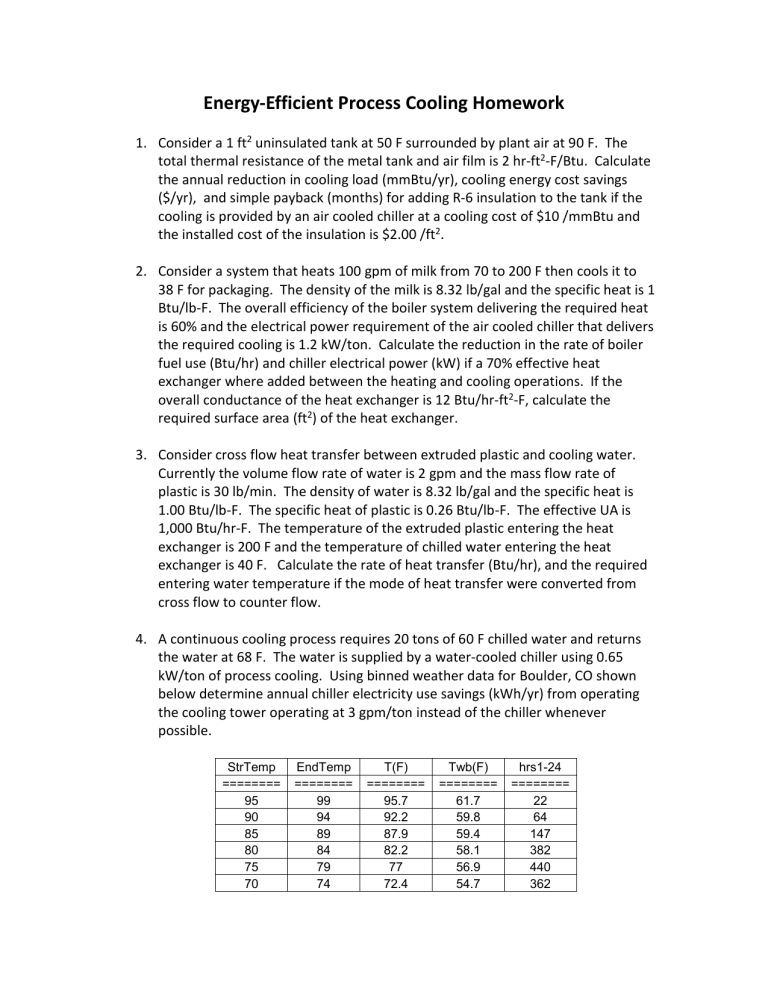

Energy-Efficient Process Cooling Homework 1. Consider a 1 ft2 uninsulated tank at 50 F surrounded by plant air at 90 F. The total thermal resistance of the metal tank and air film is 2 hr-ft2-F/Btu. Calculate the annual reduction in cooling load (mmBtu/yr), cooling energy cost savings ($/yr), and simple payback (months) for adding R-6 insulation to the tank if the cooling is provided by an air cooled chiller at a cooling cost of $10 /mmBtu and the installed cost of the insulation is $2.00 /ft2. 2. Consider a system that heats 100 gpm of milk from 70 to 200 F then cools it to 38 F for packaging. The density of the milk is 8.32 lb/gal and the specific heat is 1 Btu/lb-F. The overall efficiency of the boiler system delivering the required heat is 60% and the electrical power requirement of the air cooled chiller that delivers the required cooling is 1.2 kW/ton. Calculate the reduction in the rate of boiler fuel use (Btu/hr) and chiller electrical power (kW) if a 70% effective heat exchanger where added between the heating and cooling operations. If the overall conductance of the heat exchanger is 12 Btu/hr-ft2-F, calculate the required surface area (ft2) of the heat exchanger. 3. Consider cross flow heat transfer between extruded plastic and cooling water. Currently the volume flow rate of water is 2 gpm and the mass flow rate of plastic is 30 lb/min. The density of water is 8.32 lb/gal and the specific heat is 1.00 Btu/lb-F. The specific heat of plastic is 0.26 Btu/lb-F. The effective UA is 1,000 Btu/hr-F. The temperature of the extruded plastic entering the heat exchanger is 200 F and the temperature of chilled water entering the heat exchanger is 40 F. Calculate the rate of heat transfer (Btu/hr), and the required entering water temperature if the mode of heat transfer were converted from cross flow to counter flow. 4. A continuous cooling process requires 20 tons of 60 F chilled water and returns the water at 68 F. The water is supplied by a water-cooled chiller using 0.65 kW/ton of process cooling. Using binned weather data for Boulder, CO shown below determine annual chiller electricity use savings (kWh/yr) from operating the cooling tower operating at 3 gpm/ton instead of the chiller whenever possible. StrTemp ======== 95 90 85 80 75 70 EndTemp ======== 99 94 89 84 79 74 T(F) ======== 95.7 92.2 87.9 82.2 77 72.4 Twb(F) ======== 61.7 59.8 59.4 58.1 56.9 54.7 hrs1-24 ======== 22 64 147 382 440 362 65 60 55 50 45 40 35 30 25 20 15 10 5 0 -5 -10 69 64 59 54 49 44 39 34 29 24 19 14 9 4 -1 -6 67.9 62.5 57 52.1 47.4 43 37.5 32.1 27.7 23.1 17.7 12.1 7.2 2.8 -1.9 -6.6 53.7 51.7 47.1 43.2 40.1 37.2 34.2 30.9 28 25 21.2 17.4 14.3 11.3 8.3 5.4 630 907 698 754 620 775 834 717 542 320 201 130 89 74 37 15 5. A cooling tower with a design flow rate of 3 gpm/ton-chiller capacity has a single-speed 40-hp fan that cycles on and off to deliver cooling water at a setpoint temperature of 90 F. When running, the fan is 80% loaded and 90% efficient. The wet-bulb temperature is 65 F and the temperature range of the cooling water is 8 F. Determine the fan power savings (kW) from adding a variable frequency drive to the cooling tower fan and modulating fan speed to achieve the desired set-point temperature. 6. A cooling tower is sized to cool condenser water from an 80-ton chiller plant, with a design flow rate of 3 gpm/ton-chiller capacity. The cooling tower operates 5,000 hours per year. The water utility charges $2.00 per ccf for water discharged to sewer, and assumes that all water entering the plant is discharged to sewer. Assuming the evaporation rate is 0.75%, calculation the annual sewer cost savings ($/yr) from applying for a “sewer exemption” for water evaporated from the cooling tower. 7. A critical, 5,000 hour per year, cooling load in a facility with aging chillers is 400 tons. The company is considering replacing the two 400-ton standard-efficiency water-cooled constant-speed chillers with two 400-ton high-efficiency watercooled variable-speed chillers. Chiller performance is given by the “StandardEfficiency” and High-Efficiency” performance maps in the text. The chillers operate at the coldest possible condensing water temperature. Determine the annual electricity savings (kWh/yr) from replacing the current constant-speed chillers with variable-speed chillers if both chillers in each system were operated at 50% of full load. 8. For this problem consider a single plant visit. For this plant, the avoided cost of demand is $14 /kW-month and the avoided cost of energy is $0.02 /kWh. Compressed air to the plant is supplied by a 75-hp air-cooled rotory-screw compressor with a 93% efficiency motor that generates 4 scfm/hp. The compressor runs in load/unload mode and draws 60% of full load power when unloaded. The plant and compressor run 5,000 hr/yr. A production line uses 10 copper tubes with nominal diameters of 1/8-inch and inside diameters of 0.125 inch to blow moisture off a product. Air-saver nozzles that consume 10 scfm of compressed air are found to perform just as well as the open tubes. Calculate the annual cost savings from installing air-saver nozzles on the open tubes. Assume the compressed air pressure is 100 psig at the tubes and ambient pressure is 15 psia.