EFFECTS OF SODIUM BISULPHATE CATALYST ON THE DEHYDRATION OF CASTOR OIL FOR THE PAINT INDUSTRY

advertisement

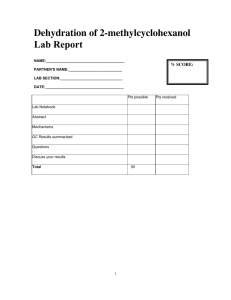

International Journal of Mechanical Engineering and Technology (IJMET) Volume 10, Issue 03, March 2019, pp. 353–363, Article ID: IJMET_10_03_036 Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=3 ISSN Print: 0976-6340 and ISSN Online: 0976-6359 © IAEME Publication Scopus Indexed EFFECTS OF SODIUM BISULPHATE CATALYST ON THE DEHYDRATION OF CASTOR OIL FOR THE PAINT INDUSTRY Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye Department of Chemical Engineering, Covenant University, Nigeria ABSTRACT Crude castor oil seems to have many industrial applications. However, its Iodine value range <100 (82 - 88 gI2/100g) makes it not applicable in the paint industries since it is considered a non-drying oil. Experimentally, dehydration of its fatty oil is the only way of converting its non- drying attributes into a drying one. This process involves heating the oil to a temperature of 250OC in the presence of catalyst such as sulphuric acids, phosphoric acids, clays and metal oxides under an inert, atmospheric or vacuum condition. Albeit a lot of research has been carried out on the different catalyst used in dehydrating castor oil and the effect of catalyst percentage variation in an overall continuous process, this study was however on the effect of sodium bisulphate catalyst on a batch process. The change in the physiochemical properties (hydroxyl, viscosity and iodine value) with respect to time and temperature was considered. In the course of this study, Sodium bisulfate and Sodium bisulfite is chosen as the catalyst and anti-polymerization agent respectively. The dehydration of castor oil in the presence of catalyst speeds up the rate at which the maximum dehydration is obtained (60min) but at the same time, speeds up the rate of polymerization. The Iodine value rapidly decreases until it attains maximum dehydration wherein polymerization (hardening of oil) takes place simultaneously. However, dehydration reaction without catalyst takes longer time to reach maximum dehydration (180 min), but does not readily polymerize when maximum dehydration is reached Key words: Dehydration, Castor oil, Drying oil, Paint Industry Cite this Article: Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye, Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry, International Journal of Mechanical Engineering and Technology 10(3), 2019, pp. 353–363. http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=3 1. INTRODUCTION Castor oil is a pale yellow non-edible vegetable oil extracted from the bean seeds of the Castor oil plant (Ricinus Communis L.). The plant belongs to the spurge family Euphorbiaceae. The family Euphorbiaceae is a wide, diverse and numerous group of the http://www.iaeme.com/IJMET/index.asp 353 editor@iaeme.com Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry angiosperm, including the species of great economic importance such as rubber tree (Hevea Brasilens) and Cassava (Manihot Esculenta) [1]. Although Castor bean is very useful, it is also considered one of the deadliest natural poison ever known to man due to the presence of ricin: a very toxic substance to human, animals including insects. Its species include Gibsonii, Carmencita pink, Carmencita Bright Red, Impala, Red Spire and Zanzibarensis [2] Castor oil is commonly found in the South Eastern Mediterranean region, Eastern Africa, and generally in the tropical and subtropical regions of the world [3,4,5 and 6].Currently India is the world’s leading producer and exporters of castor seed. Other major producers include: Brazil, China, Paraguay and Ethiopia [7]. In Nigeria, castor plant can be found growing in Lagos, Ogun, Enugu, Ebonyi and most commonly in the North region (Daily Trust Newspaper, 2018). The percularity of castor oil is due to the presence of the hydroxyl fatty acid known as ricin-oleic acid (C18H34O3); an 18- carbon hydro-xylated fatty acid having initially only one double bond [8]. Generally, Castor oil consist of 