5. SPILLWAY

It is a structure constructed to pass surplus flood water on the D/S of reservoir and Dam.

Essential requirements of a spillway

(i)

(ii)

(iii)

(iv)

(v)

The spillway must have sufficient capacity.

It must be hydraulically and structurally adequate.

It must be so located that it provides safe disposal of water i.e., spillway

discharge will not erode or undermine the D/S toe of the dam.

The bounding surface of spillway must be erosion resistant to withstand high

scouring velocity created by the drop from reservoir surface to tail water.

Usually some devices are needed for energy dissipation on the D/S side of

spillway.

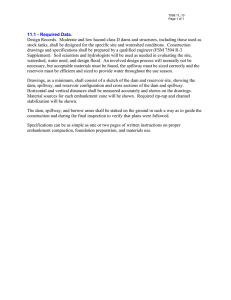

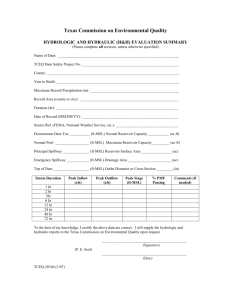

Spillway Capacity

The required capacity of spillway i.e., maximum outflow rate through spillway must

be determined by flood routing knowing (i) Inflow rate v/s time (ii) Reservoir

capacity curve (reservoir surface elevation v/s reservoir storage) (iii) Discharge curve

(out flow v/s reservoir water surface elevation). However the required capacity of a

spillway depends on the following factors:

(i) Inflow flood

(ii) Available storage capacity

(iii) Discharge capacity of outlet works

(iv) Whether gated or un-gated spillway

(v) Possible damage if a spillway of adequate capacity is not provided.

Note that large dam with inhabited area on the D/S side needs large protection.

Whereas, Small dams with uninhabited area on its D/S side needs limited protection.

Size of Dam

Small

Intermediate

Large

Inflow flood for safety of Dam

100 years of flood

Standard Project flood

Probable maximum flood (PMF)

However, floods of large or smaller magnitude may be used if the hazard involved in the

eventuality of a failure of a particular dam is high or low. A reservoir with larger storage

capacity will normally require a smaller out flow rate through the spillway. If the out

flows through the spillway are supplemented by release through the outlets then the

required capacity of spillway may be reduced. For gated spillway more water is stored.

By proper operation of gate higher heads may be developed so that greater out flow

through the spillway is possible to pass the flood.

1

Types of Spillway

Classification based on the time when the spillways come into operation

(a) Main or service spillway

(b) Auxiliary spillway

(c) Emergency spillway

Main or service spillway

Main spillway is the one which comes into operation and is designed to pass the entire

spillway design flood.

Auxiliary spillway

It is provided as a supplement to the main spillway and its crest is so located that it comes

into operation only after the floods for which the main spillway is designed is exceeded.

Thus it is provided in conjunction with the main spillway. Conditions favorable for the

provision of auxiliary spillway are the existence of a saddle or depression along the rim

of the reservoir which leads into a natural water way. On the crest of auxiliary spillway

instead of a control gate a fuse plug (earth dam or dyke) may be provided, which allows

the water surface in the reservoir to rise above the crest of spillway and is so designed

That when overtopped it automatically washes out thus releasing excess flood water.

Emergency spillway

It is also provided in addition to main spillway but it comes into operation only during

emergency which may arise at any time which may not have been considered in the

normal design of main spillway. Some of the situations which may lead to emergency

are:

(i)

an enforced shut down of the outlet works

(ii)

a malfunctioning of spillway gates.

(iii)

The necessity of bye passing the regular spillway because of damage or failure

of some part of the structure

(iv)

Further an emergency may also arise if a recurring flood occurs before a

previous flood is evacuated by the main spillway and outlet works.

Emergency spillways are also provided in the saddles or depressions if available. It is

often provided as breaching section which is a portion of the dam with its crest lower

than the main dam and is so designed that it is washed out when the water in the reservoir

reaches a predetermined elevation. The breaching section is also called fuse plug spillway

Classification according to flow through the spillway

(i)

controlled or gated spillway

(ii)

un controlled or un-gated spillway

2

Classification based on the prominent features pertaining to the various component

of the spillway:

The various components of a spillway are

Control structure,

Discharge channel

Terminal structures – energy dissipaters

Entrance & outlet channels.

With respect to control structures discharge channel etc. the spillway is classified into

following types.

