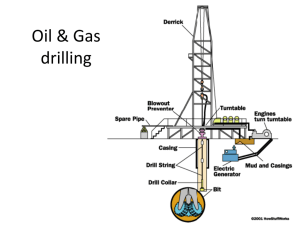

PDB 3063 DRILLING ENGINEERING II DRILLING SIMULATOR LAB REPORT SEMESTER SEPTEMBER 2018 PROGRAMME GROUP MEMBERS : PETROLEUM ENGINEERING : 1. MUHAMAD AMIRUL KHAIRI BIN MOHAMED AMIR 23884 2. AHMAD YAZID AIMAN BIN YAHYA 23871 3. MUHAMAD IZZAT IMRAN BIN ABDUL AZIZ 23829 4.MOHAMAD KAMAL ARIFF BIN AMINUDDINN 23961 5. AHMAD MAHYUDDIN BIN MOHD SIRHAN 23488 6. AHMAD AL-‘AFIQ BIN ABIDULLAH 23891 Experiment date : 19/02/2019 Submission date : 26/02/2019 1.INTRODUCTION 1.1 DRILLING FLUID The drilling-fluid system commonly known as the “mud system” is the single component of the well-construction process that remains in contact with the wellbore throughout the entire drilling operation. Drilling-fluid systems are designed and formulated to perform efficiently under expected wellbore conditions. The active drilling-fluid system comprises a volume of fluid that is pumped with specially designed mud pumps from the surface pits, through the drill string exiting at the bit, up the annular space in the wellbore, and back to the surface for solids removal and maintenance treatments as needed. The capacity of the surface system usually is determined by the rig size, and rig selection is determined by the well design. For example, the active drilling-fluid volume on a deep water well might be several thousand barrels. Much of that volume is required to fill the long drilling riser that connects the rig floor to the seafloor. By contrast, a shallow well on land might only require a few hundred barrels of fluid to reach its objective. A typical water based drilling mud contains clay, usually bentonite, to give it enough viscosity to carry cutting chips to the surface, as well as a mineral such as barite (barium sulphate) to increase the weight of the column enough to stabilize the borehole. Drilling fluid is the essential part of the drilling operation; the density, viscosity, and weight will help determined the quality of the drilling fluid and the suitability of the situation which is based on the economic viability. Drilling fluid have three main categories: Water-based mud Oil based mud Gaseous drilling fluid The main functions of drilling fluid are: Cleans the hole by transporting drilled cuttings to the surface, where they can be mechanically removed from the fluid before it is recirculated downhole. Balances or overcomes formation pressures in the wellbore to minimize the risk of well-control issues. Supports and stabilizes the walls of the wellbore until casing can be set and cemented or open hole-completion equipment can be installed. Prevents or minimizes damage to the producing formation. Cools and lubricates the drill string and bit. Transmit hydraulic energy to tools and bit. Ensure adequate formation evaluation. Facilitate cementing and completion. Minimize impact on environment. Allows information about the producing formations to be retrieved through cuttings analysis, logging-while-drilling data, and wireline logs. Suspend and release cuttings. Seal permeable formations. 1.2 WELL CONTROL Well-control means methods used to minimize the potential for the well to flow or kick and to maintain control of the well in the event of flow or a kick. Well-control applies to drilling, well-completion, well-workover, abandonment, and well-servicing operations. It includes measures, practices, procedures and equipment, such as fluid flow monitoring, to ensure safe and environmentally protective drilling, completion, abandonment, and workover operations as well as the installation, repair, maintenance, and operation of surface and subsea wellcontrol equipment. Understanding pressure relationships and the pressure itself are very important in well control. This technique is used to minimize the potential for the well to flow or kick. It includes measures, practices, procedures, and equipment, such as abandonment, and workover operations as well as installation, repair, maintenance, and operation of surfaces and subsea well-control equipment. Four notable pressure that well control help to maintain: Fluid Pressure, Hydrostatic Pressure, Fracture Pressure, and Bottom Hole Pressure. 