Introduction to well logging techniques

advertisement

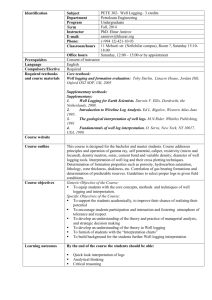

An Introduction to Well Logging

Pardeep Kumar

DGM(Geophy-Wells)

Prog. No.:GT-Batch,ONGC,Academy

Dec. 17th, 2014

INTEG, GEOPIC

ONGC, DEHRADUN

SOURCES OF INFORMATION IN SUBSURFACE

Field Geological Survey: Exposures of Sedimentary rocks.

Surface Geophysical Survey:

Seismic(2D,3D,4D) @ Non-Seismic(Gravity, Magnetic, sea bed logging )

Mud Logging - Hydrocarbon shows during drilling, ROP , Gas Counts

Cores & Cuttings - SWC/CC

Geological :

Megascopic Study, Thin Sections, XRD, SEM, XRF, EDX

Reservoir :

Porosity, Permeability, wettability, Bulk/Grain density,

Swirr, Electrical Petrophysical parameters.

Borehole Geophysical Survey : Well Logs, Well seismic (VSP)

Well tests : RFT/MDT, DST, Conventional Test

WELL LOGGING TECHNOLOGY

Logging - “ Eye ” of E&P

Industry.

Well Log - Record of

Physical

properties

measured with respect to

depth.

Well Logging involves• Data Acquisition

• Data Processing

• Interpretation of Results

WELL Logging set up at drill site

FEATURES OF WELL LOGGING

INDUSTRY

High Tech Industry

Capital Intensive

Rapid Technological

Obsolescence.

Globally dominated by

only 2 or 3 MNC players

India among the select

few countries with inhouse

logging

5 capabilities

LOGGING EQUIPMENT

• SURFACE EQUIPMENT

(LOGGING UNIT)

Truck/Offshore Skid

• DOWN HOLE TOOLS –

SOPHISTICATED

SENSORS &

ELECTRONICS

• ELECTRO-MECHANICAL

CABLE

Tool Conveyance

Open - Cased Hole

Measurements :

• The Traditional Wire-line Logging.

• LWD (Logging While Drilling)

• Logging on Drill Pipe (TLC)

• TRACTOR

Real time Monitoring

Importance of well logging

Usefulness of Well Logging

Well

Birth of Logging

September

5th,

1927

when

H.

Doll

and

Schlumberger brothers,

Conard & Marcel made

semi

continuous

resistivity measurement

in 1600 ft deep France`s

Pechelbronn field

First Log Recorded in Petroleum Industry

Semi-continuous resistivity measurement

at discrete depth points by H.D. Doll, in

in 1600 ft deep well in Pechelbronn field of

France

Logging was thought to be replacement for

Coring and therefore was known as

Electrical Coring.

Later on well Logging became a popular

and most Useful technique for formation

evaluation

History of Well Logging Technology

Cont…

History of Well Logging Technology

WELL LOGGING SERVICES IN ONGC

Departmental

services cater to

95% of the data acquisition in onshore areas.

Conform to International Quality

Standards.

In

house

Processing

&

Interpretation

Cost effective vis-à-vis Contract

14

services

ECONOMICS OF

DEPT. LOGGING SERVICES

Cost of Logging Equipment

•

•

•

•

15

OHU & Tools

CH/PLU & tools

Expected Life

Pay Back Period

:Rs. 25 – 30 Crores

:Rs. 15 - 16 Crores

:8 - 10 Years

< 3 Yrs.

Well Logging set up in ONGC

Logging Bases

Nazira, Jorhat, Agartala, Rajahmundry,

Karaikal, Ahmedabad, Ankleshwar,

Mehsana, Kolkata, Mumbai

Logging Institute

Centre for Excellence in Well Log

Technology, Vadodara

MAP

Material Planning & Acquisition, Logging

Services

Logging Manpower also available in

Institutes

• Keshva Deva Malviya Institute of Petroleum Exploration,

Dehradun

• Geo Data Processing & Interpretation Centre, Dehradun

• Institute of Reservoir Studies, Ahmedabad

Assets

MH Asset, N&H Asset, B&S Asset, Ahmedabad Asset,

Mehsana Asset, Ankleshwar Asset, Assam Asset, Tripura

Asset, Rajahmundry and Cauvery Asset

Basins

Western Offshore, Western Onshore, A&AA Basin, Cauvery

and KG Basin, Frontier Basin, MBA Basin

Others

E&D Directorate, Dehradun, CEC, ONGCA, D(E) office, Nhava

Material Acquisition & Planning

Centralized procurement for:

Logging Units

Logging Tools

Equipment, Logging cables

Perforation Material

Hiring of Contractual Services

Wireline Services

LWD Services

Mud Logging Services

LWD Contractual Services

Resistivity-GR : ARC resistivity, Geo-vision & GR

Porosity

: Neutron & Density with Imaging

EcoScope

: Resistivity-GR & Neutron-Density

StethoScope

: Formation Pressure while Drilling

PeriScope

: Bed Boundary Detection

Wireline Open Hole Services

Service

Departmental

Contractual

Resistivity

DLL, HDIL, HRI, DFL, MSFL, DLL, AIT, HRI, HRLA,

MSFL

MLL

Porosity

SDLT, DSNT, BCDT, DAL

LDL, CNL, BCS, DSI,DAL

Dipmeter

FED, SED, STAR

FMI, SED, STAR, XRMI

Formation

Tester

SFT, SFTT, RCI

MDT, XPT, SFTT, RCI

Coring

SWC

CST, MSCT

Other Tools

GR, NGRT,FIAC

GR, NGS, CALI,CMR, ECS

Cased Hole Services

Service

Departmental

Contractual

Cement Evaluation

CBL-VDL, CAST

CBL-VDL, CAST, USIT,

SCMT

Depth Correlation

N-GR-CCL

N-GR-CCL

Perforation

Gun Perforation, TTP

Gun Perforation, TTP, TCP

Back-Off Services

FPIT- String Shot

FPIT- String Shot

Cutters

Tubing/ Casing/ Split

Cutters

Tubing/ Casing Cutters,

Colloidal

Bridge Plug Setting

BP/ CR

BP/ CR/ MPBT

Analysis Behind

Casing

CHFR/ CHFD/ CHFP/ RST

LOG OF WELL – CAMBAY-1 Date 01.11.1958

Unit -Russian OKC-56

TYPES OF LOGGING

Depending upon the condition of bore hole, logging

operations are classified as;

Open Hole Logging : Reservoir Identification

& Evaluation ( Reservoir Characterisation

/Formation Evaluation)

Cased Hole Logging : Well Completion, Well

Integrity.

Production Logging : Production Problems

& Reservoir Monitoring

ROLE OF OPEN HOLE LOGGING

• Among the whole set of geo scientific data the

log data is most precise, depth controlled,

well resolved and most representative of the

in-situ reservoir condition.

• Well log data plays an important role in

decision making for casing lowering, initial

testing of prospective zones, hydrocarbon

reserve estimation and future reservoir

monitoring.

Contd.

ROLE OF OPEN HOLE LOGGING

Helps Assest and Basin managers for regular prospect

evaluation for making investment decisions and

regularly updating the remaining reserves and accretion

Helps geologists to correlate different sedimentary

sequences across the field, deduce the depositional

environment, stratigraphic and structural features of

the subsurface formation to firm up a geological model.

ROLE OF OPEN HOLE LOGGING

Helps drillers to identify the zones of lost

circulation, know the free point of a stuck pipe and

to calculate the amount of cement required for

efficient primary cementation job.

Knowledge of fracture pressure gradient, stress

anisotropy for break out analysis, mud weight

optimisation.

WELL LOG IS HOROSCOPE OF WELL

IT IS USED SINCE DRILLING TO

ABANDONMENT OF THE WELL.

Wireline Open Hole Services

SERVICE

RESISTIVITY

FORMATION

DENSITY

LOGGING TOOLS

DLL, HRLA, MSFL, MCFL, MLL, DFL,

DIL, AIT, HDIL, HRI, HRAI, RTEx, RTScanner, 3DEx

LDL, SDLT,

NEUTRON

POROSITY

CNL DSNT

SONIC

BCS, BCDT, DAL

FORMATION

TESTER

MDT, XPT, SFT , SFTT, RDT,RCI

SIDE WALL

CORING

SWC CST, MSCT

GEOMETRICAL RESPONSE PARAMETERS OF LOGGING TOOLS

Subsurface Lithology & Bore hole Environment

Different Saturation States of Formation around Bore hole

Role of Cased Hole Services

• CEMENT EVALUATION : TO ASSESS SEALING BEHIND

CASING AND ISOLATION OF ZONES.

• PERFORATION : MEANS TO ESTABLISH COMMUNICATION

BETWEEN FORMATION AND BOREHOLE

CRITICAL FOR IMPROVING PRODUCTIVITY, RECOVERY

FACTOR, SAND CONTROL AND REDUCE TIME FOR

ACTIVATION.

• PLUG SETTING : ISOLATION OF ZONES.

• CUTTER : HELPS RETRIEVE TUBINGS / CASING/ DRILL

PIPE ETC. SALVAGE OPERATION SAVES WASTEFUL

EXPENDITURE.

• BACK OFF SERVICES : HELPFUL IN LIQUIDATING STUCK

UPS.