89.5% ricin-oleic acid, 4.2% linoleic acid, 3% oleic acid, 1% stearic acid, palmitic acid(1.0%), Dihydroxystearic acid (0.7%), Linolenic acid(0.3%) and Eicosanoic acid (0.3%). Previous research works have documented that ricinoleic acid is the major constituent in the oil; over 89% [5]; 90.2% [9]; 89.2-94.9% [10]; about 70-90% by [11]; 87-90% [12]. The hydroxyl functional group of Ricinoleic acid (RA) gives castor oil specific properties and attributes [13]. It makes the oil a natural polyol therefore giving it oxidative stability. It gives castor oil a relative high shelf life by preventing the formation of peroxide. The Hydroxyl group in ricinoleic acid also presents a functional group location in which various chemical reactions such as dehydration, halogenation, alkoxylation, sulfation and esterification can be performed [14]. According to [15] the high content of Ricin-oleic acid and other physiochemical properties present, makes castor oil a very valuable commodity in the medical, pharmaceutical and industrial sector at large (cosmetic, chemical ,petrochemical, food, automobile and fuel). Albeit, crude castor oil seems to have many industrial applications, its Iodine value range <100 (82 - 88 gI2/100g) makes it not useful in the paint industries since it is considered a nondrying oil. Generally, Oils are classified based on their Iodine value range into drying, semidrying and non-drying oils. Generally, as the iodine number increases, the drying capacity of the oil increases Non-drying oil iodine values fall below 100. When brought in contact with oxygen or exposed to air, there is no appreciable drying. Examples include olive oil, argan oil, mineral oil, babassu oil and coconut oil [16]. Semi-drying oil iodine values fall within the range of 100-130. These oils dry within acceptable limits that is partially dry when exposed to air. Examples of semi-drying oil include sesame oil, cottonseed oil and corn oil [16]. Drying oil are oil that when spread into a film becomes hard, tough, and elastic upon exposure to air (Britannica.com). They dry rapidly in contact with atmospheric oxygen and usually have Iodine values within the range of 130-190. According to [17], Examples of drying oil with their respective iodine value are Tung (234), Linseed (190.4), Catalpa (195.5) and sunflower oil (139.1). These oils consist of glycerol tri-esters of fatty acids that are characterised by high level of polyunsaturated fatty acids such as oleic acid, linoleic acid as well as related saturated and unsaturated acids. The capacity of drying oil is related to the amount of double bonds in its fatty acids, their positions in the molecule (conjugated or isolated), and the geometric arrangement of the substituents around the double bonds (cis or trans configuration). http://www.iaeme.com/IJMET/index.asp 354 editor@iaeme.com Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye Drying oils are the basic vehicles of oil paints. The hardening of drying oil is generally considered to be due to the action of oxygen (oxidation). The primary reaction considered are the formulation of unsaturated ester hydro-peroxides, the decomposition of these materials and their subsequent cross-linking. The process begins when drying oil is exposed to atmospheric oxygen. The oxygen molecule in air attaches itself to a carbon-hydrogen(C-H) bond adjacent to one of the double bonds within the unsaturated fatty acid forming hydroperoxides. The hydro-peroxides formed are very reactive compounds that easily take part in cross-linking reactions. Bonds form between neighbouring fatty acid chains result in a polymer network. The polymer network is visible as skin like film formed on samples. In summary, drying oils polymerize thereby forming a visible film [16]. 