1.2.1. Drilling System Oil well drilling engineering may be divided into following drilling systems. A system with various machines, equipment and instruments. Drilling system usually consist of: 1. Rotating system 2. Power system 3. Circulating system 4. Hoisting system 5. Pressure control system 1.2.1.1. Rotating System To create rotation force towards drill bit at the bottom hole and provide helps when tightening and loosing pipe connection. In order to drill ahead, the bit has to be rotated to its maximum allowable rotating penetration thus it’s been used to rotate the drill string hence the drill bit. There are two rotating source which are: • Rotary Table with a Kelly System • Top Drive System 1.2.1.2. Power System The source of power that provide energy to the rig for drill operation, which consist one to four more diesel engines. These engines produce several thousand house power (Hp) which are typically connected to the electric generator. 1.2.1.3. Circulating System Pumping fluid through the whole active fluid system, including the borehole and all the surface tanks that constitute the primary system. The drilling fluid will be pump to carry the drill cuttings from the face of the bit to the surface. In the fluid circulating system (above), the drilling is pumped from the suction tank/mud pit through the standpipe to the Kelly. From the Kelly the fluid continues its journey into the drill pipe and exits the drill pipe through the drill bit. The fluid then has to go through the space between the drill string and the borehole wall called the annulus and flows to the surface through the mud return line. At the surface the fluid then goes through the separating facilities such as the shale shaker. This journey is then repeated once again over and over again throughout the drilling of the well. 1.2.1.4 Hoisting System Used to raise and lower the drill string and casting into and out of well. The hoisting system is large pulley system which is used to lower and raise equipment into and out of the hole. This system is the main component that performs the drilling operation by either lifting or lowering the casing or drill pipes to drill and finally complete the well. The major components of a Hoisting System are derrick, block & tackle system, draw works and miscellaneous hoisting equipment like elevators, hooks and weight indicator. 1.2.1.5 Pressure Control System To prevent blowout and maintain kick during drilling and tripping. The equipment is called Blowout Preventer (BOP), BOP is a large valve at the top of a well that may be closed if the drilling crew loses control of formation fluids. By closing the valve the drilling crew will most likely gain control of the reservoir, and procedures can then be initiated to increase the mud density until it is possible to open the BOP and retain pressure control of the formation. 1.3. KICK AND BLOWOUT A kick is a well control problem in which the pressure found within the drilled rock is higher than the mud hydrostatic pressure acting on the borehole or rock face. When this occurs, the greater formation pressure has a tendency to force formation fluids into the wellbore. This forced fluid flow is called a kick. If the flow is successfully controlled, the kick is considered to have been killed. An uncontrolled kick that increases in severity may result in what is known as a “blowout.” 1.4. SWABBING Swabbing is generally considered harmful in drilling operations, because it can lead to kicks and wellbore stability problems. In production operations, however, the term is used to describe how the flow of reservoir hydrocarbons is initiated in some completed wells. 2.OBJECTIVES OF EXPERIMENT The objectives of this experiment are as follow: I. To have experience of dealing with drilling equipments in the field. II. To learn about the misconducts which could lead to blow out in rig. III. To conduct drilling operation simulation by using DrillSim 500. IV. To identify any kick indications by using DrillSim 500. V. To control any kick confronted during drilling operations. is dead) Open the BOP annular or upper ram, close BOP upstream choke valve and flow check well. 3.PROCEDURES Drilling Test 1. The slow rate of pump 1 is set at 30 spm (203 psi). 2. The slow rate of pump 2 is set at 30 spm (204 psi). 3. The mud pump 1 and 2 is increased to achieve a total of 600 gpm (8-1/2” hole size). 4. The TDS Drive is switched on and the rotary speed is set to 100 rpm. 5. The Draw Work is switched on and the speed is increased continuously. 