Cased Hole Services

SERVICE

LOGGING TOOLS

CEMENT EVALUATION

CBL-VDL, CAST, USIT, SCMT

DEPTH CORRELATION

N-GR-CCL

PERFORATION

GUN PERFORATION, TTP, TCP

BACK-OFF SERVICES

FPIT- STRING SHOT

CUTTERS

TUBING/ CASING CUTTERS,

COLLOIDAL

BRIDGE PLUG SETTING

BP/ CR/ MPBT

Role of Production Logging

HOW MUCH OF WHAT IS COMING FROM WHERE ???

HOW MUCH IS GOING WHERE ???

• Analyse problems of sick wells &

suggest remedial measures in aged &

depleted fields.

• Can be done under dynamic conditions

without loss of production Deployment

of rigs not essential

• Monitor profile of flowing wells &

injection wells for better reservoir

management.

• Should be done at the start of

production life of a well , which will act

as a base log for future analysis.

Production Logging Services

1

TEMPERATURE

2

FLUID DENSITY

3

FLOW METER: SPINNERS

4

PRESSURE: STRAIN GAUGE/ QUARTZ

GAUGE

5

HOLD UP: GAS / WATER

6

CASING INSPECTION: MULTI ARM

CALIPER

Schematic Diagram of Completed Well

Casing

Tubing

Packer

Tubing Shoe

Perforations

Gas Zone

Gas Zone

Oil Zone-1

Oil Zone-1

Shale

Shale

Oil Zone-2

Oil Zone-2

Water Zone

Water Zone

PLUG

Grease Injection Schematic

Pack Off

Assembly

Grease Seal

Flow Line

Grease Line

Riser Pipe

Grease Drum

Wire Line BOP

ROLE OF CASED HOLE / PRODUCTION LOGGING

Helps surface and subsurface managers to diagnose

well/reservoir problems such as movement of oil water

contacts, gas water contacts, development of secondary gas

cap, water coning, gas cusping, water fingering, preferential

break through of injected water, water /polymer injection

profiling, casing leakage, channeling behind casing, cement

quality for optimal recovery and efficient reservoir

management.

TYPICAL LOG PRESENTATION

TYPICAL LOG PRESENTATION

TYPICAL LOG PRESENTATION

Detection and location of reservoirs from well logs

Hydrocarbon

Reservoir-rock

Seal-rock

and/or

source-rock

Hydrocarbon

Hydrocarbon

Hydrocarbon

Detection and location of reservoirs from well logs

ELAN Processed Results along with Log Data

IDENTIFICATION OF OWC & GOC

Shale

Shaly/sand G.B.

Shale

GOC

OWC

Shale

Tools Nomenclature

DLL

Dual Latero Log

HRI

High Resolution Induction Log

HDIL

High Resolution Dual Induction log

AIT

Array Induction Tool

HRLA

High resolution Lateral Array Resistivity

MSFL

Micro Spherical Focused Resistivity Log

MLL

Micro Latero Log

LDL

Litho Density Log

SDLT

Spectral Density Litho Tool

CNL

Compensated Neutron Log

DSNT

Dual Spaced Neutron Tool

BCS

Borehole Compensated Sonic

BCDT

Borehole Compensated Sonic Tool (DITS)

DAL

Digital Acoustic Log

Tools Nomenclature

DSI

Dipole Shear Sonic Imager

FED

Four Arm Electrode Dipmeter

SED

Six Arm Electrode Dipmeter

FMI

Formation Micro Imager

STAR

Simultaneous Acoustic & Resistivity Imager

XRMI

Extended Reach Micro Imager

XMAC

Cross Multi Pole Acoustic Tool

SFT

Selective Formation Tester

MDT

Modular Dynamic Tester

MDT-LFA

Modular Dynamic Tester-Live Fluid Analyzer

MDT-CFA

Modular Dynamic Tester-Chromatographic Fluid Analyzer

XPT

Extreme Pressure Express

RCI

Reservoir Characterization Tool

RDT

Reservoir Description Tool

Tools Nomenclature

SWC

Side Wall Coring

CST

Sequential Core Sampler Tool

MSCT

Motorized Sidewall Coring Tool

GR

Gamma Ray

NGS

Natural Gamma Ray Spectral

CMR

Combinable Magnetic Resonance

MRIL

Magnetic Resonance Imaging Log

ECS

Elemental Capture Spectroscopy

CALI

Caliper

PEX

Platform Express

CBL-VDL

Cement Bond Log – Variable Density Log

USIT

Ultra Sonic Imaging Tool

SCMT

Slim hole Cement Mapping Tool

CAST

Circumferential Acoustic Scanning Tool

RST

Reservoir Saturation Tool

Tools Nomenclature

CHFR

Cased Hole Formation Resistivity

CHFD

Cased Hole Formation Density

CHFP

Cased Hole Formation Porosity

FPIT

Free Pint Indicator Tool

BP / CR

Bridge Plug / Cement Retainer

TCP

Tubing Conveyed Perforation

TTP

Through Tubing Perforation

TLC

Tough Logging Conditions

LWD

Logging While Drilling

MPBT

Mechanical Plug Back Setting Tool

VSP

Vertical Seismic Profiling

CPLT

Compact Product Logging Tool

Max Track

Tractor Conveyance

FSI

Flow Scan Imager

Tools Nomenclature

3DRI

3D Resistivity Imager / RT Scanner

TWSS

Multi level Tri-axial Well Seismic Service

PSP

Production Service Platform

WSTPL

Well Shuttle Services

FPWD

Formation Pressure While Drilling (StethoScope)

