubber bag, will be filled with water, so that it can expand or deflate as needed [10]. Maintenance of rubber weirs, especially the rubber parts, must be carried out with high intensity, given the trivial disruption to rubber can result in the dam not functioning at all. Equipment for the operation of rubber weirs include the number of blowers 1 set with the capacity specifications of the pump (Blower) no less 14 m³ / minute, maximum pressure 4000 mmaq, pump drive in the form of diesel fuel motor, control panel / operation 1set, installation of filler / waster 1 set , valves for operation and safety 1 set [18; 15]. Rubber dams have many advantages, such as simple hydraulic structures, short construction times, perfect seismic performance, and low resistance to water flow in the flood season. The first case study of a rubber dam is on the Janjawati River [16]. Rubber dams have been used in China for the past 40 years because water conservation structures are cheaper compared to conventional fenced structures such as dams, especially in small and medium rivers [20]. Figure 1. Weir operations (Dnyaneshwari Kolte et al, 2017). Rubber weir filled with water, the developer media used is water. It has special advantages over rubber dams filled with air so that the deflating process is easy. http://www.iaeme.com/IJCIET/index.asp 220 editor@iaeme.com Analysis of Physical Model Rubber Weir Contain Water as Motion Weir for Flood and Rob Handling Figure 2. Weir pattern (Dnyaneshwari Kolte et al, 2017). Figure 3. The water pressure system in the weir (Abdullah Ali Nasser Alhamati et al,2005) Infrared dam is a flexible and easily foldable cylindrical inflatable rubber structure made of rubber material attached to a rigid base and inflated by air, water, or a combination of air / water. http://www.iaeme.com/IJCIET/index.asp 221 editor@iaeme.com Fatchur Roehman, Slamet Imam Wahyudi and M. Faiqun Niam Figure 4. Membrane work system (Abdullah Ali Nasser Alhamati et al, 2005) The behavior of air or water thrust increases physically and theoretically to be analyzed by different conditions of internal, upstream and downstream pressure depths. Figure 5. Weir model on the flum (Abdullah Ali Nasser Alhamati et al , 2005) Experimental data obtained at laboratory test facilities for dams that are increased by air and water increases and are compared with theoretical results estimated from computer programs developed by describing height, cross-sectional profiles and cross-sectional areas of the dam [1]. 2.1. Characteristics of Weir Bodies The rubber material used has a specification of abrasion test hardness using the H18 method with a load of 1 kg at 1000 times rotation not exceeding 0.8 m3 / mile. Tensile strength at normal temperature ≥ 150 kg / cm2 and tensile strength at a temperature of 1000 ≥ 120 kg / cm2 [11]. Rubber material is reinforced with a nylon thread arrangement that provides tensile strength in accordance what is needed to resist the force. Rubber base material is commonly used synthetic rubber such as ethylene propylene diene monomer (EPDM), chloroprene rubber http://www.iaeme.com/IJCIET/index.asp 222 editor@iaeme.com Analysis of Physical Model Rubber Weir Contain Water as Motion Weir for Flood and Rob Handling (CR) [12]. The thickness of the cover is taken about 3 mm on the surface 7 mm. Clamping system placement of a rubber tube on the foundation using steel anchored. For low weirs with H ≤ 1.00 m can be used a single armature, whereas for H> 1.00 m, usually used double armature. Weir influenced the tide always use double armature [8]. 