6. The WOB is maintained at 35.000 lbs. 7. Next, adapt the drilling of the the WOB at weight of 35.000 lbs by adjusting the handbrake at every time. 8. The kick indication should be identified during the operation of the experiment. 9. When kick happens, the operation must be continued with the kick procedure. Well Control Drillers Method 1. The surface instrumentation is to be monitored. When “positive” kick happen, it is followed by step 2. 2. The off bottom and space out are to be picked up. It is to ensure the tool joint is not across the arm. When it happened, the rotary was to be stop. 3. Pump 1 and pump 2 is to be stopped. Either the Blow Out Preventer or Upper Ram is close and Blow Out Preventer upstream choke valve is open. 4. The final (stabilized) result of SIDPP and SICP is to be measured and recorded. The final pit gain is also to be read and recorded. The SICP constant is to be maintained by adjusting the remote choke while bringing the pump up to 30 strokes per minute simultaneously. 5. Then, read and record the new circulating drill pipe when the casing pressure is stabilized. The initial circulating drill pipe pressure constant is to be maintained by adjusting the remote choke until the influx which is the kick is out. 6. The pump should be stopped and close remote choke completely once the influx is out while maintaining the last CP constant. The theoretically measurement of SICP and SIDP should be the same if there is no influx entering the wellbore. 7. To kill mud weight is by increasing the mud weight. While maintaining the SICP constant, open remote choke and start pumping at 30 strokes per minute. Proceed by maintaining the SICP constant once it reaches the desired pump rate until it kills mud reach bit. 8. Begin to maintain FCD (final drill pipe circulating pressure) constant once kill mud reach bit until the kill mud reach surface. 9. Once the kill mud reaches the surface, stop the pump at once and followed by closing the remote choke. Observe and record the SIDPP, SICP and the pit volume. SIDPP and SICP will show zero reading if the well is dead. 10. BOP upper ram to be opened, BOP upstream choke valve and flow check well to be closed. Well Control Engineers Method 1. The surface instrumentation is to be monitored. When “positive” kick happens, step 2 is followed. 2. The off bottom and space out are to be pick up. It is to ensure the tool joint is not across the arm. When it happened, the rotary was to be stopped. 3. Observe and record the final (stabilized) SIDPP and SICP. Observe and record the final pit gain. Then, prepare the kill sheet. 4. The mud weight is increased to kill mud weight. The remote choke should be opened and bring the pump to kill rate at 30 spm slowly. the casing pressure constant is to be maintained by adjusting remote choke. 5. Proceed the drill pipe pressure schedule and maintain it by remote choke adjustment as stated to kill sheet when the pump is up to kill rate and casing pressure stable. 6. Begin to maintain FCD (final drill pipe circulating pressure) constant once kill mud reach bit until the kill mud reach surface. 7. Once the kill mud reached the surface, the pump was stopped at once and followed by the closing of the remote choke. The SIDPP, SICP and the pit volume are observed and recorded. SIDPP and SICP showed zero reading when the well is dead. 8. BOP upper ram to be opened, BOP upstream choke valve and flow check well to be closed. 4.RESULT Current Well Data : Pump No.1 DISPL Current Drilling Mud 0.121 Weight : 9.5 ppg Casing Shoe Data Size : 9.625 inch M.Depth : 3000 ft T.V Depth : 3000 ft Pump No.2 DISPL bbl/stroke 0.121 bbl/stroke (PL) Dynamic Pressure Loss (psi) Slow Pump Pump No.1 Rate Data 30 SPM 199 Pump No.2 30 SPM 200 200 199 Hole Data Size : 8.5 inch M. Depth :6000.0 ft T.V. Depth : 6000.0 ft Pre- Recorded Value Data Length (feet) Capacity (Bbls/foot) Volume Pump Strokes Time (Barrels) ( strokes) (minutes ) Volume …………………… Pump displacement Pump strokes ……………… Slow pump rate 835.84 27.86 118.56 979.83 32.661 144 1190 39.67 Drill Pipe 5340 0.0178 95.052 Heavy Wall Drill Pipe 570 0.0087 4.959 Drill Collars 180 0.0061 1.098 Drill String Volume 101.109 DC x open hole 180 0.0032 5.76 DP / HWDP x OPEN HOLE 2820 0.040 112.80 Open Hole volume DP