DBBI

Directional Bed Boundary Imaging Tool (PeriScope)

ELAN PROCESSING RESULTS ALONGWITH

OPEN HOLE LOGS & OVERLAYS

ESTIMATION OF RESERVES

For oil, the number of barrels in Place is given by

N=7758 × ø (1-Sw) × h × A

where ø is the porosity, Sw is water saturation, h is the

pay thickness in feet and A is the areal extent in acres.

For gas, the number of cubic feet in situ is given byG=43560 × ø (1-Sw) × h × A

SPONTANEOUS POTENTIAL

(SP LOG)

SPONTANEOUS POTENTIAL LOG

Simplest Log from Recording Point of View But Very Useful from

application point of view.

SP is naturally occurring electrical potentials opposite each lithological

unit penetrated in a well bore with respect to local potential of earth surface.

Measured potential between a movable electrode & a fixed surface electrode

SP is generally recorded along with resistivity by including a ring type electrode

in the resistivity tool body or a cylindrical electrode in the cable armour and

presented in first track

SP is generated due to electrochemical and electro kinetic phenomenon

Membrane potential, Liquid junction potential and Electro-kinetic potential

REQUIREMENTS FOR OCCURRENCE OF SP

•ELECTRICALLY CONDUCTIVE BOREHOLE FLUID

(BRINE, WATER BASED MUD)

•A SANDWICH OF A POROUS AND PERMEABLE BED

BETWEEN LOW POROSITY AND IMPERMEABLE FORMATIONS.

(SAND SHALE SEQUENCE)

•SALINITY CONTRAST BETWEEN THE BOREHOLE FLUID AND

THE FORMATION WATE

•PRESSURE DIFFERENTIAL BETWEEN BOREHOLE AND

FORMATION ( NOT ESSENTIAL IF SALINITY CONTRAST EXISTS)

SPONTANEOUS POTENTIAL

STATIC SP (SSP)

Electro-kinetic Potential

The electro-kinetic potential also known as streaming or filtration potential

is caused by filtration of mud through the mud cake, shale and sometimes

low permeability reservoir sections. This potential is generally regarded as

very small and is neglected in practice. Potential developed across shale and

mud cake is considered to cancel each other.

EK = D ΔP Rmf,

4

Where, , D, P, Rmf & are Zeta potential of rock surface in relation to

saturating brine, dielectric constant of mud filtrate, pressure differential,

resistivity and viscosity of the mud filtrate respectively.

This potential is denoted by EH also as the relation was given by Helmholtz.

As , D, Rmf and depends upon the salinity of the mud filtrate and nature

of ions , EK strongly depends upon the chemistry of invading solution.

IDEALISED AND REAL SP LOG EXAMPLES

FIELD EXAMPLES

NaCl Mud, Rmf>Rw

KCl Mud, Rmf<Rw

PSEUDO STATIC SP (PSP)

SP DEFLECTION (AMPLITUDE)

AGAINST SHALY SANDS MEASURED

FROM SHALE BASELINE .

PRESENCE OF SHALES REDUCE SP

AMPLITUDE.

THIS FACT IS USED TO COMPUTE

VOLUME OF SHALE IN A SHALY

SAND

VSH = 1- PSP/SSP

OR

VSH= (SPSh – SPZone)/ (SPSh-SP Sd)

Applications of SP Log

Identification porous permeable reservoir zones

Define bed boundaries

Well to well correlation

Information about depositional environment

Determination of formation water resistivity

Estimation of shale content in a shaly reservoir.

Identification of hydrocarbon zones

Computation of realistic water saturation in LRLC reservoirs

NATURAL GAMMA RAY LOG

NATURAL GAMMA RAY LOG

GR IS MEASUREMENT OF NATURAL RADIOACTIVITY

OF THE FORMATION

RADIOACTIVE ELEMENTS TEND TO CONCENTRATE IN

SHALES.