2.2. Experimental Scale Analysis A good rubber weir has criteria including being able to deflate automatically and manually under the planned conditions. So that the required data is the planned debit Q100 of 305.09 m3 / sec with weir type of water filling, volume / quantity of 1 set and base width 30 m and height weir 3 m [13; 14]. The dam elevation is +1.50 and the base elevation is -1.50 while the water level is downstream -1.20 and the slope of the foundation wall is 1: 1. For a maximum bubbling time no more than 45 minutes as well as emptying no more than 45 minutes. Manually controlling the clamping system with a double clamp and max pitch of 200 mm armature. While ethylene propynele mnome (EPM) or cloprene rubber weir material as well as the carpet used is the same as rubber weir material. Armature bolts and nuts use stainless steel (SUS 304) and base plate using SS 400 galvaniced carbon steel and rubber clamp plate using FCD 500 galvanized cast iron. For a 1 year guarantee and the number of 1set pumps with a capacity of 0.20 m3 / sec and the height of the pump head adjusted to the fill pipe installation. Pump drive is an electric motor and water fill pipe installation and valves for operation and security 1set generator power supply135 kva as a pump drive [2]. 2.3. Hydraulic characteristics Rubber weir functions to raise the water level by inflating the body and lowering the water level by deflating it[5; 6]. The hydraulic design of the weir is flood water level + 2.40, embankment elevation +3.40, weir height 3.00 m, weir -1.50 base elevation, and weir 30 m width. Drain door is 1 piece, width is 2.0 m, runoff capacity is 350.41 m3 / sec, upstream apron length is 20 m, 0.50 m thick and downstream apron length is 8 m. The door thickness is 0.50 m and the floor length of the dam is 20 m and is 2.0 m thick while the pool length is 10 m and thick 1.0 [4; 7]. 3. METHODS The method used is to make a form of water-filled rubber weir and a closed water circuit framework, circuit canal assembly, simulation of elevation and rolling style of water-filled rubber weir in the laboratory, data processing, data analysis, preparation of results and discussion, conclusion. For more details can be seen in Figure 6 Research Flow Chart below. http://www.iaeme.com/IJCIET/index.asp 223 editor@iaeme.com Fatchur Roehman, Slamet Imam Wahyudi and M. Faiqun Niam Figure 6. Research Flow Chart http://www.iaeme.com/IJCIET/index.asp 224 editor@iaeme.com Analysis of Physical Model Rubber Weir Contain Water as Motion Weir for Flood and Rob Handling 4. RESULT AND DISCUSSION Simulation of water-filled rubber weir using a circuit canal prototype made of elbow steel frame and the cover of glass 4 mm Length 6 m, Width 0.6 m and height 0.4 m, consisting of two regulator doors, two pumps for let and out let, filler tank and function also as a return water reservoir, thomson tool, 2% slope used in the laboratory. Table 1. Bending simulation results B N o Weir shape 1 ϒ water H Shape Factor (m ) (Ton/m3 ) (m) Triangel 0,4 0,1 0,5 1 2 rectangula r 0,4 0,1 0,5 1 3 Cylinder 0,4 0,1 0,5 1 4 Trapezoid 0,4 0,1 0,5 1 Weight(to n) arm (m) Momen hold it down (Horizon tal) Information SF=V/K x y x y Bolster (Vertik al) 0,0 06 0,0 12 0,0 12 0,0 06 0,01 2 0,01 2 0,01 2 0,01 2 0,3 5 0,3 5 0,3 5 0,3 5 0,1 5 0,0021 0,0018 Bolster 1,166667 0,2 0,0042 0,0024 Stable 1,75 0,3 0,0042 0,0036 Bolster 1,166667 0,6 0,0021 0,0072 Bolster 0,291667 Gambar 7. Grafik simulasi empat bentuk bendung di laboratorium Figure 7. Circuit canals and weirs in the laboratory http://www.iaeme.com/IJCIET/index.asp 225 editor@iaeme.com Fatchur Roehman, Slamet Imam Wahyudi and M. Faiqun Niam 5. CONCLUSIONS Experiments in the laboratory can be concluded that the selection of material types and shapes used for rubber dams filled with water should be flexible and have high tensile strength so that it is not easily torn and strong against the pressure of flow stability. The type of water-filled rubber weir is not yet in the free market in Indonesia. Planning water-filled rubber weirs utilizes geomembrane material as a form of appropriate technology so that people can cope with sea tide that enters the mouth of small rivers around the shoreline by spreading water-filled rubber dams, so as to prevent flooding in residential areas near the coast. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] Abdullah Ali Nasser Alhamati, Behavior of Inflatable Dams under Hydrostatic Conditions Received: Sept 1, 2004; Revised: Nov 18, 2004; Accepted: Mar 8. Annual Book of ASTM Standards, Standard Test Methods for Rubber Properties in Tension, 8.01(D412), 1985. Ahmad IA, A Rubber dam usage for endodontic treatment: a review. Int Endod J, 42(11), 2009, pp. 963-972. Binnie, G.M., Thomas, A.R, and Gwyther, J.R, Inflatable Weir Used During Construction of Mangala Dam. Proceedings of the Institution of Civil Engineers; Part 1, 54, 1973, pp. 625-639. Dumont, U, The use of inflatable weirs for water level regulation. International Water Power and Dam Construction, 41(10), 1989, pp. 44-46. Harrison, H.B, The analysis and behavior of inflatable dams under static loading. Proceedings of the Institution of Civil Engineers, 45, 1970, pp. 661-676. Dedi Tjahjadi Abdullah, Ir, Bendung karet di Indonesia, makalah pada seminar bendung karet, 1999, Serang. Dimension, Civil Engineering. The Stability Analysis of the Lusi Mud Volcano Embankment Dams Using FEM with a Special Reference to the Dam Point P10. D, 14 (2), 2012, pp. 100–109. Dnyaneshwari Kolte, International Conference on emerging trands in Engineering, Science and Management RUBBER DAM, ISBN: 978-93-86171-32-0, 17, 2017, pp. 29-33. Kodoatie, R.J dan Sugiyanto, Bendung Karet Isi Udara Kali Jajar. Departemen Pekerjaan Umum, 2002, Semarang. Marfai, Muh Aris, and Lorenz King.. Nicholas, M.H. and Rangaswami, N., Flexible dams inflated by water. Journal of Hydraulic Engineering, ASCE, 109(7), 1983, pp. 1,044-1,048. Parbery, R.D, Factors affecting the membrane dam Inflated by air pressure. Proceedings of the Institution of Civil Engineers, Part 2, 65, 1978, pp. 645-654. Plaut, R.H., and Fagan, T.D, Vibrations of an inextensible, air-inflated, cylindrical membrane. Journal of Applied Mechanics, 55, 1988, pp. 672-675. Paul Wing Ming Tam and Xue-qing Zhang, Management of Rubber Dams in Hong Kong, Canadian Journal of Civil Engineering. 29, 2002, pp. 409-420. Roehman Fatchur, The Effectiveness Of Water-Filled Rubber Weir Management On Flood Mitigation Caused By Rain And “Rob” (Java Slang) In Demak District, Proceedings of International Conference : Problem, Solution and Development of Coastal and Delta Areas Semarang, Indonesia – September 26th, , 2017, Paper No. C-64 Takasaki, M, The omata inflatable weir, at the Kawabi hydro scheme, Japan. International Water Power and Dam Construction, 41(1) 1989, pp. 39-41. http://www.iaeme.com/IJCIET/index.asp 226 editor@iaeme.com Analysis of Physical Model Rubber Weir Contain Water as Motion Weir for Flood and Rob Handling [17] [18] [19] [20] Tam, P.W.M, Use of inflatable dams as agricultural weirs in Hong Kong. Journal of Hydraulic Engineering, ASCE, 124(12), 1998, pp. 1,215-1,226. Wahyudi, S. Imam, Moh Faiqun Ni‟am, and Le Bras Gilbert, Problems, Causes and Handling Analysis of Tidal Flood, Erosion and Sedimentation in Northern Coast of Central Java: Review and Recommendation, International Journal of Civil & Environmental Engineering 12 (4) 2012, pp. 65–69. 21. River Polder System in Kudus Regency, Central Java, Indonesia.” AIP Conference Proceedaings 1818. doi:10.1063/1.4976928, 2017. X.Q. Zhang, P.W.M. Tam and W. Zheng, Construction Operation and Maintenance of Rubber Dams, Canadian Journal of Civil Engineering. 29, 2002. pp. 409-420. http://www.iaeme.com/IJCIET/index.asp 227 editor@iaeme.com