(i)

(ii)

(ii)

(iii)

(iv)

(v)

(vi)

Free over-fall or straight drop spillway

Over flow or Ogee spillway

Chute or open channel or trough spillway

Side channel spillway

Shaft or morning glory spillway

Conduit or tunnel spillway

Siphon spillway

Free over fall or straight drop spillway

A free over fall spillway is the one for which the control structure is low height narrow

crested weir having its down face vertical or nearly vertical. The over flowing water may

be discharged as in the case of a sharp crested weir. Water flowing over the crest drops as

a free jet clearly away from the down stream face of the spillway. Occasionally the crest

of this spillway is extended in the form of an overhanging lip to direct small discharges

away from the D/S face.

Over flow or Ogee spillway

Overflowing water in this case is guided smoothly over the crest of the spillway and is

made to glide over the down stream face of the spillway.

The profile of the ogee weir is generally confined to the lower nappe that would be

obtained for maximum head over spillway. The control structure is a weir which is ogee

or S shaped.

The shape of such a profile depends upon the

Head

The inclination of U/S face of the overflow section and

The height of the overflow section above the floor of the entrance channel.

The ogee profile should provide maximum possible hydraulic efficiency, structural

stability and economy and also avoid the formation of objectionable sub-atmospheric

pressure at the crest. The ogee profile may be categorized into three groups:

3

(i) Overflow dams with vertical U/S face

The following equation as given by U.S. corps of engineers may be used for finding

coordinates (X,Y) for the D/S profile

X1.85 = 2 (Hd) 0.85*Y

Where X & Y are coordinates as shown in the figure and Hd is the design head.

For U/S profile following coordinates with origin at crest are recommended

(ii)

Over flow dams with sloping U/S face

The D/S profile may conform to the following equation:

Xn = K (Hd)n-1 Y

Where: n., K are variable parameters which depends on the inclination of U/S face of the

dam. Hd is the design head. These are called standard “WES standard spillway shapes”

Values of constant K,n , R1,R2, a and b

Shape of

K

N

R1/Hd

R2/Hd

a/Hd

B/Hd

U/S face

Vertical

2.000

1.850

0.5

0.20

0.175

0.282

3V: 1H

1.936

1.836

0.68

0.21

0.139

0.237

3V: 2 H

1.939

1.810

0.48

0.22

0.115

0.240

3V: 3H

1.873

1.776

0.45

0.00

0.119

0.000

4

The curved profile of the crest section is continued till it meets tangentially the straight

sloping portion of the overflow dam section (spillway).The slope of the d/s face of the

overflow dam usually varies in the range of 0.7(H):1(V) to 0.8:1 and is basically decided

on the basis of stability requirements. The location of the point of tangent depends upon

the slope of the d/s face, where the value of dy/dx for the curved profile and the straight

segment must be equal at the end of the sloping surface of the spillway.

U/S profile of the Weir Crest

(a) Vertical U/S face: The u/s profile should be tangential to the vertical face and

should have zero slope at the crest axis to ensure that there is no discontinuity

along the surface of the flow. The u/s profile should conform to the following

equation:

y = {0.724 (x+ 0.270 Hd)1.85/(Hd )0.85 }+ 0.126 Hd - 0.4315(Hd)0.375(x + 0.270 Hd)0.625

Alternatively the u/s slope may be considered to consist of compound circular curve with

values of R1= 0.50 Hd and R2 = 0.20 Hd

The chord length up to R1, and R2 is given as a = 0.175 Hd and b = 0.282 Hd

Discharge Computation of over ogee crest

The discharge over ogee spillway is computed from the basic equation of weir given

below:

Q = Cd Le H1.5

Where, Q = Discharge in cumec

Cd = coefficient of discharge, its value varies from 2.1 to 2.5

H = Head of over flow in meters including velocity of approach head.

H = Hd + Ha

Le = effective length of overflow crest in meters

Le = L -2(N*kp+ka)*H

L = Net length of the crest

N = Number of piers

kp = piers contraction coefficient

ka = abutment contraction coefficient

Pier Contraction coefficient kp

Pier condition

kp

Square nosed piers with corners

Rounded on a radius equal to 0.1

of pier thickness

0.02

Rounded nose piers

Pointed nose piers

0.01

0.0

Abutment Contraction coefficient ka

Abutment condition

Rounded abutment where R>0.5Hd

& wall is placed not more than 45o

to direction of flow

Rounded abutment with head wall at

900 to the direction of flow when

0.5Hd > R > 0.15Hd

Square abutment with head wall at 90o

to the direction of flow

ka

0.0

0.10

0.2

5

The discharge coefficient is influenced by a number of factors:

(i)

Height of spillway above stream bed or depth of approach

(ii)

relation of the actual crest shape to the ideal nappe shape

(iii)

upstream face slope

(iv)

downstream apron interference, and

(v)

down stream submergence

(vi)

Ratio of actual total head to the design head

(vii) effect of head due to velocity of approach

The effect of these factors is discussed below:

Height of spillway or Effect depth of approach

The height of spillway above stream bed or approach channel affects the velocity of

approach which in turn affects the coefficient of discharge. With increase in height of

spillway the velocity of approach decreases and the coefficient of discharge increases.