– POTASSIUM SERIES , K 40(1.46 MEV

– URANIUM SERIES , TH232 (2.61 MEV )

– THORIUM SERIES, U 238(1.76 MEV)

DOLOMITES MAY HAVE SOME URANIUM CONTENT

NATURAL GR SPECTRUM

Radioactive potassium

Isotope (K40) with half life

1.3x109 years

Argon 40

Uranium238 (U238) with

half-life of 4.4 x 109 years

Thalium 208

Thorium232 (Th232) with

half-life of 1.4 x1010 years

Bismuth 214

GAMMA RAY LOG

CLEAN SANDS AND CARBONATES EXHIBIT LOW GR

SHALES AND SHALY SANDS ARE HIGHER IN

RADIOACTIVITY

FELDSPARS AND MICAS RICH IN RADIOACTIVITY

AMONG CLAY MINERALS ILLITE HAS MAXIMUM GR

SOMETIMES SILTS ARE MORE RADIOACTIVE THAN

SHALES

HOT SHALES EXHIBIT TREMENDOUSLY HIGH GR (

THOUSANDS API)

SOURCES OF RADIOACTIVITY IN SHALES

SHALES ARE FINE GRAINED CLAY RICH ROCKS

CONTAINING MICA, FELDSPAR, CALCITE, DOLOMITE ,

QUARTZ & ORGANIC MATTER.

1.

RADIOACTIVE ELEMENT (K-40) IS FOUND ONLY IN

CRYSTAL LATTICE ILLITE CLAY. EVEN MORE

CONCENTRATION IS FOUND IN MICA & FELDSPAR.

2. THORIUM IS ABSORBED ON CLAY PARTICLE

SURFACES. THORIUM IS PRESENT IN MICAS &

FELDSPARS.

3. URANIUM ASSOCIATED WITH ORGANIC SHALES

PROVIDES HIGH GR

GR LEVELS AGAINST SEDIMENTARY ROCKS

GAMMA RAY TOOL

• GR ENTERING TOOL BODY AFTER PASSING

THROUGH FORMATION & BOREHOLE ARE

COUNTED WITH SCINTILLATION /G.M. COUNTER

• GAMMA RAYS PASSING THROUGH ROCKS ARE

SLOWED AND ABSORBED AT A RATE WHICH

DEPENDS ON THE FORMATION DENSITY.

• COUNT RATE (CPS) IS CONVERTED INTO API UNITS

AND PRESENTED ON LOG GENERALLY IN FIRST

TRACK.

Estimation of Clay Volume from GR

O il

Examples of GR variation across Formation

P y rit e

B io t it e

Q u a rt z

ILD ILD @ M IN C O M

1

MD

1 : 200

150

m

G R C O . W E _ D S _ f in

0

6

( gAPI )

C A LI C A LI@ M IN C

-1 0

( mV )

100

( ohm .m )

M SF L.D F M SF L@ D

0.45

1

100

( ohm .m )

R T @ A S C IILoad;1

1.95

70

T EN S

0 0)

(4 5m0V

1

( ohm .m )

100

( m 3 / m 3 ) -0 . 1 5

R H O B . W E _ D S _ F in

2.95

( g/c m 3 )

D T . W E _ D S _ F in a l

140

( us /ft )

B M S _ to p

3450

3250

3475

3500

0.5

( m 3/m 3 )

Sw

0

1

( m 3/m 3 )

0

N P H I . W E _ D S _ F in

1

T VDS S

16

( in )

S P S P @ M IN C O M 2;

100

( ohm .m )

ILM ILM @ M IN C O M

PH IE

40

B ound W ater

R F _ c ly s t n

SW

C la y

E LA N _V O LU M E S E

PH IE

1

( V/V )

0

APPLICATIONS OF GR LOG

• Determination of lithology (sand , shale, coal, limestone etc.)

for identification reservoir layers, seals.

• Estimatation of shale or clay volume in shaly reservoirs

• Stratigraphic correlation of depositional sequences and

formations

• Determination of depositional environment

• Determination of source rock potential

Depositional Environment from GR Log

CALIPER LOG

CALIPER LOG

EXAMPLE OF HEAVING/SWELLING CLAY

APPLICATIONS OF CALIPER LOG

Identification of porous and permeable zones.

Used for applying environmental corrections to various log

measurements

Helps in decision making for formation testers and side wall

Coring.

It provides volume of cement slurry required for efficient

cementation job with knowledge of casing outer diameter

Annular Volume={Cali2 -(Casing OD) 2 }* Casing Length

RESISTIVITY LOGS

RESISTIVITY LOGS

Resistivity of formation rock is the key parameter in

determining hydrocarbon saturation.

Resistivity

resistivity.

devices

record

values

of

apparent

Interpretation depends upon assumption that the

logging sonde is surrounded by an Infinite,

homogeneous and isotropic medium.

The capability of measuring true formation resistivity

as close as possible is an ultimate objective

Determination of Resistivity

Ohms law:

V = I*R

where:

V

= Voltage, Volts,

R

= Resistance, Ohms,

I

= Current, Amps.

R

r

A

l

= *l/A

= Resistivity, Ohm.m,

= Resistance, Ohms,

= Area, m2,

= Length, m.

