BRC-Quick-Start-Guide

advertisement

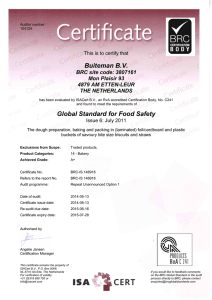

BRC Quick-Start Guide Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Introduction to BRC What is BRC? BRC is an international Food Safety Management Systems standard, and is one of the GFSI recognized certification schemes. It contains requirements for food processors to follow to build an effective food safety management system. There are also editions of the standard for food packaging manufacturers, storage and distribution and now agent and brokers. The requirements of the standard address the key elements that must be in place for your organization to ensure production of safe product. BRC Certification is recognized by GFSI, an important consideration when choosing a certification scheme because many major manufacturers and retailers require a GFSI recognized certification. Other recognized certification schemes include FSSC 22000 and SQF. Over 16,000 facilities worldwide are certified to the BRC Global Standard for Food Safety. To add your organization or facilities to this list you will need to build a management system that addresses all of the requirements of the standard, contract with a Certification Body to perform a certification audit, and pass the audit to become certified. Your organization will then need to have regular audits by the Certification Body to maintain registration. The BRC Certification Audit During the certification audit the Auditor will examine your BRC System to determine: • If the documented system meets the requirements of the standard • If the system has been implemented effectively • If there is evidence of Management Commitment to the maintenance and improvement of the system • If activities comply with regulatory, customer and BRC requirements Findings: Nonconformities may be identified during the audit. These are categorized as minor or major. A nonconformity is elevated to major if it presents a risk of unsafe product, or if it indicates that your organization completely failed to address a requirement. If there has been production of unsafe product it will be considered a critical nonconformity. If nonconformities can be evaluated, root cause identified and corrected within 28 days, your organization can proceed to certification. If the items are more difficult to resolve, you will need to provide your certification body with a corrective action plan within 28 days. The actions will be reviewed at the next audit. However, if the audit score is less than a "B", there must also be another visit by the certification body to verify the actions. A critical finding or a grade of lower than "C" means that your organization will not be certified. You must start with a new certification audit. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Introduction to BRC BRC: Frequently Asked Questions Do we need to have a copy of the standard? Yes. Your auditor will write a major nonconformance if you do not have a copy available. Purchase your copy when you make the decision to implement BRC. You must understand the requirements. A copy of the guidance document "Global Standard for Food Safety Issue 6: Interpretation Guideline" is also recommended. You will find it very useful as you build your system. Both can be purchased from the BRC Global Standards site http://www.brcglobalstandards.com. What is a vertical audit? A vertical audit is an audit of a specific production run. The auditor will choose a production run, something within the last few months, and will look at all of the records associated with that run. The auditor is able to see that all records are maintained, all controls and verifications taking place, all operators trained on the work they are performing, all times/temperature requirements met and any other information relating to the run. What is a mass balance audit? A mass balance audit checks the amount of a raw material that is received agains the amount used in product or processes. Packed final product should not exceed the quantity of raw material received. What is an audit score? The audit will be scored based not the number and category of nonconformances found. The details are in the BRC Global Standard, Section III. What is the Unannounced audit program? Once you are registered and have achieved a grade of "B" or better, your organization may choose the unannounced audit program. You can find the details of this program in the BRC Global Standard, Section III. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Introduction to BRC Training for the HACCP Team Leader and Project Manager There are various options for training programs to meet the requirement of demonstrating knowledge and understanding of the BRC Standard. There are onsite classroom courses 2-3 days long as well as online courses. You will need to demonstrate to your auditor that you have been trained on and understand the code. Train your Project Manager and/or HACCP Team Leader using our Complete Training Package. The package includes: A. Introduction to BRC Covers all the requirements of the Management System Elements and the Site Standards/Prerequisite Programs. B. (There is no “B” course for BRC; the introduction covers both the Management System Elements and the Prerequisite Programs) C. The Gap Analysis Checklists and Tutorial Includes checklists for the Management System Elements and Site Standards/ Prerequisite Programs. D. BRC Templates and Implementation Tools Includes document templates and detailed implementation plans E. Internal Auditing Includes an online, interactive practice audit. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Steps to BRC Certification In this section we outline our recommended steps to follow to prepare your organization for BRC Certification. In the next few sections we will take a look at each step in more detail and provide guidance and resources for completing the steps. First take a look at this overview of the project steps: 1. The Project Manager completes training on the Management System Elements and Site Standards/Prerequisite Programs. (course A) 2. The Project Manager works with the management team to prepare the project plan. This is detailed in the next section of the quick start guide. 