1.1. Modification of Castor Oil Although castor oil has always been regarded as a non-drying oil due to its low iodine value, as early as 1928, patents were already made regarding the production of drying oil directly from castor oil. J. Scheiber went further to develop a method for producing a drying oil from castor oil by dehydrating its fat oils [18]. [19] called it the de-hydration process while [20] highlighted the four factors that need to be considered in the dehydration reaction. They include: the reaction going into completion in order to obtain an oil of good drying and film properties, the rate of polymerization being controlled to avoid the formation of a viscous or gelled product, the catalyst used either being innocuous if left in the oil or readily removable and finally there should be an increase in the amount of two double bond conjugation over the 20-30% that is usually obtained. Dehydration is carried out by heating the oil to 250OC in the presence of catalyst such as sulphuric acids, phosphoric acids, clays and metal oxides under an inert atmospheric or vacuum condition [21]. During the reaction, the hydroxyl group and adjacent hydrogen atom located at the C-11 or C-13 position of the ricinoleic acid come together to form water that is removed. These results in the production of two acids with double bonds each; a conjugated and non-conjugated acid (Castoroil.in). During dehydration of Castor oil, ricinoleic acid is transformed into 9, 11/ 9, 12 linoleic acids and commercially 9, 11 isomer [22]. The presence of conjugated double bonds makes it possible for polymerization to occur which should be avoided with the presence of an anti- polymerization catalyst [23]. It should be noted that during the de- hydration process, the elements of water are split off alongside the fission of fatty acid chains resulting in the formation of aldehydes and free carboxylic acids. As a result of the reaction, water is released as vapour. Therefore, an efficient condensing system must be made available in order to handle the water vapour released and the other volatile decomposition products evolved during the reaction [21]. Efficient stirring provides opportunity for intimate contact between the oil and the catalyst while large surface area helps to speed up the rate of heat transfer [21] Although castor oil has various physiochemical properties, the rate of the overall dehydration process is evaluated by changes in the hydroxyl, iodine and viscosity value. Iodine Value (IV) determines the unsaturation level of an oil sample. It refers to the amount of Iodine in grams that 100 grams of the oil sample is able to take up. Iodine number can also be used to identify the form of a substance. That is, if the Iodine number is in the range of 0-70, it is fat but if it exceeds this range, it is an oil High IV suggest high level of unsaturation in oils and vice versa. Hydroxyl Value refers to the weight of potassium hydroxide in milligrams equivalent to the amount of acetic acid needed to acetylate 1 gram of the oil. It is simply a means of measuring the number of hydroxyl groups present in the oil sample. During dehydration, the hydroxyl group from the ricinoleic acid is removed as water along with the adjacent hydrogen http://www.iaeme.com/IJMET/index.asp 355 editor@iaeme.com Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry atom. Therefore, the study of the disappearance or decrease in hydroxyl content with time shows the course of dehydration [20]. Generally, as the hydroxyl group decreases, its viscosity also reduces while the iodine value increases [20]. The elimination of every hydroxyl group leads to the creation of a new double bond along with the already existing double bonds thereby increasing the unsaturation level (Iodine value). Viscosity is defined as the resistance of a liquid to flow. Castor oil is a vegetable oil with relatively high viscosity in comparison to other oils. This is because of the presence of the hydrogen bonds formed by the Hydroxyl groups [5]. The viscosity in this study is a parameter that will be monitored in order to determine the rate of disappearance of the hydroxyl groups during the dehydration reaction. 