A simplified schematic diagram of the borehole environment

and the effects produced by the invasion of drilling fluids

Types of Resistivity Logs

DIFFERENCE BETWEEN INDUCTION & LATERO LOG MEASUREMENTS

Effective Resistance, Ra

Ra = Rm + Rxo + Rt

Highest resistantion element

dominates the signal

1/Ra = 1/Rm+ 1/Rxo+ 1/Rt

Lowest resistance element

dominates the signal

CHOICE OF APPROPRIATE RESISTIVITY TOOL

Choice of better tool for Rt determination

depending upon Rmf/Rw ratio and porosity. At

lower right use both logs in area under

appropriate Rw curve.

Choice of better tool for Rt determination based on

Rmf/Rw ratio and Sw for step profile of invasion and

worst case of Annulus. 6FF40 is configuration for

deep induction in DIL tool.

Relationship Between Resistivity

& Hydrocarbon Saturation

Un-invaded Zone

Flushed Zone

RESISTIVITY LOG EXAMPLE

Interpretation of Resistivity Log

Neutron Tool

Neutron Porosity Log

•Neutron logs respond to the fundamental formation

property of hydrogen richness.

•If all of the formation's hydrogen is contained in

the form of liquids, and if these liquids completely

occupy the total pore volume, hydrogen richness is

an index to porosity.

•Hence, a neutron log is used to determine Porosity

through Hydrogen Index.

HYDROGEN INDEX OF FLUIDS

Hydrogen Index is defined as the ratio of amount of

hydrogen present in a given volume of rock or any

substance to the amount of hydrogen present in equal

volume of water

HI of water :

1

HI of light H.C (h <0.25): 0.2h

HI of heavier H.C (h >0.25): h +0.3

NEUTRON RADIATION

• Neutrons are uncharged particles having mass

approx. equal to that of protons They are classified

by the amount of energy they possess. This energy

is directly related to their speed of travel.

1. Fast neutrons > 100 KeV of energy

2. Intermediate neutrons -100 KeV to 100 ev

3. Slow neutrons < 100 ev of energy

• Epithermal neutrons - between .1 and 100 ev

• Thermal neutrons - < 0.025 ev at room temp.

RELATING COUNT RATE TO POROSITY

• In high porosity, liquid-filled formations, the

neutron flux is thermalised close to the source, so

that relatively few neutrons or capture gamma

rays are detected.

– Thus high porosity is indicated by a low neutron

counting rate.

– The reverse reasoning will relate low porosity to a

high count rate.

FIELD EXAMPLES

FORMATION DENSITY TOOL

• Most useful of all

porosity tools.

• Measures formation bulk density

(RHOB) and photoelectric absorption

factor (Pe)

• Based upon principle of Compton

scattering and photo-electric

absorption of gamma ray

• Pe is dependent on Z, the atomic

number, and is used to identify

lithology.

Density Tool utilizes Cesium 137

(Cs137) gamma ray source and

two Sodium Iodide scintillation

detectors mounted on an

articulated pad.

INTERACTIONS OF GAMMA RAYS WITH MATTER

In Compton scattering Gamma photons collide with the orbital electrons

If the energy given to the electron is greater than the binding energy of the

electron, the electron will be ejected from the atom and the photon is

"scattered," at an angle to its original path.

The energy reduction is proportional to the scattering angle θ

hν′

=

hυ / {1+ (1-Cosθ) ε} , Where, ε = hυ/meC2

Photoelectric effect occurs when the incident gamma ray is completely absorbed

by the electron. It is favoured in low photon energy & high Z targets

RELATIVE IMPORTANCE OF INTERACTIONS

FORMATION DENSITY TOOL

Measures formation porosity based upon mixing law;

In fully water bearing formation

ρb =

Φ

Φ *ρf + (1- Φ) *ρma

= (ρma - ρb)/(ρma – ρf )

APPLICATIONS OF DENSITY TOOL

• Measurement of bulk density & hence porosity

• Lithology determination using Pe.

• Lithology determination using density-neutron

Overlay & cross plots.

• Synthetic seismogram and acoustic

impedence logs for calibration of bore hole

gravimetry and well seismic surveys.

RELATING GAMMA INTERACTIONS TO LOG VALUES

Gamma rays lose their energy when they

collide with electrons of formation material

By measuring the number of gamma rays and

their energy levels at a given distance from

the source, the electron density of the

formation can be predicted.

Denser formation gives low count rate

Understanding the relationship between

electron density and bulk density is an

essential part of the density measurement

e = b * (2 Z / A)

Most cases, 2 Z / A = 1

e = b

RELATING GAMMA INTERACTIONS TO LOG VALUES

energy spectrum divided into

four energy windows SOFT,

SFT2, HRD1 and HRD2.

Total counts occurring in

windows HRD1 and HRD2 are

due to Compton Scattering, and

are used in combination with

the SS detector count rate to

determine bulk density.

Pe is derived from the ratio of

the counts in the SOFT window

to HRD2 window.