Model tests indicate that the coefficient of discharge becomes fairly constant when height

of spillway > 3.0 Hd, where Hd is the design head including the head due to velocity of

approach.

Various text books give a plot of Cd versus Hd which is reproduced here in the form of a

table

P/Hd

Cd

P/Hd

Cd

P/Hd

Cd

0.0

1.7

0.1

1.875

0.2

1.97

0.3

2.025

0.4

2.06

0.5

2.09

0.6

2.12

0.7

2.135

0.8

2.15

0.9

2.16

1.0

2.17

1.5

2.185

2.0

2.195

2.5

2.2

3.0

2.205

4.0

2.210

In the table P is the height of spillway.

When u/s face is inclined the above Cd values gets multiplied by a factor from 0.995 (for

P/ Hd = 1.5) to 1.04 (for P/ Hd = 0.2)

6

Negative Pressure over spillway surface

H > Hd the pressure on the crest will be negative (sub atmospheric) may lead to

cavitation. Model tests show that till H < 1.25 Hd there is no harmful cavitation

effect.

H < Hd the pressure on the crest is positive. Lower nappe of the jet attaches itself

to the boundary. Also when H > Hd lower nappe may leave the boundary for some

distance on d/s face and may attach again as the air mass in between the boundary

and the lower nappe gets sucked out. This may lead to the vibration of the

structure.

Avoid negative pressure as:

(i)

It increases overturning moment at the crest

(ii)

It increases the force required for lifting of the gates

(iii)

It causes decrease in the capability for automatic control

(iv)

It causes vibration which extends all over the structure. The vibration also

causes cracks in the mortar of stone lining of the crest.

7

Problem:

Design ogee spillway for the following data:

(i)

Height of the spillway crest = 100.0 m

(ii)

Number of spans = 10

(iii)

Length of each span (clear) = 12.5

(iv)

Thickness of each pier = 3 m

(v)

D/s slope of spillway = 0.8(H): 1(V)

(vi)

Rock condition = good

(vii) Design discharge = 8500 m3/s

Design (i) Head over crest & coefficient of discharge

(a) Clear Water Way = 10x12.5 = 125

Let us assume Cd =2.21 maximum value

(b) Effective length of spillway = Le = L - 2[N Kp+ Ka]Hd

Cut water (90o) nosed piers are supposed to be used with rounded abutments.

Kp = 0.01 and Ka = 0.1 and hence Q= 2.21[125 - 2(9x0.01 + 0.1) Hd] Hd3/2

(c) By trial and error Head over the crest Hd =10.024

(d) P/ Hd = 100/ 10.024 = 9.976 > 4.0 Hence Cd =2.21

(e) D/S profile

The profile recommended is X1.85 = 2 (Hd)0.85Y = 2(10.024)0.85Y = 14.188 Y

or, Y = X1.85 /14.188

The calculated coordinates of d/s profile are

Xm

1.0

2.0

3.0

4.0

5.0

Ym

0.0705

0.2540

0.5380

0.9159

1.3841

Xm

7.0

9.0

11.0

13.0

14.28

Ym

2.5793

4.1061

5.9519

8.1072

9.6455

The slope of d/s glacis = 0.8(H):1(V)

Differential equation of d/s profile dy/dx = 1/0.8 = 1.25

d/dx [ X1.85 /14.188] = (1.85/14.188) X0.85 = 1.25

so, X= 14.28 and Y = 9.6455

(f) U/S profile R1 = 0.5 Hd = 0.5x 10.024= 5.012

and R2= 0.2 Hd = 0.2x10.024= 2.00048

b= 0.282 Hd = 2.827 a = 0.175 Hd = 1.754

Alternatively calculate the profile from the given equation.