1.2. Aim and Objectives of this Research Albeit a lot of research has been carried out on the different catalyst used in dehydrating castor oil and the effect of catalyst percentage variation in an overall continuous process, this study will be on the effect of sodium bisulphate catalyst on a batch process. The change in the physiochemical properties (hydroxyl, viscosity and iodine value) with respect to time and temperature will also be considered. In the course of this study, Sodium bisulfate and Sodium bisulfite is chosen as the catalyst and anti-polymerization agent respectively. 2. METHODOLOGY 2.1. Oil Extraction White Big Size (WBS) Castor seeds were collected from Ogun State, Nigeria. De-hulling: The seeds were de hulled manually by hand Screening: The damaged seeds were sorted and selected from the good seeds by hand picking. Damaged seeds are discarded. Drying/Cooking: Selected seeds are further dried in an oven to a temperature of 60ᵒC in order to reduce moisture content. Grinding: Grinding to form paste was done using a manually operated grinding machine Figure 1 The Soxhlet Extraction Set Up. Solvent Extraction: A Soxhlet extractor was used with hexane as commercial solvent to extract oil from the castor paste. The round bottom flask was filled with 250 ml of hexane. 200g of the sample was wrapped in a filter cloth and placed in the thimble located at the center http://www.iaeme.com/IJMET/index.asp 356 editor@iaeme.com Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye of the extractor. The commercial hexane was heated to a constant temperature of 60 0C. This is allowed to continue for four (4) hours. This procedure was repeated for eight (8) samples of castor paste each weighing 200g. The samples are then removed from the tube, dried in the oven and weighed again. The eight (8) samples of castor paste then underwent a second phase of extraction known as the recycle extraction to further extract oil that left after the first phase. 2.2. Dehydration Reaction Castor oil was fed into the three-necked flask. The oil is then heated to the reaction temperature of 2500C Catalyst (1% NaHSO4 and 1% NaHSO3) on the weight of oil was added to the heated oil when the reaction temperature was attained. Timing begins after the reaction temperature had been attained and the catalyst has been added. Efficient stirring with the aid of the magnetic stirrer is set. Nitrogen was passed over the surface of the oil using an inert gas inlet tube connected through the condenser. The Nitrogen gas passed is used to create an inert atmosphere capable of removing water and enhance the reaction The experiment was performed with and without the use of a catalyst. From both set of experiments, samples were withdrawn at intervals of 30,45,60, 90,120 minutes and taken for further analysis Figure 2 Dehydration Reaction (Laboratory Scale) 2.3. Physiochemical Characterization 2.3.1. Viscosity With the aid of a Ostwald viscometer and equation (1) below, the viscosity of the oil at intervals of 30,45, 60, 90,120 minutes was taken Viscosity = C × t Where C is constant (51.65) and t is time 2.3.2. Iodine Value (1) About 0.1 to 1.5 grams of oil was weighed and poured into an Iodine flask. http://www.iaeme.com/IJMET/index.asp 357 editor@iaeme.com Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry 25 ml each of Carbon tetrachloride and hanous solution each 25 ml were properly mixed and added to the oil in the iodine flask. The content of the flask is also shaken well to ensure complete mixing. Standardized sodium thiosulfate solution is titrated against the content of the iodine flask. The indicator used is standard potassium dichromate solution with starch The same process was repeated for the non-catalyst samples The iodine values of the different samples were calculated from equation (2) below (2) Where Z is the amount of Iodine consumed by the oil (ml), M1 the strength of thiosulfate, A the weight of oil and bottle (gram) and B the weight of the bottle alone (gram) 3. RESULTS AND DISCUSSION OF RESULTS 3.1. Oil Extraction Results of Oil Extraction Using Solvent Extraction Method Initial Weight of Castor Bean Seeds = 2000g = 2kg Weight After De-hulling = 1700g Weight of seed samples before drying = 200g Weight of seed samples after drying = 199.66 Therefore, Moisture content = ×100 Table 1 Results of Oil Extraction