CURVE

ENERGY WINDOW

DOMINANT INTERACTION

SOFT

60 - 100 keV

Photoelectric Absorption

SFT2

100 - 140 keV

Photo & Comp for low Z

HRD1

140 - 200 keV

Scattering

HRD2

200 - 540 keV

Scattering

LOG EXAMPLE

Figure-34: Sandstone Reservoir from

Western Onshore Basin, Upper Part

(1200-1272 m.) is shale from GR, Cali,

SP(+ve),

Neutron(CNCF),

Density(ZDEN).Interval 1272-1306 m

is reservoir with Gas Oil Contact at

1284 m and Oil Water Contact at 1

296 m. Zone below 1306 is again

Shale. See hydrocarbon effect on

Resistivity and SP. Gas Effect on

Neutron.

SONIC LOG(ACOUSTIC VELOCITY)

• The Sonic Log is a porosity log that measures interval transit

time (Δt) of compressional sound wave travelling through the

formation along the axis of the borehole.

• Acoustic transit time Δt and is usually expressed in

microseconds per foot.

• Velocity, v and transit time Δt are related by:

Δt (μsec/ft) = 106 / v(ft/sec)

• Sonic tools consist of transmitters and receivers arranged

according to the goals of the measurement.

• The tool response is affected by the formation matrix, fluid

and porosity

Acoustic wave Propagation from a Monopole source

ACOUSTIC WAVE PROPAGATION IN FLUID FILLED BOREHOLE

SONIC VELOCITY OF FLUIDS

Formation Fluid

Sonic

velocity(ft./sec)

5,300

Travel

Time(μsec/ft)

189

5,000

200

4,800

208

4,600

218

Oil

4,200

238

Methane

1,600

626

Air

1,100

910

Water with 20%

NaCl

Water with 15%

NaCl

Water with 10%

NaCl

Water (pure)

SONIC VELOCITY OF EARTH FORMATIONS

Formation

Sandstone:

Unconsolidated

Semi-consolidated

Consolidated

Limestone

Dolomite

Shale

Calcite

Anhydrite

Granite

Gypsum

Quartz

Salt

Sonic velocity(ft./sec) Travel Time(μsec/ft)

³17,000

18,000

19,000

21,000

23,000

6,000-16,000

22,000

20,000

20,000

19,000

18,000

15,000

58.8 or more

55.6

52.6

47.6

43.5

167-62.5

45.5

50.0

50.0

52.6

55.6

66.7

BASIC SONIC TOOL PRINCIPAL

ACOUSTIC LOGGING APPLICATIONS

SONIC LOG EXAMPLE

SONIC POROSITY ESTIMATION

Wyllie time-average equation

ROCK SAMPLING(SIDE WALL CORING)

Chronological Sample Taker

Mechanical sidewall coring

These types of tools allow the sampling of rock at a desired depth. These rock

samples allow a better evaluation of the porosity and permeability, as well as their

mineralogical composition, the clay type and distribution, the grain

and pore size.

(Schlumberger’s courtesy)

FORMATION TESTER PRINCIPLE

DOWN HOLE FLUID SAMPLING

Pressure

Invaded Zone

Quartzdyne Gauge (L)

Time

Drawdown

pump

Piston Position

Sensor

Packer

Back-up arm

Sample Isolation

Valve

CASED HOLE SERVICES

CEMENT QUALITY EVALUATION

CEMENT BOD LOG-CBL

CBL/VDL

The CBL measurement is the

amplitude in millivolts of the first

arrival E1 at the 3 –foot receiver.

No

Cement

It is a function of the attenuation

due to the shear coupling of the

cement sheath to the casing.

The attenuation rate depends on

the cement compressive

strength, the casing diameter,

the pipe thickness, and the

percentage of bonded

circumference

Good

Bond

Cement Quality Evaluation –

Cont.

Cement Quality Evaluation –

Cont.

• Basic interpretation

5

– Free pipe

• No cement to casing bond

• No attenuation of the signal

Free Pipe Signal

3

E1

T0

Threshold

2

TT

T

•

Cement Quality Evaluation –

Cont.

Good cement to casing

bond

– If casing is well bonded,

soundwave

will

be

attenuated.

– The received CBL amplitude

will be low.

CBL: Free Pipe

5

3

2

CBL: Good Bond

T

Cement Quality Evaluation –

Cont.

• Variable density log

– 5 ft Receiver for VDL

Analysis

– Allows

easy

differentiation between

casing and formation

arrivals

Tx

R3

R5

5 ft

Cement Quality Evaluation –

Cont.

• Factors affecting CBL

Free Pipe Signal

E1

– Good cement – Stretch

T0

Good Bond

Signal

Threshold

TTTT’

DT

– Good cement – Cycle skipping

Threshold E1

E3

T0

TT

TT’

E2

Cement Quality Evaluation –

Cont.

