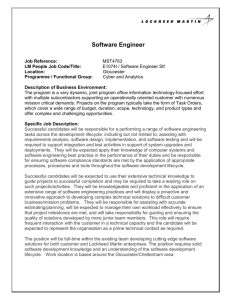

Strategies for supply management as a product moves through the product lifecycle. Introduction: 1.Supply Chain Management Supply chain is an integrated process incorporate of entities, that form a network of interdependencies, such as suppliers, manufactures, distributors and retailers. A form of organizing participating entities that all operate together in a mutual cooperation basis, which control and improve component and information flows. Include acquire raw materials and flow of information in order to convert them to specified final products and are carried out to meet customer needs (Beamon,1998), (Christopher M, 2013., Skjott-Larsen T, 2007). The ultimate goal of supply chain management is to fulfil customer's demand with more efficiency. In the manufacturing aspect it is to create the right product, for the right customer, within the right quantity, at the right time. However, there is no specific general guideline to organise particular supply chain. Strategies are varying such as pull and push strategies. The manner to manage the supply also depends on the cooperation between suppliers and customers, which in a result determine the rate of response in changing customer needs, as well as strategies that enable efficient operations and cost control. There are many factors which determine organising the upstream supply, one factor that has great impact on the supply chain and its operation as described by( Fisher M.L., 1997) is the structure of the offered product. He divided the products into functional and innovative, this concept also proposed and developed by Kaipia and Holmstrom (Kaipia, R., Holmstrom, J., 2007). 2.Product Types and Lifecycle Product lifecycle is another significant factor that covered by number of studies on supply chains particularly to focus on the product management in relation to product implementation in the market (Mruk, 1994., Lambert, 2008). The entire product lifecycle with its stages are widely described in the literature on marketing. According to (Kotler, P., L , Keller, K.L, 2012) product lifecycle defined as the formation of the product concerning the relationship between sales volume and profits in the entire span of the product's life, from the moment of appearance in the market until its withdrawal from the market. The future success or failure of the product within the market is a matter of proper understanding of the PLC by companies, which consequently help managers take decisions relating to the appropriate period to implement and withdrawal the product in the market. According to Hofer (1975, p. 798). One of the most fundamental factors to determine the best and appropriate business strategy is to clearly understand the stages of the product lifecycle. Furthermore, it has been identified by Biggadike (1981), that the product lifecycle consider as one of the five main marketing contributions which led to strategic management. Additionally Michael porter (1980, p. 157), observes the product lifecycle as "the grandfather of concepts for predicting the probable course of industry evolution. Broadly, there are three types that products can be categorised, functional, innovative and hybrid (Huang et al., 2002). Functional type of products classified its demand to be forecasted quite accurately and their market share remains fairly constant. This type enjoy long lifecycle with surface design modification that lead to different product types. They categorised with lower product variety and relatively long lead times. Innovative products on the other side are new products capture a wider share of the market as a result of organisational development. this type is undoabtly differ from other available product types and more adapted to the customer requirements i.e. mass customisation. Innovative products have unpredictable demand. They made as a result of customers specification in the design area which include their any changing requirements. This type categories with shorter lifecycle and high product variety and shorter lead times. Hybrid products are a mixture of both functional and innovative components. As Fisher’s stated in his product framework, functional products require physically efficient supply chain. On the other hand, innovative type of products require marketing responsiveness supply chain. Generally, all products have a lifecycle that represent a product category within a curve of unit sales over time (Wiersema, 1982), the division of stages proposed by Kotler is the most widely applied which classified into four discrete stages excluding the research & development stage since it does not consist of physical product flows. The stages are : introduction, growth, maturity and decline. All organisations should be fully understood of the product lifecycle, because all markets and products strategic considerations are influenced by product life cycling. Understanding the shape of cycling result to right product life cycle strategy. Each stage shows the changing of customers demand and the variety of sales in each phase. The first step where product is introduced, sales will be low, the