Runs 1 2 3 4 5 6 7 8 TOTAL Weight of Weight of Sample To Be Sample After Extracted (g) Extraction (g) 200 200 200 200 200 200 200 200 200 186.0 182.0 182.0 193.4 193.0 194.6 191.5 194.4 1507.4 Weight of oil Weight of Weight of oil Extracted (g) Samples After Extracted (g) Recycle Extraction (g) 24.9 171.8 14.2 25.0 165.4 12.1 30.9 166.4 10.0 24.8 174.4 19.3 25.4 163.4 15.0 20.6 182.6 16.2 20.5 184.5 14.0 25.4 173.4 10.3 197.5 1381.4 110.8 3.1.1. Moisture Content The moisture content is dependent on the seed variety, place of origin, harvesting time and storage time. The moisture content of the seeds need to be determined in order to know how much water is needed to be removed by drying and determine its shelf life. Table 1 above shows the number of extraction cycles that was performed. The resulting weight loss was recorded after each extraction cycle. The moisture content present in the Castor seeds used was 0.2%. This corresponds with values reported in other works usually between 0.2% and 4.12% [24]. The presence of excess water in seeds make the castor seeds makes them susceptible to hydrolysis by lipase enzyme. These reactions caused leads to the production of free fatty acid, which results in an increase in the acid value. The quality of castor oil is http://www.iaeme.com/IJMET/index.asp 358 editor@iaeme.com Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye reduced due to this reaction thereby rendering the oil unsuitable for biodiesel manufacture and limiting its use in the chemical industry (Omari et al., 2015). 3.1.2. Percentage Yield The percentage yield of the extraction process was calculated from equation 3 below (3) 13.66% Previous works have reported that the yield of Castor oil from the African castor bean usually falls between the values of 35.7% to 51.9 %. For example, research was conducted on the adaptation and performance capacity of 19 castor bean genotypes in Mediterranean climate and reported that seed oil content depends on both genotype and environmental conditions thereby giving a possible yield ranging from 44.5 to 54.2% [25] .As stated previously, the productivity or yield varies depending on factors such as seed harvesting practices, environment, genotype and extraction method (Tchuentu., 2017). Table 1 above shows the number of extraction cycles that were performed. The resulting weight loss is recorded after each extraction cycle. Therefore, substituting the required values into equation 3 we are able to calculate for the yield (13.66%). Continuous recycling will yield greater yield value but for the sake of this experiment, 308.3g of oil is obtained by extracting 1700g of castor paste. 3.2. Dehydration of Castor Oil 3.2.1. Analysis of Physicochemical Properties From table 2 below, it is observed that the crude castor oil has an Iodine value of 95.32 g/100g, which is above the value of the ASTM standard (80-88). However, the values for viscosity of crude and dehydrated castor oil comply with expectations. The high value of Iodine value indicates that there is a high level of unsaturation of the oil therefore the amount of Iodine that can be taken by the oil is high. The viscosity of the crude castor oil used is 2832cps, which is within the standard range of Castor oil as a non-drying oil Table 2: Dehydration of Castor Oil with/without Catalyst With catalyst. Time(min) 0 30 45 60 90 120 Without catalyst. Iodine Value Viscosity(cps) (g/100g) 95.32 2832.0 106.0 2587.0 113.3 2246.0 158.0 1357.0 140.0 2364.0 115.0 3774.0 Time(min) 0 30 45 60 90 120 150 180 Iodine Value Viscosity(cps) (g/100g) 93.9 2624.0 110.2 2581.0 120.0 2478.0 122.1 2398.0 124.6 2330.0 127.0 2299.0 135.0 1044.0 139.0 2145.0 3.2.2. Dehydration Reaction with Catalyst (Viscosity with Time) From figure 1 below, it is evident that the maximum dehydration is reached at the first sixty minutes. Within this time, there is an increase in the viscosity of castor oil until maximum dehydration is attained and the viscosity drops to 1357.0cps. This is because the principal reaction in the dehydration process is the splitting off the hydroxyl groups in the