3. Management identifies the “BRC Steering Team”. See the example BRC Steering Team first team meeting agenda and information in the BRC Steering Team section. 4. The Project Manager takes the “Conducting the Gap Analysis” training, downloads the checklists from the training and plans and leads the Gap Analysis Audit. 5. Based on the Gap Analysis results, the BRC Steering Team identifies the Task Teams needed to address changes or implementation of processes for each of the BRC System Elements. For example: a. Management Commitment b. Food Safety Plan c. Document Control d. Records Completion and Maintenance e. Internal Audits f. Supplier and Raw Material Approval g. Specifications h. Corrective Action i. Control of Nonconforming Product j. Traceability k. Complaint Handling l. Management of Incidents, Withdrawal and Recall m. Site Standards n. Product Design and Development o. Allergen Management p. Providence, Assured Status, Identity Preserved Foods q. Product Packaging r. Product Inspection and Laboratory Testing s. Product Release t. Control of Operations u. Personnel Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Steps to BRC Certification 6. The BRC Steering Team assigns team members to each task team, and a team leader for the each team. Some of the processes may be assigned to the steering team or HACCP team. See the example table for our recommendations. 7. Identify training requirements for those assigned to the task teams. “Introduction to BRC” is our recommended training for those team members. 8. Identify training requirements for the HACCP Team. “Introduction to BRC” is our recommended training for the HACCP team members. 9. The BRC Steering team completes the Gantt chart or the detailed project plan provided in the Templates Package with the projected dates and timelines for the task team activities. 10. The task teams meet as scheduled to complete the changes to and implementation and documentation of the new processes. Use the document templates, forms and implementation plans from the BRC Template and Implementation Tools Package or Complete Training Package. 11. The BRC Steering team reviews and approves all the procedures and documentation developed by the task teams. 12. The BRC Steering team identifies individuals to be Internal Auditors, and prepares an initial internal audit schedule. The individuals complete “Internal Auditor Training”. 13. Start the internal audits when the BRC System Elements processes are completed. 14. Hold management review meetings, conduct internal audits and complete corrective actions. Follow the new BRC Procedures that the task teams developed, maintain records and make improvements. Run your system for approximately 3 months then have your certification audit. The steps outlined here are recommended steps based on our experience implementing management system. Adapt them as needed for your organization. The training programs and documents we have referenced are all available on our site: www.22000-Tools.com. They are available individually, or in our Complete Training Package or Premium Training and Templates Package packages. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. The Project Plan It is important to prepare a project plan to help organize and manage the project. A sample project plan template is provided in Appendix A. Lets look at how to prepare the plan. A. First, identify your project goals. Answer the questions: 1. When will you begin your project? Consider the date of the Gap Analysis as the beginning date. 2. What is your target date for having the BRC Certification? You will work backwards from this date as you prepare your project timeline. Your date should be reviewed later. This will be your schedule, but as you perform the gap analysis and develop and the task list , you can determine whether that date is realistic. It will depend on the status of your current food safety management system and the resources available to you as you complete the system. B. Identify responsibilities for the project. 1. Identify the BRC Project Manager. 2. Identify who makes up Senior Management. 3. Identify the BRC Steering Team. As you saw in the steps in the previous section, the BRC Steering Team plays a key role in managing the project. The Project Manager should be the team leader, and senior management should make up the rest of the team. C. Start to fill in the timeline for the project. 1. Schedule training for the Project Manager. 2. Schedule the Gap Analysis. Remember that the Project Manager should complete the Gap Analysis Training and download checklists before the Gap Analysis. 3. Plan anywhere from 2 to 5 days for the Gap Analysis. It will depend on the size of your company, the number of auditors and the number and complexity of your processes. 4. Schedule the BRC Steering team meeting to assign the task team members, and schedule training for the team members. 5. Schedule training for the task team members. 6. Announce your project to all employees. Plan a meeting or meetings to make employees aware of the project, what BRC Certification is, and why it is important to the organization. 7. Document your target completion date and target dates for your certification audits. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. The Gap Analysis Once you have outline the project timeline, it is time to complete the Gap Analysis and identify the specific tasks that will need to be done to build your BRC System. The gap analysis will identify where your current system meets requirements, and where changes and additions to your system must be designed and implemented. The outcome of the gap analysis will be a task list for your project. You will assign the tasks to the task teams that you have identified. 1. Complete the “Gap Analysis Checklist & Training” session to learn how to plan and conduct the gap, what to do with your results, and download checklists for your audit. Note that this training is included in the Complete Training Package. 