x Casing 3000 0.048 Total Annulus Volume 262.56 2169.83 72.33 Total Well System volume 363.669 3005.5 100.18 10 82.64 373.669 3088.17 Active Surface Volume Total Active Fluid Volume Kick Data SIDPP = 262 psi SICP = 243 psi PIT GAIN = 5 barrels Kill Mud Weight = 10.34 ppg Initial Circulating Pressure = 199 + 262 = 461 psi Final Circulating Pressure FCP = 1.09 + 201 = 200.09 psi K= 461 – 200.09 = 260.91 psi K x 100 / E = 31.22 psi/ 100 strokes Strokes Pressure ( psi ) 0-100 461.00 100-200 429.78 200-300 398.56 300-400 367.34 400-500 336.12 500-600 304.90 600-700 273.68 700-800 242.46 800-900 211.24 Stroke Pressure static & dynamic drill pipe pressure ( psi) 500 450 400 350 300 250 200 150 100 50 0 0 1 2 3 4 5 6 7 8 9 Strokes 5.DISCUSSION OF RESULTS The purpose of conducting this experiment is to simulate the real time drilling operation and the proper steps to be taken when a kick happens during drilling. It is very important for kicks to be controlled well in order to prevent blow out from happening. There are several methods that can be used to control a kick which are Well Control Driller’s Method and Well Control Engineer’s Method. Well Control Driller’s Method is used most of the time because it is much simpler compared to the other methods besides giving lesser risk of encountering a stuck pipe. The main idea of Well Control Driller’s Method is to kill the well with constant bottom hole pressure. The Well Control Driller’s Method requires two separate circulations of drilling fluid in the well. The first circulation removes influx by using the original mud weight. In this experiment, the original mud weight used is 9.5 ppg. The initial circulating pressure is maintained constant until the influx is out. The initial circulating pressure is calculated with the following formula: 10 INITIAL CIRCULATING PRESSURE = DYNAMIC PRESSURE LOSS + SIDPP where dynamic pressure loss = 199 psi SIDPP = 262 psi As a result, the calculated initial circulating pressure was 461 psi. In the case of the original mud weight being insufficient to balance the formation pressure, the well is then killed by circulating a heavier mud which is called kill mud during the second circulation. Second circulation kills well with kill mud. Alternately, during second circulation, a drill pipe pressure schedule can be calculated and followed while pumping kill mud from surface to bit. We start with bringing pumps to kill rate by holding casing pressure constant. After that, we need to hold drill pipe pressure constant then continue circulating with constant drill pipe pressure until kill mud weight reaches at surface. After the kick is totally removed from the well, when the well is shut-in, drill pipe and casing pressure will be the same value. If the pressure is not the same value, this means that there is influx left in the wellbore or trapped pressure. The final circulating pressure is calculated with the following formula: 𝐊𝐈𝐋𝐋 𝐌𝐔𝐃 𝐖𝐄𝐈𝐆𝐇𝐓 FINAL CIRCULATING PRESSURE = 𝐂𝐔𝐑𝐑𝐄𝐍𝐓 𝐌𝐔𝐃 𝐖𝐄𝐈𝐆𝐇𝐓 X DYNAMIC PRESSURE LOSS where kill mud weight = 10.34 ppg current mud weight = 9.5 ppg dynamic pressure loss = 199 psi As a result, the calculated final circulating pressure was 216.60 psi. A kick happens when the formation pressure is higher than the wellbore pressure which causes the fluid to flow into the wellbore. Whereas if the formation pressure is lower than the wellbore pressure, the formation will then be damaged. There are two reasons that cause the lower pressure of the wellbore as compared to the formation. Firstly, it could be due to the mud weight is too low. Secondly, the hydrostatic pressure exerted on the formation by the fluid column is not large enough to hold the formation fluid in the formation. Kill line can be used to inject higher density drilling fluid in the case of Blowout Preventer (BOP) is closed. While operating the driller brake, the lever should be given a jerk in order to slowly lower down the drill string. If the lever is push upwards and held in position, the drill string will lower rapidly, which may result in damaging the drill bit and drill collar. The driller brake is also used to lift up the bit to prevent it from getting stuck. In this experiment when the kick occurred, the shut in drill pipe pressure (SIDPP) recorded was 262 psi, while the shut in casing pressure (SICP) was 243 psi with pit gain of 5 barrels. In order to stop the kick, the original drilling mud had to be replaced with a higher density drilling mud (kill mud weight). Kill mud weight is calculated with the formula: 𝐒𝐈𝐃𝐏𝐏 KILL MUD WEIGHT = CURRENT MUD WEIGHT + 𝐓𝐕𝐃 𝐗 𝟎.