ricinoleic acid together with a neighbouring hydrogen atom to yield water. The hydroxyl groups being http://www.iaeme.com/IJMET/index.asp 359 editor@iaeme.com Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry split of are responsible for the thickness or viscosity of the castor oil. The viscosity of the oil tends to decrease as the hydroxyl group present in the oil are eliminated. When polymerization occurs due to crosslinking network formed by the hydro-peroxides, the viscosity begins to increase 4000 VISCOSITY(cps) 3500 3000 2500 2000 1500 1000 500 0 0 20 40 60 80 100 120 140 TIME (min) Figure 3 Variation of Viscosity with time in a dehydration reaction with catalyst 3.2.3. Dehydration Reaction without Catalyst (Viscosity with Time) It is observed in Figure 2 that the viscosity of castor oil undergoing a dehydration reaction without catalyst takes about 150 minutes to attain maximum dehydration (Viscosity=1044cps at max. dehydration). This low viscosity value maybe due to prolonged heating. The graph shows that viscosity decreases at an almost steady rate before dropping drastically at 120 minutes. It continues dropping until it reaches maximum dehydration at 150 minutes. It is shown that within the ranges of 120 and 150 minutes, reaction can be stopped and properly dehydrated castor oil can be obtained although with darker colour. 3500 VISCOSITY(cps) 3000 2500 2000 1500 1000 500 0 0 50 100 150 200 TIME(min) Figure 4 Variation of Viscosity with time in a dehydration reaction without catalyst 3.2.4. Dehydration Reaction with Catalyst (Iodine Value with Time) Figure 3 shows the change in Iodine value with time in a reaction with catalyst. From the data, it can be seen that maximum dehydration is obtained within the first sixty minutes when using a catalyst. The Iodine value increases continuously until it attains maximum dehydration (IV=158g/100g). Further prolongation of heating leads to polymerization and simultaneous drop in Iodine value. http://www.iaeme.com/IJMET/index.asp 360 editor@iaeme.com Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye 160 IODINE VALUE(cps) 140 120 100 80 60 40 20 0 0 20 40 60 80 100 120 140 TIME(min) Figure 5 Variation of Iodine Value with time in a dehydration reaction with catalyst. 3.2.5. Dehydration Reaction without Catalyst (Iodine Value with Time) Figure 4 below shows the change in Iodine value with time in a dehydration reaction without catalyst. The Iodine value increases continuously with time. At the point where maximum dehydration is attained, the Iodine value continues to increase. This is evidence to show that polymerization does not occur simultaneously after maximum dehydration is reached. Thereby it can be said that the presence of a catalyst is effective in promoting polymerization. The viscosity of the oil tends to decrease as the hydroxyl group present in the oil are eliminated. However, the viscosity begins to increase when polymerization occurs due to crosslinking network formed by the hydro-peroxides. In the reaction without use of catalyst, the Iodine value slowly and progressively increases until it attains a value above 130 thereby making it a drying oil. The rate of polymerization is reduced at the risk of reducing the rate of dehydration. This is because the oil did not show signs of polymerization or hardening though the colour of the oil darkened as continuous heat was being applied. 160 IODINE VALUE(cps) 140 120 100 80 60 40 20 0 0 50 100 150 200 TIME(min) Figure 6 Variation of Iodine value with time in a dehydration reaction without catalyst 4. CONCLUSIONS From the data obtained, it is evident that the dehydration of castor oil in the presence of catalyst speeds up the rate at which the maximum dehydration was obtained (60min) but at the same time, the rate of polymerization. If reaction is not carried out under typical http://www.iaeme.com/IJMET/index.asp 361 editor@iaeme.com Effects of Sodium Bisulphate Catalyst on the Dehydration of Castor Oil for the Paint Industry controlled situations where the limiting temperature mark is exceeded, the DCO required will not be obtained. However, dehydration