volume begins to grow significantly when customers become aware of the product and it benefits. During this phase, the organisation is likely to obtain additional costs related to the initial distribution of the products. The period observed from the moment of sales growth until a drop in sales is covered by the growth stage (Levitt, 1965). Competition increase in this phase with rapid growth of sales. the growth stage is frequently followed by a decline of sales and the beginning of product maturity stage, this is the longest phase and most profitable. sales volume continue to increase but in slower rate. the aim of the maturity stage is to maintain market share and extend the product lifecycle. at the end of this stage, a fall in the monthly sales will occur as the market becomes saturated and the product becomes technologically obsolete. which called the decline stage where the product is rejected firstly by customers then the company offers its withdrawal from the market. Figure 1 Stages of Product Life Cycle 3. Supply strategies Typically, there are two fundamental strategies classified the supply chain, lean supply chain which is practically equivalent to Fisher's physically efficient, and Agile supply chain equivalent with his market responsiveness. Lean represents continues improvement and developing a value stream that focus on eliminating of waste (Naylor, Naim & Berry, 1999). According to Brunn and Mefford, 1999, manufacturing companies since the early 1990s have implemented a lean production strategy in order to increase their competitiveness. Lean strategy is supported by reduction of the cycle times, work in progress and finished goods inventories, consequently to achieve cost reduction, enhance efficiency, internal responsiveness and flexibility. An agile supply strategy in contrast to lean is aim to provide customer driven products with unique features that basically focus on responding to unpredictable market changes, in order to maintain a competitive advantage in the rapidly changing environment. It seeks to achieve flexibility in quick delivery and lead time. supplier attributes within the agile strategy involve speed, flexibility and quality. in the aspect of product design strategy, it is designed to meet customer needs. shortened product lifecycles and rapidly changing customer's requirements led to increase the pressure on the entire supply chain in order to quickly deliver products and services in a more responsive aspect. To compare the two different strategies and their impact on the length of product life cycle, standard products position within lean supply chain consider relatively long lifecycle times approximately more than two years. while innovative products in agile strategy have short lifecycle (3months - 1 year). 4. The Impact of Product Lifecycle on Supply and Operation 5. Product-based supply management team compared with traditional approaches to procurement 6. Supply and Operation strategies integration References Skjott-Larsen T., Schary P.B., Mikkola J.H., Kotzab H., “Managing the Global Supply Chain.”, Copenhagen Business School Press, Liber, Sweden, 2007. Christopher M., “Logistics and Supply Chain Management.” Financial Times / Prentice Hall, UK, 2013. Beamon, B.M., 1998. Supply chain design and analysis: Models and methods. International Journal of Production Economics 55, 281–294. [12] Kaipia, R., Holmström, J., “Selecting the right planning approach for a product”, Supply Chain Management: An International Journal, Vol. 12, Iss. 3, 2007, pp. 3-13 [5] Fisher M.L., “What is the Right Supply Chain for Your Product?” Harvard Business Review, Vol. 75, No.2, 1997, pp. 105-116. [19] Lambert D.M. (edit.), “Supply Chain Management: Processes, Partnerships, Performance.” SCMI, USA 2008. [24] Mruk H., Rutkowski I.P., „Analiza, planowanie, wdrażanie, kontrola. Strategia produktu.” Polskie Wydawnictwo Ekonomiczne PWE, Warszawa 1994. [15] Kotler, P., Keller, K.L. “Principles of Marketing”, Pearson Education, New Jersey, 2012. Hofer, Charles W. and Dan Schendel (1978), Strategy Formulation: Analytical Concepts , St. Paul, MN. : West Publishing Co. Biggadike, E. Ralph (1981), "The Contributions of Marketing to Strategic Management", Academy of Management Review, Vol. 6, #4 pp.621-632. Porter, Michael E. (1980), Competitive Strategy: Techniques for Analyzing Industries and Competitors , New York: The Free Press. Huang, S.H., Uppal, M., Shi, J., (2002). A product driven approach to manufacturing supply chain delection. Supply Chain Management: An International Journal 7 (3/4): 189–199 Levitt, T., “Exploit the product life cycle”, Harvard Business Review, vol 43, November– December 1965, pp. 81–94 Wiersema, F.D., (1982). Strategic marketing and the product life cycle. Marketing Science Institute, Cambridge, MA, April. Naylor, J. B., Naim, M. M., & Berry, D. (1999). Leagility: Integrating the lean and agile manufacturing paradigms in the total supply chain. International Journal of Production Economics, 62(1–2), 107–118. Bruun, P., & Mefford, R. N. (2004). Lean production and the internet. International Journal of Production Economics, 89(3), 247–260.