Equation for u/s profile

0.27 Hd = 2.706

Hd 0.85 = 7.09

Hd0.375 = 2.373

0.126 Hd = 1.264

0.4315 Hd0.375 = 1.024

1.85

y = [{0.725 (x+2.706 ) }/ 7.09] + 1.264 - 1.024 (x + 2.706)0.625

8

Chute Spillway or Trough Spillway

An ogee spillway is mostly suitable for concrete Gravity dam when the spillway is

located within the body of dam. For Earth & Rock-fill dam, a separate spillway is

generally constructed in a flank or saddle, away from main valley. Some times even for

gravity dams a separate spillway is required because of the narrowness of the valley. In

such circumstances a separate spillway may have to be provided. The trough spillway or

chute spillway is the simplest type of spillway which can be easily provided

independently and at low costs. It is lighter & adoptable to any type of foundation and

hence provided easily on Earth & Rock-Fill dam. It is also called at times Waste Weir. If

it is constructed in continuation of the dam at one end, it may be called a Flank weir. If it

is constructed in a natural saddle in the bank of the river separated from the main dam by

a high ridge it is called a Saddle Weir.

A chute spillway essentially consists of a steeply sloping open channel placed along a

dam abutment or through a flank or saddle. It leads the water from the reservoir to the

downstream channel below the base of the channel is usually made of reinforced concrete

slabs 25 to 50 cm thick. Light reinforcement of about 0.25% of concrete area is provided

in the top of the slab in both directions. The chute is some times of constant width but is

usually narrowed for economy and then widened near the end to reduce the discharging

velocity. Expansion joints are usually provided in the chutes at intervals of about 9to 12m

in either direction. The expansion joint s should be made water tight so as to avoid any

under seepage and its troublesome effects. Under drains are also provided, so as to drain

the water which may seep through the trough bottom and side walls. These drains may be

in the form of a perforated steel pipes, clay tiles or rock filled trenches.

Slope of chute can conform to available topography leading to minimum excavation, but

the slope should be steep enough to maintain supercritical flow to avoid unstable flow

9

conditions. When a vertical curve is provided at a point where chute slope changes it

must be gradual & designed to avoid any separation of flow.

Side Channel Spillway

In a side channel spillway, the crest of the control weir is placed along the side of the

discharge channel. The crest is approximately parallel to the side channel at the entrance.

Thus the flow after passing over the crest is carried in a discharge channel running

parallel to the crest. Water flows over the crest into the narrow trough of the discharge

channel opposite the weir; it turns approximately at right angle and then continues in the

discharge channel.

The side channel spillway is usually constructed in a narrow canyon where sufficient

space is not available for an overflow spillway, and where there is neither a suitable

saddle, nor there is a availability of a wide flanks to accommodate a chute spillway. In

such cases, if a crest of length required for the flow to occur perpendicular to the crest is

provided, heavy cutting would be required making the cost of constructing a chute

spillway or an overflow spillway prohibitive.

The crest of a side channel spillway is usually an ogee- shaped section made of concrete.

Sometimes it consists of a flat concrete pavement laid on an earthen embankment or the

natural ground surface.

10

11

Saddle Siphon Spillway

The saddle Siphon spillway consists of an air tight reinforced concrete cover called

“Hood” or “cowl” provided over an an ogee shaped body wall to form a siphon duct.

Hence this spillway is also known as „Hood siphon spillway‟ or „Hood siphon‟.The top of

the body wall forms the crest of the siphon spillway and hence it is located at full

Reservoir level.The entrance and the exit lips of the hood are so shaped that siphon duct

has bell mouthed entry and exit. The inlet of the siphon duct is kept submerged well

below the full reservoir level so that floating debris etc., does not enter the siphon duct

and also the formation of vortices and draw downs which might break the siphonic action

is avoided. Thr outlet of the siphon duct is kept submerged in a cup like basin which

forms a water seal so that air cannot enter the siphon duct from this end. However,

instead a cup like basin a cistern may be created by constructing a low weir a little away

from the outlet on the down stream of the outlet. A small de-primer hood is provided

above the main hood and both these hoods are connected through an air vent. The inlet of

the de-primer hood is kept slightly above the full reservoir level

At full reservoir level water stands up to the crest of the spillway and hence there is no

flow. When the water level rises above the full reservoir level i.e., above the crest of

spillway, water starts flowing over the crest and the inlet of the de-primer hood gets

submerged with the result that entry for air into the de-primer hood and the main hood

gets sealed. Thus air cannot enter from both the inlet and outlet of the siphon duct and the

air remaining entrapped in the top portion of the siphon duct above the sheet of the water

flowing over the crest is gradually sucked by the flowing water. As the air is sucked the

pressure drops to less than atmospheric in the top portion the siphon duct which was

having atmospheric pressure at the starting of the flow. Thus a difference of pressure

develops between the outside atmosphere and the air inside the siphon duct which creates

a suction pull and draws in more water over the crest. This in turn takes in more air along

with it which further increases the suction pull and draws in more and more water over

the crest. This sucking action which increases progressively and gradually creates the

necessary pull for the commencement of the syphonic action and the siphon duct start to

run full. The action of the siphon spillway from the moment the water just starts to flow