reaction without catalyst takes longer time to reach maximum dehydration (180 min), but does not readily polymerize when reached. Though the colour changes are evident, it still produces castor oil of similar viscosity and Iodine value. ACKNOWLEDGEMENT I want to express my deep thanks to the management of Covenant University, Nigeria for providing an enabling environment for this research. I also want to express my profound gratitude to my co- authors for their wonderful contributions REFERENCES [1] Khaliq, e. a. (2017). Chemical Composition and Oil Characterization of some Accessions of Ricinus Communis Seeds. Journal of Business and Financial Affairs. [2] Brickell, C. (1996). The Royal Horticultural Society A-Z Encyclopedia of Garden Plants. [3] Phillips, R. a. (1999). Annuals and Biennials. Macmillian. ISBN 0333748891. [4] Salunke, D. a. (1992). Post-harvest Biotechnology of Oil Seeds. CRC Press, pp. 161-170. [5] Ogunniyi, D. (2006). Castor Oil: A Vital Industrial Raw Material. Bioresource Technology, 97: 1086-1091 [6] Salihu, B., & Gana, A. a. (2014). Castor Oil Plant (Ricinus Communis L.): Botany, Ecology and Uses. . International Journal of Science and Research (IJSR). [7] Kyari, M. (2008). Extraction and Characterisation of Seed Oils. International Agrophysics, 139-142. [8] Jumat et al. (2010). Fatty Acid Composition and Physicochemical Properties of Ma;aysian Castor Bean Ricinus Communis L. Seed Oil. [9] Conceicao, M. R. (2007). Thermoanalytical Characterization of Castor Oil Biodiesel . [10] Gupta, S. H. (1951). The Fatty Acids and Glyceridesof Castpr Oil. Journal of The Science of Food and Agriculture, 245-251. [11] Foglia, M. H. (2000). Lipase Catalysed Production of Biodiesel fuel from some Nigerian Lauric Oils. Biochemical Society Transactions. [12] Meenal S, P. V. (2006). Enzymatic Hydrolysis of Castor Oil: Process Identification Studies. Chemical Engineering Division, Mumbai University Institutre of Technology, Matunga, Mumbai 400019 [13] Odunlami, O. A., Elehinafe F. B., Pearl A. A. Abatan O. G and Mamudu A. O, Assessment of Carbon Monoxide Emission from Different Brands of Split Airconditioners, International Journal of Mechanical Engineering and Technology, 9(9), 2018, pp. 655–662. [14] Clautilde et al. (2016). Physicochemical Properties of Cake and Oil from three Castor Bean Accessions (Ricinus Communis L) Grown in Field in two Agroecological Zones of Northern Cameroon. International Journal of Research Studies in BioSciences, 6-15. [15] Akpan et al. (2006). Extrraction, Characterisation and Modification of Castor Seed oil. Leornado Journal of Science [16] Ktani. (2011, December 10). Understanding The Drying Capacity of ktanihairsense.blogspot.com.ng. [17] Adrianova, A. L. (1977). The Drying Properties of Catalpa Oil. http://www.iaeme.com/IJMET/index.asp 362 Oils. editor@iaeme.com Angela O. Mamudu, Enobong A. Charles, Francis Elehinafe, Olayemi Odunlami and Damilola Akinneye [18] Scheiber J. (1949). Dehydrated Castor Oil and Ricinoleic Acid. [19] Noureddini, H., & Harkey, D. A. (1998). A Continuous Process for The Conversion of Vegetable Oils Into Methyl Esters of Fatty Acids. Chemical and Bimolecular Engineering Research and , University of Nebraska. [20] Guner, F. S. (1997). Castor Oil Dehydration Kinetics. Journal of The American Oil Chemist Society, 409-412. [21] krishna.inc.in. (2014). Dehydrated Castor oil. MSME/Chemical. [22] Vishwanadum et al. (1995). Reaction Rates of Simultaneous Dehydration and Hydrogenation of Castor oil. Journal of the American Oil Chemists' Society, 1033-1036 [23] Okoro, E.E., Igwilo, K.C., Mamudu, O.A., Ekeinde, E.B., and Dosunmu, A. Data on Shale-Water based drilling fluid interaction for drilling operation. Data in Brief, Elsevier, 19(2018)1620-1626 [24] Omari et al. (2015). Fatty Acid Profile and Physicochemical Parameters of Castor Oils In Tanzania. Green and Sustainable Chemistry, 154-163. [25] Koutroubas, S. ,. (1999). Adaptation and yielding ability of Castor plant (RicinusCommunis L.) genotypes in Mediterranean climate. http://www.iaeme.com/IJMET/index.asp 363 editor@iaeme.com