𝟎𝟓𝟐 where current mud weight = 9.5 ppg SIDPP = 262 psi TVD = 6000 ft As a result, the calculated kill mud weight was 10.34 ppg. A graph of Static & Dynamic Drill Pipe Pressure vs Strokes is plotted. The graph is decreasing linearly which concludes that static and dynamic drill pipe pressure decreases as the number of strokes increases. 6.ANSWER TO GIVEN QUESTIONS 1. Explain the correlation between bottom hole temperature and hydrostatic gradient. Downhole temperature is an important factor affecting cement thickening time, rheological properties, compressive strength development, and set time. When the bottom hole temperature increases, it means that the pressure also increases. When the water column increases with depth, the pressure at the bottom is higher than the pressure at the top. This increment of pressure is constant at the decreasing of the depth. Hydrostatic pressure at specific point in water column will drop with constant value at the depth. 2. There are a variety that can cause abnormal formation fluid pressure. List 4 of the principal causes - Compaction effects - Diagenetic effects - Differential density effects - Fluid migration effects 3. What does MAASP stands for? What is the right time to re-calculate this parameter? MAASP stands for Maximum Allowable Annulus Surface Pressure. It is an absolute upper limit for the pressure in the annulus of an oil and gas well as measured at the wellhead. One major threat to annulus integrity is overpressure within the annulus which could lead to burst or collapse of a casing or damage to the formation below. Therefore, MAASP is calculated to provide a surface pressure, which will produce the limiting pressure at the shoe. There are four different ways in an annulus may be over pressured which are the right time to recalculate MAASP :a)Burst of the outside casing b)Collapse of the inside casing c)Fracturing of the formation at the shoe d)Overpressure of the surface equipment11 4. A well can be induced to flow by swabbing which happens due to the reduction of bottom hole pressure when pulling pipe. List 3 conditions that can cause swabbing. -Pulling Speed Faster tripping speed, higher chance to swab influx. It is very critical to monitor the well while pulling out and the pulling speed must not induce the well control situation. - Mud Properties Poor mud properties as high rheology, high viscosity, and high gel strength as this have high tendency to induce swab kick while pulling out. It is very critical to monitor the drilling fluid properties and personnel should have action plans to keep the mud in a good shape. - Swelling/Heaving Formations Swelling and heaving formation will reduce wellbore diameter resulting a small clearance between an open hole and a BHA or a bit. While pulling out with a small clearance, it has higher chance to swab in the well. 5. List at least 2 causes of the increase in rate of penetration during drilling. -Type of drill bit used The bit type selected has a large effect on penetration rate. For rolling cutter bits, the initial penetration rate is often highest in a given formation when using bits with long teeth and a large cone offset angle. However, these bits arc practical only in soft formations because of a rapid tooth destruction - Bit Hydraulics The penetration rate increase is felt to be due mainly to improved cleaning action at the hole bottom. Wasteful regrinding of cuttings is prevented if the fluid circulated through the bit removes the cuttings as rapidly as they are made. - Weight on the bit Penetration rate then increases rapidly with increasing values of bit weight for moderate values of bit weight. However, when the bit weight is too big it will decrease the penetration rate rapidly. 