12

over the crest to the instant when the siphon duct starts flowing full is known as

„PRIMING‟, (or it is said to have „primed‟). It may however difficult to expel the

entrapped air from the siphon since it has to be forced through the water in the sealing

basin and hence it may not get primed quickly. Moreover relatively large rise in water

level above the crest of spillway may be needed before it gets primed. To assist quick

priming many priming devices can easily be fitted along with the siphon.

The siphoning action once initiated will continue as long as water level in the reservoir is

above the full reservoir level. The operating head for the spillway is then equal to the

difference between water levels on the U/S and the D/S of the spillway. When the water

level in the reservoir drops to such a level that the inlet of the de-primer hood gets

13

exposed then the air enters the siphon duct and breaks the siphoning action thus stopping

the flow. This action is called de-priming of the siphon spillway.

Another form of saddle siphon spillway provided in the body of Dam is called „Tilted

Outlet type‟. It has a vertical lower limb and hence the draught of falling water is enough

to cause priming and no other device is needed for its priming. However the outlet is

tilted upwards in order to develop water seal at the bend and thus facilitate early priming.

For De-priming air inlet pipe is provided.

Advantage The main advantages of the siphon spillway are

(i)

Its automatic operation without any mechanical device ,and

(ii)

Its ability to pass higher discharge at relatively low surcharge head resulting in

lower height of dam as well as less surrounding area to be acquired for

submergence.

Disadvantage

(i)

It is an expensive structure and has limited capacity.

(ii)

It has a serious disadvantage due to occurrence of sudden surges and

stoppages of out flow as a result of erratic siphonic action, thus causing severe

fluctuations in the down stream river stage.

(iii)

A minor crack in the cover of the siphon would interfere with the siphon

Therefore the siphon spillway is always constructed in batteries so that entire

spillway is not affected even if cracks have developed either in one or few

units.

(iv)

The structrure and foundation have to be strong enough to resist the vibration.

(v)

There exists a possibility of clogging of the siphon due to debris and floating

material.

(vi)

Like other type of closed conduit spillways, a siphon spillway too is

incapable of handling flows appreciably greater than the designed capacity.

Hence, siphon spillways must be provided in conjunction with an auxiliary or

emergency spillway.

Shaft Spill Way

In shaft spillway water enters a horizontal crest, drops through a vertical or a sloping

shaft and then flows to the down stream river channel through a horizontal or nearly

horizontal conduit or tunnel. A rock out crop projecting into the reservoir slightly

upstream of the dam would be an ideal site for a shaft spillway. Depending on the level of

out crop and the required crest level, a spillway may have to be either constructed or

excavated. The diversion tunnels if available can be utilized for discharge tunnels of

spillway. Radial piers provided on the spillway crest ensure radial flow towards spillway

and also provides support to the bridge connecting spillway and the dam or the adjoining

hill.

A shaft spillway with a funnel shaped inlet is called 'Morning Glory' or Glory Hole

spillway. One of the distinguishing characteristics is that near maximum capacity of the

spillway is attained at relatively low heads. Therefore a shaft spillway is ideal when

maximum spillway discharge is not likely to be exceeded. Because of this feature,

14

however, the spillway becomes unsuitable when a flow larger than the selected inflow

design flood occurs. This disadvantage can be got rid of by providing an auxiliary or

emergency spillway and using the shaft spillway as service spillway.

Depending upon the type of crest, the shaft spillway can either be standard crested or

flat crested. In a standard crested spillway, the water begins its free fall immediately

upon leaving the crest where as in flat crested spillway water approaches upon the crest

on a flat slope before beginning its free fall. The standard crested spillway would have a

smaller diameter crest since its coefficient of discharge is greater than a flat crest.

Therefore if the shaft spillway is to be constructed in the form of a tower, it would be

economical to have a standard crested spillway. However a flat crested shaft spillway has

a smaller funnel diameter and is therefore more advantageous when the spillway is to be

excavated in rock.

15