2. Identify any other auditors that will be involved, and brief them on the audit plan and techniques. 3. Inform employees that the audit will be taking place, and the purpose of the audit. You want employees to feel comfortable answering auditors questions; understanding the purpose of the audit will help establish their comfort with the process. 4. Conduct the audit and document findings on the checklists. 5. Create a task list, or use the list provided in the BRC Templates and Implementation Tools or Complete Training Package. Where ever you identify requirements that are not yet being complied with, document a task on the list. a. 6. The BRC Templates and Implementation Tools and Complete Training Packages provide both an overall project task list, and individual team task lists. If you have purchased the package, simply add the tasks to the lists provided. Many common tasks are already on the individual team task lists as well as information on the process requirements and a place to assign timelines. Provide the appropriate task list to each task team. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. The BRC Steering Team Once the Gap Analysis has been completed, start your BRC Steering team meetings. During the first team meeting discuss the responsibilities of the BRC Steering team. If there are members that were not involved in creating the project plan, review the project plan and list of steps to implementation. Proposed agenda for the 1st BRC Steering Team meeting: 1. Review the list of steps to implementation. 2. Review the responsibilities of the BRC Steering Team (these responsibilities will not all be completed in the first meeting, but should be reviewed to clarify the purpose of the team.) 3. a. Identify task teams and members b. Identify training requirements for task team members, HACCP team members and employees. Use the Premium Training and Templates Package to provide multiple training sessions to train the Project Manager, HACCP Team, Internal Auditors and others. c. Meet regularly to monitor the project timeline and task team activities and provide resources as needed to meet project goals. d. Choose a certification body, and schedule the certification audit. e. Review procedures and other documentation created by the task teams. f. Review and customize the Management Responsibility procedure. Complete tasks assigned to management. g. Assign internal auditors and create an audit schedule. h. Resolve issues as they arise. Identify task teams, team leaders and members. Assign timelines for each team to meet. See our example table in Appendix A. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. The Task Team Meetings The team leader is responsible for scheduling the meetings according to the timeline on the gantt chart. During the first team meeting discuss the purpose of the BRC Steering Team and Task Teams. Give an introduction to the purpose of the individual Task Team that is meeting. Proposed agenda for the fist team meeting: 1. Discuss the responsibilities of the BRC Steering Team and the Task Teams. 2. Review the list of steps for the implementation project. 3. Provide a copy of the procedure and forms templates for the BRC System Elements process that the team has been assigned. 4. Review the procedure and forms. 5. Provide a copy of the teams task list. Discuss the tasks that have been assigned. 6. Discuss the proposed timeline that was assigned by the BRC Steering team for the task team, and start to assign dates and responsibilities for the individual tasks on the list. 7. Determine the frequency of the team meetings, and schedule the next meeting. Prepare the next meetings agenda, and identify action items to be completed before the next meeting. Assign responsibility for the action items. At subsequent meetings you will review action items and progress and assign new action items as needed to complete the task list. The team goal is to design and implement a new process that meets the requirements of the BRC Standard for that system element. The team will accomplish this by using the document templates and the information from the gap analysis. The new process will be documented in the procedure. The procedure and any related forms or documents will be given to the BRC Steering team for review. Once the procedure is approved, the team will be responsible for seeing that it is effectively implemented. Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Appendix A BRC Project Plan Project Goals: Start Date: Target Date for Completion: Responsibilities: Project Manager: Senior Management: BRC Steering Team: Timetable: Step Start Date Completion Target The BRC Project Manager completes online training Conduct Gap Analysis BRC Steering Team Meetings Training for Task Team Members Task Team Meetings Announce the Project to all Employees System Complete Certification Audit Certificate in Hand - Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. Appendix A Example Task list with task team timelines assigned. Tasks Assign processes to teams for implementation Management Commitment Food Safety Plan Document Control Records Completion and Maintenance Internal Audits Supplier and Raw Material Approval Specifications Jan Feb Mar April May June July Aug Sept X X X X X X X X X X X X X X X X X X X X X X X Management of Incidents, Withdrawal Site Standards X X X Product Design and Development Allergen Management Providence, Identity Preserved Foods Product Packaging X X X X X X X X X X Control of Operations Personnel Conduct Employee Training Train Internal Auditors Start Internal Audits and Management Review CERTIFICATION AUDIT X X Complaint Handling Product Inspection and Laboratory Testing Product Release Nov Dec X Corrective Action Control of Nonconforming Product Traceability Oct X X X X X X X X X X Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC. X Appendix A Brought to you by Vinca LLC. Visit us at: www.22000-Tools.com and www.Vinca-Online-Training.com Copyright © 2014 Vinca, LLC.