Chapter 1

advertisement

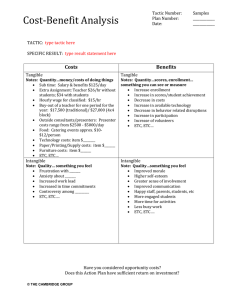

Operations Management - The systematic design, direction, and control of processes that transform inputs into services and products for internal, as well as external, customers Supply Chain Management – The synchronization of a firm’s processes with those of its suppliers and customers to match the flow of materials, services, and information with customer demand. Most companies do not make the things we buy. Role of Operations in the Organization – see slide show Process – Any activity or group of activities that takes one or more inputs, transforms them, and provides one or more outputs for its customers. Manufacturing: Physical, durable output Output can be inventoried Low customer contact Long response time Capital intensive Quality easily measured Service: Intangible, perishable output Output cannot be inventoried High customer contact Short response time Labor intensive Quality not easily measured Each activity in a process should add value to the preceding activities; waste and unnecessary cost should be eliminated. The supply chain view – see slide show Corporate Strategy Provides an overall direction that serves as the framework for carrying out all the organization’s functions o Strategy – plan o Tactic – act Operations Strategy Specifies the means by which operations implement corporate strategy and help build a customer-driven firm. Operations strategy – see slide show Competitive priorities vs competitive strategy Productivity = output/input Trends in ops. Mgmt. Global Compteition Advantages: o Increased market penetration o Comparative cost advatnages Disadvatages o Political risks o Lower skilled workers o Supply chain disruptions Natural disasters