6. Mention at least 5 components of drill stem. (Used in place of drill string in some locations. It component are from the swivel down to the bit.) - Drill pipe A heavy seamless pipe which is used to rotate the bit and circulate the drilling fluid. Lengths of drill pipe 30ft long are coupled together with tool joints to make the drill string. - Drill collars A heavy, thick-walled steel tube which provides weight on the bit to achieve penetration. A number of drill collars may be used between the bit and the drill pipe. - Kelly The heavy square or hexagonal steel pipe which runs through the rotary table and is used to rotate the drillstring. - Blow Out Preventer (BOP) A valve installed on top of the wellhead to control wellbore pressure in the event of a kick. - Drill bit Drill bits are cutting tools used to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck. 7. Shown below is a pressure versus volume plot of a leak off test. The leak off was carried out with a 10.6 ppg mud. The casing shoe is at 4000 ft TVD. a) What is the maximum pressure that the exposed formations below the shoe can support? Pmax = (0.052 x MW x TVD) + Psurface = (0.052 x 10.6 x 4000) psi + 1100 psi = 3304.8 psi ≈ 3305 psi b) What is the “Fracture Gradient”? A measure of how the strength of the rock (i.e. its resistance to break down) varies with depth. Besides, it is the slope and pressure required in order to initiate a fracture or a crack into a rock formation. It is necessary to break into the arrangement of the rocks underground, so that conducive channels can be prepared for the oil and gas to flow easily. When fracturing is to be done, several factors should be considered, such as the slope, depth and pressure required to break the formation. It is through fracture gradient determination that these factors are taken care of by carrying out a leak-off test prior to the fracturing. c) What is the maximum mud weight? Max. MW = = 15.88 ppg d) If drilling was resumed and the mud weight was increased to 12.6 ppg, calculate the MAASP. MAASP = (Max MW – Current MW) x 0.052 x TVD = (15.88 - 12.6) x 0.052 x 4000 = 682.24 psi 8.Given the following data : Depth Bit size : 10000 ft : 81/2" Shoe depth : 8500 ft TVD Mud weight : 12.6 ppg Collars – 600 ft capacity : 0.0077 bbl/ft Metal displacement : 0.03 bbl/ft Drill-pipe 5” capacity : 0.0178 bbl/ft Metal displacement : 0.0476 bbl/ft Casing/pipe annular capacity : 0.0476 bbl/ft Casing capacity : 0.0729 bbl/ft One stand of drill-pipe : 94 ft Assuming the 12.6 ppg mud gives an over balance of 200 psi. a) If 10 stands of pipe are removed “dry” without filling the hole, what would be the resultant reduction in bottom hole pressure? Barrels displaced = Number of stands pulled x Average length per stand, ft x Pipe displacement, bbl/ft = 10 x 94 ft x 0.0476 bbl/ft = 44.744 bbl 𝑩𝒂𝒓𝒓𝒆𝒍𝒔 𝒅𝒊𝒔𝒑𝒍𝒂𝒄𝒆𝒅,𝒍 𝒃𝒃𝒍 𝒃𝒃𝒍, 𝑪𝒂𝒔𝒊𝒏𝒈 𝒄𝒂𝒑𝒂𝒄𝒊𝒕𝒚 −𝑷𝒊𝒑𝒆 𝒅𝒊𝒔𝒑𝒍𝒂𝒄𝒆𝒎𝒏𝒕, 𝒇𝒕 Reduction in BHP = x 0.052 𝒙 𝑴𝑾, 𝒑𝒑𝒈 𝒇𝒕 x 0.052 x 12.6 ppg = 1158.75 psi b) If 5 stands of pipe had been pulled “wet” without filling the hole, the resultant reduction in bottom hole pressure would be? Barrels displaced = Number of stands pulled x Average length per stand,ft x (Pipe displacement,bbl/ft + Pipe capacity, bbl/ft) = 5 x 94 ft x (0.0476 bbl/ft + 0.0178 bbl/ft) = 30.738 bbl Reduction in BHP x 0.052 x MW, ppg x 0.052 x 12.6ppg = 2685.27 psi c) If prior to tripping a 20 barrel slug of 14.6 ppg mud was displaced to prevent a wet trip, what would be the expected volume return due to the U-tubing of the heavy mud? Volume of dry pipe = Slug volume = 20 bbl = 3.175 bbl 7.REFERENCES 1. R.P., Singh. (2002). Well Control Practises and Procedures to Deal with Any Uncontrolled Situation & Case Study. Summer Training Report. Ankleshwar. 2. Fracture Gradient. Petropedia. Retrieved from https://www.petropedia.com/definition/6333/fracture-gradient 3. Preschool exercises for Well Control with Answers. Transocean Sedco Forex. Jakarta Learning Centre. Retrieved from https://www.slideshare.net/SteffonesK/transocean-wellcontrol-59235508 . 4. Worked Examples. Cairns Centre for Drilling & Well Control. Retrieved from https://www.wellcontrol.com.au/index.php/worked-examples 5. Knows About Swabbing and Well Control. DrillingFormulas.Com. Retrieved from http://www.drillingformulas.com/know-about-swabbing-and-well-control/ 6. Lecture Notes (provided by lecturer). 7. Drilling. Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Drilling . 8. Drilling Process and Machine. Engineers Edge. Retrieved from https://www.engineersedge.com/manufacturing/drilling-machinesprocess.htm . 9. Kicks. PetroWiki. Retrieved from http://petrowiki.org/Kicks .