• Basic interpretation

5

– Free pipe

• No cement to casing bond

• No attenuation of the signal

Free Pipe Signal

3

E1

T0

Threshold

2

TT

T

Good Cement Example

Weak casing arrival

CBL flat, low

Strong formation arrival

Cement Quality Evaluation

X

X

X

Good casing to cement to formation bond

CASED HOLE SERVICES

CEMENT QUALITY EVALUATION

CEMENT BOD LOG-CBL

CBL/VDL

The CBL measurement is the

amplitude in millivolts of the first

arrival E1 at the 3 –foot receiver.

No

Cement

It is a function of the attenuation

due to the shear coupling of the

cement sheath to the casing.

The attenuation rate depends on

the cement compressive

strength, the casing diameter,

the pipe thickness, and the

percentage of bonded

circumference

Good

Bond

Cement Quality Evaluation –

Cont.

• Variable density log

– 5 ft Receiver for VDL

Analysis

– Allows

easy

differentiation between

casing and formation

arrivals

Tx

R3

R5

5 ft

Good Cement Example

Weak casing arrival

CBL flat, low

Strong formation arrival

Cement Quality Evaluation

X

X

X

Good casing to cement to formation bond

LOG INTERPRETATION OF CLEAN FORMATION

Can you tell where to complete this well?

Gamma

Radiation

Electrical Porosity

Resistivity

good porosity

200’

poor

resistivity,

probably

water

poor

porosity

good porosity

500’

good

resistivity,

may have

oil or gas

Looks

like

good

sand

quality

poor

porosity

good

porosity

poor

porosity

poor

resistivity,

probably

water

3000’

good

porosity

}Right here! This shows a clean sand,

with good porosity and resistivity.

CLEAN

FORMATIONS

Chances of encountering clean limestone are more than sandstone

Ortho-quartzites may be considered as clean formation.

These sands are very porous and permeable

Feldspar, mica are very rare

They have also the characteristics of winnowed sand deposited on submarine

rises or of Aeolian sands

Evaluation of clean formation is basically a question of inserting the right

values of the parameters Rw, Rt & Ø with appropriate a, m, n values in

Archie water saturation equation:

Sw = (a Rw /Øm Rt)1/n

Highly saline formation waters make shaly reservoirs suitable for

evaluation with Archie’s equation as maximum current flows pore spaces

INTERPRETATION OF CLEAN FORMATIONS

Clean Zones:

Shale/Clay free from

GR, SP, Caliper,N-D.

Clastics :

Sandstone, volcaniclastics

Carbonates

Clastics :

Carbonates:

: Limestone, Dolomite

Check ResistivityFirst

Check PorosityFirst

Tight Zones : Low DT, High RHOB, Low PHIN

Water Zones :

Zone of

Low Resistivity, Good SP,

Separation between deep &

shallow Resistivity

Interest : High porosity & Resistivity

Fluid Contact :

Cross over porosity/Resistivity

Drop in resistivity

Drop in porosity

Detailed Analysis : Computation of ,SW &He

POROSITY COMPUTAION IN CLEAN RESERVOIRS

SONIC POROSITY

DENSITY

POROSITY

BEST ESTIMATE

IN OIL/WATER

ZONES

BEST ESTIMATE

IN GAS ZONES

s

Dtlog Dtma

Dt f Dtma

ma b

d

ma f

7D 2N

S

9

e

2

SATURATION DETERMINATION

Archie gave an expression for computation of water saturation

In 1942, which is still being used with some modifications.

Electrical efficiency theory (EET) was given by D.C. Herrick &

David Kennedy in 1994., which has not been well taken by

The industry.

Basic Information Needed

Lithology

Many log analyses require knowledge of lithology for

calculations (e.g., porosity logs require matrix

information, and Sw calculations use formation factor, F,

which depends on lithology)

Formation Temperature

Formation Temperature is important because mud, mud

filtrate and formation water resistivities vary with

temperature.

FORMULATION OF ARCHIE’s EQUATION

Swn xmxCw = Ct

Swn = Ct / mxCw

C= x Cw = Cw

Change from conductivity to resistivity

Swn = Rw / mxRt

Archie used a=1, m=n =2

C= mxCw = C0

C= Sw

Sw2 = Rw / 2xRt

Later on Humble

suggested

A=0.62, m=2.15, n=2

n

xmxCw

= Ct

Final expression in use

today is

ARCHIES’s Equation :

Swn

=

a Rw

m.R

t

ARCHIE’ Parameters

‘a’ , ‘m’ , ‘n’

ARCHIE’ Parameters

For Limestone :

a=1, m=2, n=2

For sandstones

a=0.62, m=2.15, n=2,

a=0.81, m=2, n=2

a=1, m=1.96,n=2

How a, m & n are calculated

1. In laboratory

2. From logs.

What are m* & n*.

Courage to Explore

Knowledge to Exceed

Technology to Excel

Thank You